Rust removal apparatus for inner walls of bend pipes

A technology of bending pipes and fixing devices, which is applied in the field of derusting devices for the bending pipes of boiler pressure parts, which can solve the problems of unacceptable appearance, wire brush turning, and ineffectiveness, etc., and achieve good derusting effect and rust removal Clean, easy-to-operate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

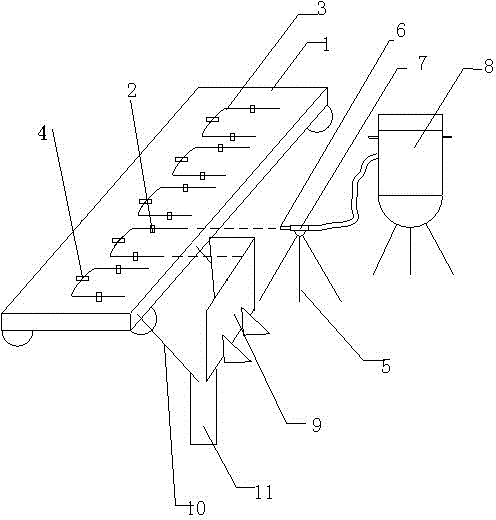

[0017] figure 1 As shown, the present invention is a derusting device for the inner wall of a bent pipe, and the derusting device includes a trolley 1 on which several bent pipes 3 are placed to move on the guide rail, and the bent pipes that need to be derusted on the inner wall are placed on the trolley , the trolley controls the time and speed of movement and motion through the PLC, and the trolley 1 is provided with a set of fixtures for fixing the elbow 3, and each set of fixtures includes a pressure ring 2 for inserting and fixing the elbow , in the middle of each side of the two pressure rings 2, there is a buckle 4 for fixing the elbow. When placing the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com