Rock damage mechanics test system under deep high-temperature high-pressure environment

A technology of high temperature and high pressure and damage mechanics, which is applied in the direction of applying stable tension/pressure to test material strength, soil material testing, and measuring devices, etc. Problems, to prevent falling damage and other secondary injuries, improve disassembly efficiency, simple and reliable hole alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

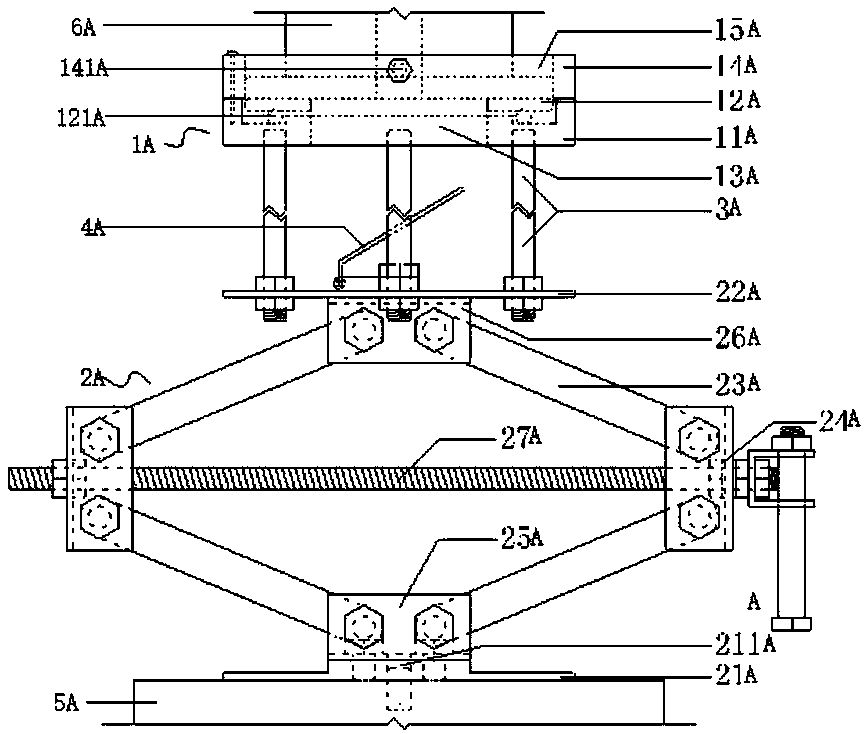

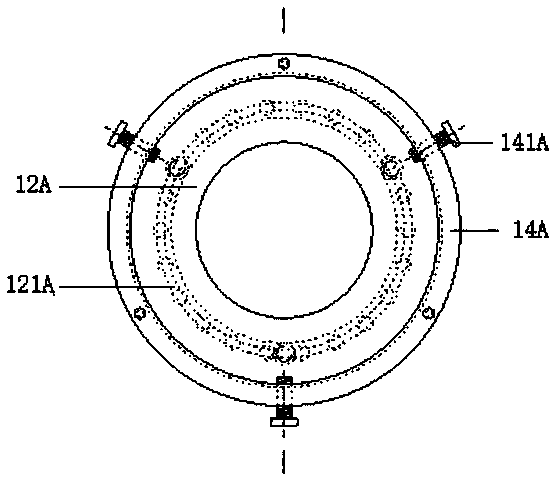

[0031] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

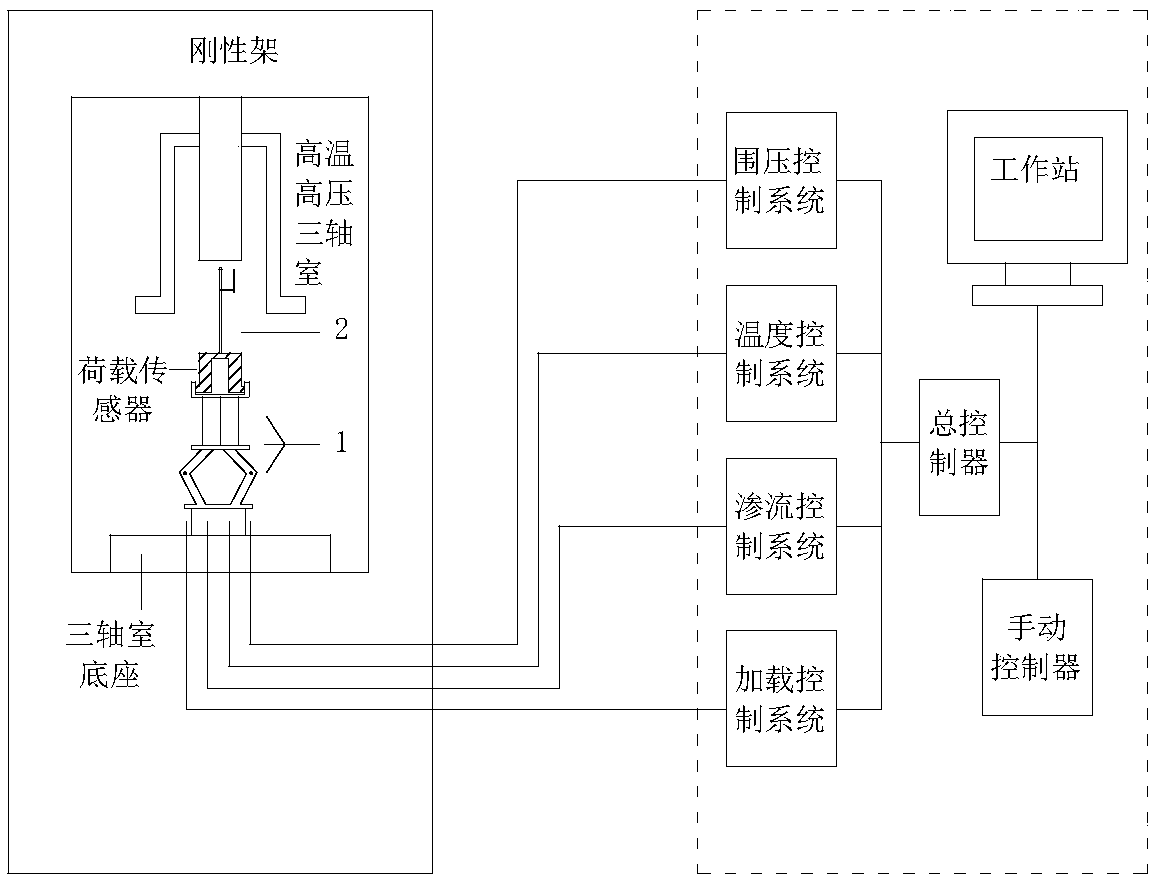

[0032] Such as figure 1 Shown:

[0033] Rock damage mechanics testing system under high temperature and high pressure environment in deep ground, including MTS triaxial testing machine and control system connected with MTS triaxial testing machine.

[0034] MTS triaxial testing machine consists of rigid frame, high temperature and high pressure triaxial chamber and triaxial chamber base. The high temperature and high pressure triaxial chamber and triaxial chamber base are mounted on the rigid frame. The high temperature and high pressure triaxial chamber is vertically opposite to the triaxial chamber base, and the central axis of the high temperature and high pressure triaxial chamber coincides with the central axis of the triaxial chamber base.

[0035] The control system includes a workstation for data processing, a manual controller for controllin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com