Wood product processing equipment

A technology for processing equipment and wood products, which is applied in the field of wood product processing equipment, can solve problems such as uneven paint thickness on the side of workpieces, and achieve the effect of improving painting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further detailed explanation through specific implementation mode below:

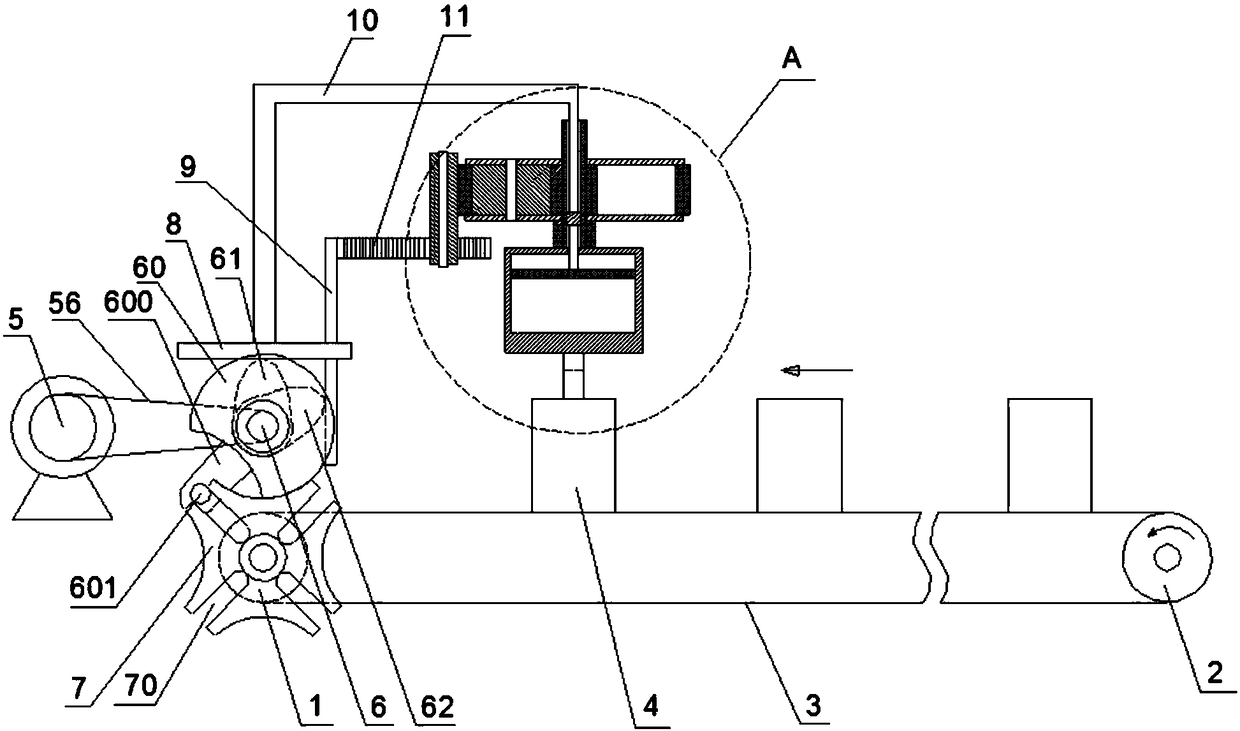

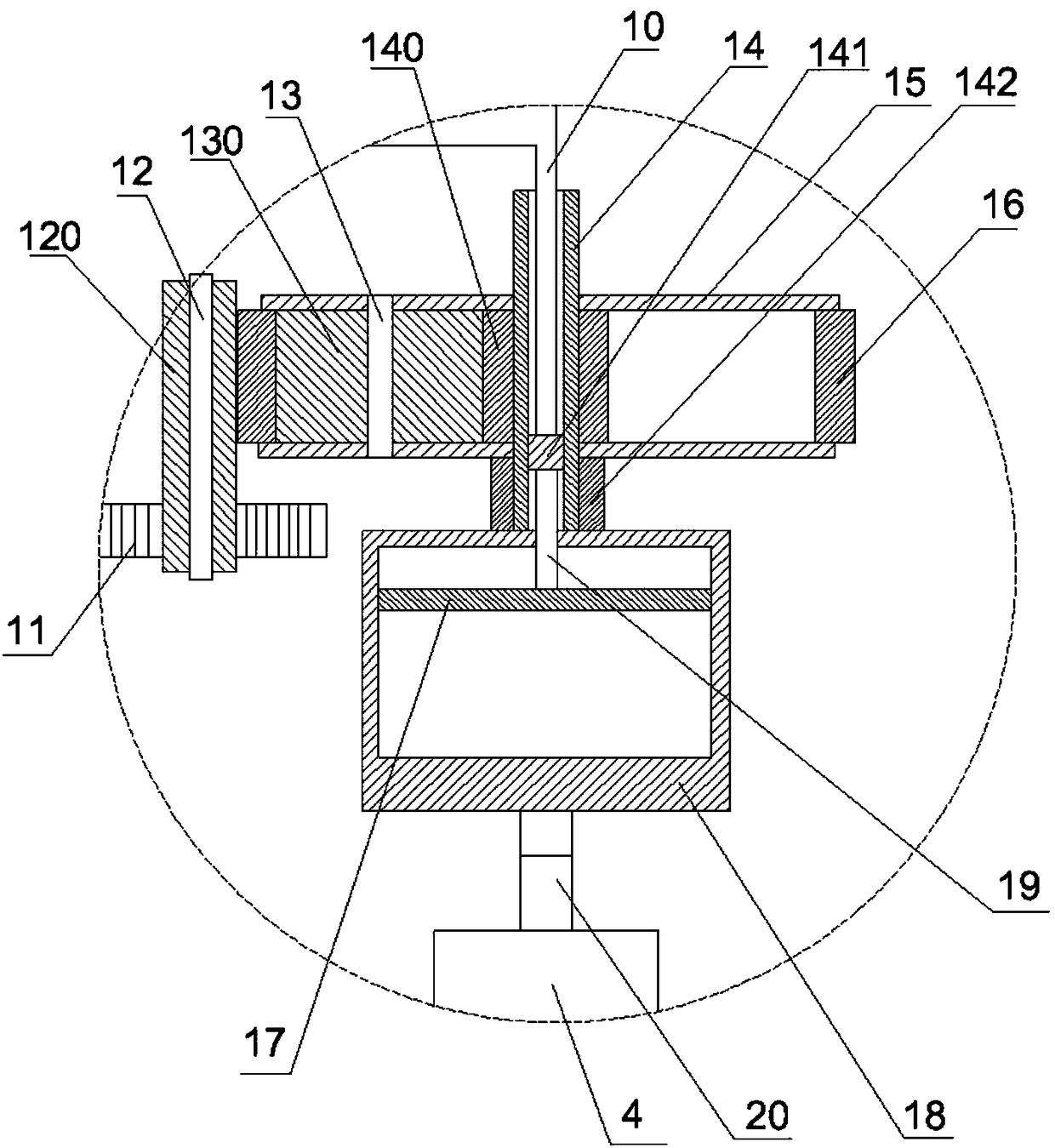

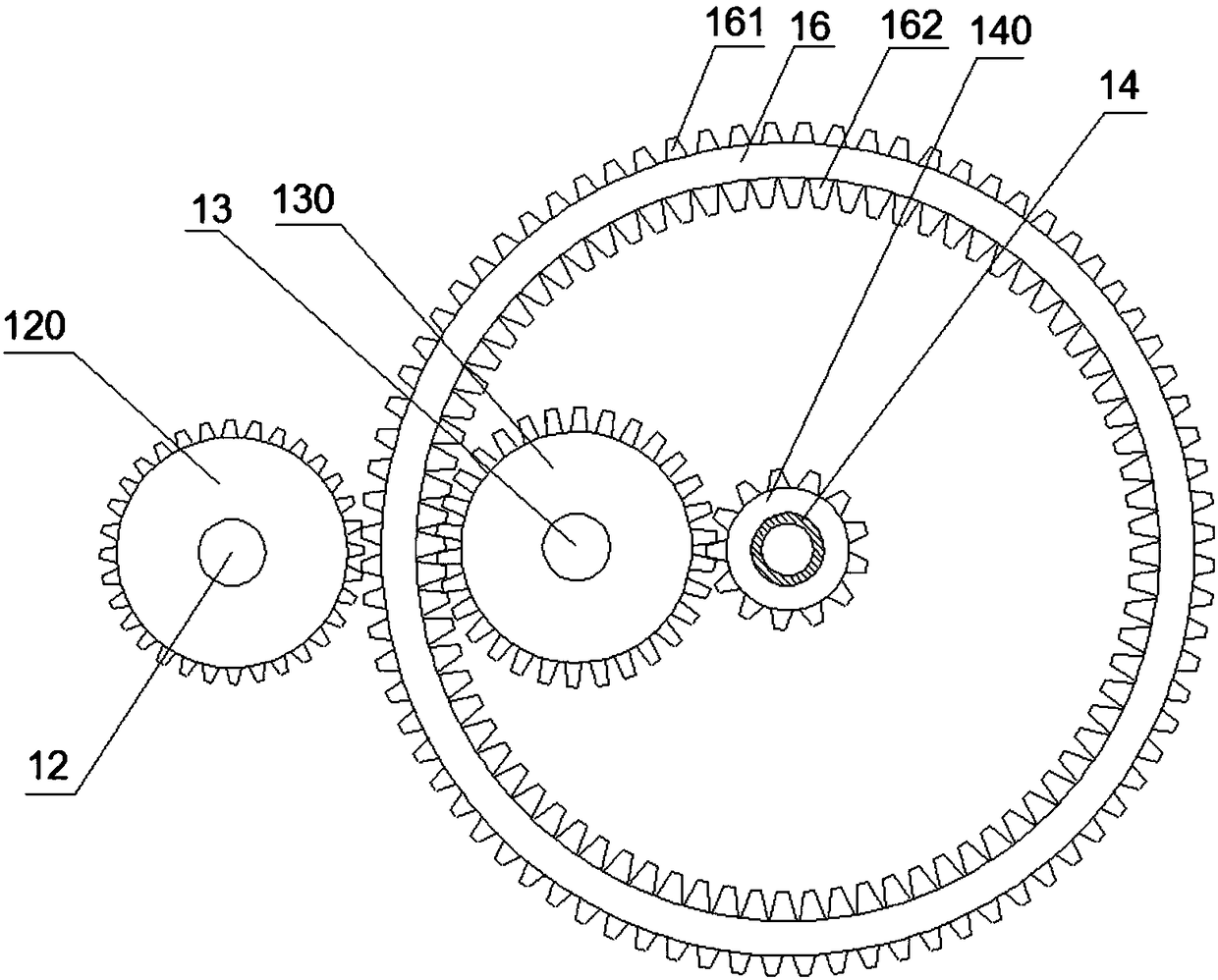

[0024] The reference signs in the drawings of the description include: driving wheel 1, driven wheel 2, conveyor belt 3, workpiece 4, motor 5, synchronous belt 56, drive shaft 6, dial 60, connecting arm 600, round pin 601, second cam 61. The first cam 62, the sheave 7, the radial groove 70, the second top plate 8, the first top plate 9, the connecting frame 10, the rack 11, the rotating shaft 12, the connecting shaft 13, the planetary gear 130, the rotating shaft 14, the sun Wheel 140, sliding block 141, sleeve 142, planet carrier 15, drive ring 16, drive tooth 161, ring gear 162, drive gear 120, piston plate 17, paint box 18, paint outlet 180, guide groove 181, the third Spring 182, centrifugal block 183, connecting rod 19, paint spraying rod 20, horizontal spraying part 201, vertical spraying part 202, paint spraying port 2010, paint inlet 2011.

[0025] like figure 1 As shown, the wood produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com