A kind of steel bar rust removal equipment for bridge construction

A technology for bridge construction and steel bars, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as time-consuming, labor-intensive, easy to be injured, and poor rust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

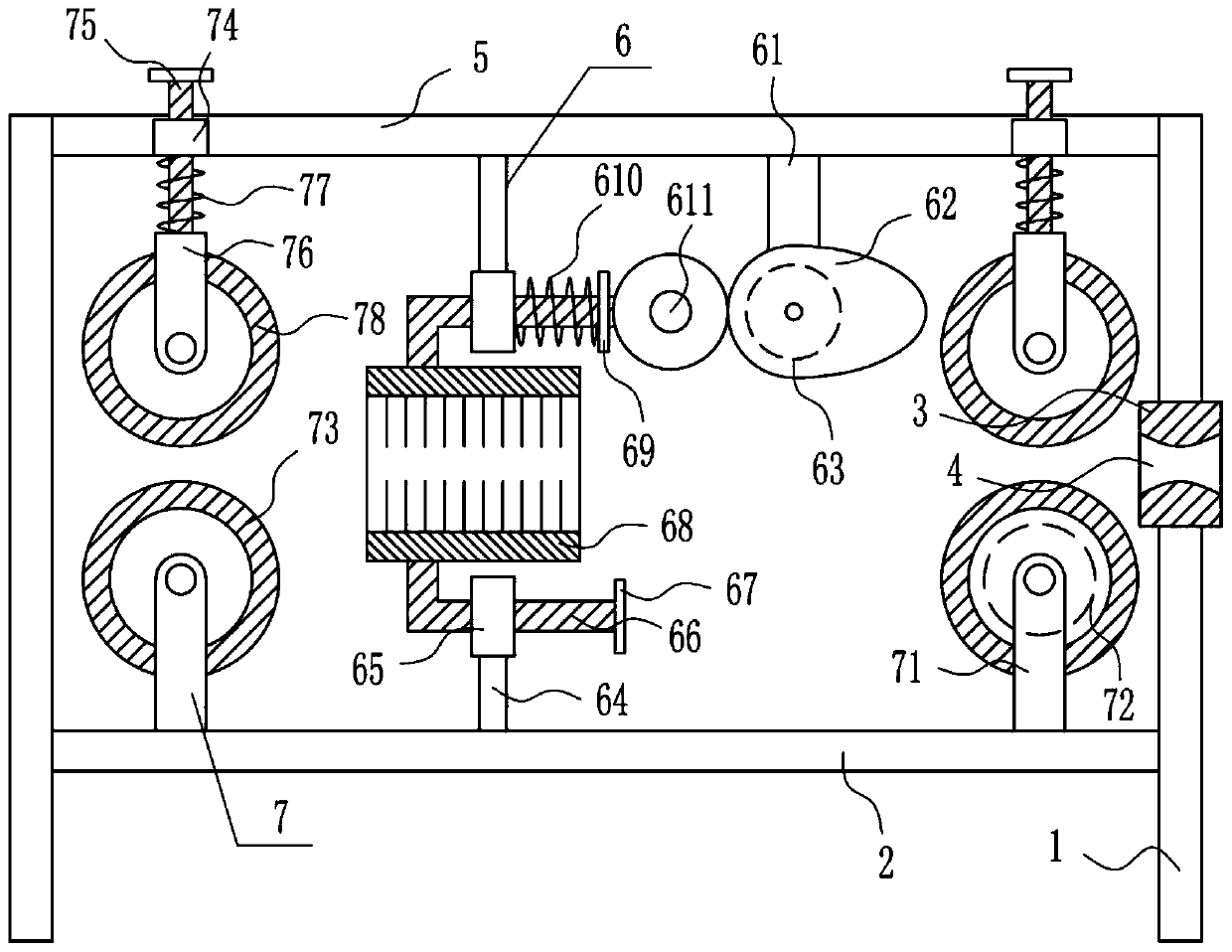

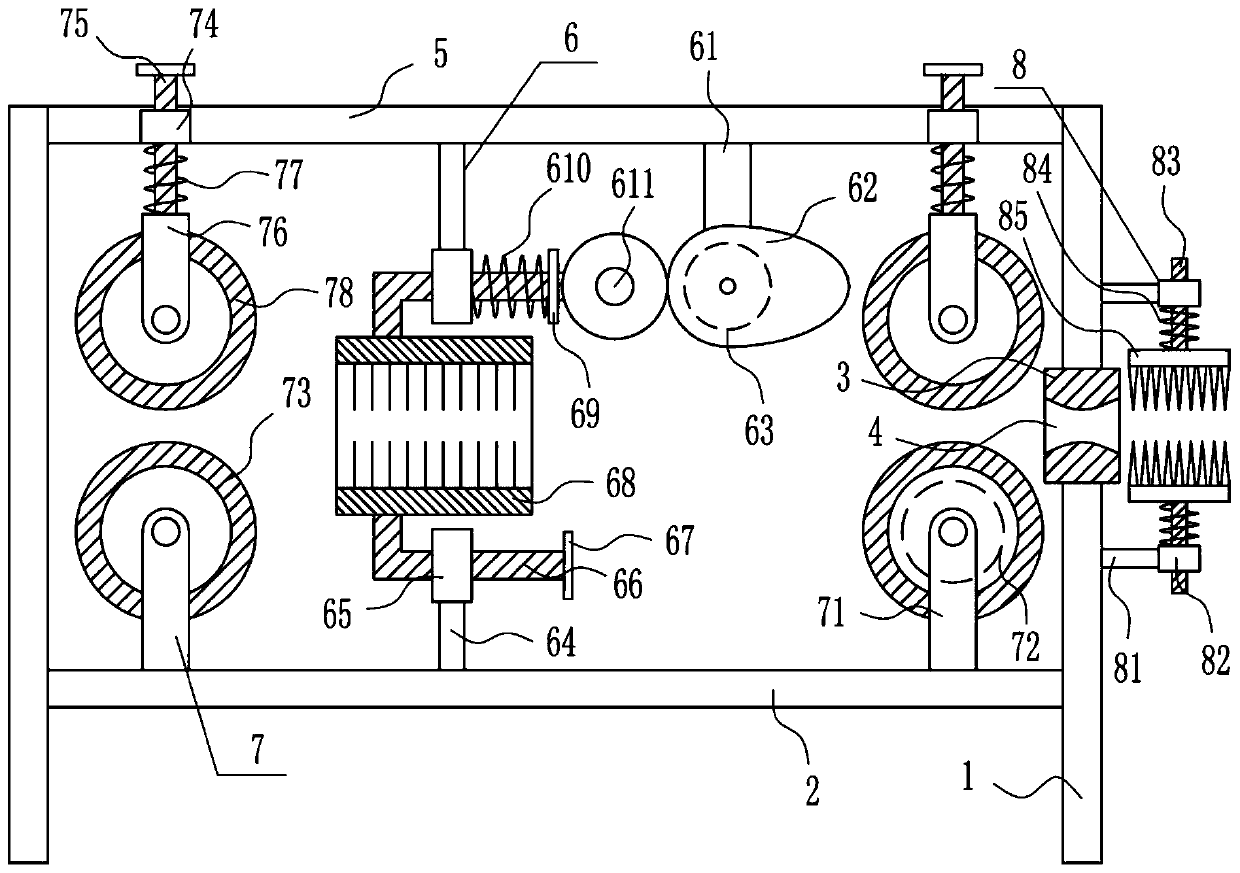

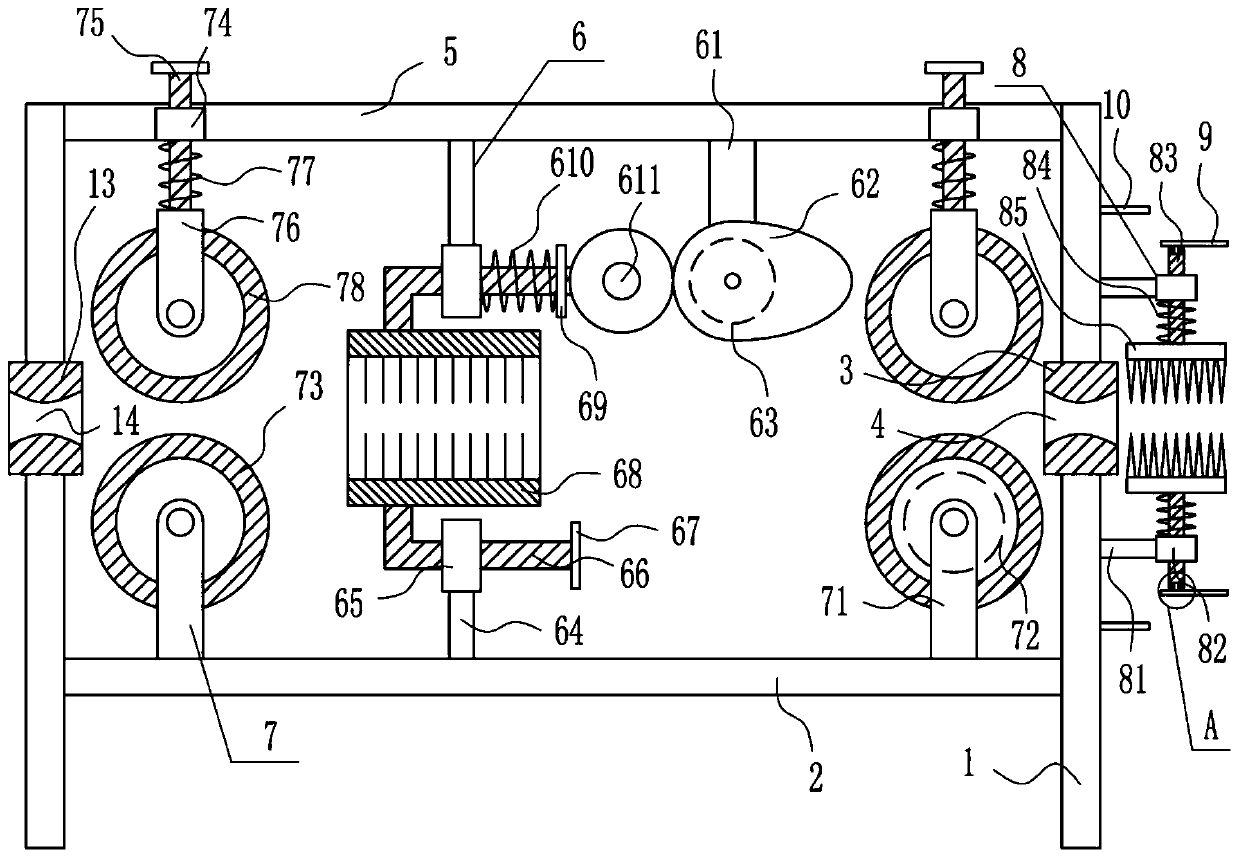

[0028] A steel bar derusting equipment for bridge construction, such as Figure 1-4 As shown, it includes a leg 1, a transverse plate 2, a first fixed block 3, a transverse rod 5, a rust removal device 6 and a conveying device 7. The left and right sides of the transverse plate 2 are both equipped with support legs 1. A cross bar 5 is installed at the top of the legs 1 on both sides, a first fixing block 3 is installed at the upper part of the front side of the right leg 1, and a first trumpet-shaped through hole 4 is opened in the middle of the first fixing block 3. A conveying device 7 is provided between the rods 5, a rust removing device 6 is provided between the top middle of the horizontal plate 2 and the bottom of the cross bar 5, and the rust removing device 6 is located between the conveying devices 7.

Embodiment 2

[0030] A steel bar derusting equipment for bridge construction, such as Figure 1-4 As shown, it includes a leg 1, a transverse plate 2, a first fixed block 3, a transverse rod 5, a rust removal device 6 and a conveying device 7. The left and right sides of the transverse plate 2 are both equipped with support legs 1. A cross bar 5 is installed at the top of the legs 1 on both sides, a first fixing block 3 is installed at the upper part of the front side of the right leg 1, and a first trumpet-shaped through hole 4 is opened in the middle of the first fixing block 3. A conveying device 7 is provided between the rods 5, a rust removing device 6 is provided between the top middle of the horizontal plate 2 and the bottom of the cross bar 5, and the rust removing device 6 is located between the conveying devices 7.

[0031] The rust removing device 6 includes a vertical rod 61, a cam 62, a first motor 63, a connecting rod 64, a first guide sleeve 65, an L-shaped rod 66, a limit plate...

Embodiment 3

[0033] A steel bar derusting equipment for bridge construction, such as Figure 1-4 As shown, it includes a leg 1, a transverse plate 2, a first fixed block 3, a transverse rod 5, a rust removal device 6 and a conveying device 7. The left and right sides of the transverse plate 2 are both equipped with support legs 1. A cross bar 5 is installed at the top of the legs 1 on both sides, a first fixing block 3 is installed at the upper part of the front side of the right leg 1, and a first trumpet-shaped through hole 4 is opened in the middle of the first fixing block 3. A conveying device 7 is provided between the rods 5, a rust removing device 6 is provided between the top middle of the horizontal plate 2 and the bottom of the cross bar 5, and the rust removing device 6 is located between the conveying devices 7.

[0034] The rust removing device 6 includes a vertical rod 61, a cam 62, a first motor 63, a connecting rod 64, a first guide sleeve 65, an L-shaped rod 66, a limit plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com