Braking torque loading device of digital control spiral bevel gear lapping machine and control method

A spiral bevel gear and braking torque technology, which is applied to the loading braking torque device and its control field of a CNC spiral bevel gear grinding machine, can solve the problems of multi-point grinding of machine tools, high-speed grinding obstacles of gear grinding machines, etc. The stability of the hydraulic motor is not high, and the maintenance and control are convenient, the grinding efficiency is improved, and the grinding effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

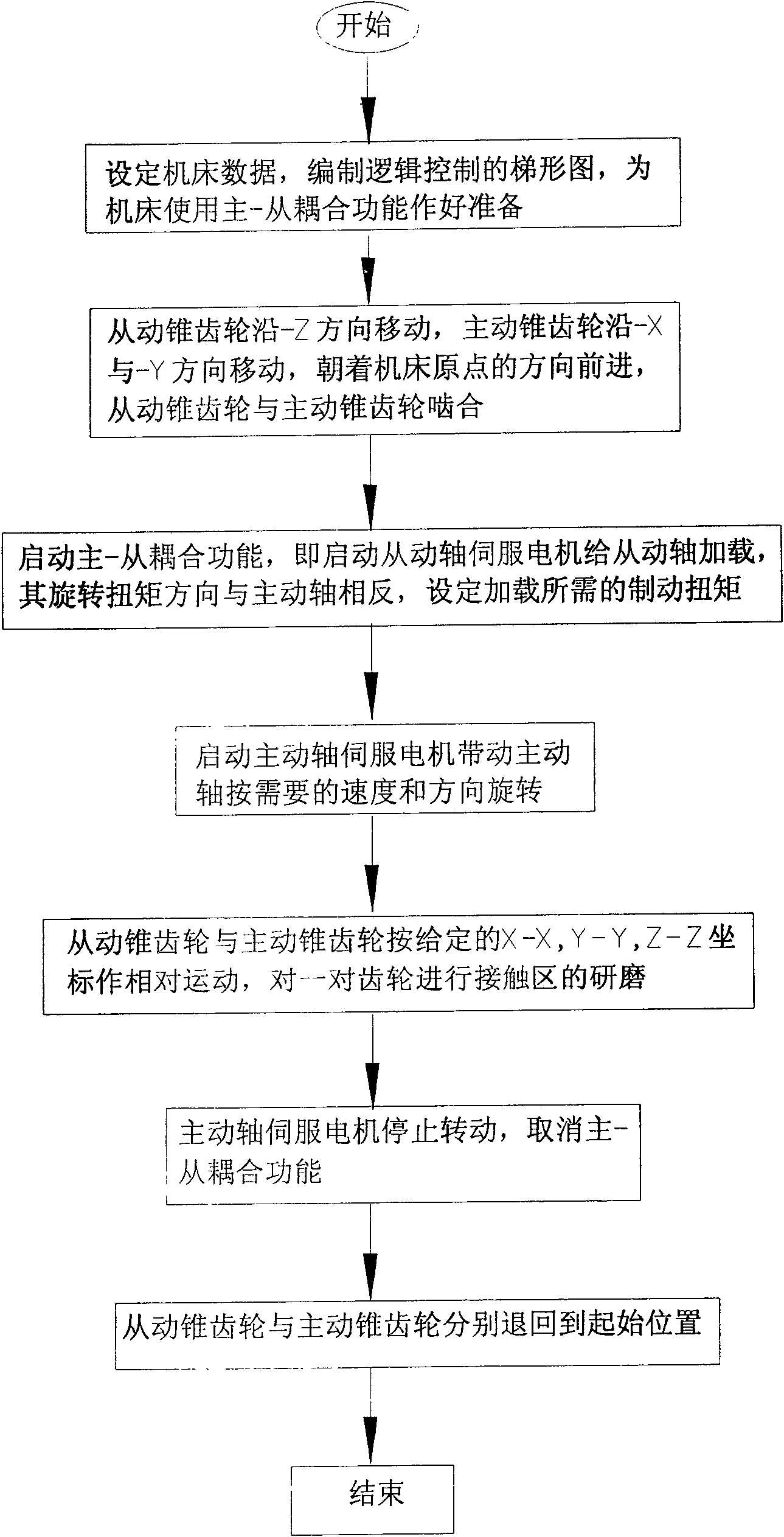

[0030] figure 2 It is a schematic plan view of the structure of the loading braking torque device of the present invention; image 3 It is a flowchart of the control method of the present invention.

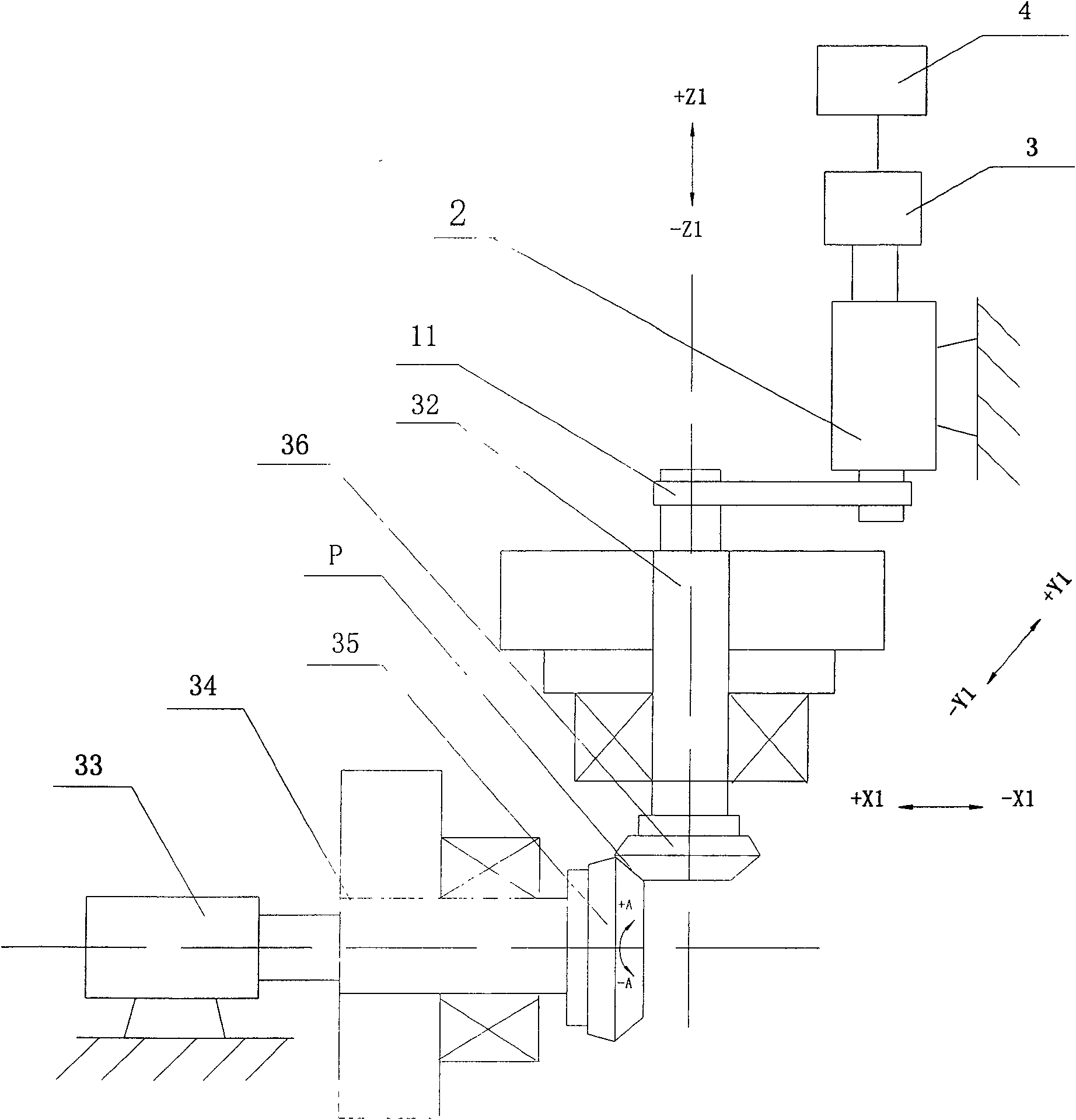

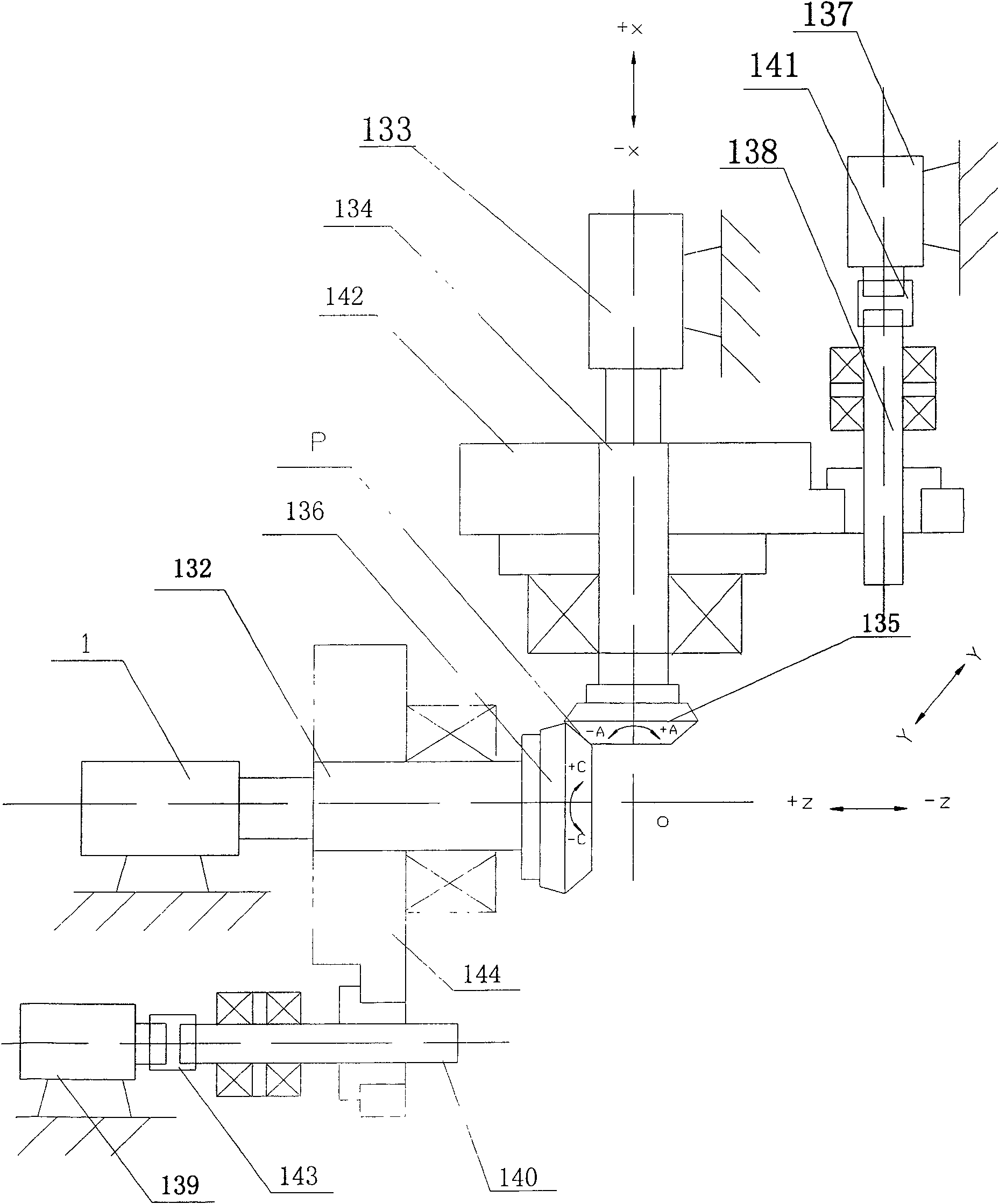

[0031] Such as figure 2 As shown, X-X, Y-Y, and Z-Z represent three linear coordinate axes respectively, and the Z-Z axis is defined as moving the driven spiral bevel gear 136 to move axially along its axis; the X-X axis is defined as the driving spiral bevel gear 135 moving along its axis Axial movement; Y-Y axis is defined as the active spiral bevel gear 135 moves along the direction perpendicular to the X-X axis and Z-Z axis, and its value is the center line of the active spiral bevel gear 135 relative to the center line of the driven spiral bevel gear 136 height difference.

[0032] The present invention provides a loading and braking torque devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com