Production equipment and technology for furniture based on polypropylene composite material

A composite material and production equipment technology, applied in the field of furniture blow molding, can solve problems such as low utilization rate of raw materials, and achieve the effect of solving low utilization rate, ensuring work stability and reliability, and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

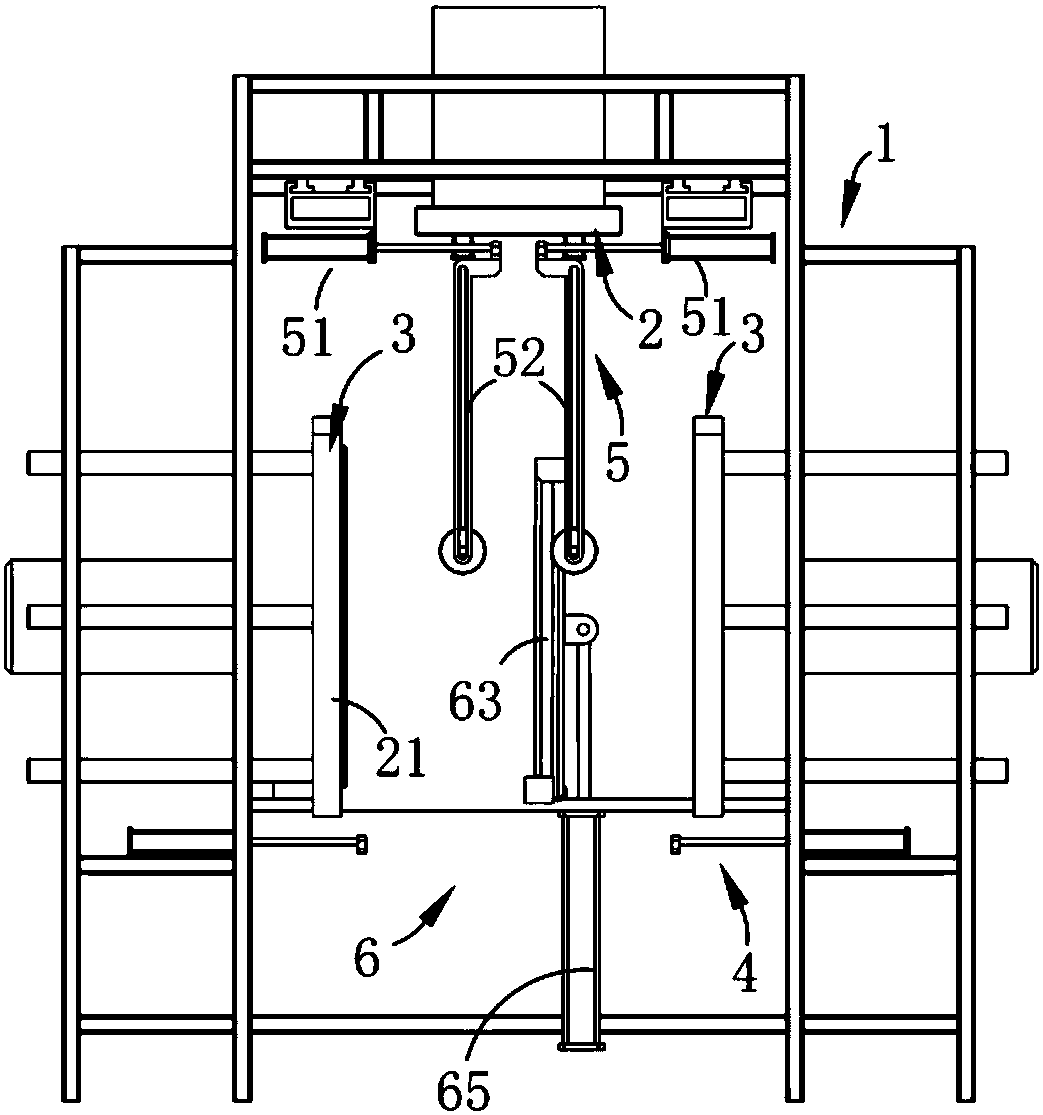

[0041] Such as figure 1 , 2 , 3 and 4, based on polypropylene composite material furniture production equipment, including a frame 1, a blow molding port 2 installed on the frame 1, a forming mold 3 and a sealing mechanism 4, it is characterized in that it also includes:

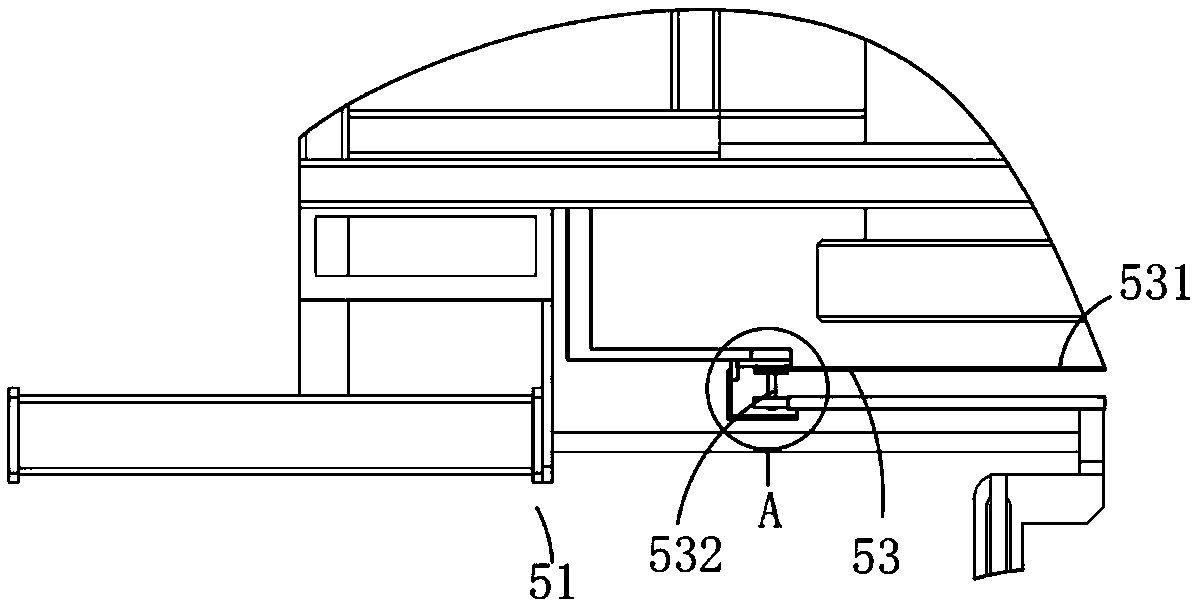

[0042]The transfer mechanism 5, the transfer mechanism 5 is located between the blow molding port 2 and the molding mold 3, which includes a clamping assembly 51 symmetrically arranged on the frame 1 and located on both sides of the molding mold 3, installed o...

Embodiment 2

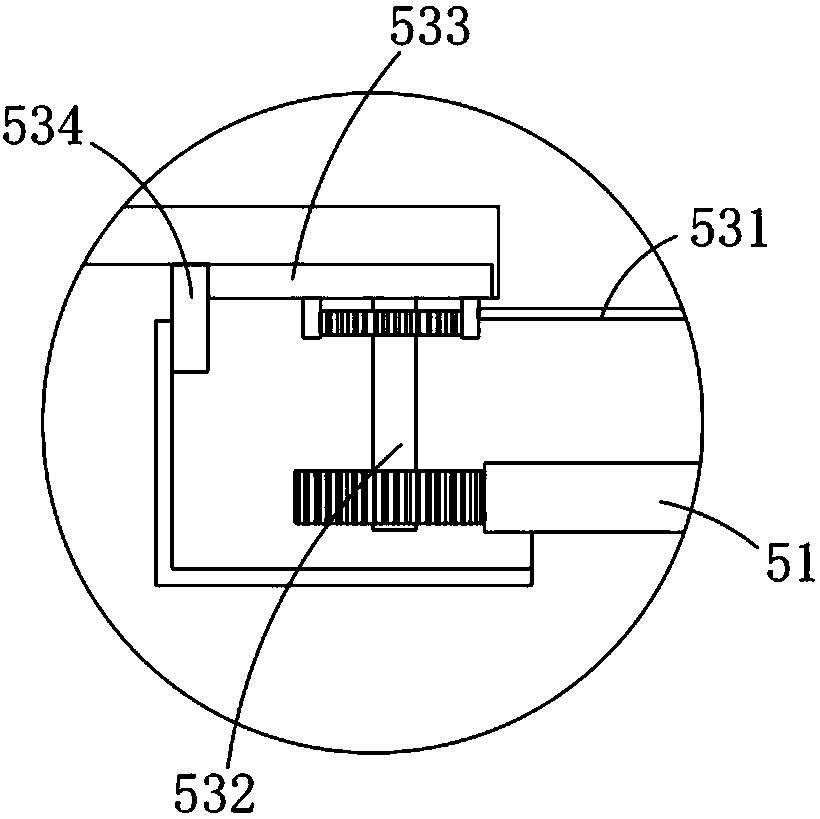

[0049] Such as figure 1 and 5 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The advantage is that the clamping assembly 51 is arranged in a symmetrical structure, which includes a sliding table 511 slidably arranged on the frame 1, a splint 512 arranged on the sliding table 511, and a clamping plate 512 fixedly arranged on the sliding table 511. The driving part 513 that drives the clamping plate 512 to reciprocate, the demoulding assembly 52 is arranged at both ends of the clamping plate 512 and is located outside the forming mold 3; in this embodiment, the driving part 513 is preferably The cylinder, wherein the two ends of the demoulding assembly 42 are fixedly arranged on the two ends of the splint 413 .

[0050] Fur...

Embodiment 3

[0052] Such as figure 1 , 7 and 9, wherein the same or corresponding parts as in the second embodiment adopt the corresponding reference numerals of the second embodiment, for the sake of simplicity, only the difference between the second embodiment and the second embodiment is described below; the third embodiment and the second embodiment The difference is that the edge material cutting mechanism 6 includes a receiving portion 61 arranged under the forming mold 3, a workbench 62 at the end of the accepting portion 61, and a reversing disc 63 arranged on the workbench 62. , a limit bar 64 fixedly arranged on the workbench 62 and in contact with the reversing disc 63 , and a transmission part 65 that drives the reversing disc 63 to move along the limit bar 64 to realize the horizontal placement of the reversing disc 63 .

[0053] Among them, such as Figure 7 , 8 As shown in and 9, the reversing disc 63 is provided with a disc structure, which includes a positioning groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com