Residual error network-based detection method for four types of damage of conveyer belt

A damage detection and conveyor belt technology, applied in conveyor objects, conveyor control devices, measuring devices, etc., can solve problems such as safety accidents, large number of sensors, and unsatisfactory effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

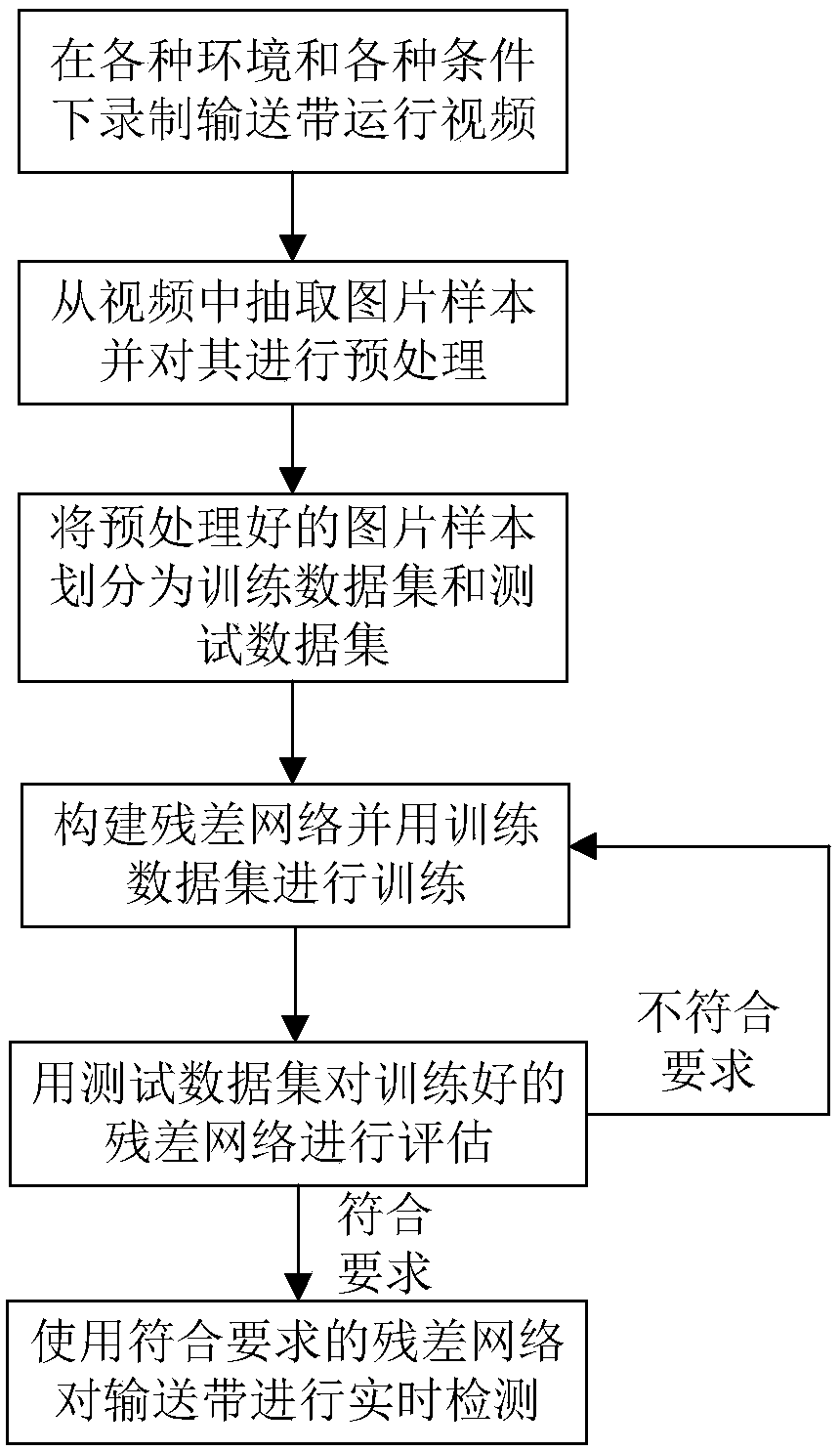

[0035] Such as figure 1 As shown, the process of the four damage detection methods based on the residual network conveyor belt is:

[0036] (1) Record the video of the conveyor belt under various environments and conditions, install a camera above the conveyor belt or use the existing conveyor belt monitoring camera for long-term uninterrupted video recording of the conveyor belt, and obtain information in different operating states and different time periods , Conveyor belt video data under different light intensities and different temperature and humidity environments;

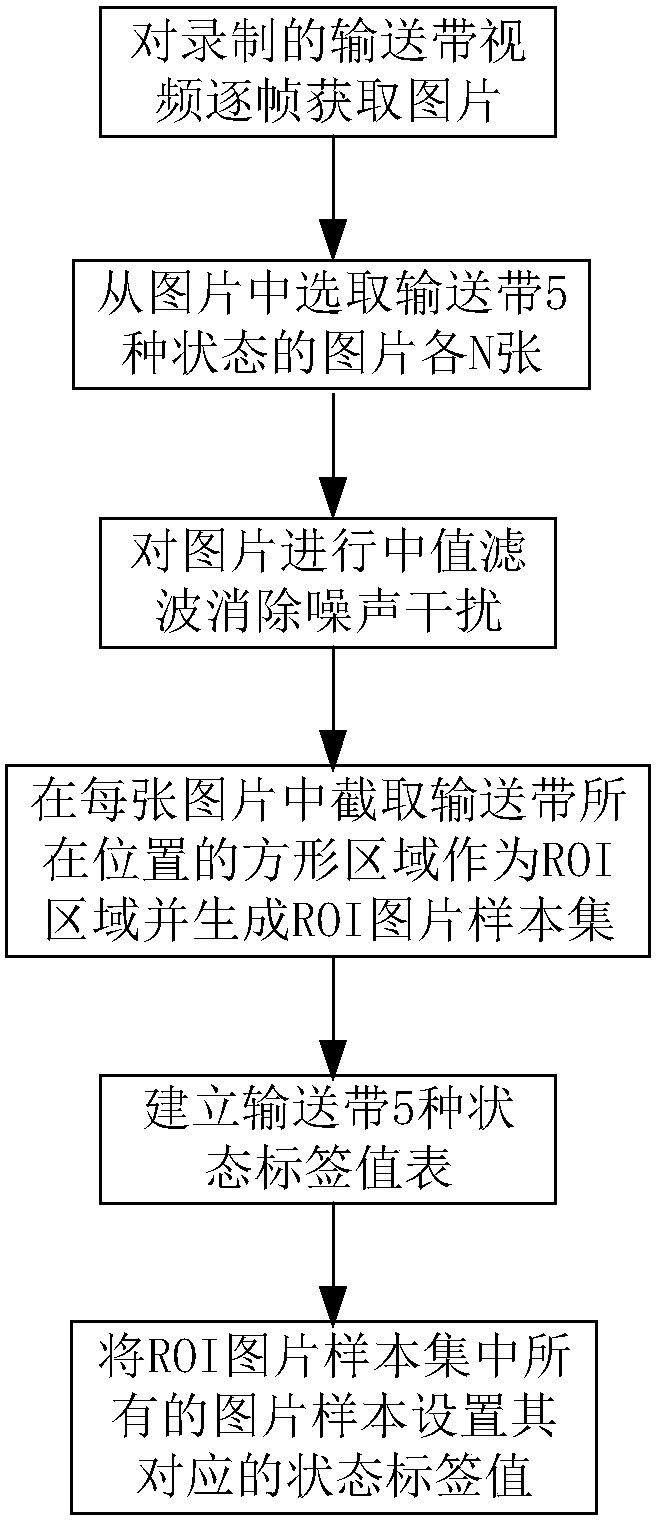

[0037] (2) Extract image samples from the recorded video and preprocess it;

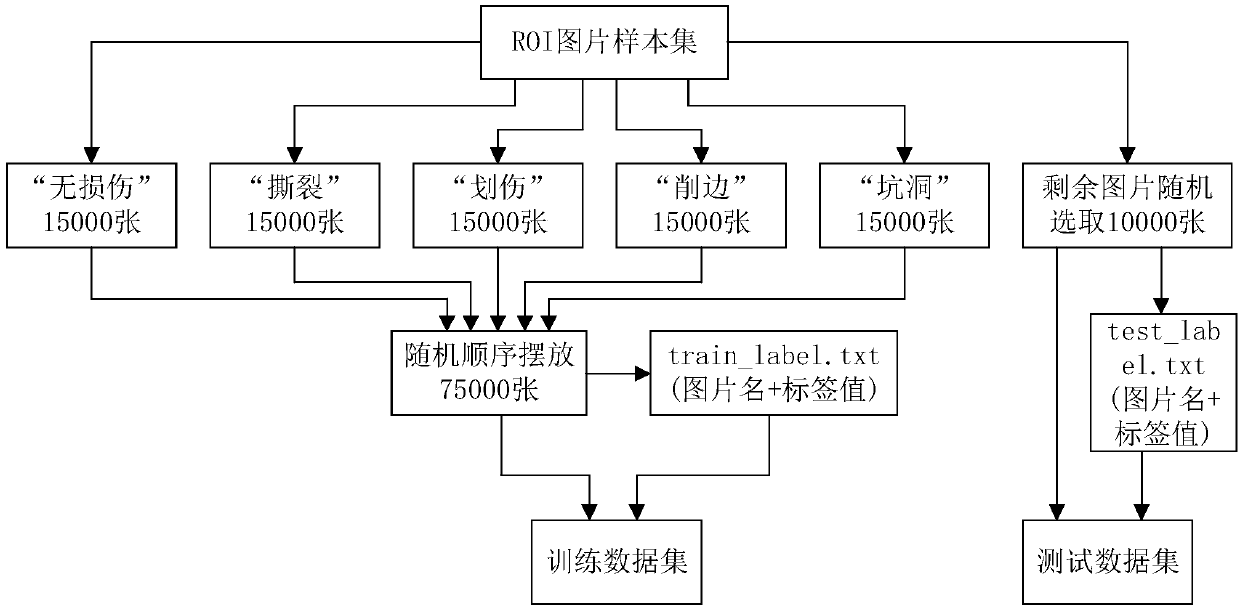

[0038] (3) Divide the preprocessed image samples into training data sets and test data sets;

[0039] (4) Build a residual network and train it with a training data set;

[0040] (5) Use the test data set to evaluate the trained residual network, input all the picture samples in the test data set into the residual network in tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com