Self-advancing and self-rotating shield machine grouting channel high-pressure dredging device and system

A grouting channel and self-rotating technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inaccessibility of people and tools, improper parameter setting, and long distance between the grout inlet and the grout outlet to reduce the risk of secondary clogging, ensure speed and efficiency, and reduce the effect of slurry sag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

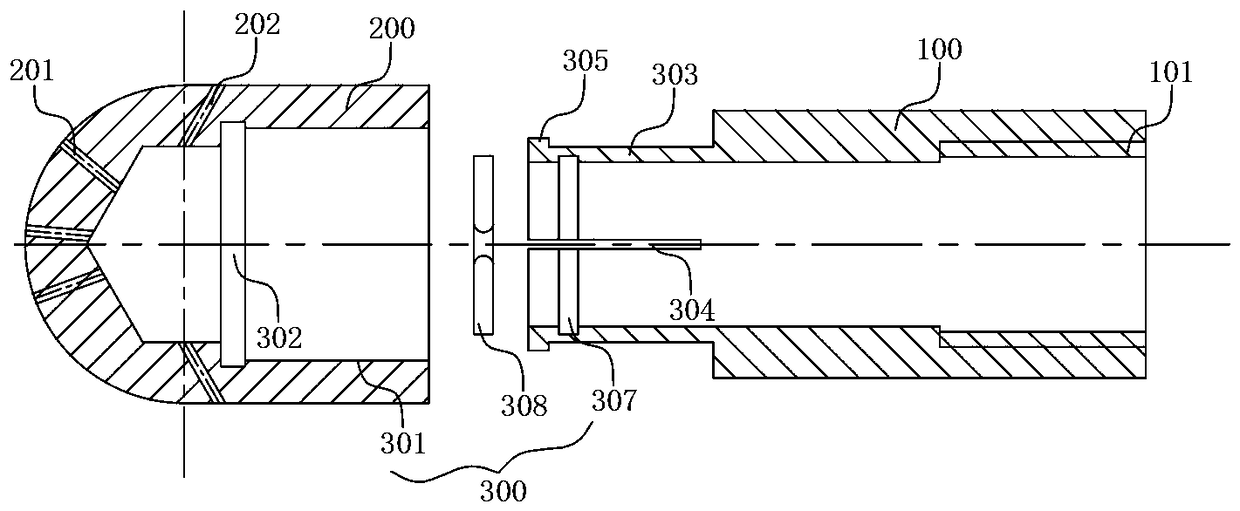

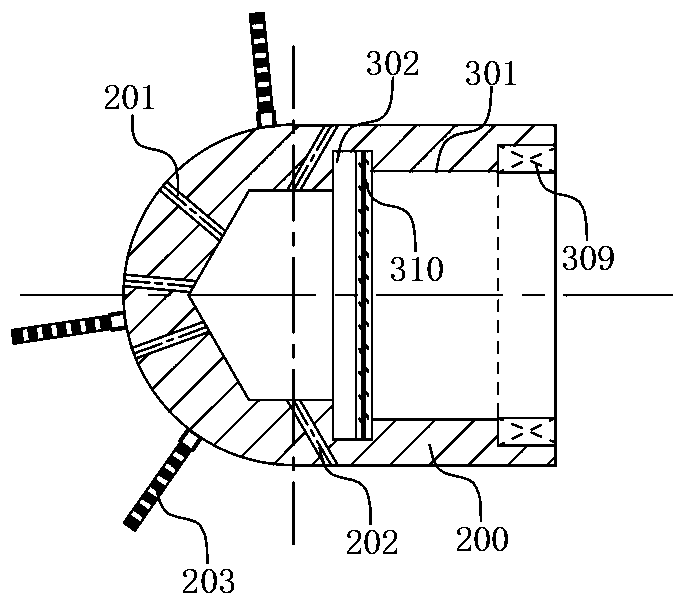

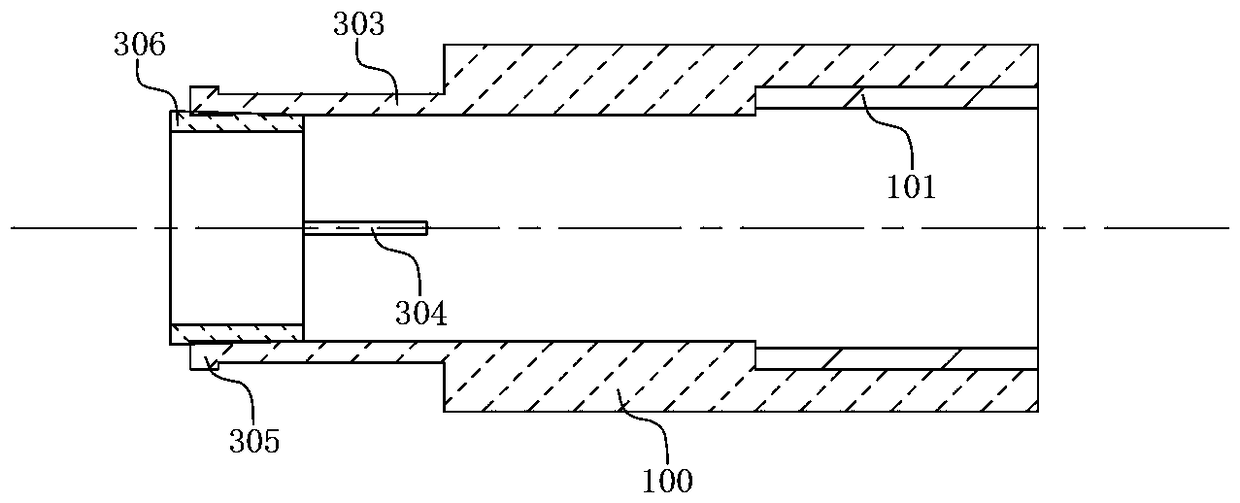

[0022] see Figure 1-Figure 3 , a self-propelled, self-rotating shield machine grouting channel high-pressure dredging device of the present invention, comprising a connecting cylinder 100 and a rotating nozzle 200, the rotating nozzle 200 is coaxially arranged with the connecting cylinder 100, and the rotating nozzle and the connecting cylinder A rotating connection assembly 300 is arranged between them, and the rotating nozzle 200 is connected to the end of the connecting cylinder 100 through the rotating connecting assembly 300, and can rotate relative to the connecting cylinder 100; wherein, the rotating nozzle 200 is sealed at the front end, and the rear end is connected to the A columnar hollow structure connected to the cylinder. The rotary nozzle 200 is provided with at least two front nozzle holes 201 and at least two r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com