Formula and stir-frying technology of hotpot seasoning

A technology of hot pot bottom material and technology, which is applied in the field of hot pot bottom material formula and frying technology, and can solve the problems that flavor substances cannot be dissolved and the utilization rate of materials is not high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

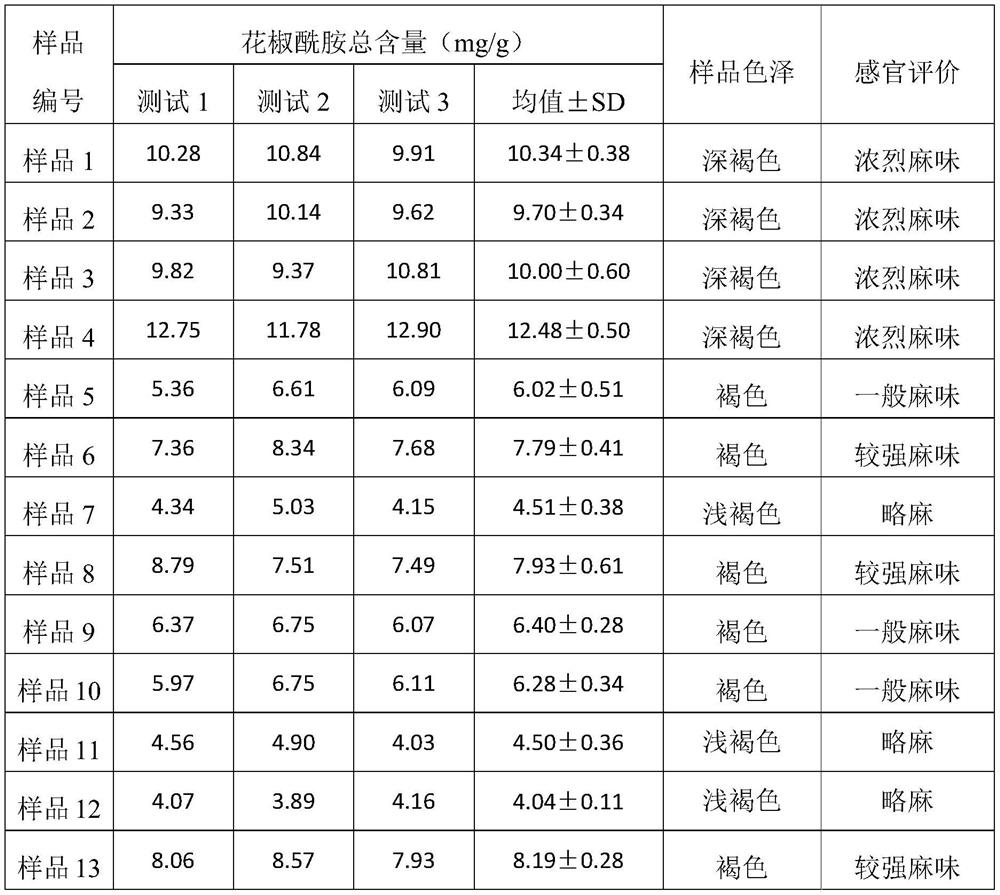

Embodiment 1

[0023] 1. Soaking step

[0024] Take 30kg of dried Zanthoxylum bungeanum (in this embodiment, Dahongpao Zanthoxylum bungeanum is specifically selected), grind it into Zanthoxylum bungeanum powder (through a 50-mesh sieve), use 6L of absolute ethanol to soak the Zanthoxylum bungeanum powder at room temperature for 20min, then filter to get the solid phase (drain the absolute ethanol) , to obtain alcohol-soaked pepper powder. Then add 18L of water to the alcohol-soaked pepper powder, then add the complex enzyme, mix well, and obtain the enzymatic hydrolysis system. The compound enzyme contains cellulase (CAS: 9012-54-8), pectinase (CAS: 9032-75-1) and protease (CAS: 42613-33-2), the mass ratio of the three is 1:2 : 1, the mass fraction of the compound enzyme in the enzymolysis system is 3%, the enzymolysis conditions are 37°C, 25min, pH7.0, after the enzymolysis is finished, the solid phase is collected by filtration to obtain the enzymolysis Zanthoxylum bungeanum powder. Add ...

Embodiment 2

[0031] 1. Soaking step

[0032] Take 40kg of dried Zanthoxylum bungeanum (in this embodiment, Dahongpao Zanthoxylum bungeanum is specifically selected), grind it into Zanthoxylum bungeanum powder (through a 50-mesh sieve), use 8L of absolute ethanol to soak the Zanthoxylum bungeanum powder at room temperature for 20min, then filter to get the solid phase (drain the absolute ethanol) , to obtain alcohol-soaked pepper powder. Then add 24L of water to the alcohol-soaked pepper powder, then add the compound enzyme, mix well, and obtain the enzymatic hydrolysis system. The compound enzyme contains cellulase (CAS: 9012-54-8), pectinase (CAS: 9032-75-1) and protease (CAS: 42613-33-2), the mass ratio of the three is 1:2 : 1, the mass fraction of the compound enzyme in the enzymolysis system is 3%, the enzymolysis conditions are 40°C, 30min, pH7.0, after the enzymolysis is finished, the solid phase is filtered to obtain the enzymolysis pepper powder. Add 15kg of white wine (60% white...

Embodiment 3

[0039] 1. Soaking step

[0040] Take 20kg of dried Zanthoxylum bungeanum (in this embodiment, Dahongpao Zanthoxylum bungeanum is specifically selected), grind it into Zanthoxylum bungeanum powder (through a 50-mesh sieve), use 4L of absolute ethanol to soak the Zanthoxylum bungeanum powder at room temperature for 20min, then filter to get the solid phase (drain the absolute ethanol) , to obtain alcohol-soaked pepper powder. Then add 12L of water to the alcohol-soaked pepper powder, then add the complex enzyme, mix well, and obtain the enzymatic hydrolysis system. The compound enzyme contains cellulase (CAS: 9012-54-8), pectinase (CAS: 9032-75-1) and protease (CAS: 42613-33-2), the mass ratio of the three is 1:2 : 1, the mass fraction of the compound enzyme in the enzymolysis system is 3%, the enzymolysis conditions are 35°C, 20min, pH7.0, after the enzymolysis is finished, the solid phase is filtered to obtain the enzymolysis pepper powder. Add 10 kg of white wine (60% white...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com