Metal material surface annular clearing device

A metal material, surface ring technology, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as axial scratches, oxide layer residues, and hinder drawing, and achieve service performance. Reliable, long-term storage and thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

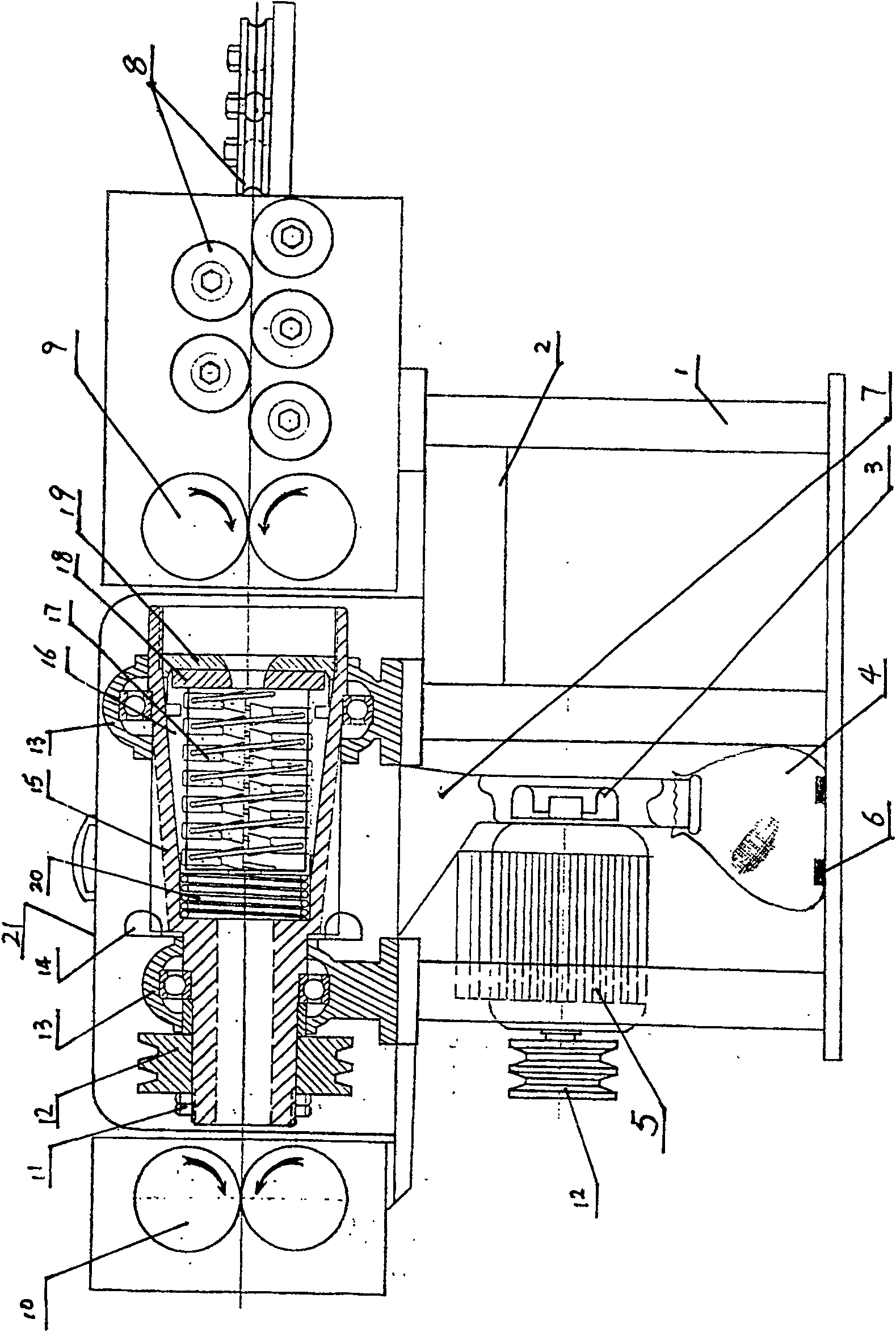

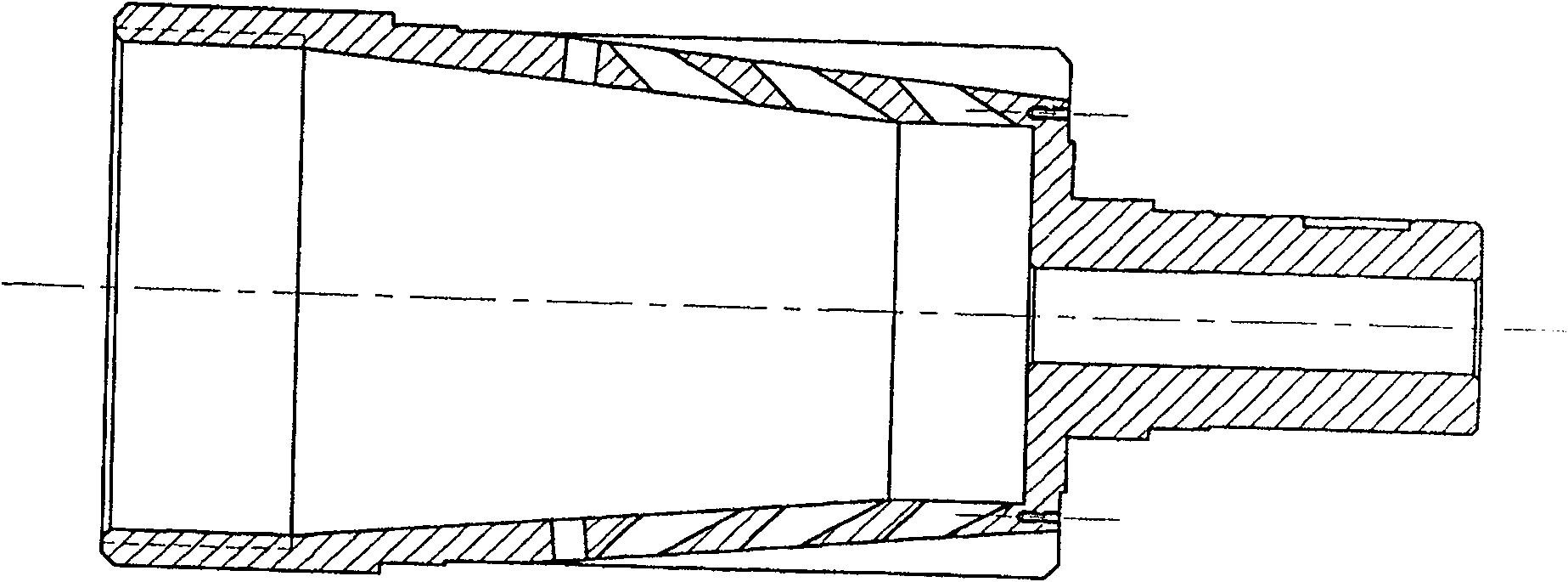

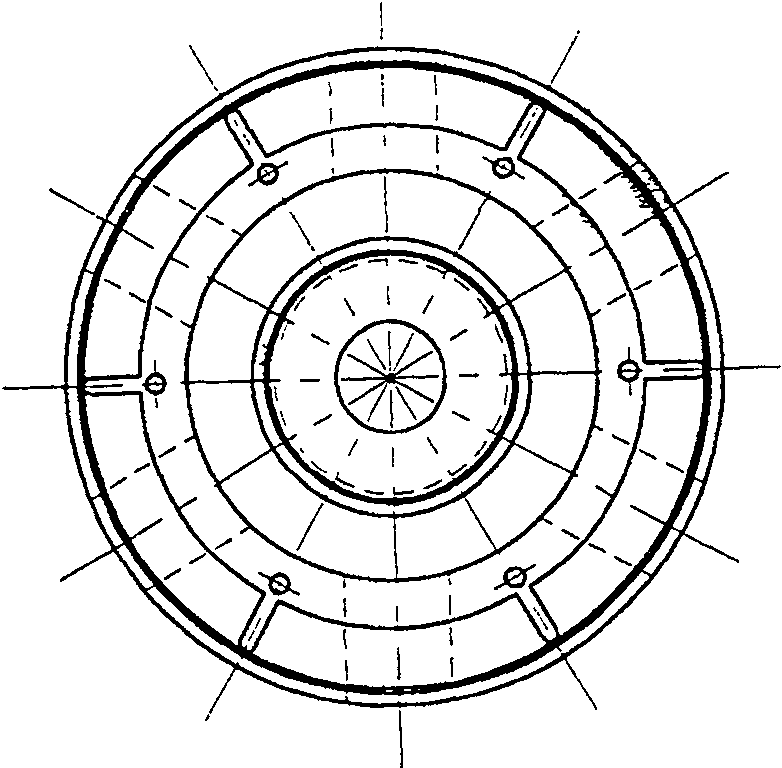

[0024] The present invention consists of a frame 1, an electric control box 2, a dust exhaust fan 3, a dust collection bag 4, a motor 5, a magnet 6, a dust bucket 7, a straightening wheel 8, a material input wheel 9, a material output wheel 10, a tightening wire 11. Pulley 12, bearing seat 13, electric fan 14, housing 15, taper sleeve 16, wire brush diameter adjustment assembly 17, taper sleeve cover plate 18, diameter adjustment wire plate 19, extension spring 20 and dust cover 21 ,Such as figure 1 As shown, the transmission, adjustment, and working parts of the present invention are all fixed on the frame 1, and are sealed and integrated by the protective cover 21, making it safe and beautiful, and easy to install. The main motor 5 is directly installed on the frame 1, and drives the housing 15 to rotate by two V-belt pulleys 12, and the housing 15 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com