Intelligent liquid supply method and system for fully-mechanized coal mining face

A technology of fully mechanized mining face and liquid supply, applied in mining equipment, mining equipment, earthwork drilling, etc., can solve the problems of complex and inability to supply liquid and liquid supply system on demand, and achieve the effect of avoiding time delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

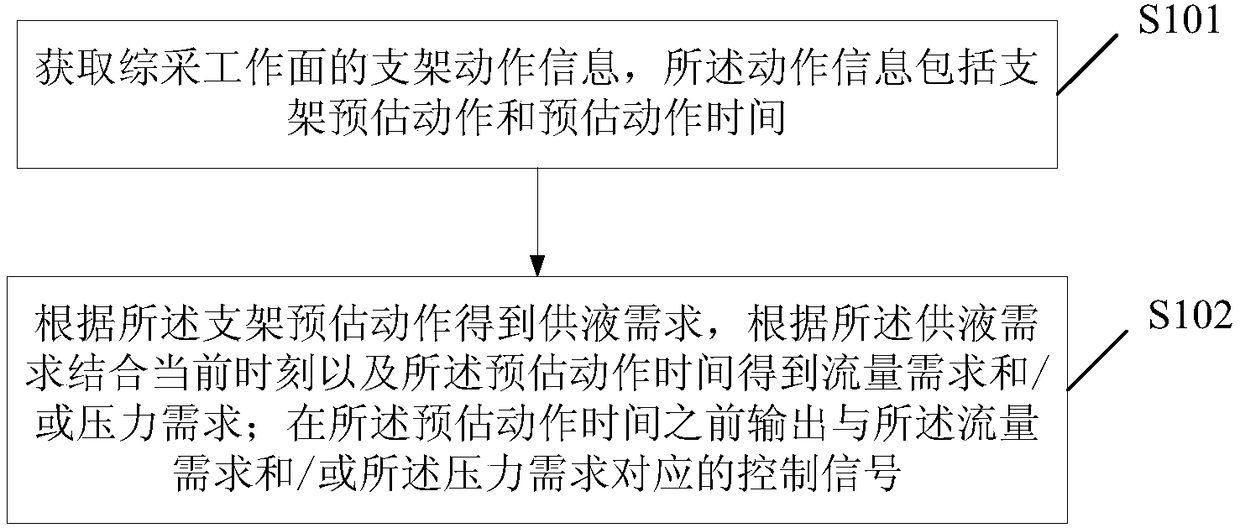

[0050] This embodiment provides an intelligent liquid supply method for a fully mechanized mining face, which is used in the control system of a liquid supply pump station, such as figure 1 shown, including the following steps:

[0051] S101: information acquisition step: acquire the support action information of the fully mechanized mining face, the action information includes the estimated action and estimated action time of the support; this information can be obtained through the support electro-hydraulic control unit, because the support electro-hydraulic control unit is used for Unified control of the working status of all supports on the fully mechanized mining face, so it can predict the next action of each support, that is, it can obtain accurate estimated action and estimated action time of supports, among which the predicted The estimated action time is the estimated start time of the action.

[0052] S102: On-demand control step: Obtain the liquid supply demand ac...

Embodiment 2

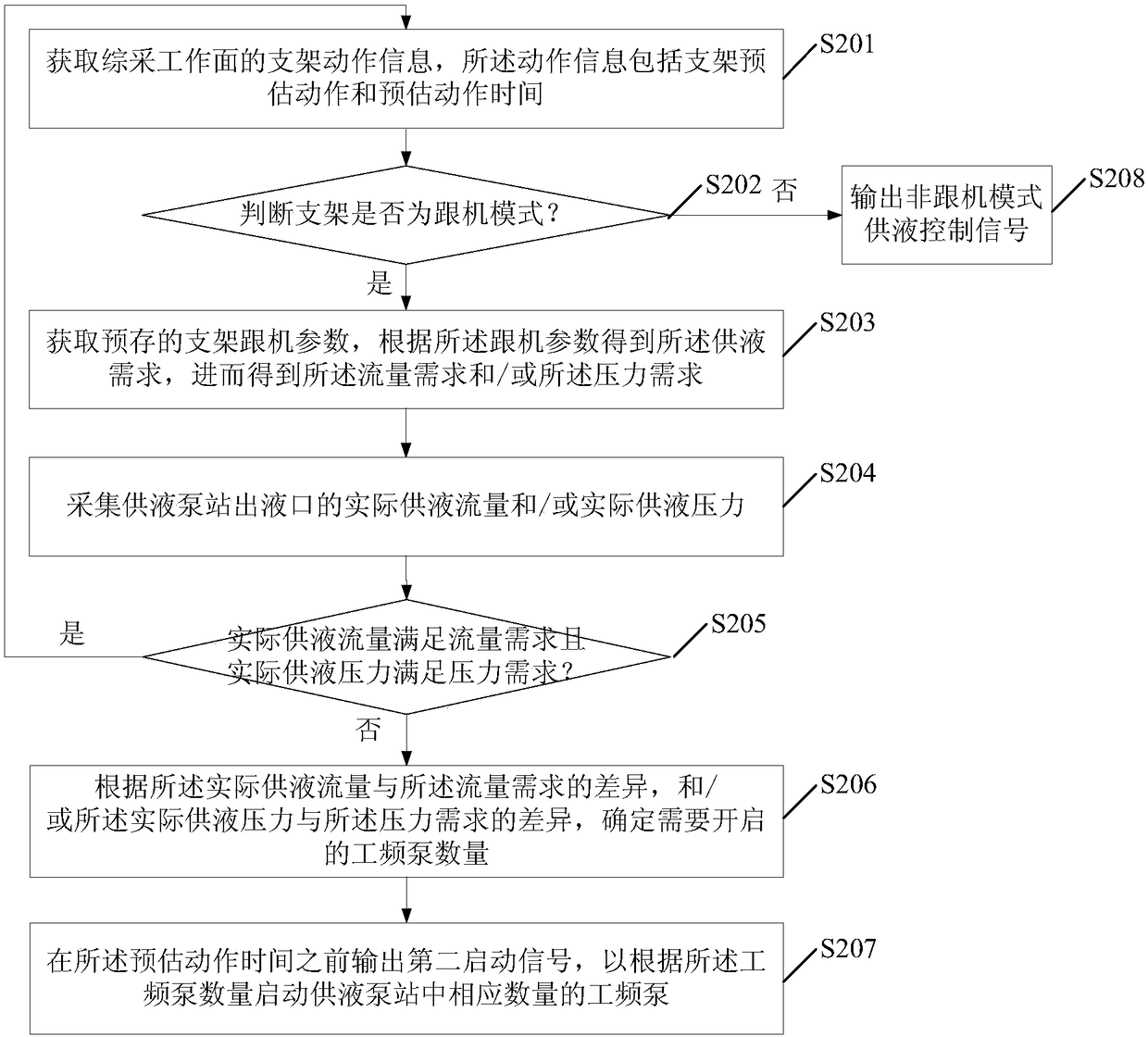

[0055] The intelligent liquid supply method for the fully mechanized mining face provided in this embodiment is used in the control system of the liquid supply pump station, such as figure 2 shown, including the following steps:

[0056] S201: Information acquisition step: Acquiring support action information of the fully mechanized mining face, the action information including estimated action and estimated action time of the support; the information can be obtained through the electro-hydraulic control unit of the support.

[0057] S202: Determine the working mode of the support according to the estimated action of the support; if the working mode of the support is follow-up mode, output a first start signal to start at least one variable frequency pump in the liquid supply pump station; and execute step S203; Otherwise, execute step S208. The following mode means that the support moves forward following the speed of the shearer. After it is determined that the working mo...

Embodiment 3

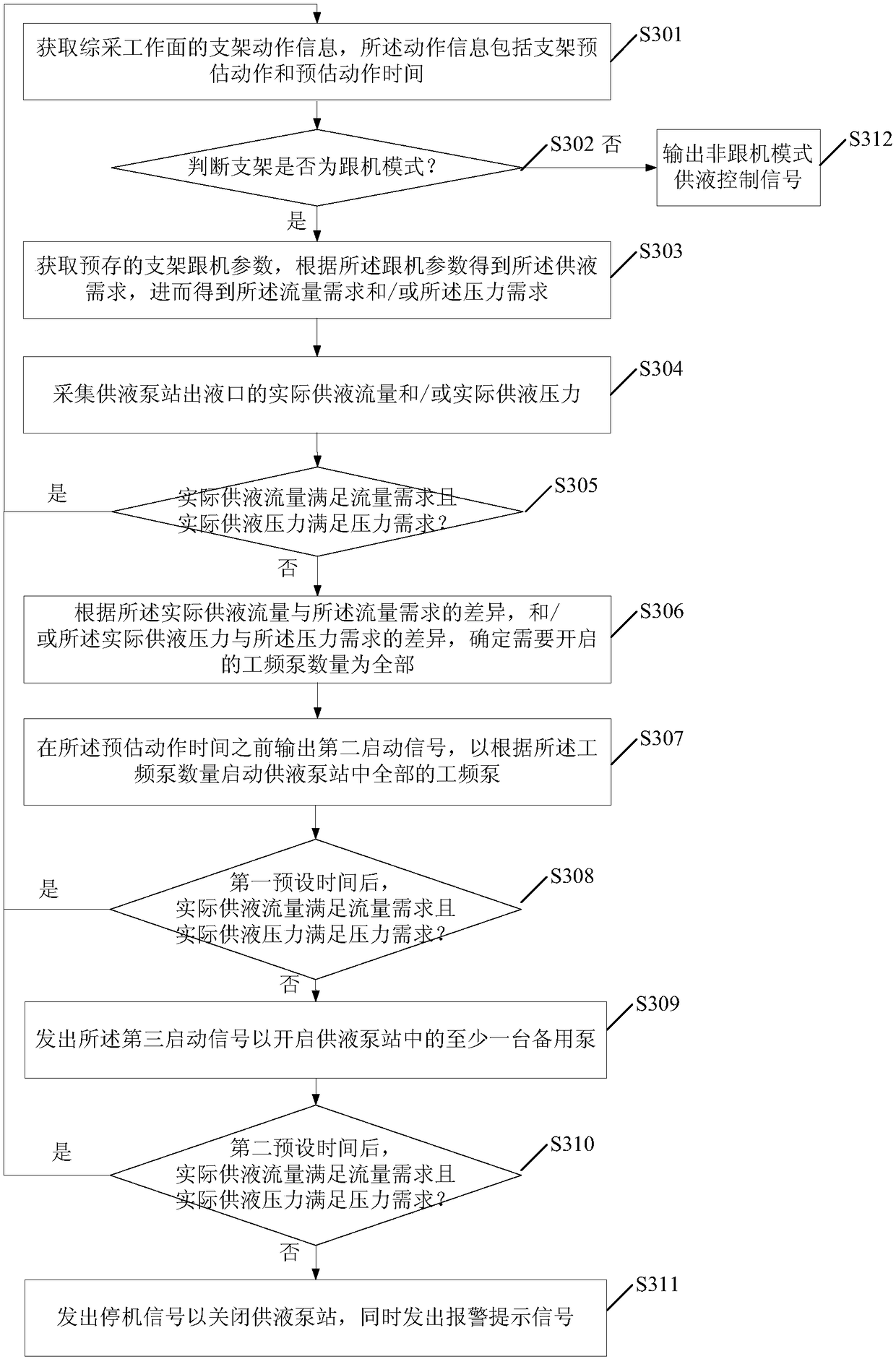

[0069] The intelligent liquid supply method for the fully mechanized mining face provided in this embodiment is used in the control system of the liquid supply pump station, such as image 3 shown, including the following steps:

[0070] S301: information acquisition step: acquiring action information of supports in fully mechanized mining face, said action information including estimated action and estimated action time of supports; this information can be obtained through electro-hydraulic control unit of supports.

[0071] S302: Determine the working mode of the support according to the estimated action of the support; if the working mode of the support is follow-up mode, output a first start signal to start at least one variable frequency pump in the liquid supply pump station; and execute step S303; Otherwise, execute step S312.

[0072] S303: Obtain the pre-stored support follow-up parameters, obtain the liquid supply demand according to the follow-up parameters, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com