Automatic focusing method based on electro-hydraulic lens with adjustable focus

An autofocus and lens technology, applied in lens, installation, optics and other directions, can solve the problems of hardware drive time delay, prone to misfocus, stepper motor error, etc., to reduce the number of focusing times, focus clearly, and improve speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical scheme and main points of the present invention clearer, below in conjunction with the accompanying drawings, the implementation steps of the present invention will be described in detail with specific examples:

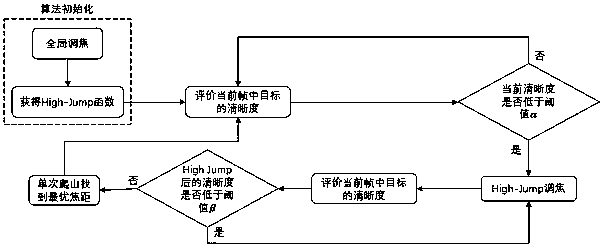

[0032] Such as figure 1 As shown, an autofocus method based on an electro-hydraulic adjustable focus lens includes the following steps:

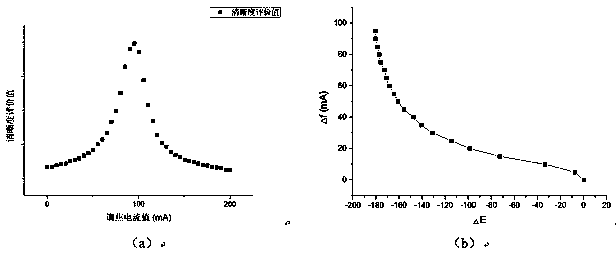

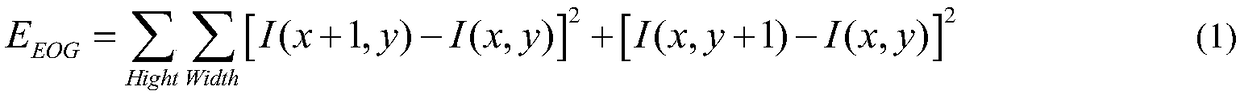

[0033] 1) The algorithm is initialized, and the High-Jump function Δf=H(ΔE) of the current target is obtained through global focusing;

[0034] 2) Evaluate the sharpness evaluation value of the target image in the current frame and determine whether it is smaller than a preset threshold α. If yes, perform step 3); if not, repeat this step;

[0035] 3) Perform High-Jump focusing;

[0036] 4) Evaluate the sharpness evaluation value of the target image in the frame after the High-Jump, and determine whether it is less than the preset threshold β. If yes, perform step 3); if not, perform step 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com