Parts cleaning device for mechanical processing

A cleaning device and machining technology, applied in the field of parts processing, can solve the problems of waste of water resources, easy adhesion of oil stains, impurities, iron filings and other debris, difficult to clean mechanical parts, etc. The effect of fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

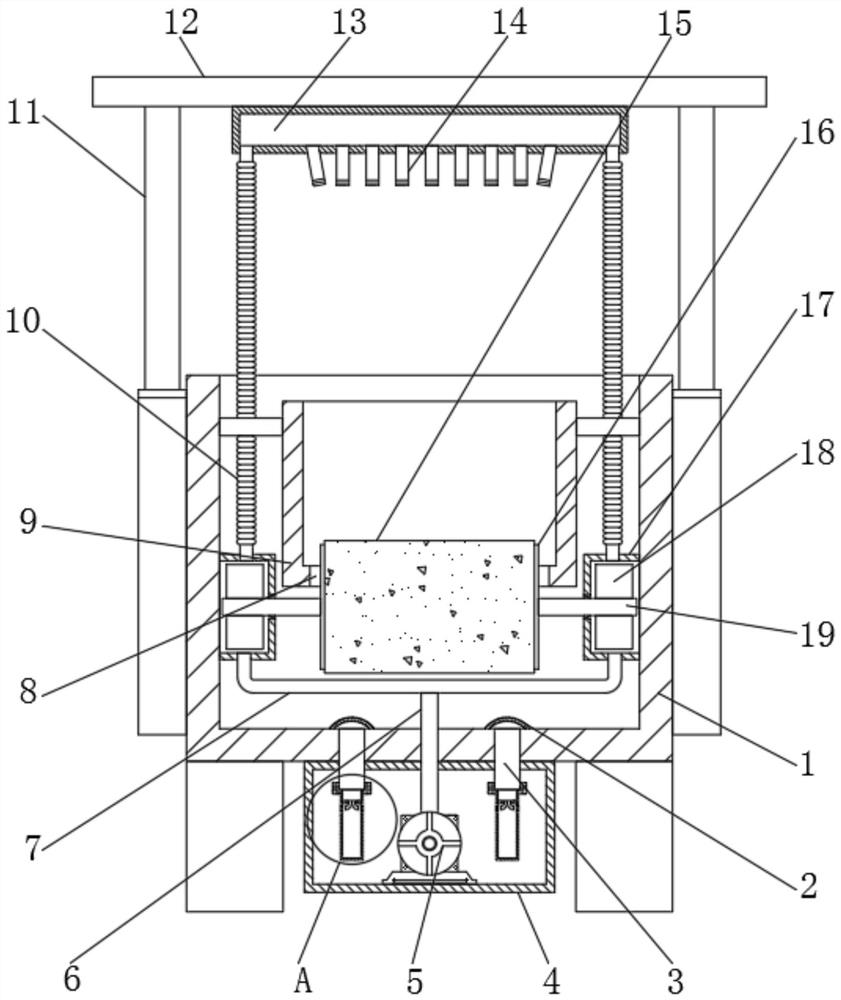

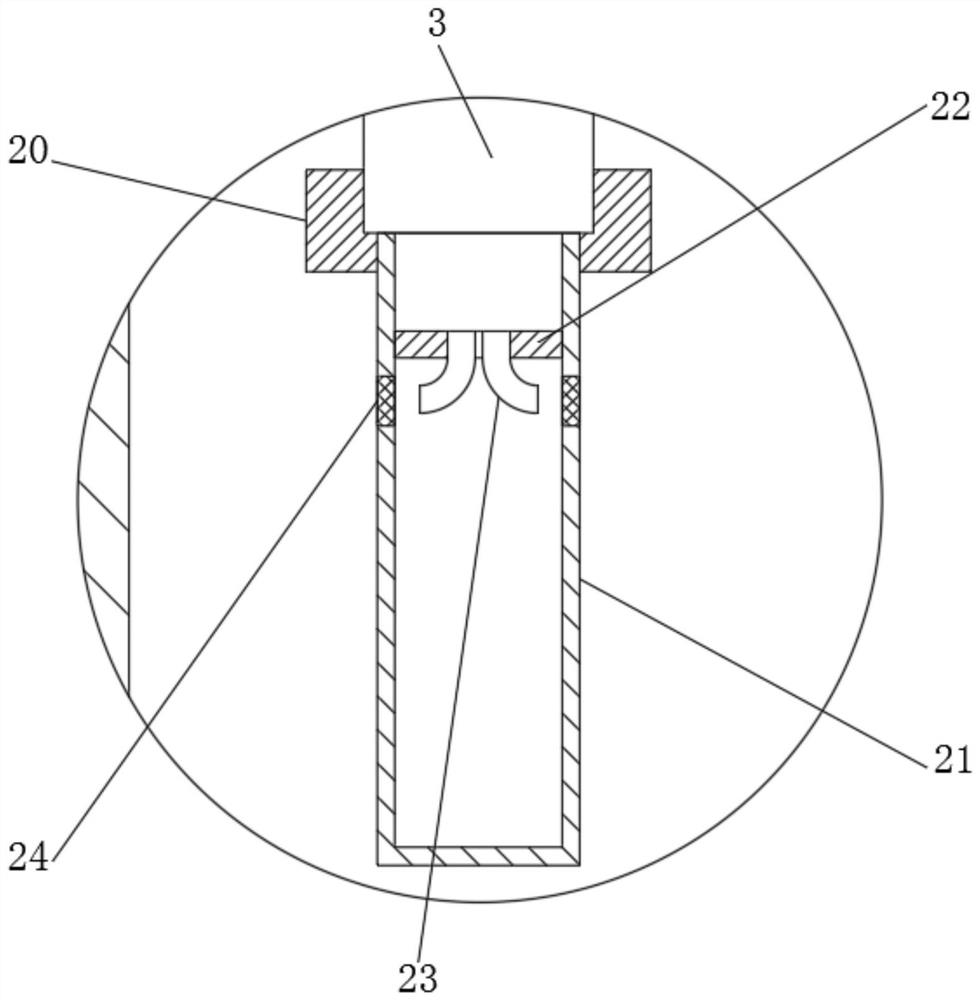

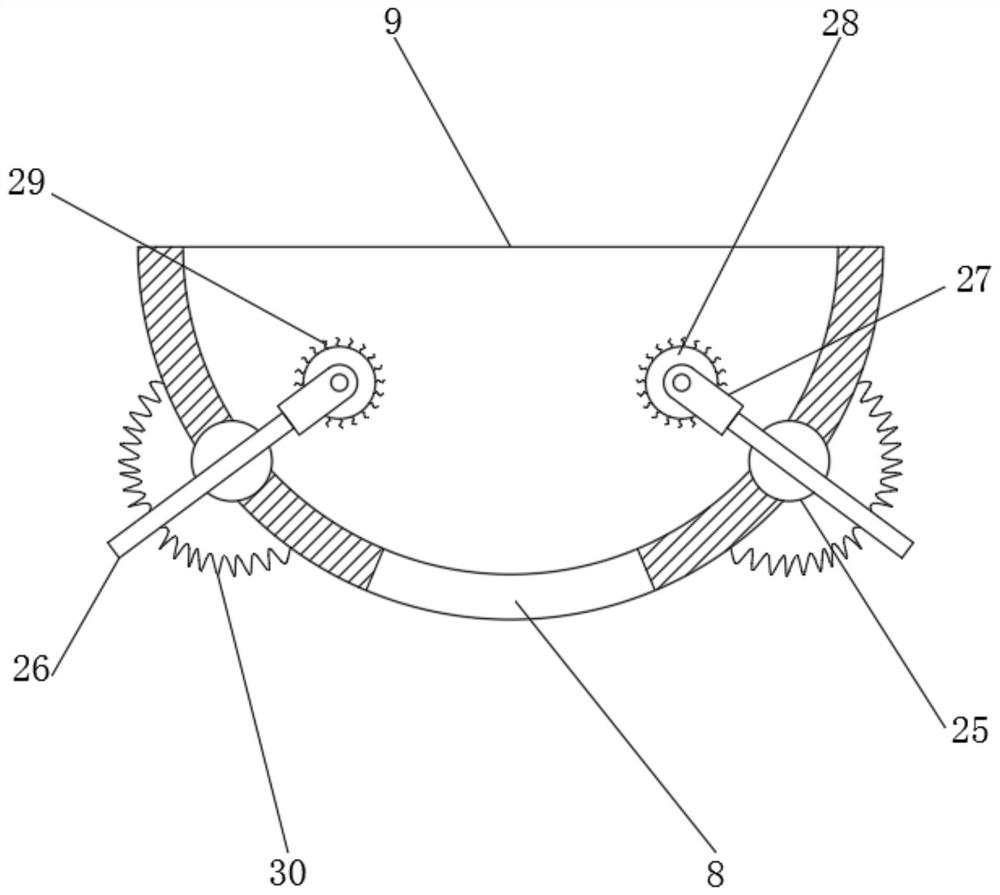

[0031] refer to Figure 1-4 , a parts cleaning device for mechanical processing, comprising a cleaning box 1, the inside of the cleaning box 1 is fixedly connected with a placement box 9 through a connecting rod, and the outer walls of the cleaning box 1 are fixedly connected with a hydraulic cylinder 11, and the hydraulic cylinder 11 One end of the piston is provided with a top plate 12, the bottom outer wall of the top plate 12 is provided with a square box 13, and the bottom outer wall of the square box 13 is provided with a plurality of nozzles 14, and the inner walls of both sides of the cleaning box 1 are fixedly connected with a fixed cover 17, and fixed The cover 17 and the square box 13 are connected by the bellows 10, the bottom outer wall of the cleaning tank 1 is fixedly connected with the liquid storage tank 4, and the inside of the liquid storage tank 4 is provided with a liquid pump 5, and the infusion end of the liquid pump 5 is provided with an infusion tube 6...

Embodiment 2

[0041] refer to Figure 5 , a parts cleaning device for mechanical processing. Compared with Embodiment 1, this embodiment also includes that four corners of the outer wall of the bottom of the square box 13 are provided with lighting lamps 32 .

[0042] Working principle: when in use, it is convenient to observe the cleaning status of the mechanical parts through the lighting lamp 32 at the bottom of the square box 13, and the use effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com