High-temperature heating clamping experiment device for fuel bundles of pressurized water reactor

A fuel rod bundle and high-temperature heating technology, which is applied in the direction of reactor fuel elements, reactors, climate sustainability, etc., can solve the problems of cost increase, electrode damage, and small contact area, so as to reduce the possibility of electrode burnout and reduce contact resistance , to overcome the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

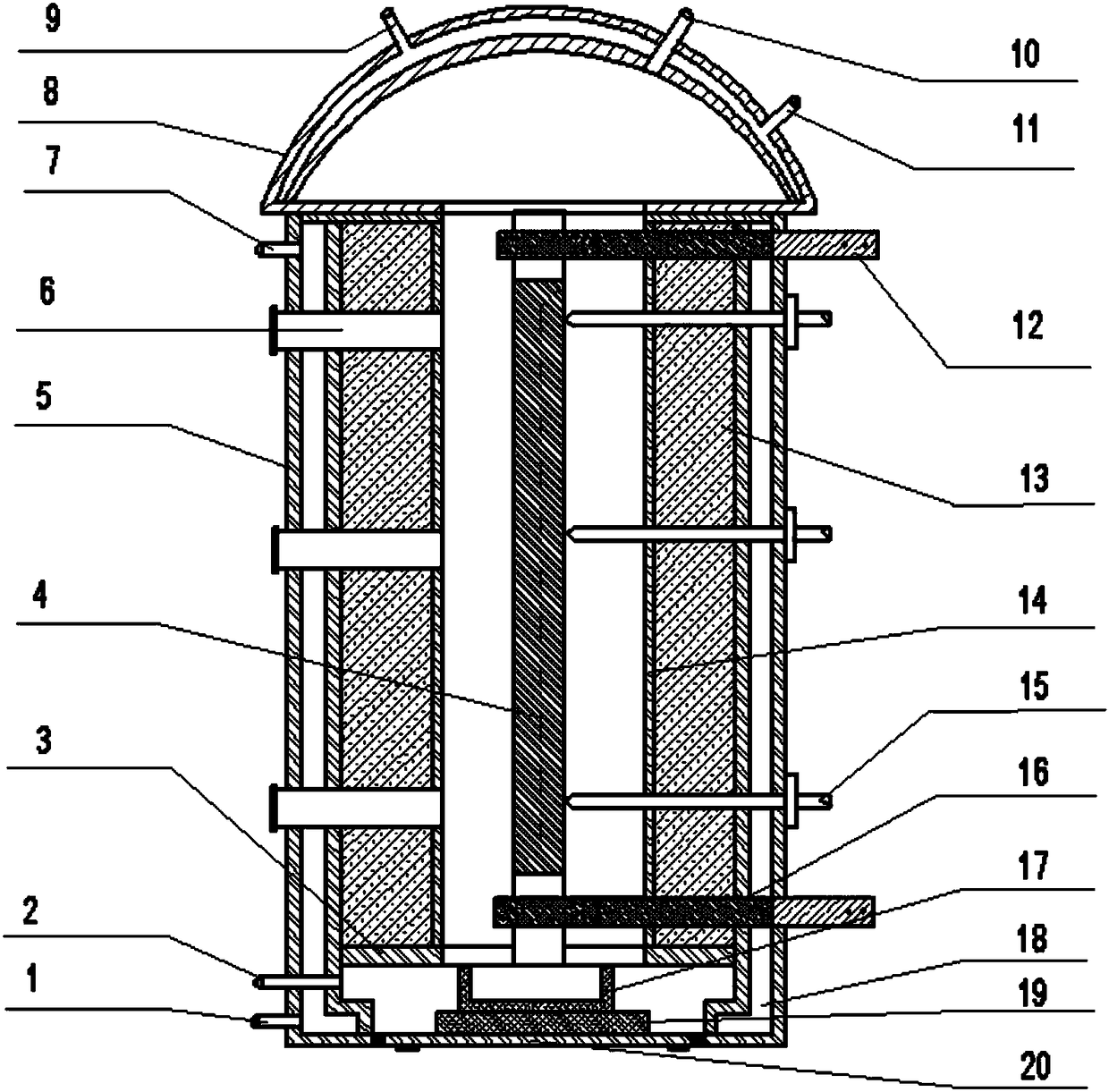

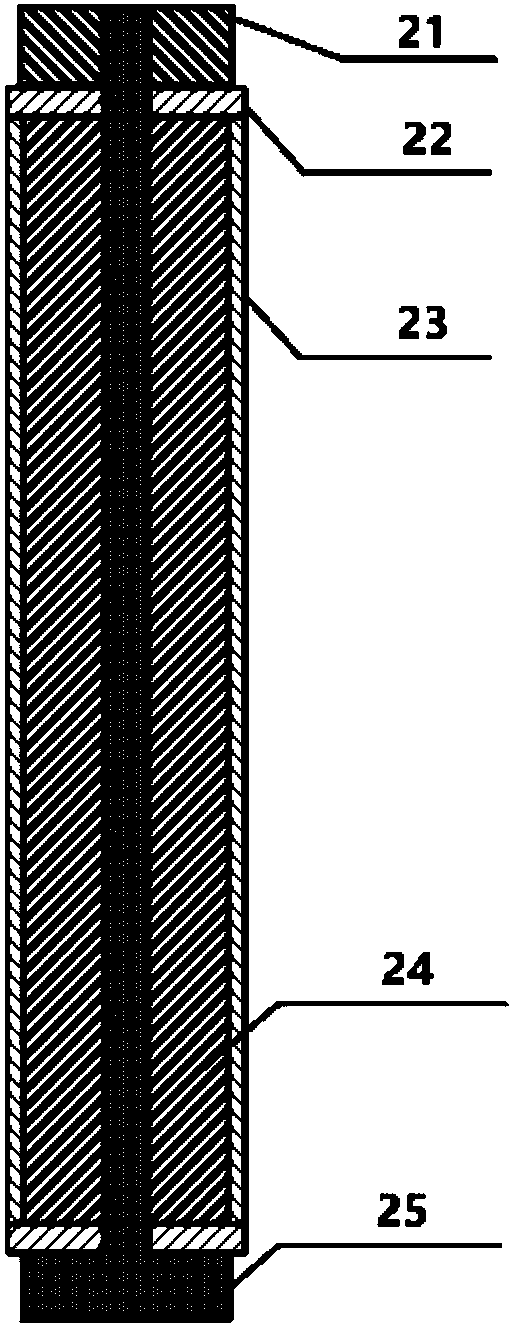

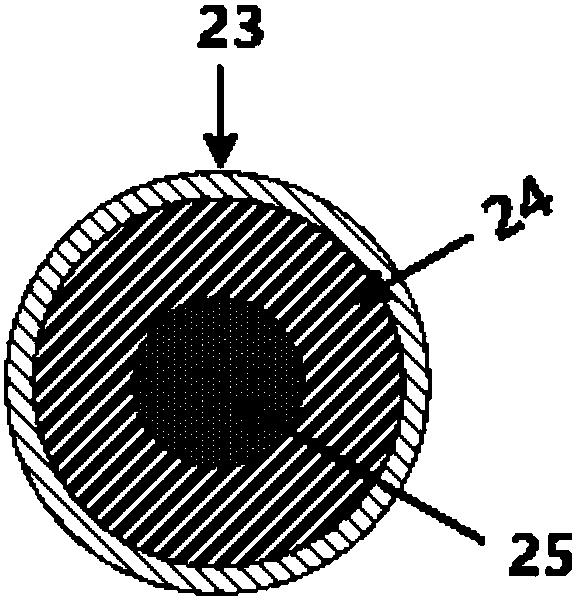

[0029] see Figure 1-Figure 7 , the PWR fuel bundle high-temperature heating and clamping experimental device of the present invention includes a high-temperature melting furnace, and fuel bundles and rhenium-molybdenum electrodes arranged inside the high-temperature melting furnace.

[0030] see figure 1 , the high-temperature melting furnace includes a furnace body 5, the furnace body 5 is a cylindrical structure with an inner diameter of 1.0 m, a height of 1.5 m, and a wall thickness of 0.01 m. The top of the furnace body 5 is provided with an arc-shaped furnace cover 8. The furnace cover 8 is designed in an arc shape, which can improve the pressure bearing capacity. The furnace cover 8 is provided with a second water outlet 9, an argon gas outlet 10 and a second water inlet 11. . A molybdenum plate 3 for supporting the high temperature heat insulation layer 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com