A commercial electric fan blade

An electric fan and fan blade technology, which is applied to the components of the pumping device for elastic fluid, non-variable-capacity pumps, pump components, etc. The effect of noise reduction is obvious and the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

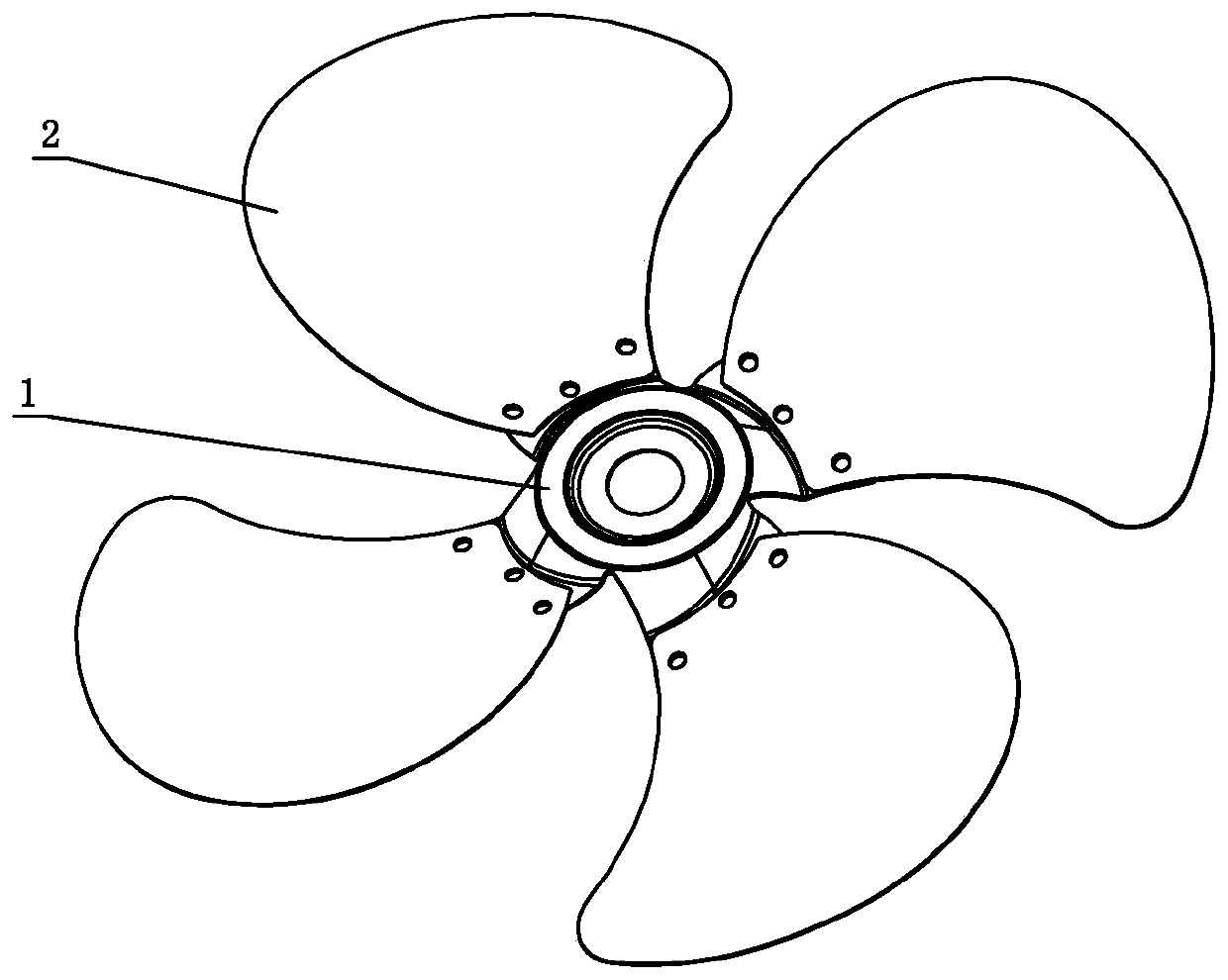

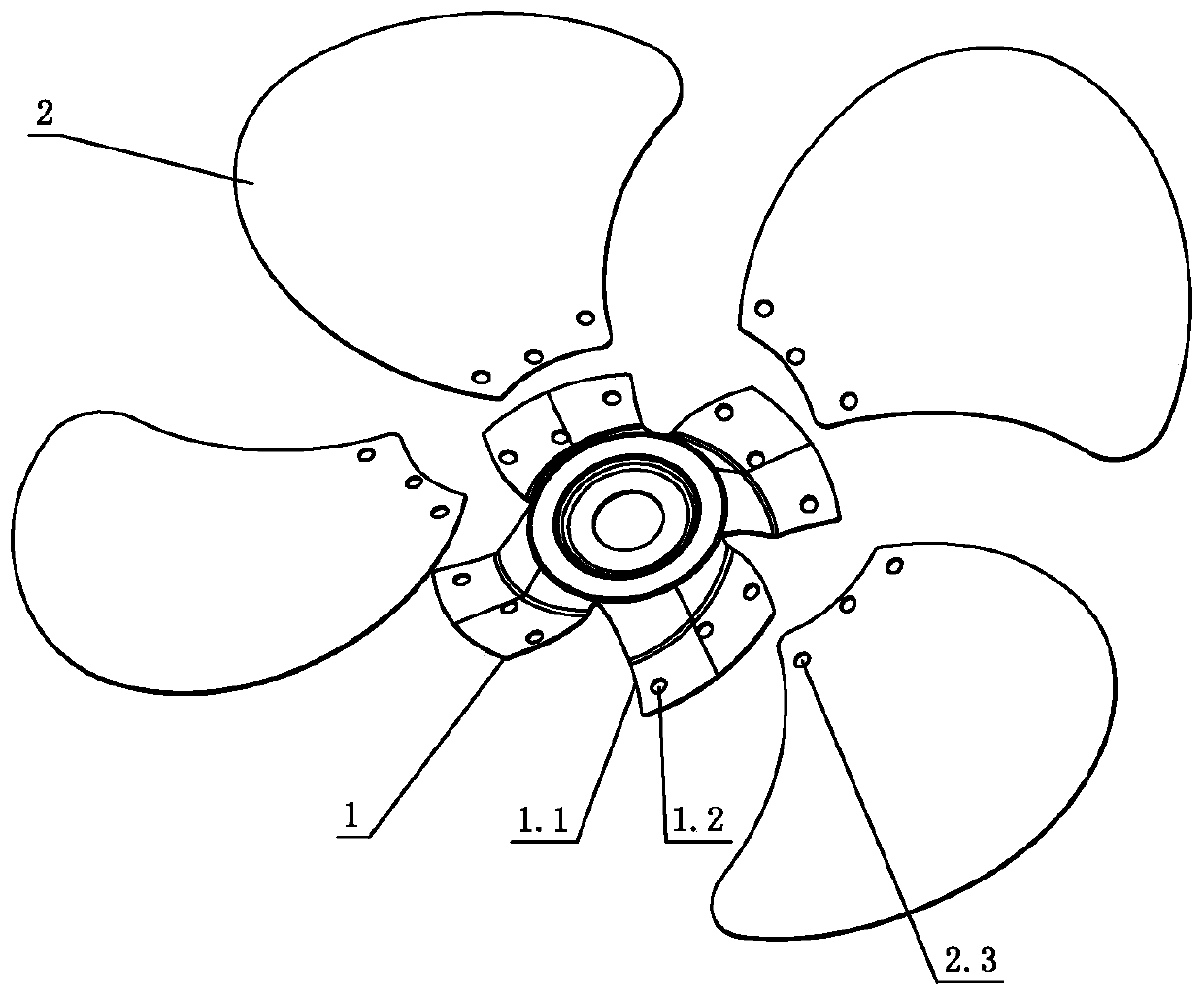

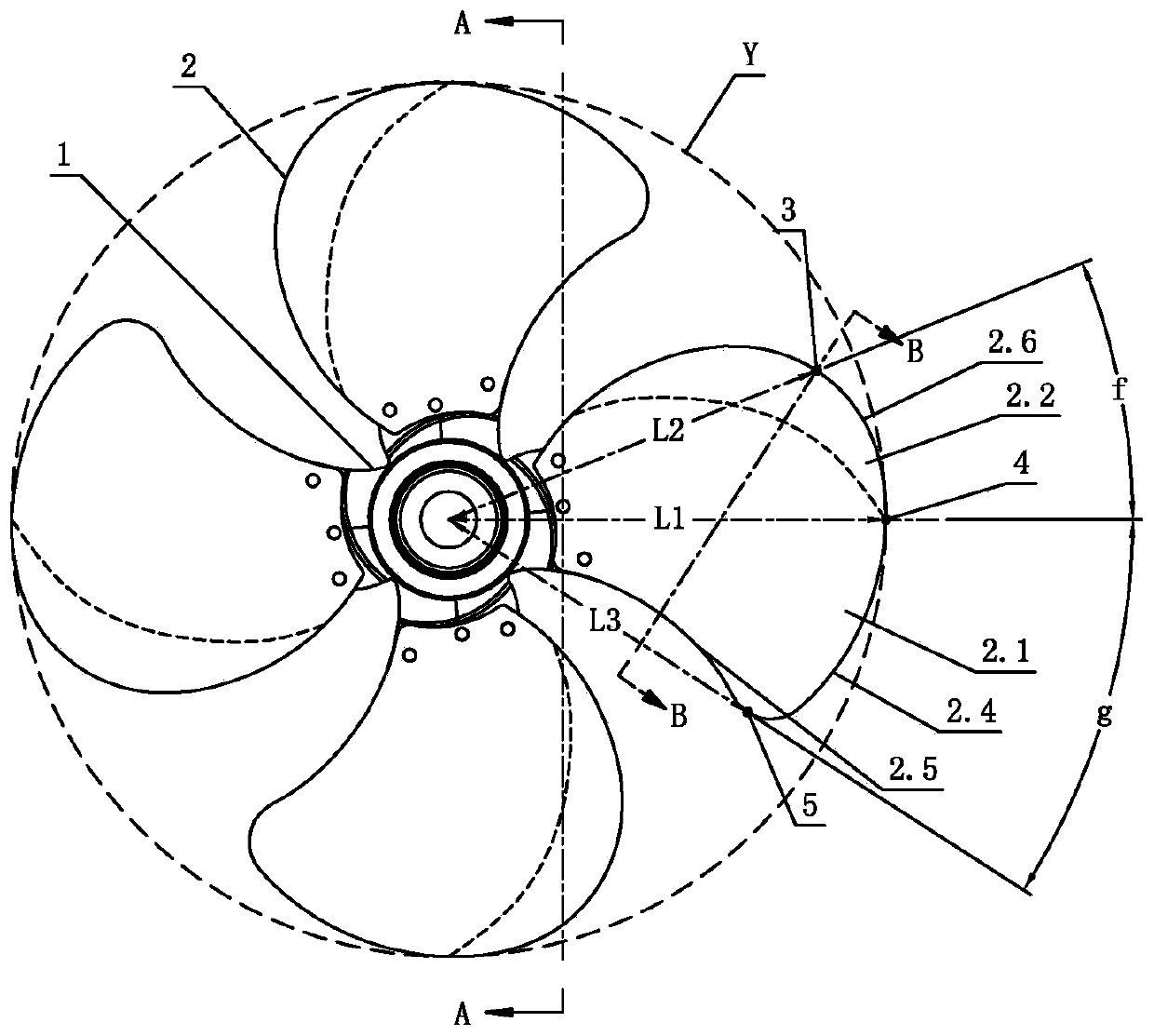

[0032] see Figure 1-Figure 5 The diameter of the commercial electric fan blade of the present embodiment is 16 inches, and the blade includes a hub 1 and four blades 2 arranged on the peripheral side of the hub 1, the root of the blade 2 is connected with the hub 1, and the blade 2 starts from the root Radially twisted and extended, each blade 2 is rotationally symmetrical and circularly distributed; the root of the blade 2 is inclined relative to the rotation axis of the hub 1, and the angle c between each other is 68°-88°; the blade 2 is twisted with a windward area 2.1 and a wind gathering area. Area 2.2, windward area 2.1 and wind gathering area 2.2 are arranged obliquely respectively, and the inclination angle e of wind gathering area 2.2 is greater than the inclination angle d of windward area 2.1, and wind gathering area 2.2 is located at the rear side of windward area 2.1, and the inclination angle of windward area 2.1 d is 5°-20°, and the inclination angle e of the w...

no. 2 example

[0041] see Figure 6-Figure 9 , the diameter of the commercial electric fan blade involved in this embodiment is 18 inches, and it is different from the first embodiment in that: in the same blade, the included angle c is 74°, the inclination angle d is 13°, and the inclination angle e is 34°; the hub 1 and the blade 2 are integrally injection molded by plastic, and the middle part of the hub 1 is formed with a spline structure 1.3.

[0042] Furthermore, the included angle f between the connecting line L1 and the connecting line L2 is 31°; the included angle g between the connecting line L1 and the connecting line L3 is 37°. in addition, Figure 7 The section line in the B'-B' direction is the section line passing through the wind gathering point 3 on the blade 2 and perpendicular to the connecting line L3.

[0043] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

no. 3 example

[0045] see Figure 10-Figure 13 , the diameter of the commercial electric fan blade involved in this embodiment is 20 inches, and it is different from the first embodiment in that: in the same blade, the included angle c is 78°, the inclination angle d is 10°, and the inclination angle e is 30°; the hub 1 and the blade 2 are integrally injection molded by plastic, and the middle part of the hub 1 is formed with a spline structure 1.3.

[0046] Furthermore, the included angle f between the connecting line L1 and the connecting line L2 is 21°; the included angle g between the connecting line L1 and the connecting line L3 is 40°. in addition, Figure 7 The section line in the B"-B" direction is the section line that passes through the wind gathering point 3 on the blade 2 and is perpendicular to the connecting line L3.

[0047] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com