Novel opposite-rubbing multi-row poultry egg cleaning machine

A technology for washing machines and eggs, applied in poultry industry, application, animal husbandry, etc., can solve the problems of broken eggs, inconvenient maintenance, etc., and achieve the effects of short service life, convenient maintenance, and reduced speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

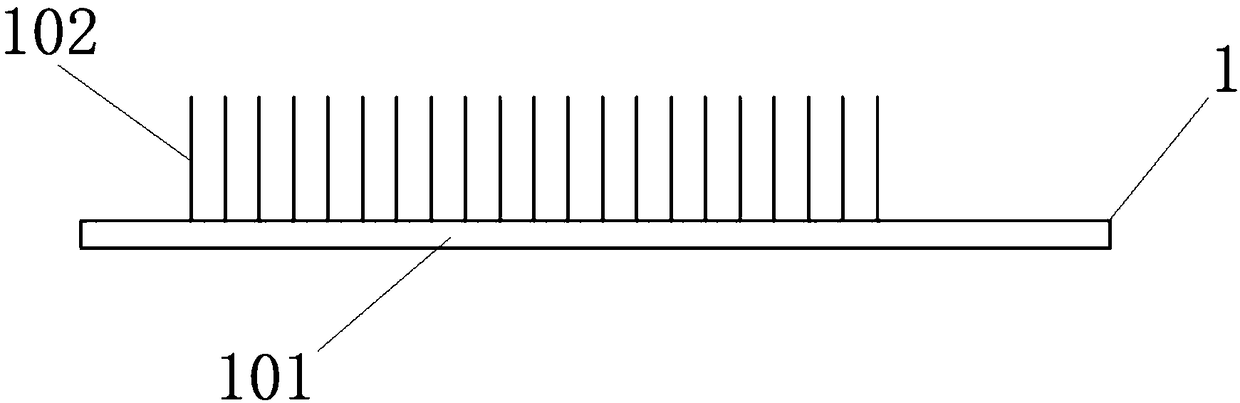

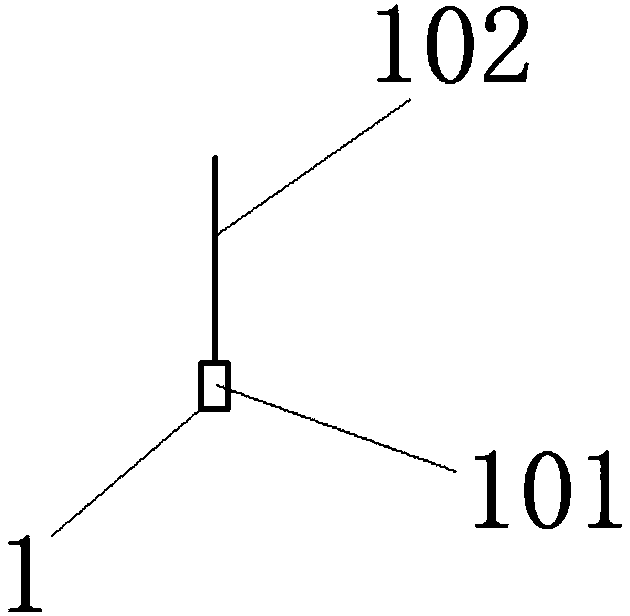

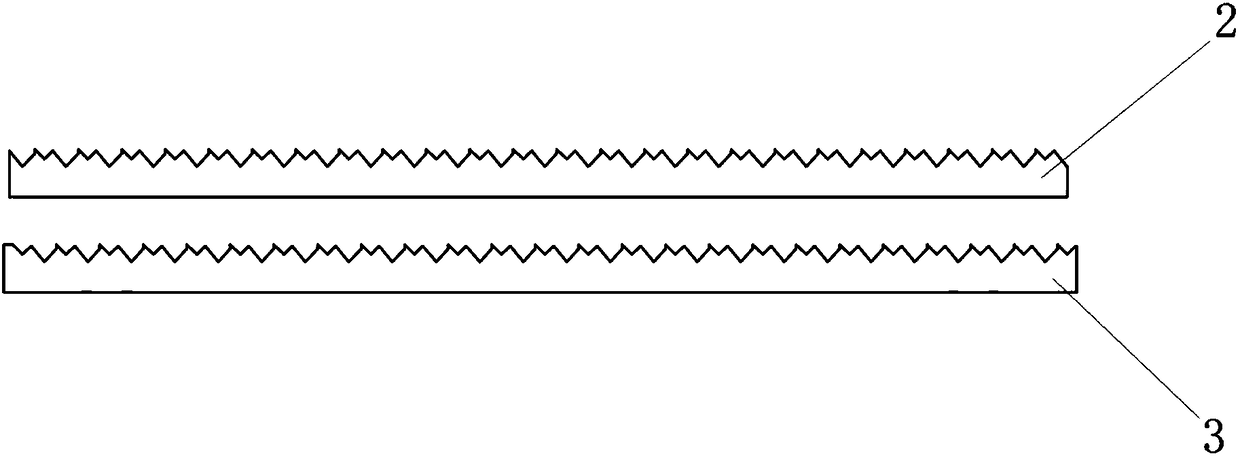

[0038] A new rubbing type multi-row poultry egg cleaning machine, such as Figure 1-11 As shown, it includes the brush 1, the first brush positioning rack 2, the second brush positioning rack 3, the first brush fixing frame 4, the second brush fixing frame 5, the egg roller 6, and the bearing slider 8. Spray head 9, crankshaft 10, bearing 11, motor 12, short connecting rod 13, long connecting rod 14, wherein:

[0039] The brush 1 includes a brush handle 101 and a brush head 102, and the brush head 102 is fixedly connected to the brush handle 101; the bottom end of the first brush fixed frame 4 is connected with a first sliding bearing 401; The bottom end is connected with a second sliding bearing 501; the crankshaft 10 includes a main journal 1001, a first connecting rod journal 1002, a second connecting rod journal 1003, and one end of the first connecting rod journal 1002 passes through a crank and the second connecting rod One end of the journal 1003 is connected, and the ...

Embodiment 2

[0045] A new rubbing type multi-row poultry egg cleaning machine, such as Figure 1-11 As shown, it includes the brush 1, the first brush positioning rack 2, the second brush positioning rack 3, the first brush fixing frame 4, the second brush fixing frame 5, the egg roller 6, and the bearing slider 8. Spray head 9, crankshaft 10, bearing 11, motor 12, short connecting rod 13, long connecting rod 14, wherein:

[0046] The brush 1 includes a brush handle 101 and a brush head 102, and the brush head 102 is fixedly connected to the brush handle 101; the bottom end of the first brush fixed frame 4 is connected with a first sliding bearing 401; The bottom end is connected with a second sliding bearing 501; the crankshaft 10 includes a main journal 1001, a first connecting rod journal 1002, a second connecting rod journal 1003, and one end of the first connecting rod journal 1002 passes through a crank and the second connecting rod One end of the journal 1003 is connected, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap