Centrifugal fan with vortex preventing sheets

A centrifugal fan and vortex technology, which is used in electromechanical devices, mechanical equipment, and mechanical energy control. Low decibel value and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

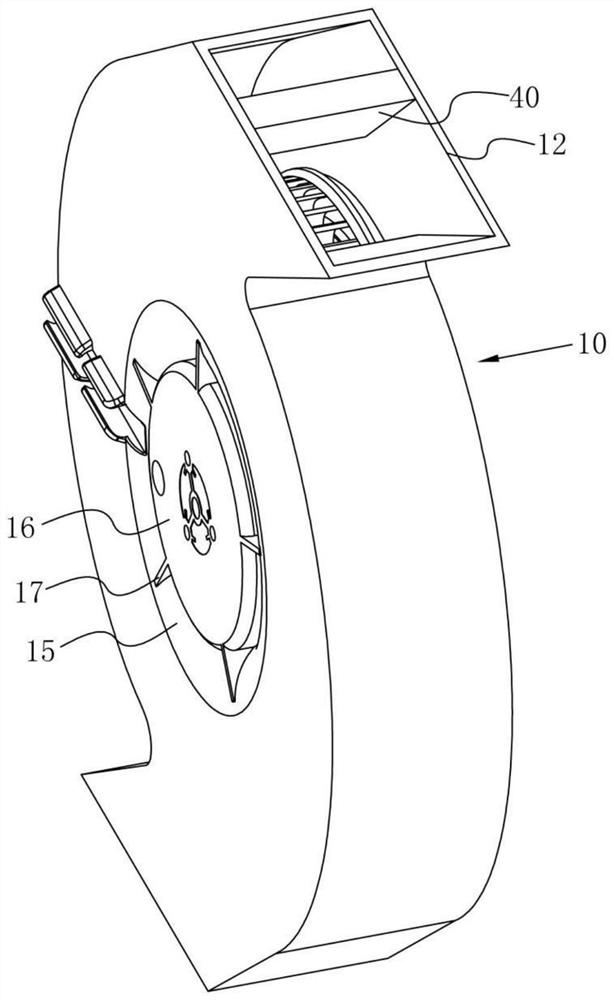

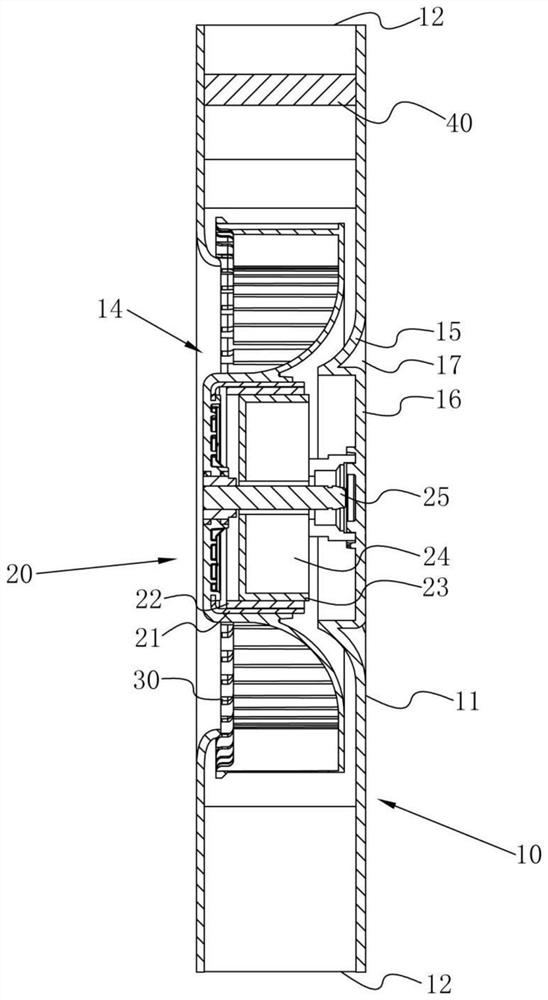

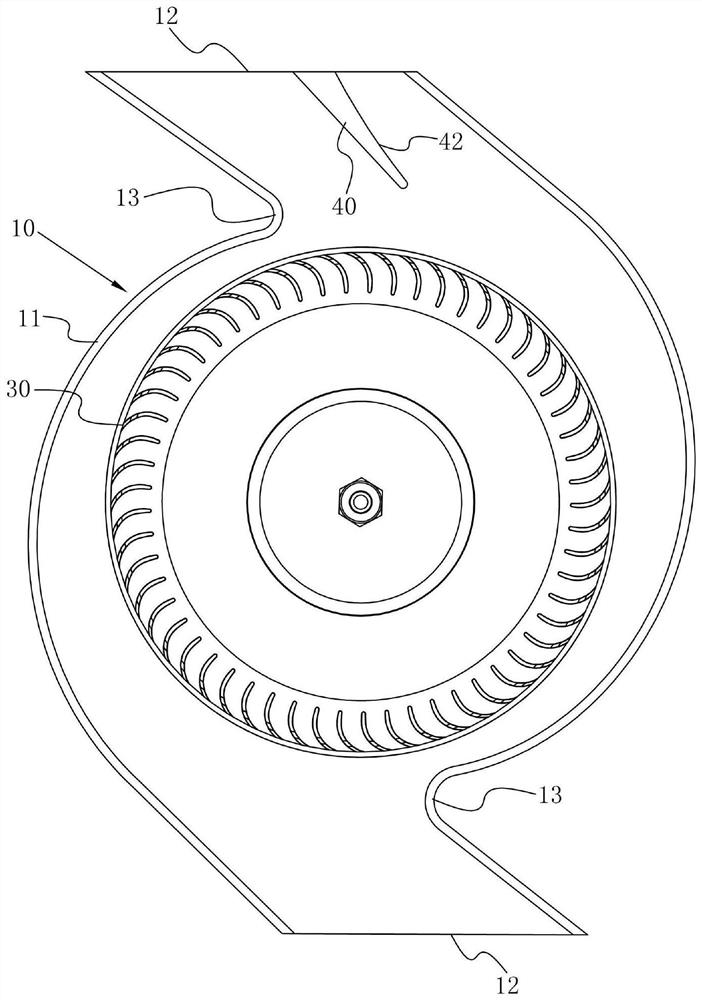

[0036] refer to Figure 1-3 , a centrifugal fan with anti-vortex plate, including a volute 10, a driving device 20 and an impeller 30. The main body 11 is provided with an air inlet 14, the driving device 20 drives the impeller 30 to rotate in the volute 10, and the rotating impeller 30 drives the air to enter the interior of the main body 11 from the air inlet 14, and is discharged through the air outlet 12 to realize the air supply of the centrifugal fan. Function.

[0037] The driving device 20 is respectively connected with the volute 10 and the impeller 30. The volute 10 includes a main body 11, an air outlet 12 and a volute tongue 13. The air outlet 12 and the volute tongue 13 are fixedly connected with the main body 11, and the impeller 30 is located in the volute 10. The volute 10 is fixedly connected with an anti-vortex sheet 40, the anti-vortex sheet 40 extends toward the air outlet 12, and the distance between the anti-vortex sheet 40 and the rotation center of the...

Embodiment 2

[0066] refer to Figure 5 , a centrifugal fan with an anti-vortex sheet, the difference from Embodiment 1 is that there are two anti-vortex sheets 40 in total, and the two anti-vortex sheets 40 correspond to the two volute tongues 13 one-to-one respectively.

[0067] This embodiment has the following advantages:

[0068] When the conventional fan is designed with dual air outlets, the parameters of the volutes 10 at the two air outlets 12 affect each other, resulting in insufficient air diffusion in each section of the volutes 10, and it is difficult to optimize the parameters of the volutes 10. By arranging the anti-vortex sheet 40 in the volute 10, after the flow is divided by the anti-vortex sheet 40, the problem of insufficient airflow diffusion in the volute 10 is effectively improved, and the air flow in the volute 10 is further controlled by the anti-vortex sheet 40, so that The outlet flow field structure of the centrifugal fan designed with double air outlets 12 has ...

Embodiment 3

[0070] refer to Image 6 , a centrifugal fan with an anti-vortex sheet, which is different from Embodiment 1 in that: the anti-vortex sheet 40 is provided with a plurality of shunt holes 41 .

[0071] This embodiment has the following advantages:

[0072] By arranging the diverting holes 41 on the anti-vortex sheet 40, the air on both sides of the anti-vortex sheet 40 can flow through the diverting holes 41, so that the anti-vortex sheet 40 can not only play a certain diverting function, but also take into account the output of the centrifugal fan. The performance of the air volume is improved, and it has the effect of controlling the noise. It achieves the advantages of good noise reduction effect, good air output stability and large output air volume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com