Feeder for nylon raw material

A feeder and raw material technology, applied in the direction of containers, large containers, chemical instruments and methods, etc., can solve the problems of enterprise loss, blockage, affecting efficiency, etc., and achieve the effect of avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

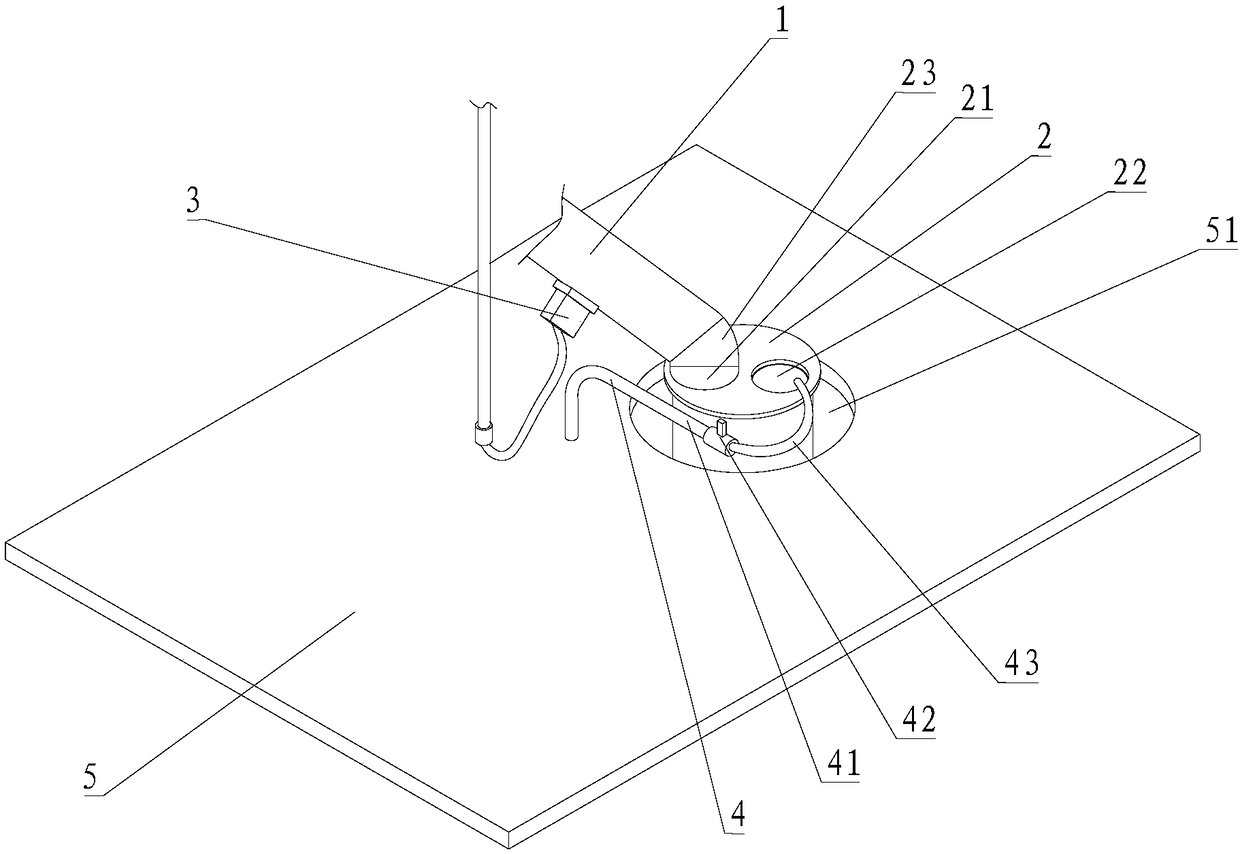

[0039] A feeder for nylon raw materials, connected between a hopper and polycondensation reaction equipment, including a feed pipe and a feed head, one end of the feed pipe is connected to the feed hopper, and the other end is a free end, the feed head is connected to the Connection of polycondensation reaction equipment;

[0040] A vibrator is arranged on the outer wall of the material tube;

[0041] The lower hopper is hollow and rounded, the top surface of the lower hopper is connected with a top cover, the top cover is provided with a feed port and a cleaning port, the free end of the material pipe is connected to the feed port, and the cleaning There is a cover plate on the mouth;

[0042] A cleaning pipeline is arranged on the side of the lower hopper, and pure water circulates in the cleaning pipeline, and the cleaning pipeline is connected with the cleaning port.

[0043] A connecting hose is also arranged between the free end of the material pipe and the material po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com