Patents

Literature

30results about How to "Affect the quality of the finished product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

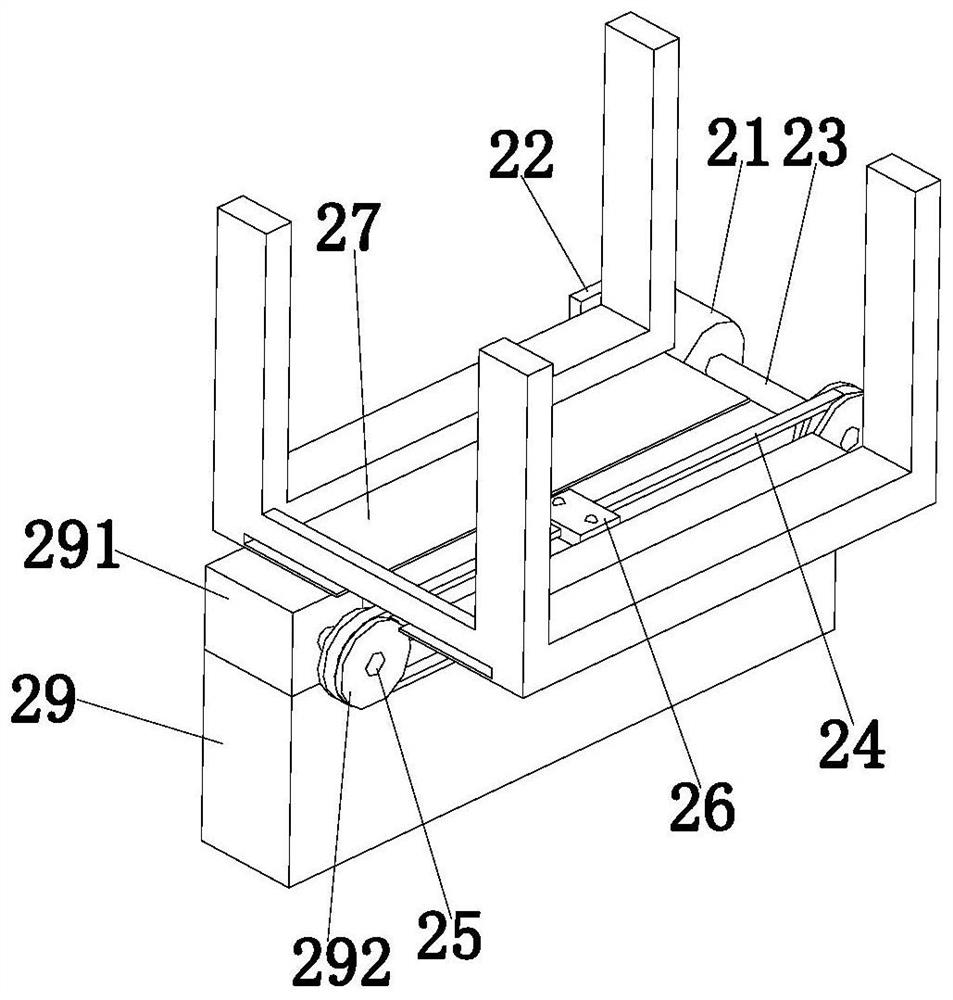

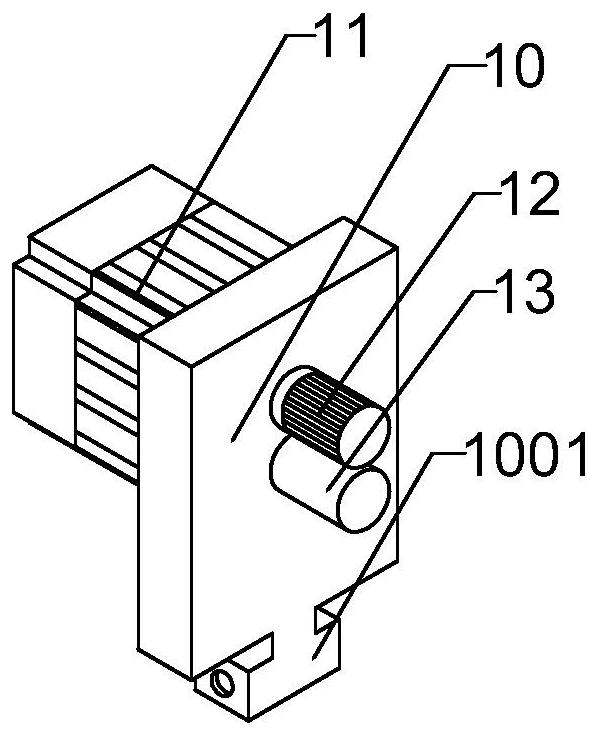

Mineral separation breaking device

The invention provides a mineral separation breaking device. The device comprises a box body, a movable jaw plate and a fixed jaw plate. A plurality of conveying rollers are arranged below a discharging opening of a breaking cavity defined by the fixed jaw plate and the movable jaw plate, and the rotation directions of the conveying rollers are consistent; a fence type screening net is defined by the conveying rollers, the lower end of the fixed jaw plate and the lower end of the movable jaw plate; and defective material outlets corresponding to the conveying directions of the conveying rollers are formed in the box body. The mineral separation breaking device has the beneficial effects of being scientific in design, sufficient in breaking, high in broken material quality and suitable for breaking flat mineral aggregate.

Owner:LUOYANG LVREN ENVIRONMENTAL EQUIP

Heat-preservation and heat-insulation carbon felt and preparation method thereof

PendingCN113026349AGood qualityImprove mechanical strengthCarbon fibresHeating/cooling textile fabricsThermal insulationThermoplastic

The invention provides a heat-preservation and heat-insulation carbon felt and a preparation method thereof, and relates to the technical field of thermal insulation material preparation. According to the heat-preservation and heat-insulation carbon felt and the preparation method thereof, the heat-preservation and heat-insulation carbon felt is composed of expandable A-stage phenolic resin with the carbon residue amount of 36-88%, a surfactant, a foaming agent, a curing agent, carbon fibers, self-adhesive pre-oxidized fibers, thermosetting resin fibers, carbon fiber precursor thermoplastic resin fibers and other materials. The heat-preservation and heat-insulation carbon felt is characterized by being prepared from the following materials in parts by mass of 30-90 parts of expandable A-stage phenolic resin with the carbon residue content of 36-88%, 2-6 parts of the surfactant, 4-10 parts of the foaming agent, 10-25 parts of the curing agent, 25-70 parts of carbon fibers, 0-40 parts of self-adhesive pre-oxidized fibers, 10-30 parts of thermosetting resin fibers and 10-35 parts of carbon fiber precursor thermoplastic resin fibers. According to the heat-preservation and heat-insulation carbon felt and the preparation method thereof provided by the invention, the preparation process is simpler and more environment-friendly, and the prepared carbon felt has better heat-preservation and heat-insulation performance, better quality and higher cost performance.

Owner:上海瑟赫新材料科技有限公司

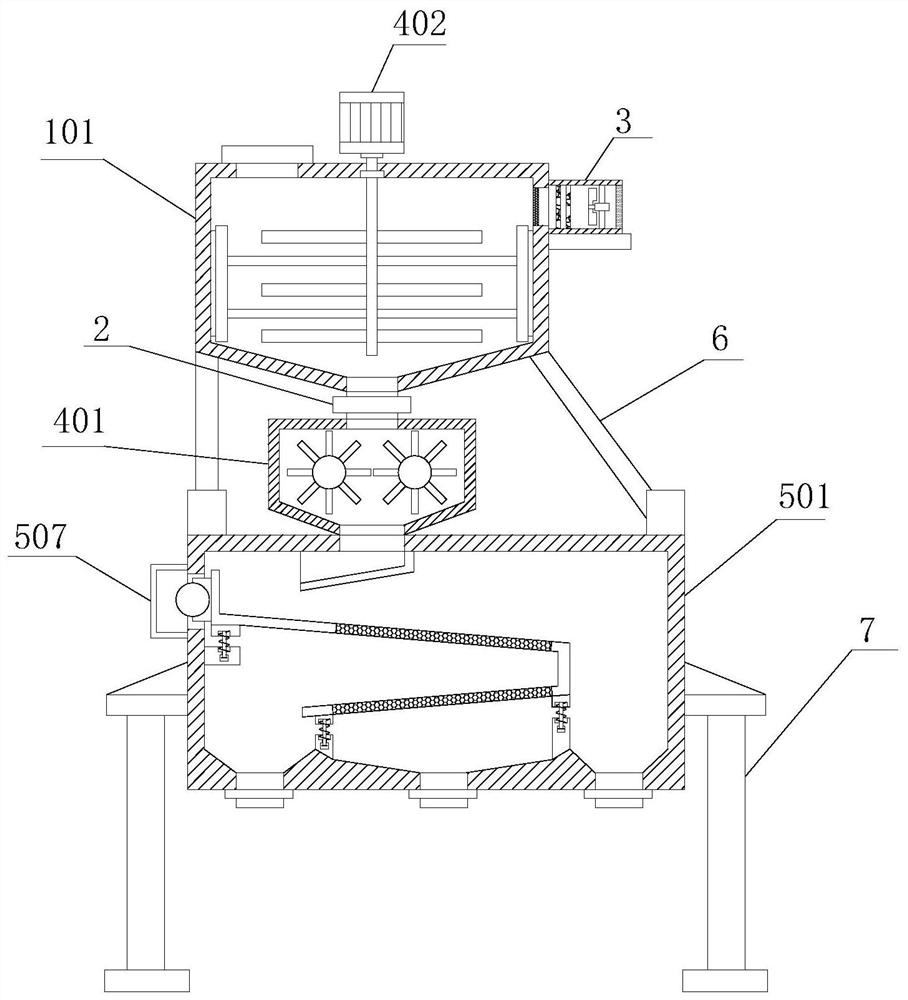

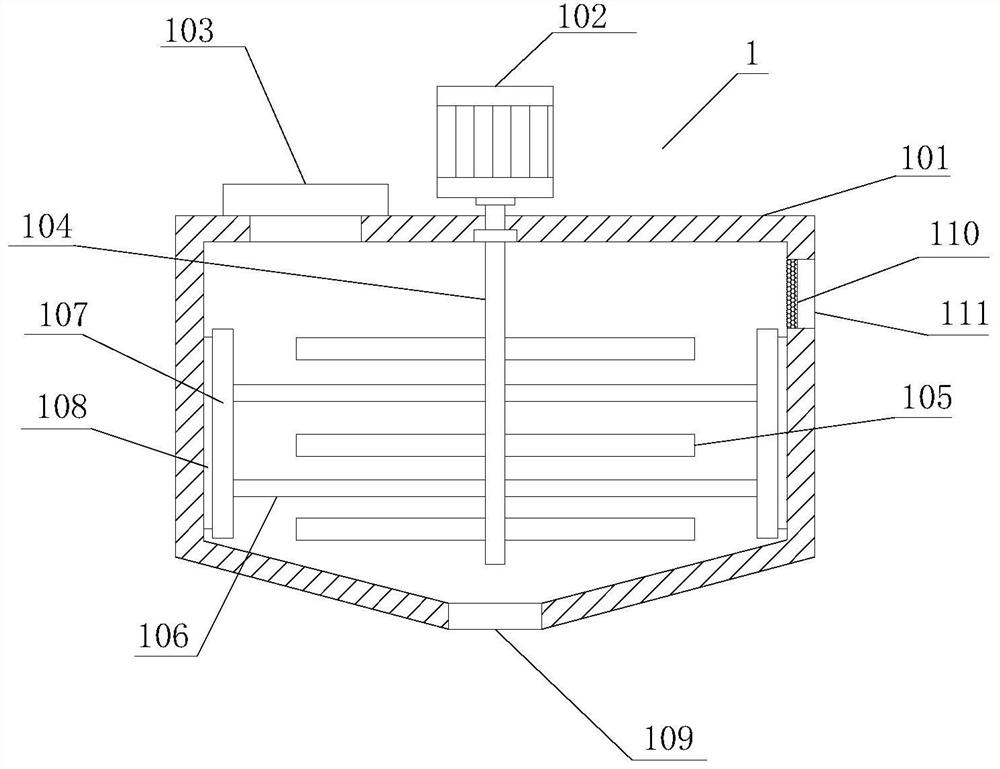

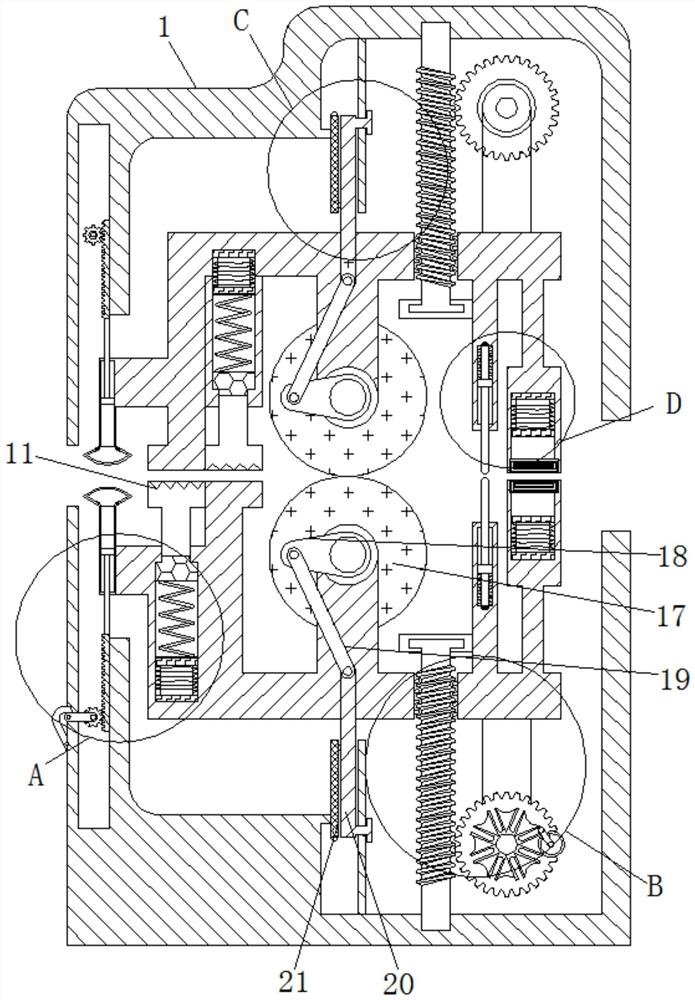

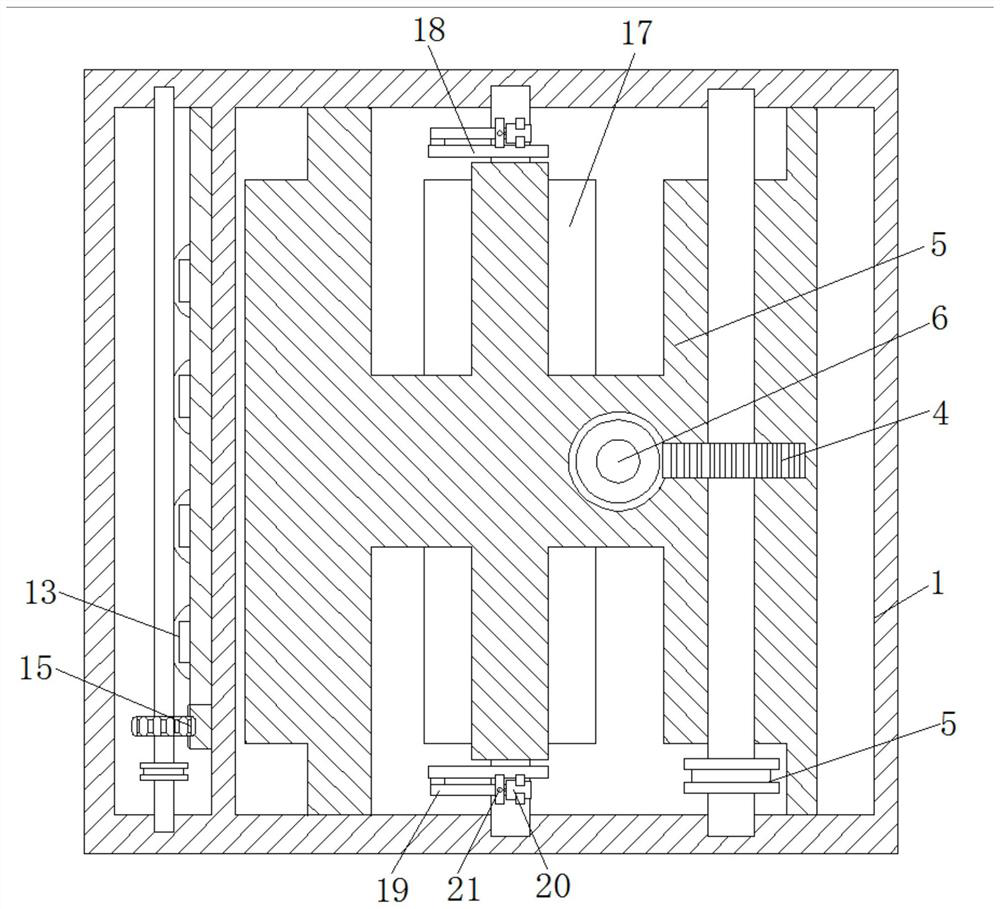

Screening device for chemical raw material production

InactiveCN112371476AAvoid bondingPrevent filter effectsSievingScreeningElectric machineryProcess engineering

The invention relates to the technical field of screening for chemical raw material production, and discloses a screening device for chemical raw material production. The screening device comprises araw material drying mechanism, a raw material crushing mechanism and a screening mechanism, the raw material crushing mechanism is arranged at the bottom of the raw material drying mechanism, the screening mechanism is arranged at the bottom of the raw material crushing mechanism, and the raw material drying mechanism comprises a drying box, a stirring motor, a stirring shaft and a scraping blade.According to the screening device for chemical raw material production, the stirring motor is started to drive the stirring shaft to rotate, so that stirring blades are driven to stir chemical raw materials, meanwhile, a heating pipe in a heating box and a fan are started to conduct hot air drying on the raw materials in a drying box, the scraping blade scrapes the inner wall of the drying box, the chemical raw materials are prevented from adhering to the inner wall, the drying box stirs and dries the chemical raw materials with large moisture, the situation that the chemical raw materials with large moisture are agglomerated, so that screening of the chemical raw materials is affected is avoided, and the screening quality is improved.

Owner:浙江古思建筑科技有限公司

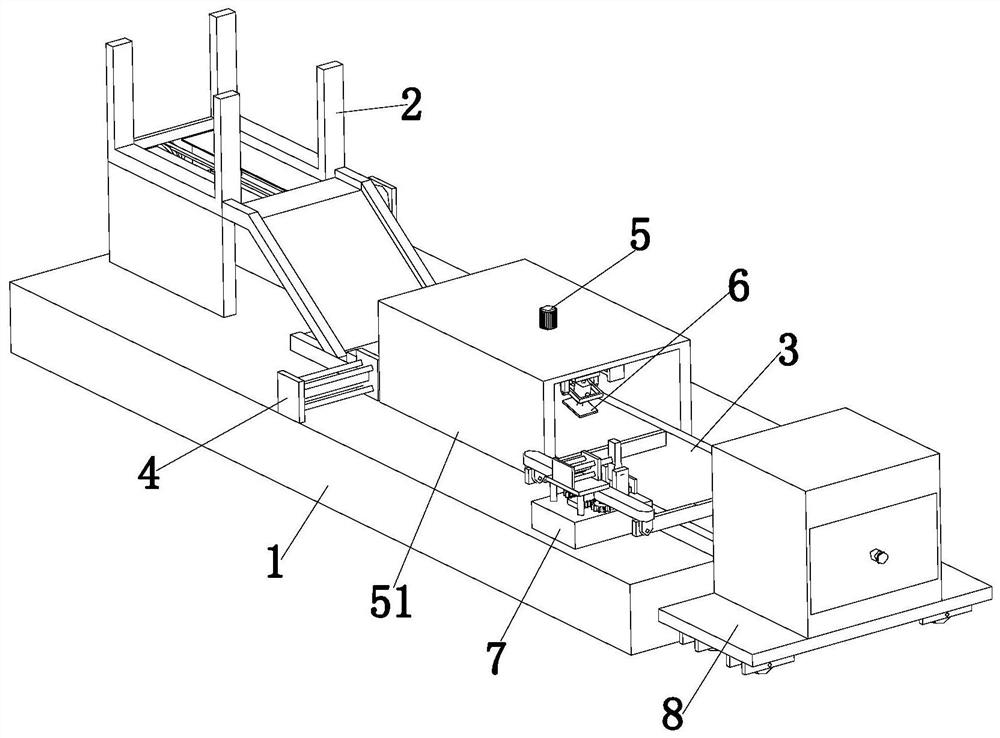

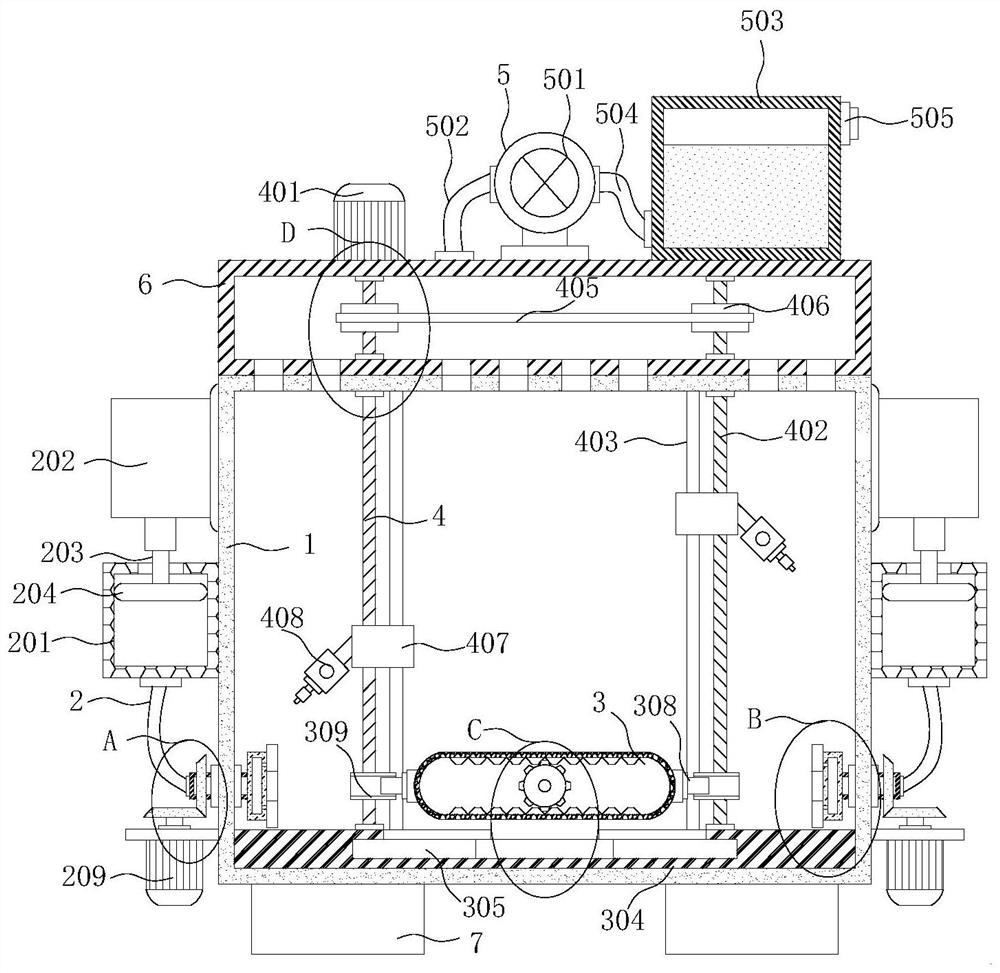

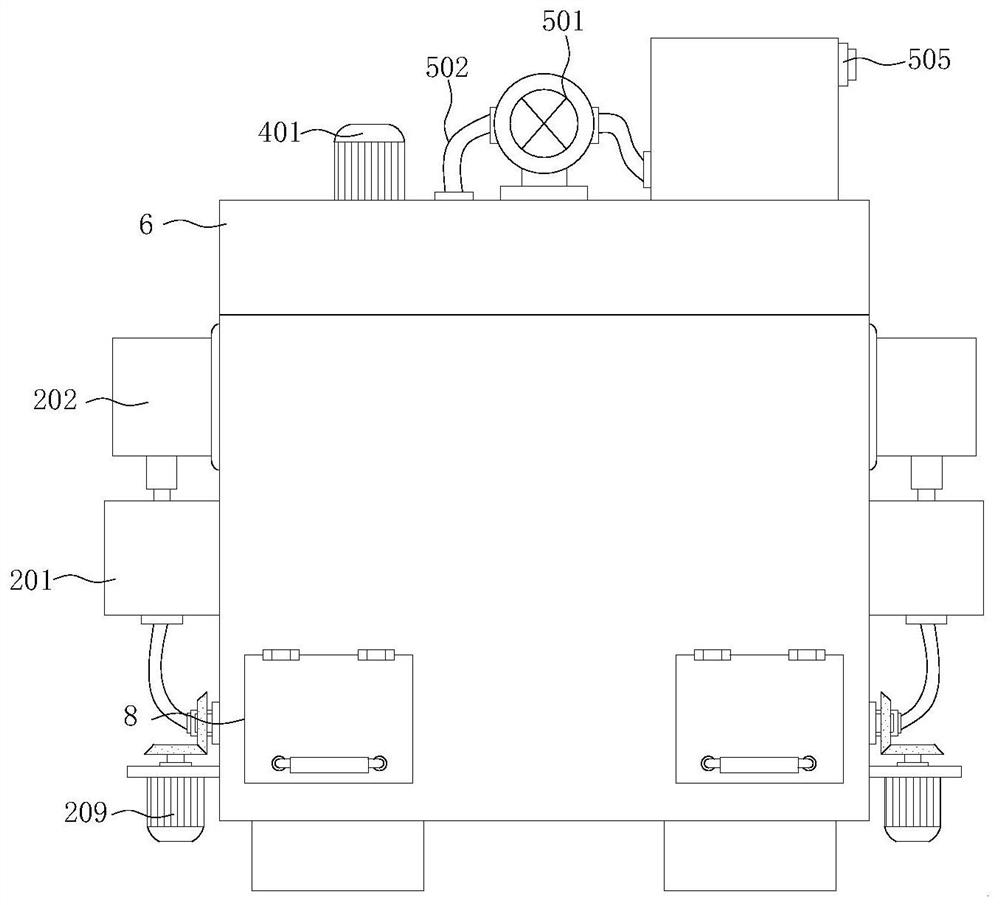

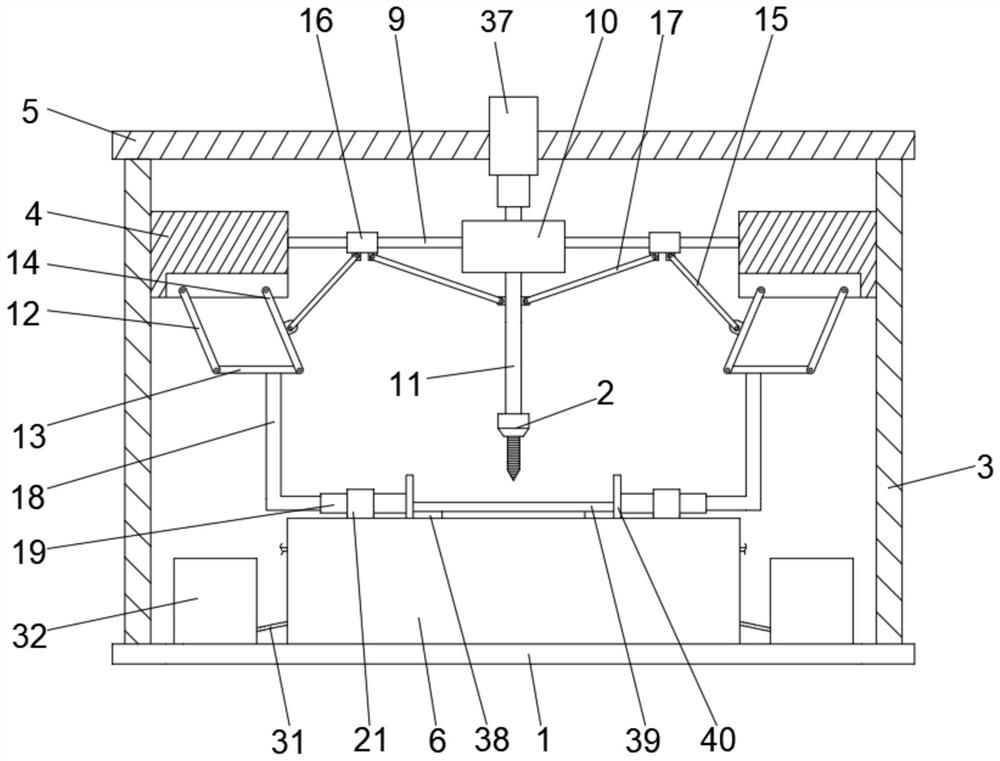

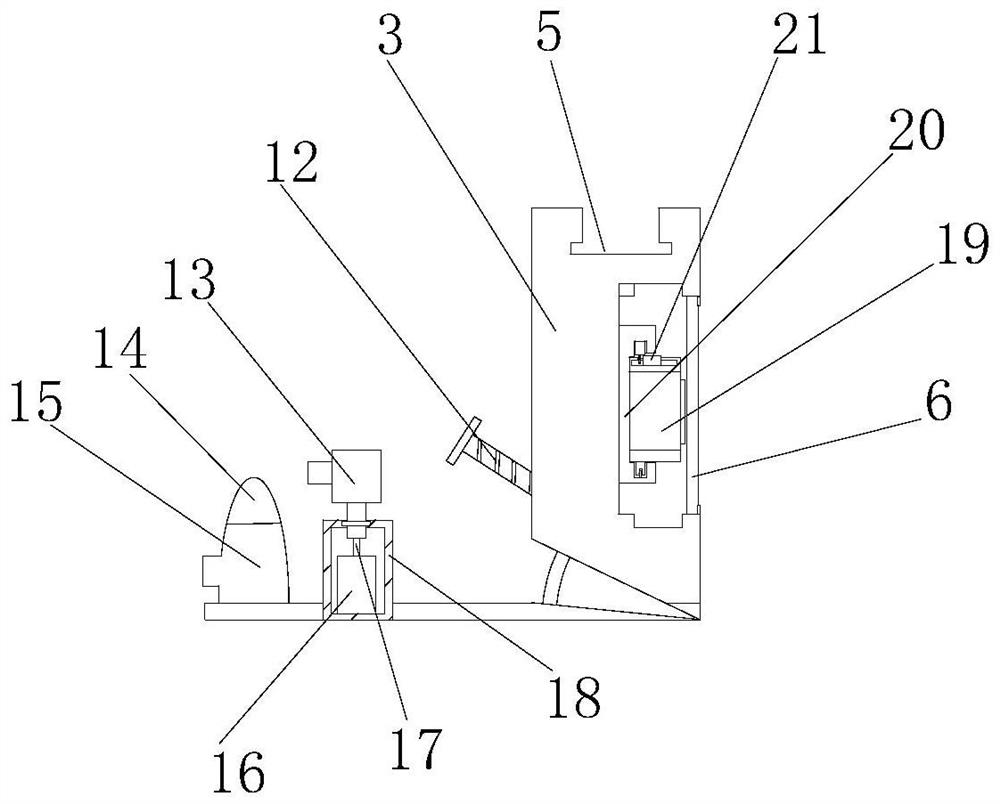

Spraying device for aluminum alloy doors and windows

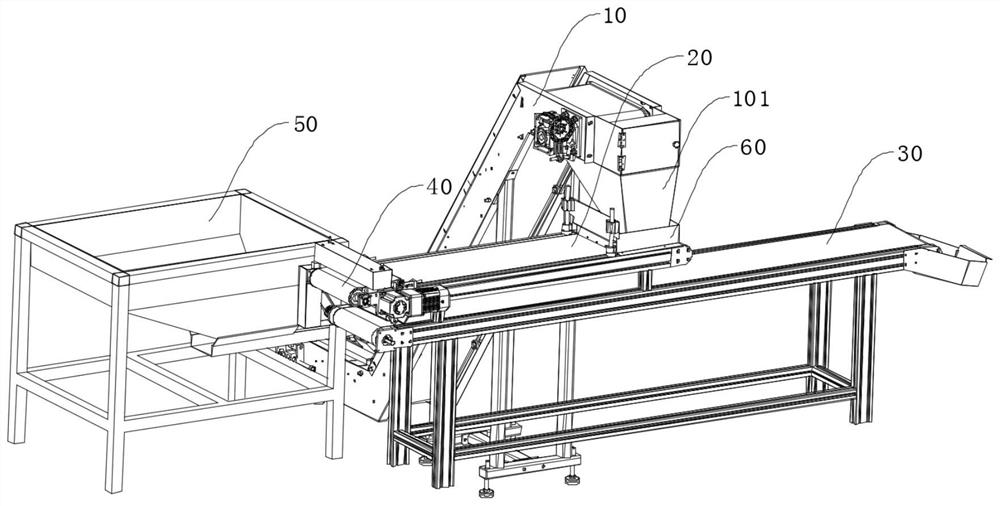

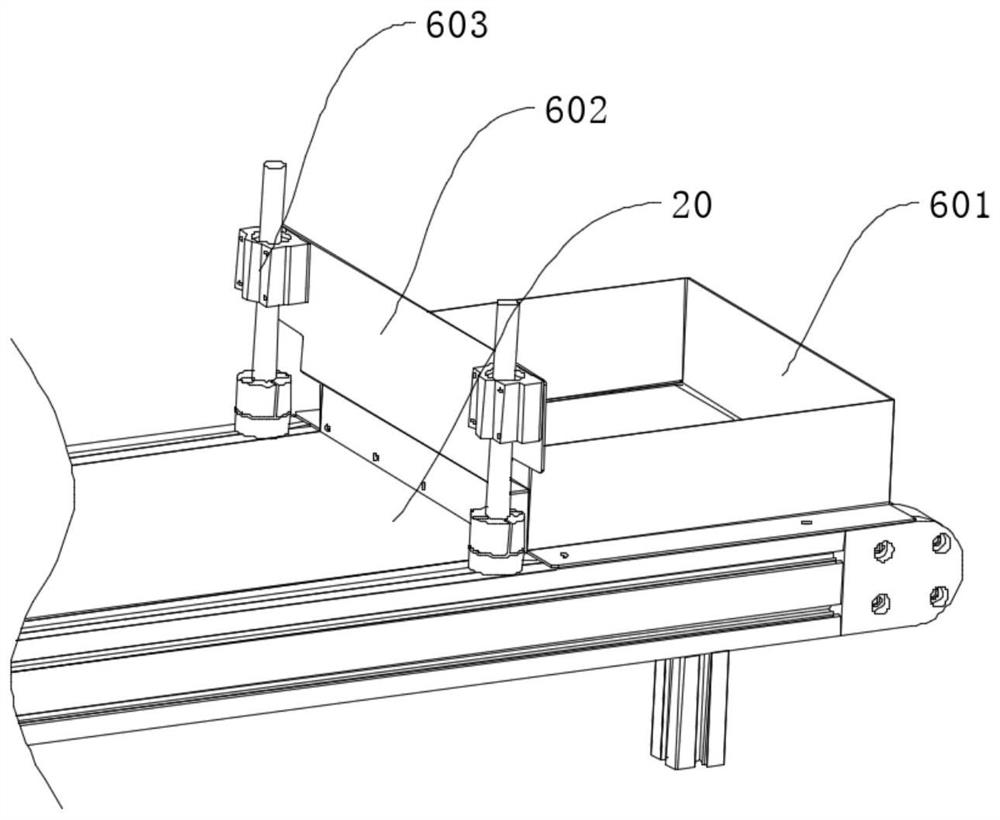

ActiveCN112427203AImprove work efficiencyAffect the quality of the finished productCleaning using toolsSpray boothsWorkbenchMaterials science

The invention relates to the technical field of aluminum alloy door and window spraying, in particular to a spraying device for aluminum alloy doors and windows. The spraying device comprises a workbench, a feeding device, a conveying belt, a wiping device, a moving device, a spraying device body, a coating trowelling device and a collecting device. The workbench is placed on the ground, and the feeding device is installed on the top of the workbench. The conveying belt is installed at the top of the workbench and located beside the feeding device, the wiping device is installed at the top ofthe workbench and is in sliding fit with the conveying belt, the moving device is installed at the top of the workbench, the spraying device body is installed on the moving device, and the coating trowelling device is installed at the top of the workbench. The collecting device is placed on the ground. By means of the coating trowelling device, the situation that surface coating of the aluminum alloy doors and windows is uneven is avoided, and the sprayed aluminum alloy doors and windows are more attractive and free of defects.

Owner:奥斯卡门窗科技(嘉兴)有限公司

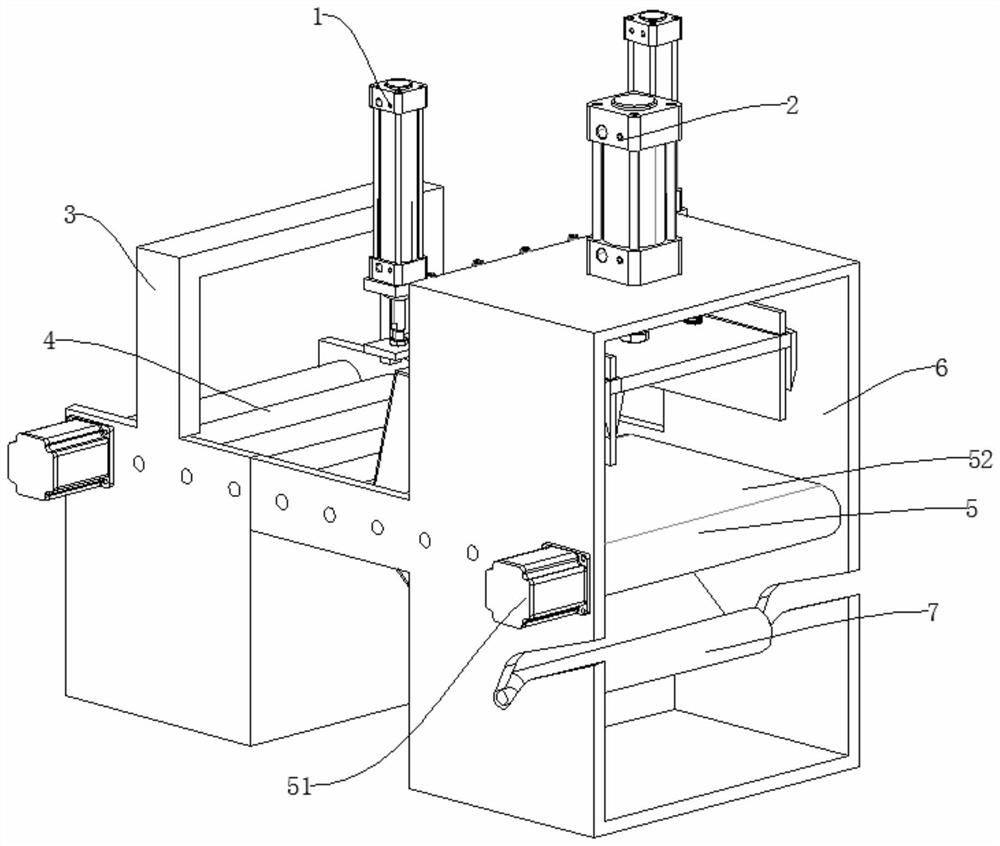

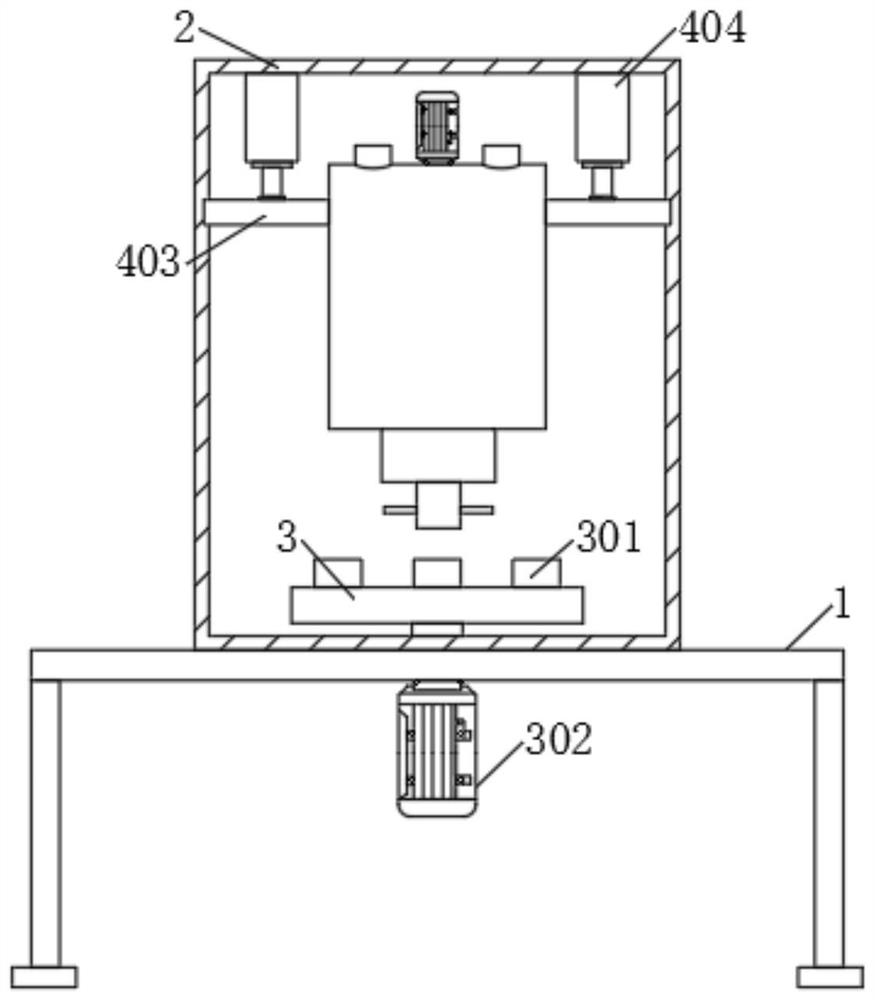

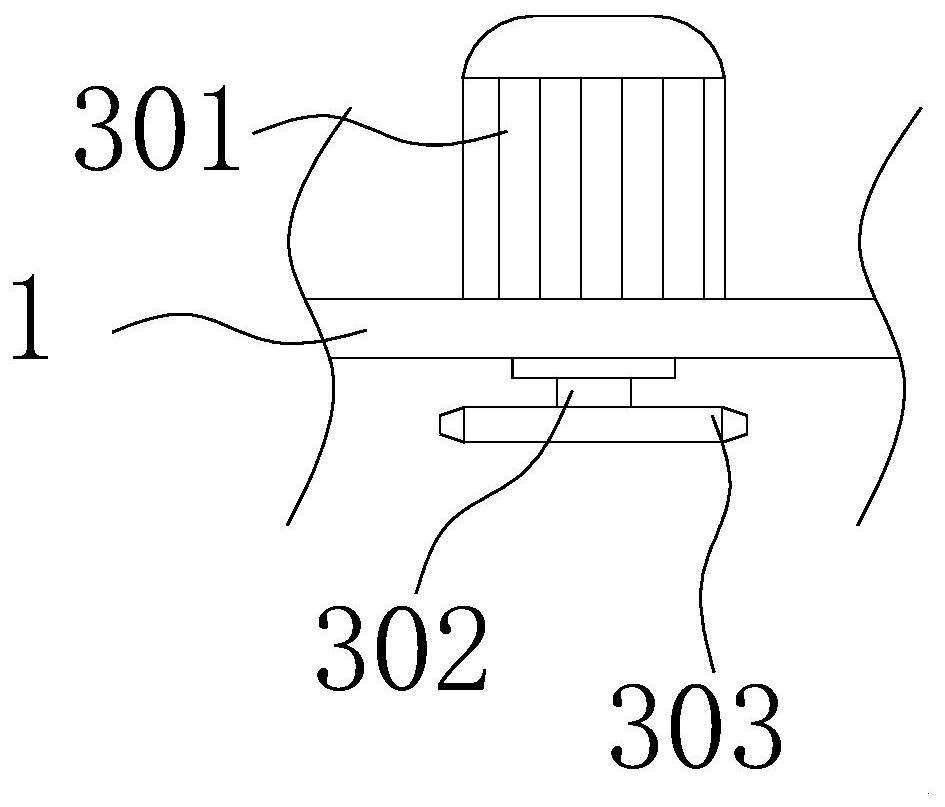

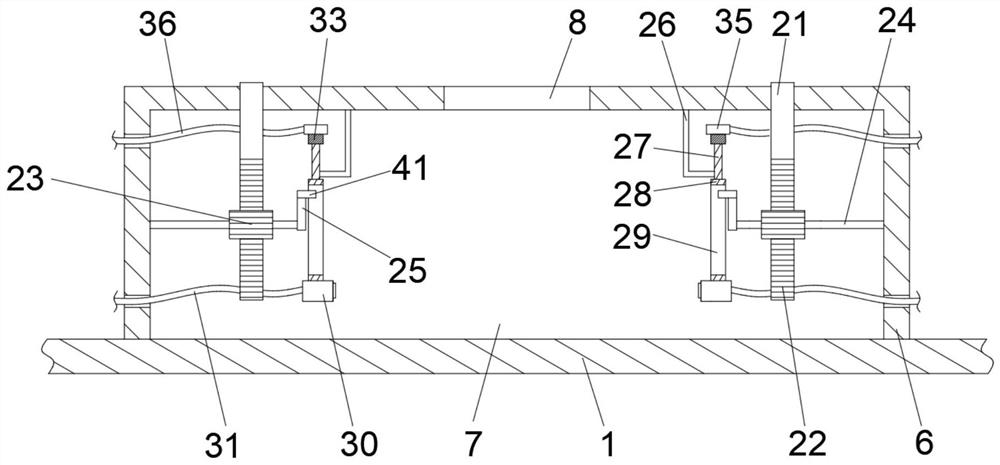

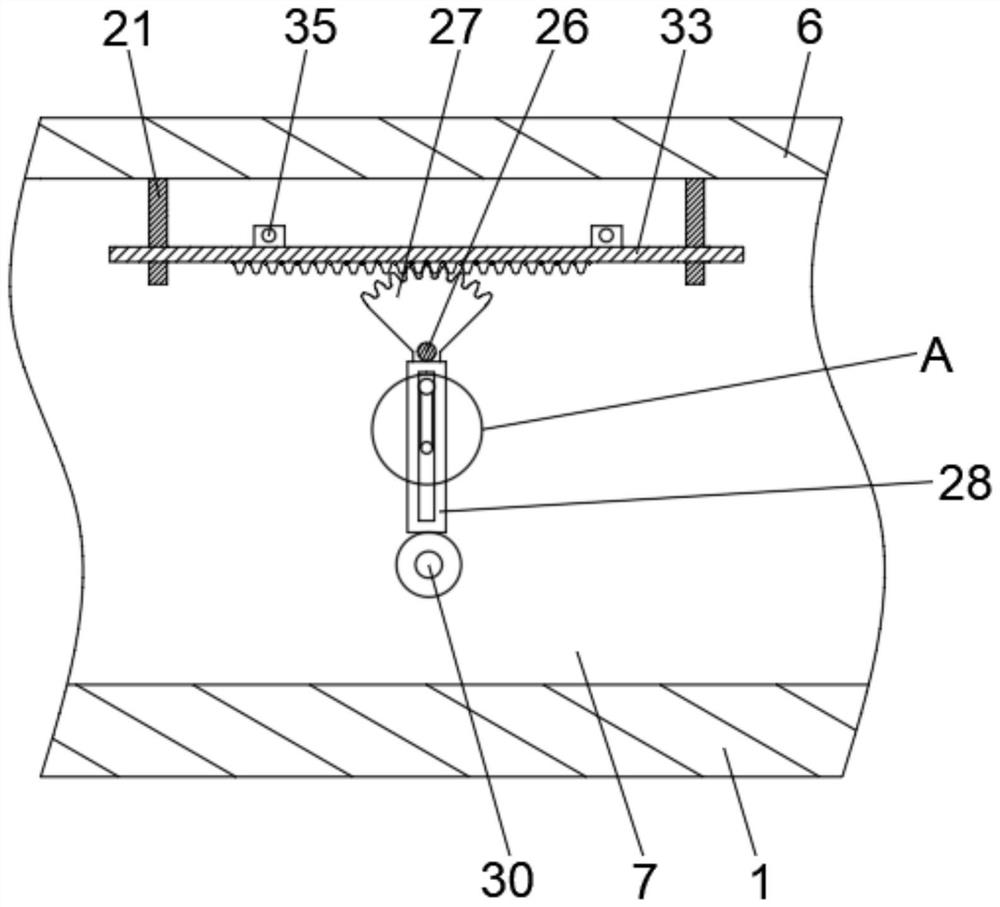

Packing and pressing device for processing paper packing case

InactiveCN111977103AReduce moisture deformationAffect the quality of the finished productConveyor wrappingWrapper twisting/gatheringStrappingCarton

The application discloses a packing and pressing device for processing a paper packing case. The packing and pressing device comprises lifting mechanisms, a pressing mechanism, a strapping machine, aconveying mechanism, a discharging mechanism, a rack and a heat sealing film roller; the strapping machine is located on one side of the rack, and the lifting mechanisms are located on one side of thetop of the rack; the pressing mechanism is located on the inner side of the top of the rack, and the conveying mechanism is located on the strapping machine and the rack; and the heat sealing film roller is arranged on the lower side of the rack. In this way, the application provides the packing and pressing device for processing the paper packing case. The packing and pressing device for processing the paper packing case is provided with the lifting mechanisms and the pressing mechanism, and used for pressing, packing and plastic encapsulated treatment to cartons strapped preliminarily, so that the damp deformation degree of the cartons is reduced in the transport or storage process; and meanwhile, the situation that tightening traces are caused by strapping and packing, and consequentlythe finished product quality of the cartons is affected can be further avoided.

Owner:襄阳申谦包装有限公司

An aluminum alloy door and window spraying device

ActiveCN112427203BImprove work efficiencyAffect the quality of the finished productCleaning using toolsSpray boothsEngineeringConveyor belt

The invention relates to the technical field of aluminum alloy doors and windows spraying, in particular to a spraying device for aluminum alloy doors and windows, including a workbench, a feeding device, a conveyor belt, a wiping device, a moving device, a spraying device, a paint smoothing device and a collecting device. The workbench is placed on the ground, the feeding device is installed on the top of the workbench, the conveyor belt is installed on the top of the workbench at the side of the feeding device, the wiping device is installed on the top of the workbench and is connected with the conveyor With sliding fit, the mobile device is installed on the top of the workbench, the spraying device is installed on the mobile device, the paint smoothing device is installed on the top of the workbench, and the collection device is placed on the ground. The smoothing device prevents the surface coating of aluminum alloy doors and windows from being uneven, making the aluminum alloy doors and windows after spraying more beautiful and free from defects.

Owner:奥斯卡门窗科技(嘉兴)有限公司

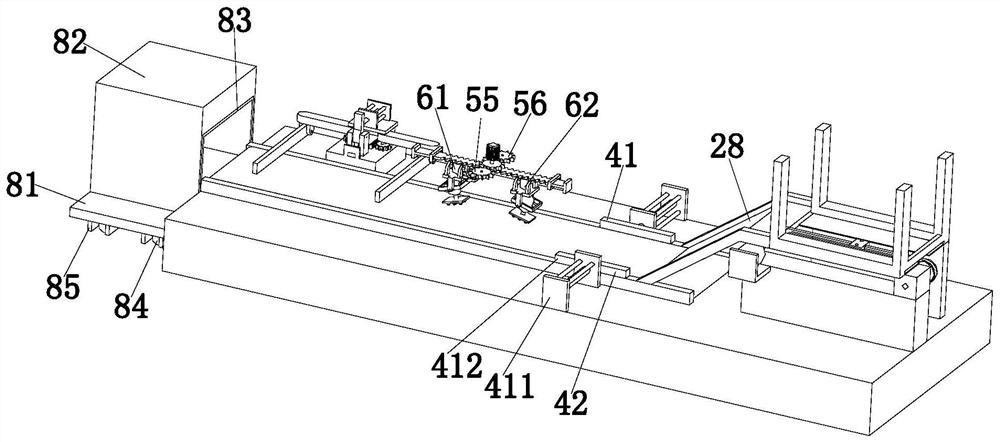

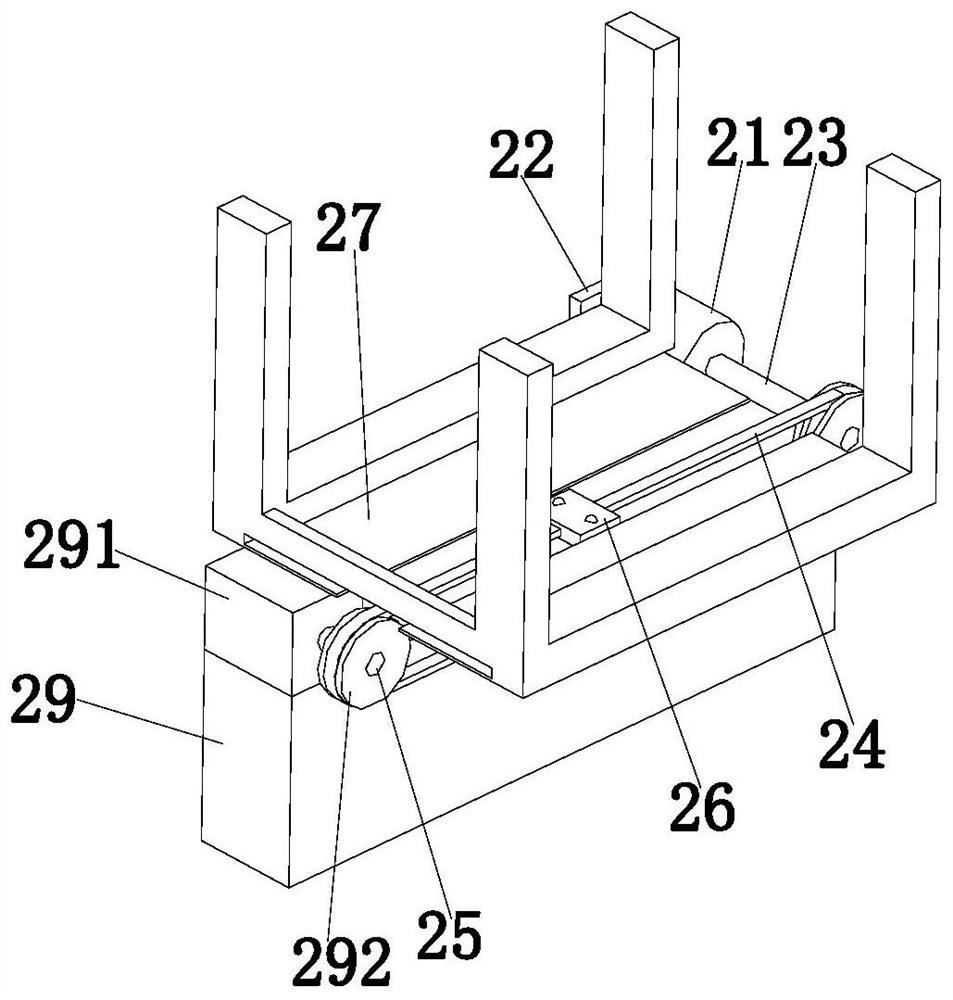

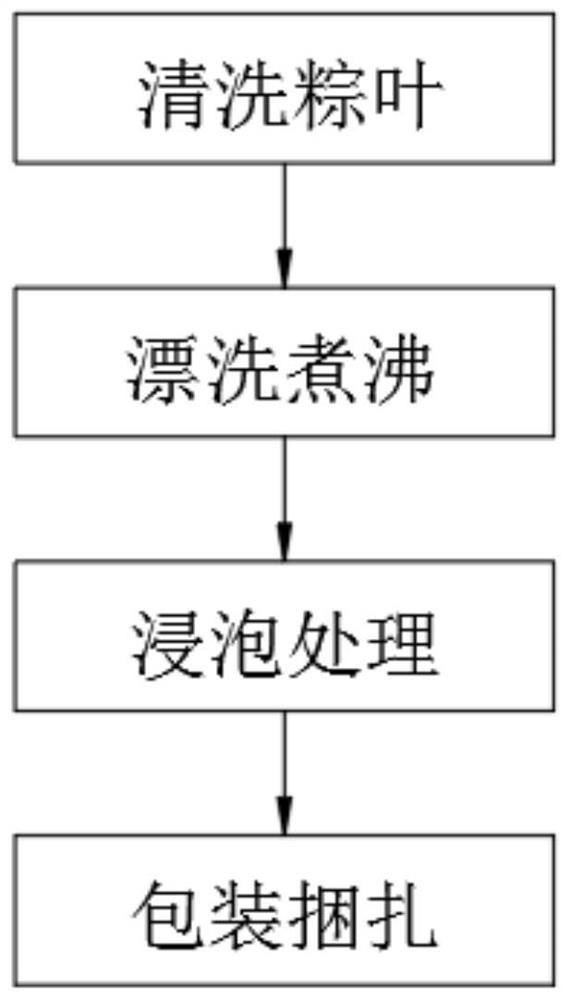

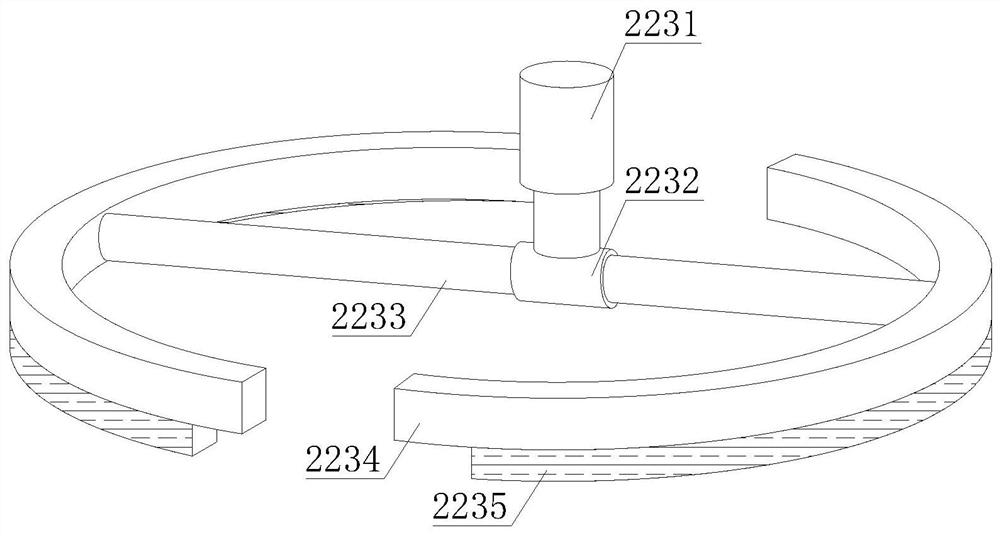

Glutinous rice zongzi capable of reducing sticky rice on zongzi leaves and production process thereof

PendingCN114431409ASoftening fiberImprove smoothnessRotary stirring mixersMixer accessoriesOXALIC ACID DIHYDRATECorn flour

The invention relates to a sticky rice zongzi with reduced sticky rice on reed leaves and a production process thereof, the production process of the sticky rice zongzi with reduced sticky rice on reed leaves comprises the following steps: S1, cleaning reed leaves, putting the reed leaves into saline water for cleaning, and then airing the cleaned reed leaves for later use; s2, rinsing and boiling: putting the air-dried reed leaves in an oxalic acid solution for rinsing, and then putting the rinsed reed leaves in boiling water for boiling to obtain treated reed leaves; s3, cleaning glutinous rice, soaking the cleaned glutinous rice in water, draining water, and adding corn flour and sodium diacetate into the glutinous rice to obtain treated glutinous rice; and S4, putting the treated glutinous rice into an auxiliary device, carrying out quantitative subpackaging, packaging the subpackaged glutinous rice and the reed leaves, and bundling the packaged glutinous rice and the reed leaves with a string so as to obtain the glutinous rice zongzi with reduced glutinous rice sticking on the reed leaves.

Owner:ANHUI BAGONGSHAN BEAN PRODS

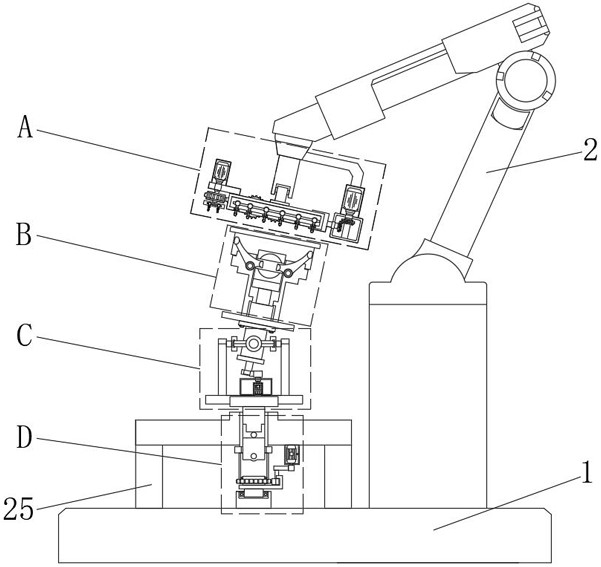

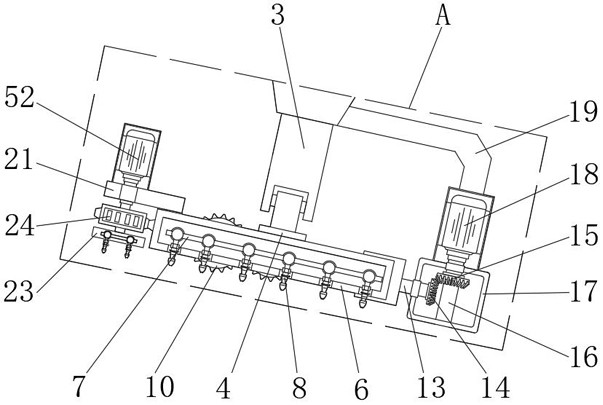

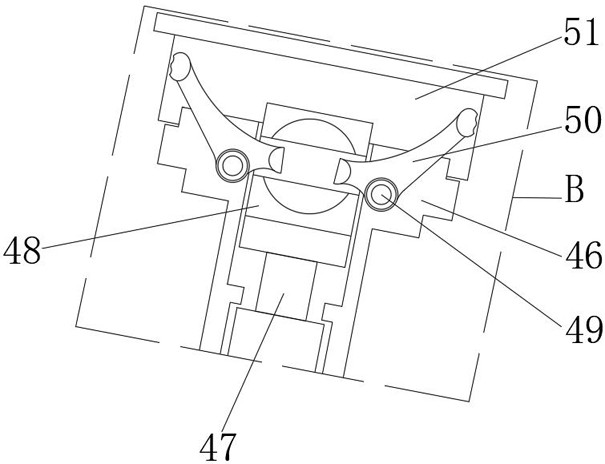

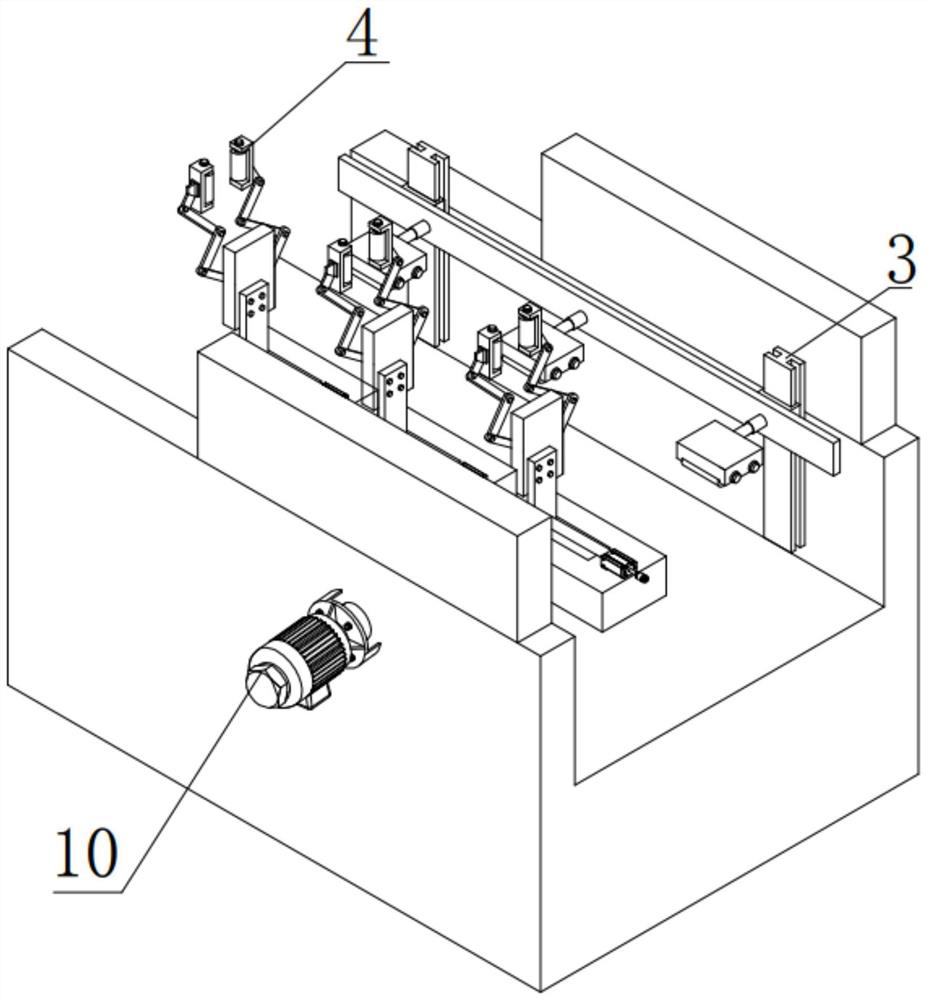

Environment-friendly motorcycle front fork pipe welding device based on intelligent manufacturing

InactiveCN113020849AUniform fixed forceEasy to replaceWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryPipe welding

The invention discloses an environment-friendly motorcycle front fork pipe welding device based on intelligent manufacturing, and relates to the technical field of welding equipment. The environment-friendly motorcycle front fork pipe welding device based on intelligent manufacturing comprises a welding box, a fixing mechanism, a moving mechanism and a welding mechanism are arranged in the welding box, and a cleaning mechanism is arranged above the welding box. According to the environment-friendly motorcycle front fork pipe welding device based on intelligent manufacturing, a third motor, a threaded rod, a sliding rod, a first belt wheel, a belt, a second belt wheel, a lifting block and a welding gun are used in cooperation, a connecting plate and a stand column are welded, in the welding process, manual welding is not needed, the situation that due to the fact that workers wear protective articles, inconvenience is brought to welding personnel, and the welding skill in an operator yard is used, the quality of a finished motorcycle front fork pipe is affected is avoided, meanwhile, the motorcycle front fork pipe is welded through double stations, and the welding efficiency of the device is improved.

Owner:重庆顺宏机械有限公司

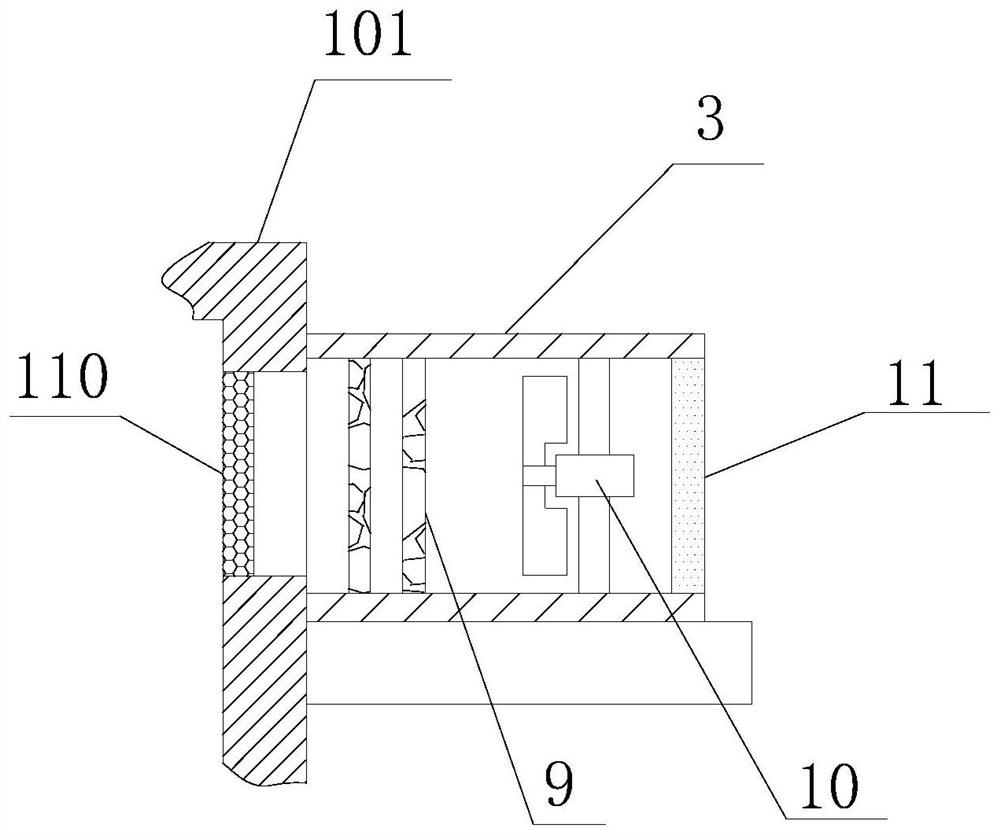

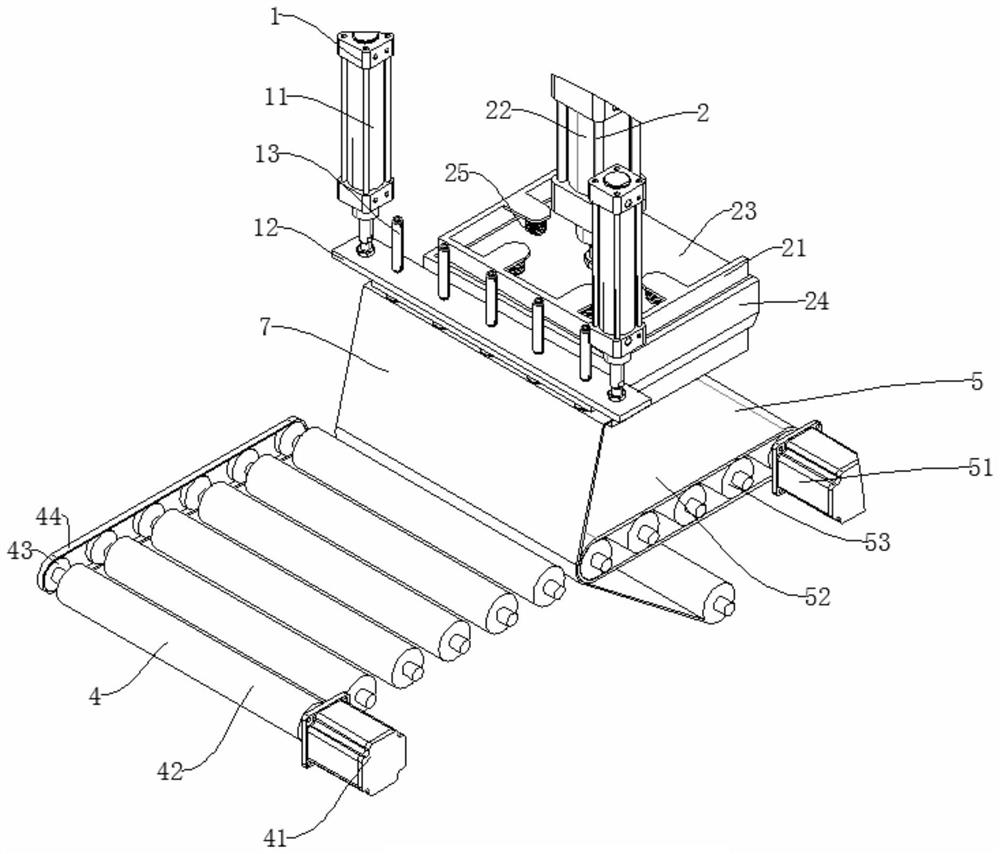

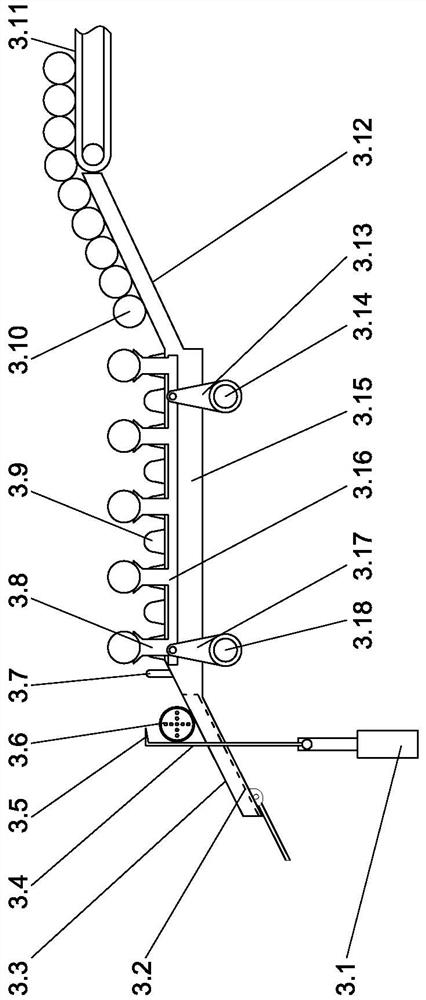

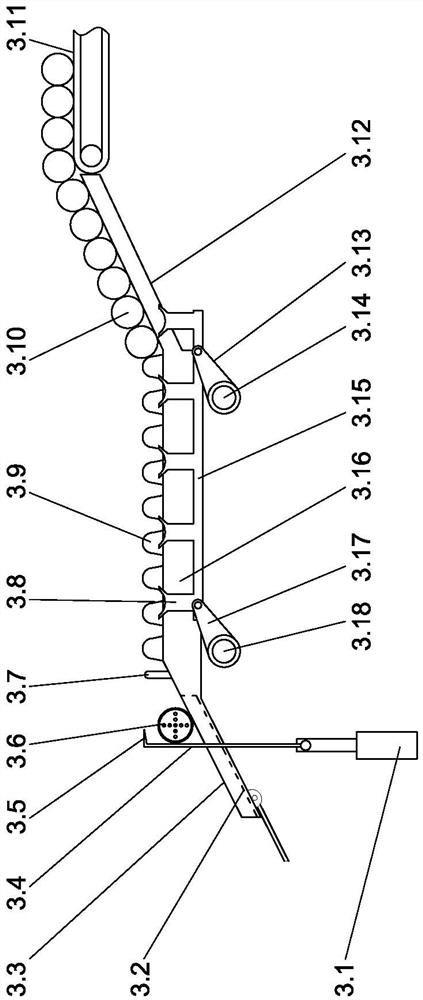

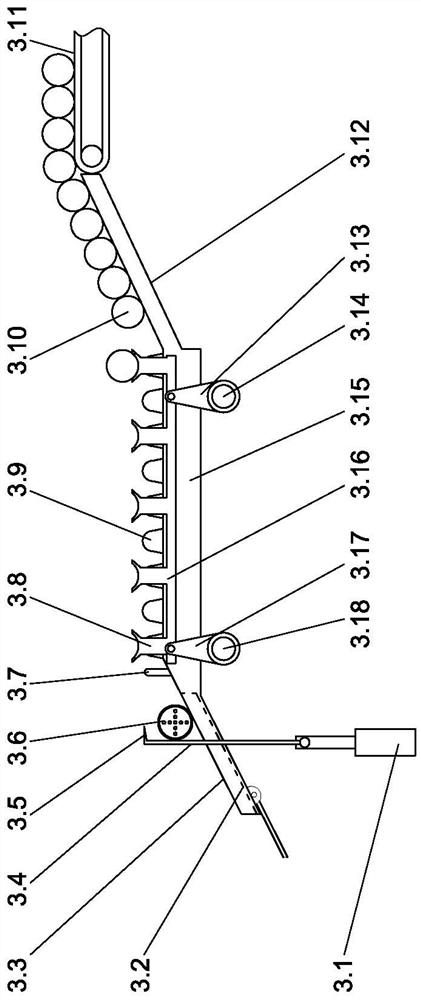

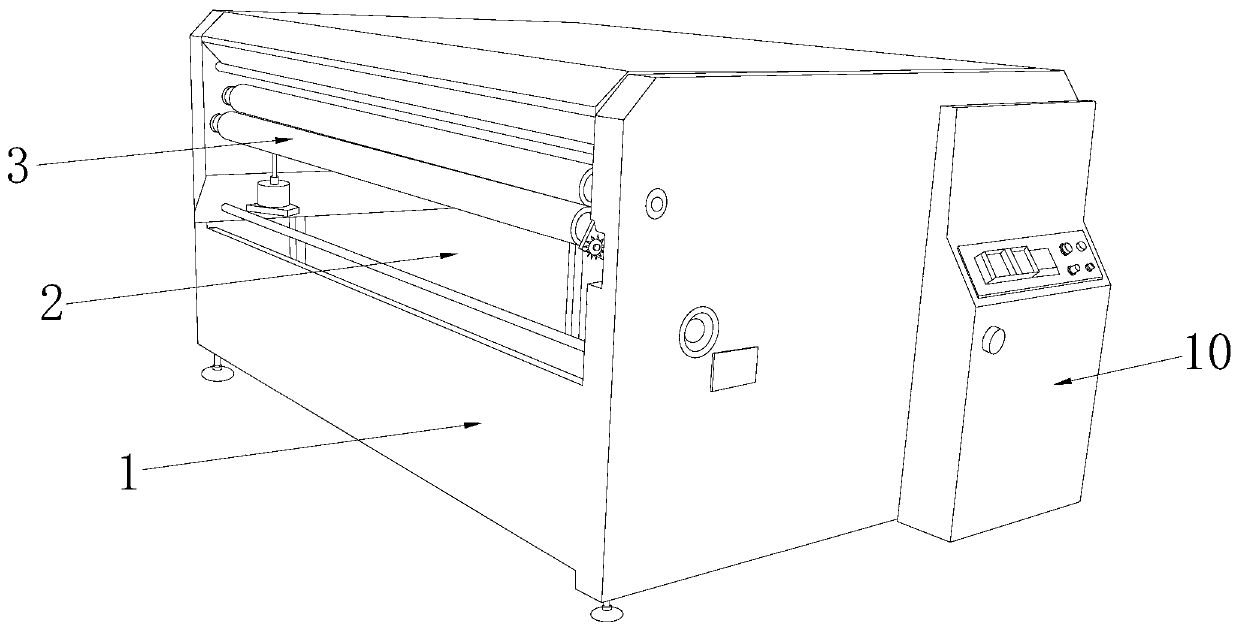

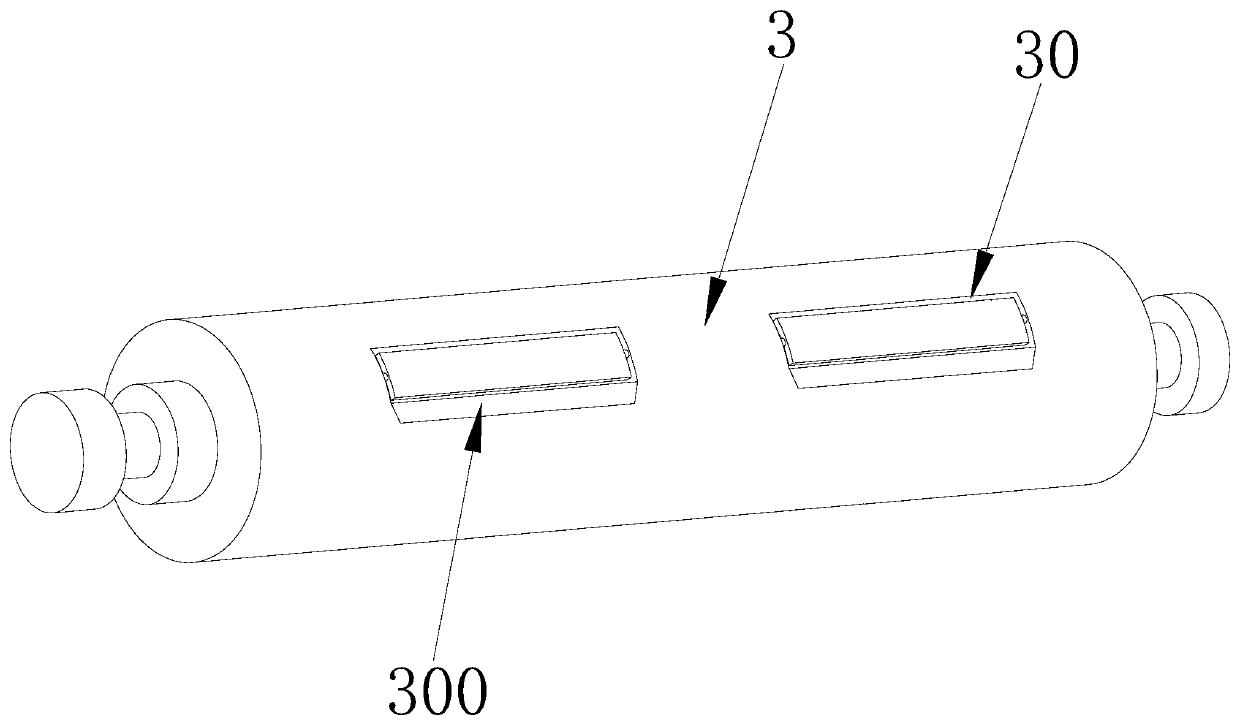

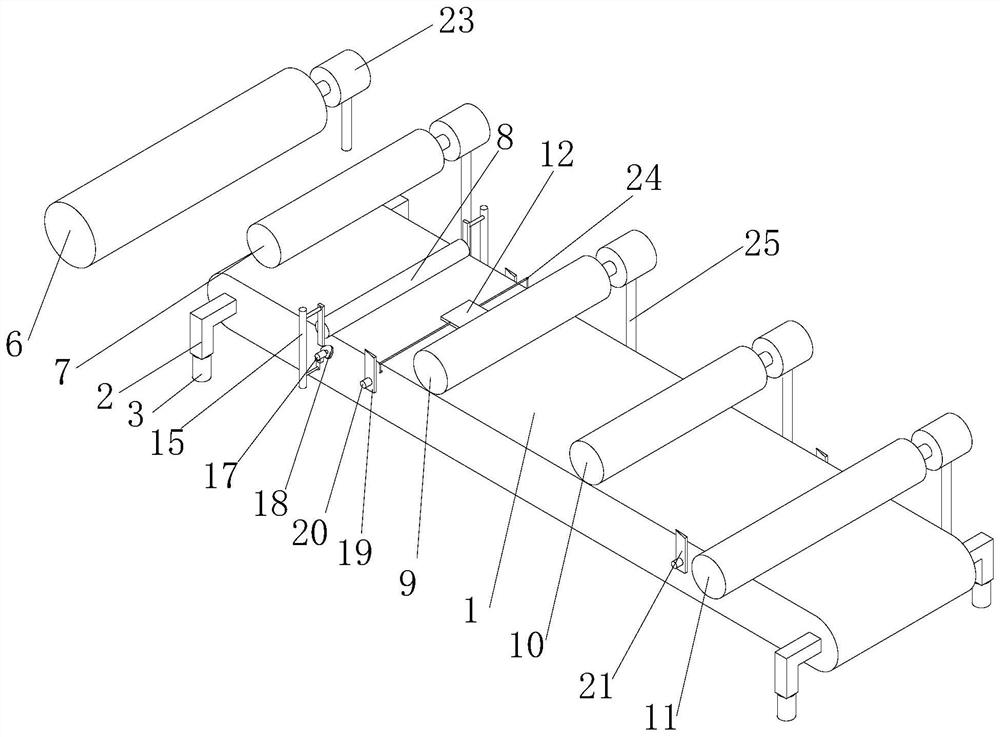

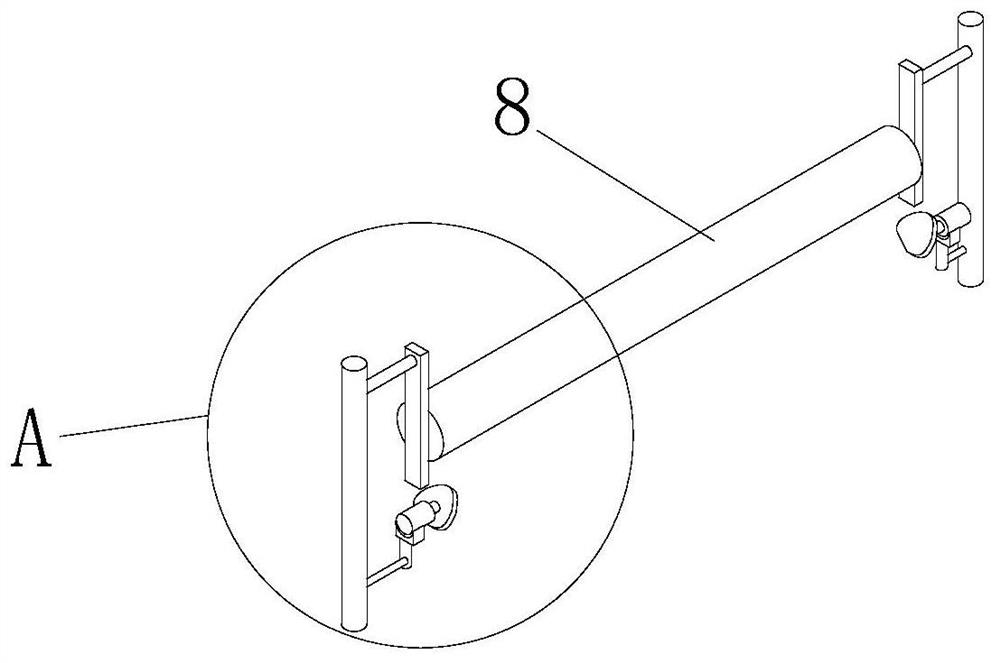

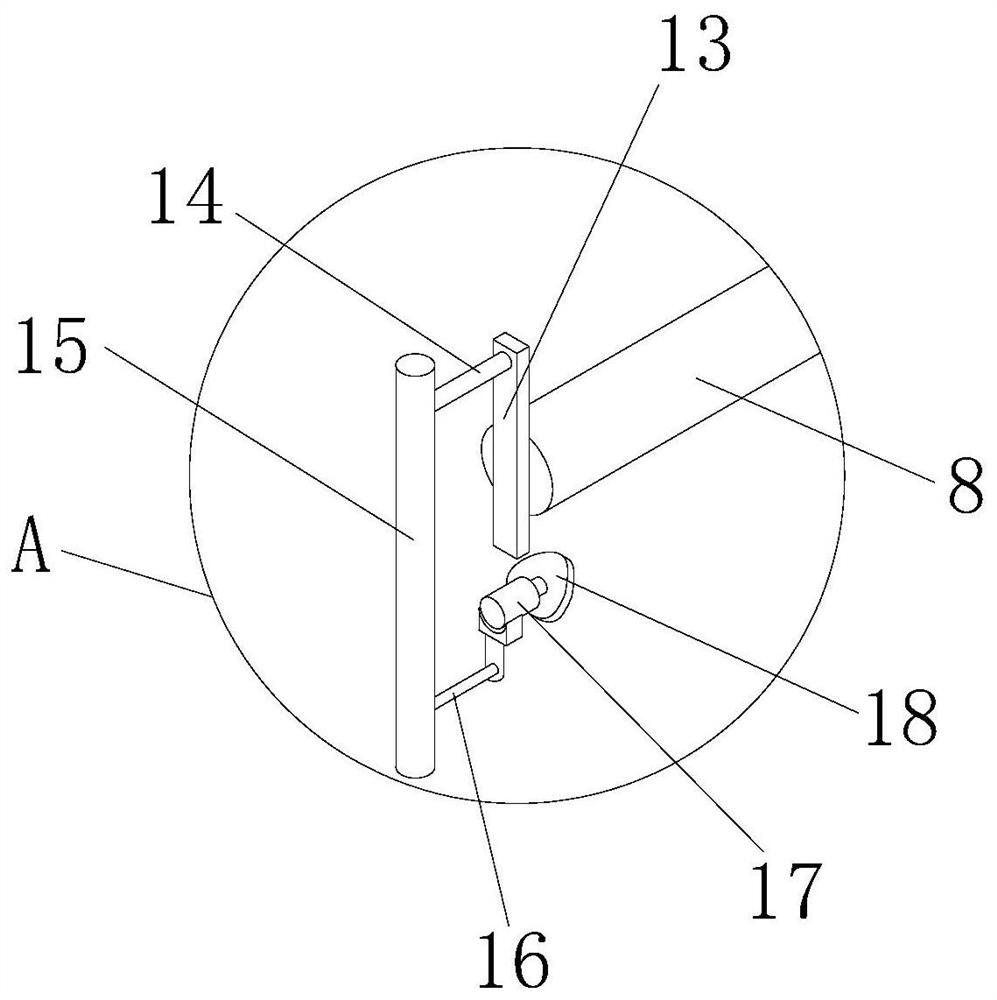

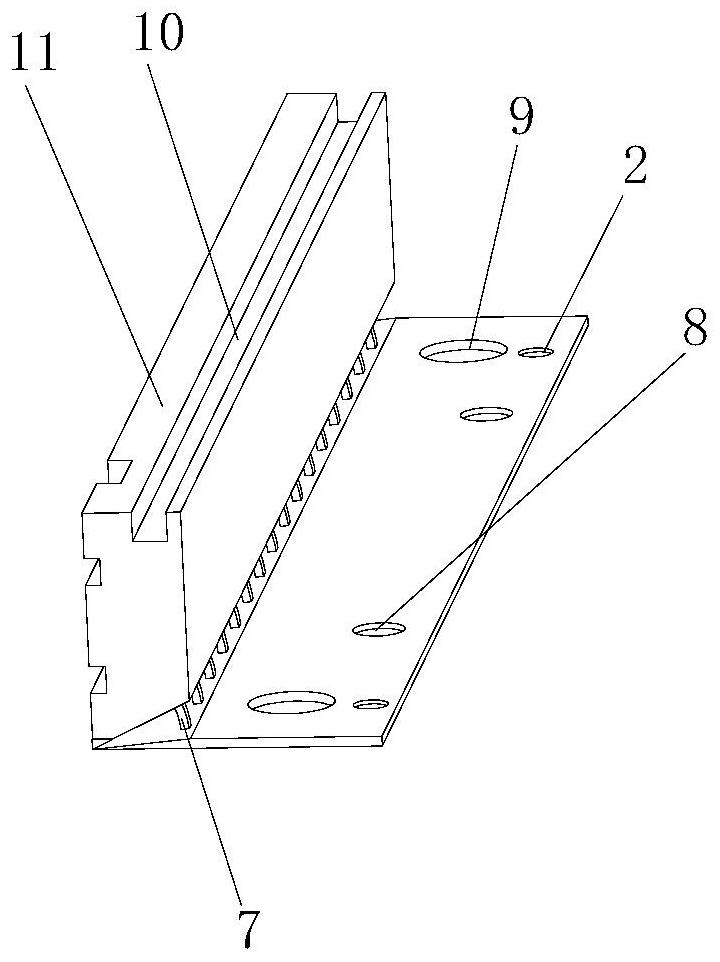

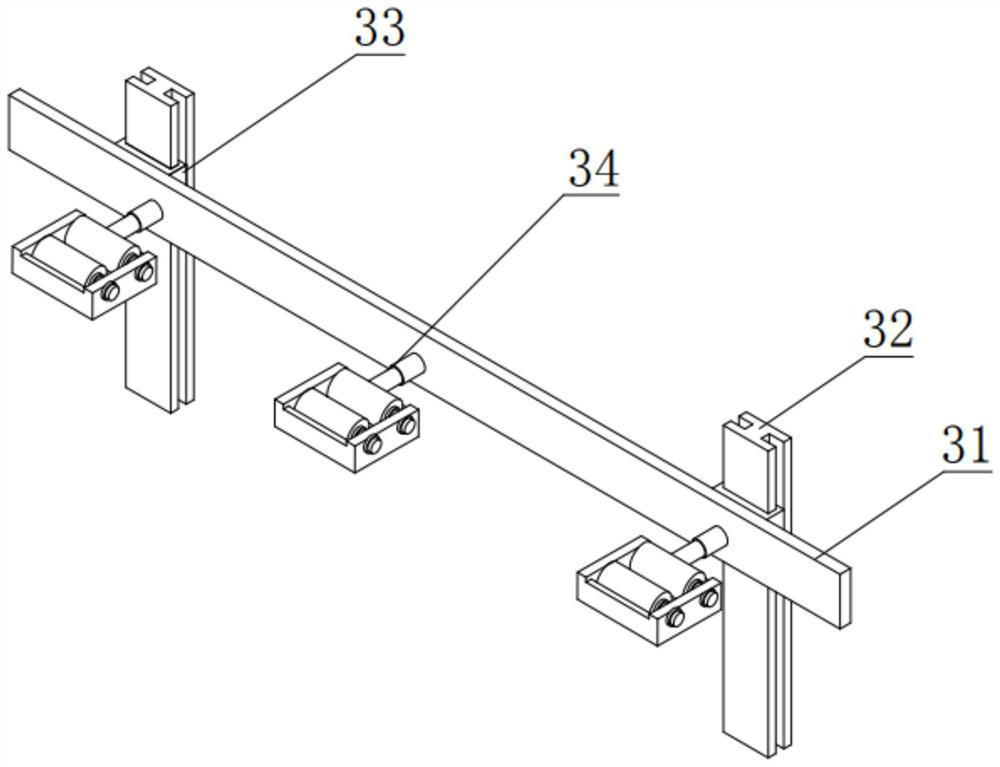

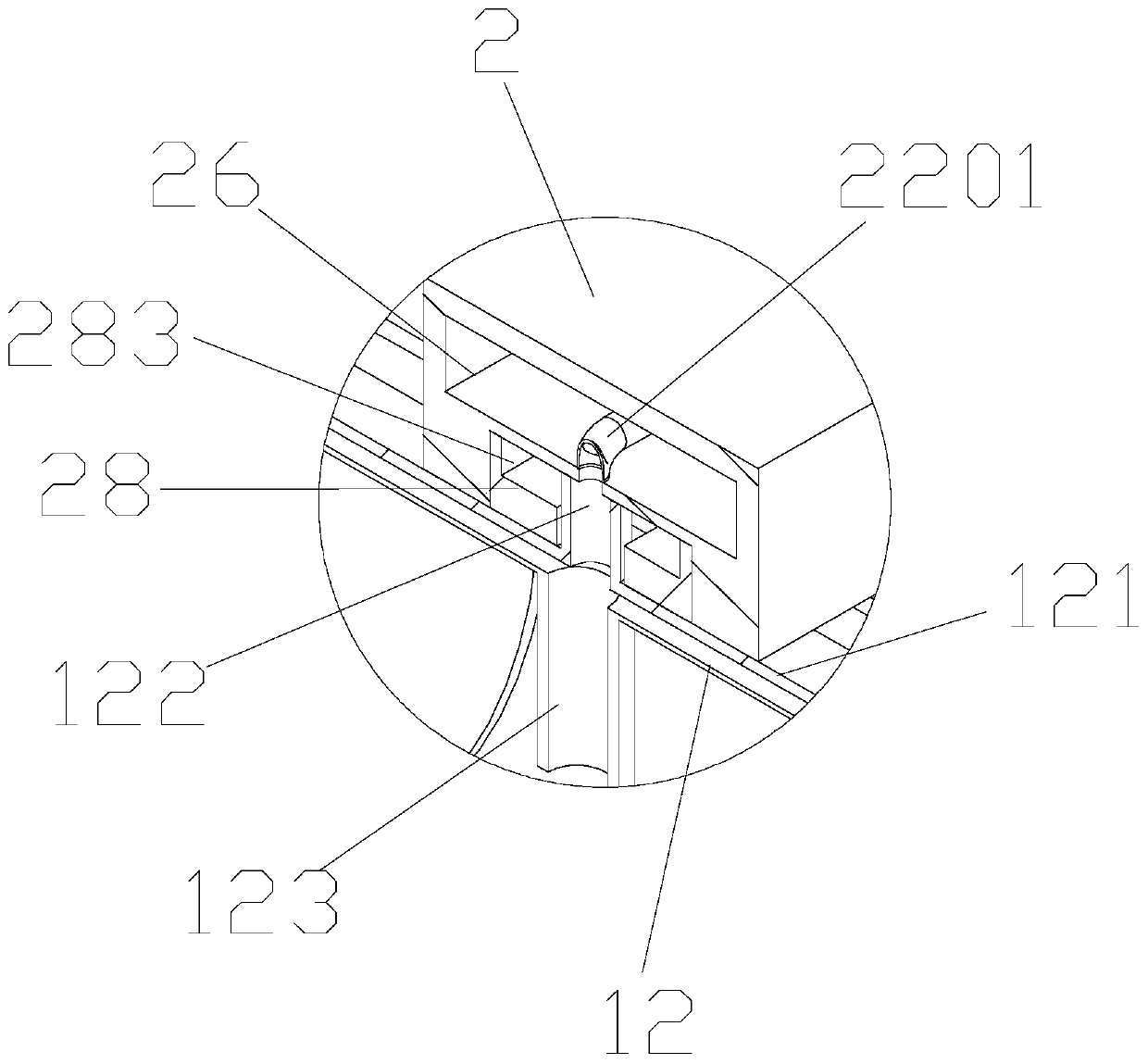

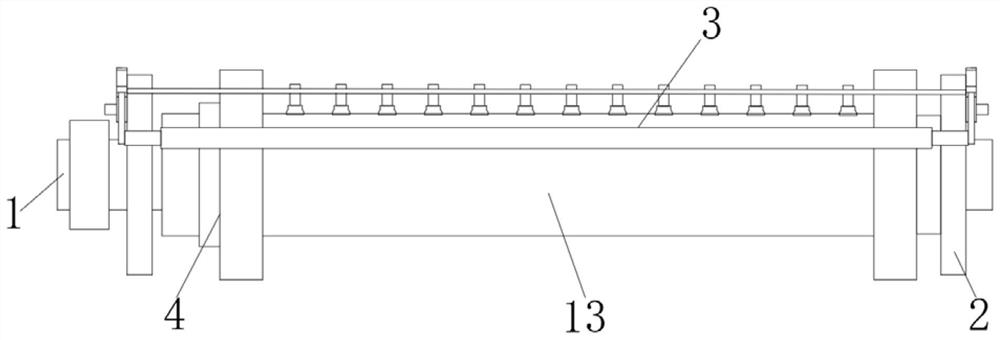

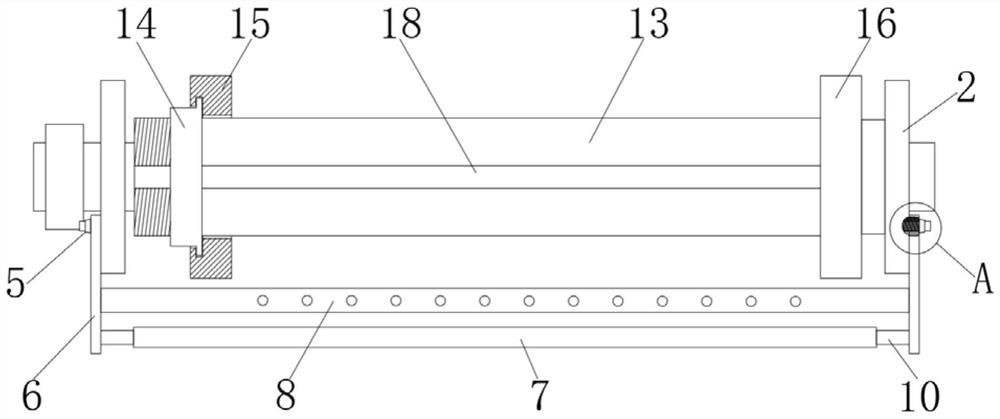

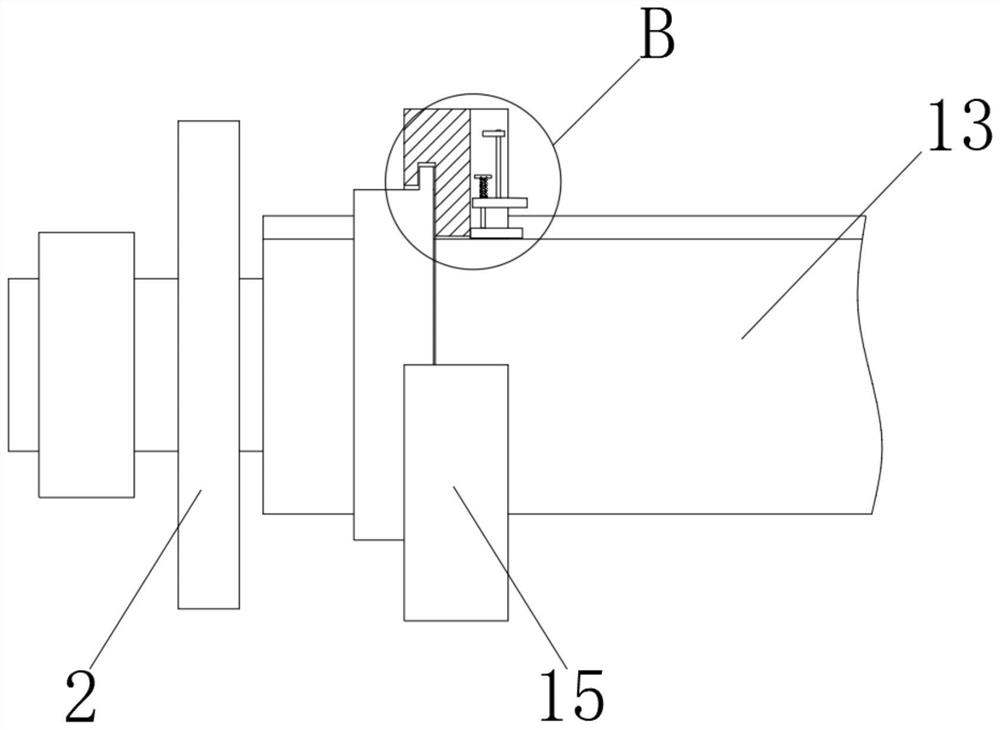

Gasket belt turn-over mechanism and double-conveyor type gasket turn-over machine

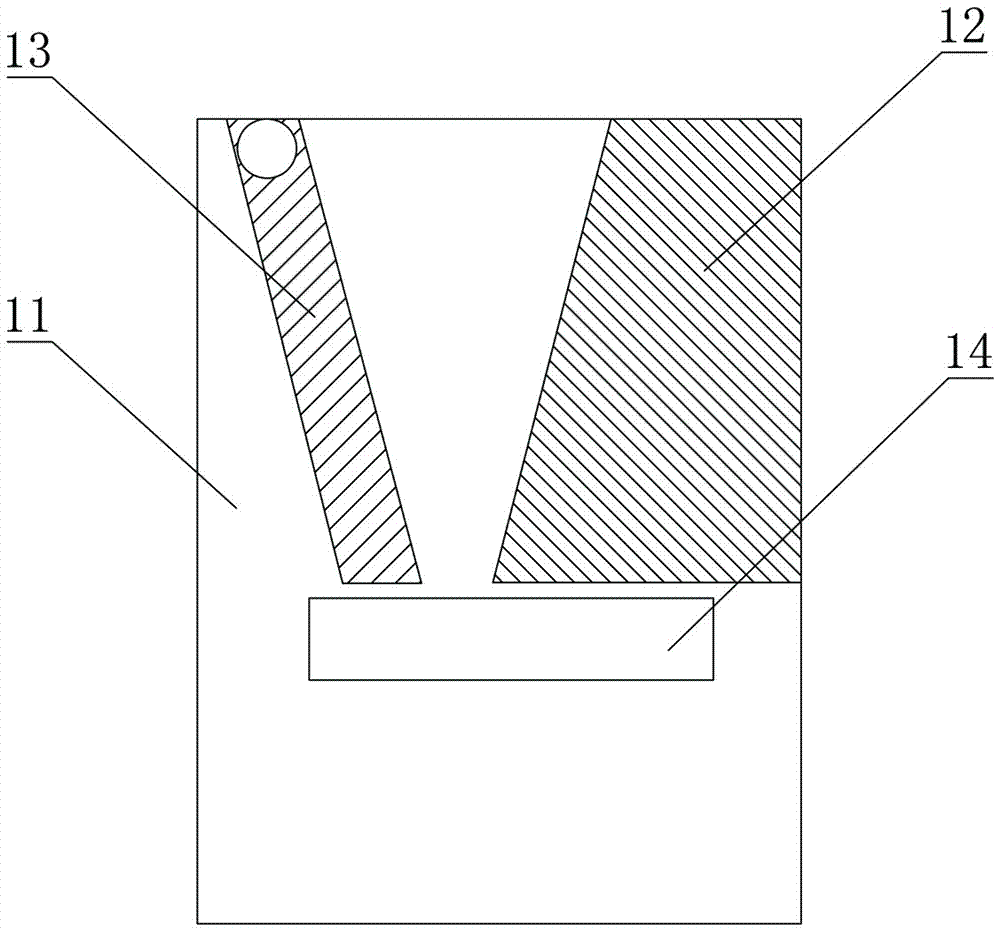

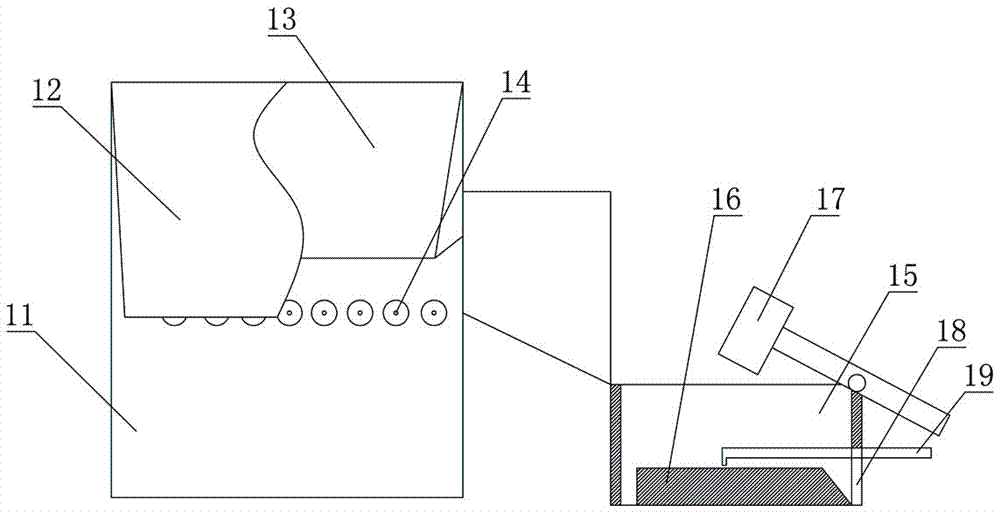

ActiveCN113044525AReduce washer spacingReduce fit lengthConveyorsConveyor partsEngineeringLeather belt

The invention discloses a gasket belt turn-over mechanism, and belongs to the technical field of gasket detection. The gasket belt turn-over mechanism is used for wrapping the end head of a belt conveyor, the wrapping surface of a turn-over belt in the belt turn-over mechanism is of a V-shaped structure, and the upper end and the lower end of the V-shaped structure extend out of the tangent point of a conveying belt and a belt conveying roller, so that the attaching length of the turn-over belt at the feeding end of the belt turn-over mechanism and the conveying belt is increased, then gaskets can be clamped in advance, the gasket conveying distance is reduced, and the continuous feeding efficiency is guaranteed; meanwhile, the attaching length of the belt turn-over belt at the discharging end of the belt turn-over mechanism and the conveying belt is reduced, the gaskets are released in advance, at the moment, the lower end of the belt turn-over mechanism is fixedly connected with a discharging sliding way for bearing discharged materials of the belt turn-over mechanism, the discharging sliding way is attached to the lower end of the V-shaped structure, the gaskets released in advance enter the discharging sliding way and freely slide, and therefore the discharging speed is greatly increased, and the gasket turn-over detection efficiency is effectively improved under the double acceleration of feeding and discharging.

Owner:JIASHAN YONGXIN FASTENER

Low-fat yogurt fermentation inoculant taking lactobacillus paracasei and lactic acid bacteria as main components

ActiveCN112680378AAffect the quality of the finished productLow in fatMilk preparationConveyorsBiotechnologyLactic acid bacterium

The invention relates to a low-fat yoghurt fermentation inoculant taking lactobacillus paracasei and lactic acid bacteria as main components, and belongs to the technical field of yoghurt preparation. The milk powder low-fat yoghurt fermentation inoculant is characterized by being prepared from the following raw materials in parts by weight: 90 parts of skim milk powder, 1 part of lactobacillus bulgaricus, 1 part of streptococcus thermophilus, and 1 part of lactobacillus paracasei. The skimmed milk powder, the lactobacillus bulgaricus, the streptococcus thermophilus and the lactobacillus paracasei are added into a mixture in proportion through a quantitative feeder, uniform dry mixing is performed, and subpackaging is performed. The invention provides the low-fat yogurt fermentation inoculant taking the lactobacillus paracasei and the lactic acid bacteria as main components, the quality of the fermentation inoculant can be improved through reasonable proportioning and in combination with advanced modern production equipment, and the situation that the finished product quality of yogurt is affected due to the fact that infectious microbes are doped in the production process is avoided.

Owner:山东悠乐滋生物科技有限公司

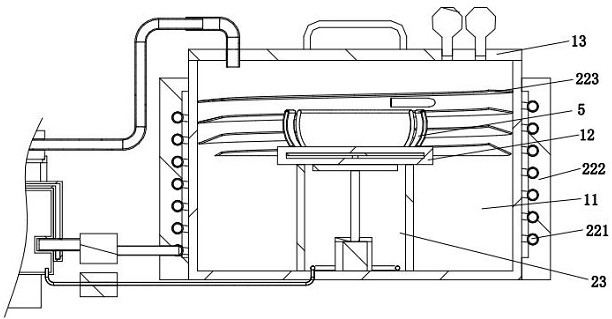

Energy-saving printing and dyeing equipment for textile mill

InactiveCN110205767AAvoid wrinklesAffect the quality of the finished productTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsTextile millPulp and paper industry

The invention discloses energy-saving printing and dyeing equipment for textile mill. The energy-saving printing and dyeing equipment structurally comprises a housing, a worktable and a bonded rollerset, the bonded roller set is provided with an air outlet, a roller, a hot air cavity and air regulating plates, the air outlet is embedded in the outer surface of the roller, the roller is embedded in the air outlet, the hot air cavity is arranged between the roller and the air regulating plates, and the air regulating plates are connected to the outer surface of the roller in a transition fit manner. The energy-saving printing and dyeing equipment has the advantages that through the 45-degree design of the angle between the air regulating plates and an air guide slot and under the cooperation of a heating net and air outlets, all hot air is centrally blown to the lining cloth so that the lining cloth can be dried before pressing and ironing and prevented from being wrinkled before pressing and ironing due to moisture resulting in that the lining cloth cannot be unfolded during pressing and ironing to cause crease deepening and affect the finished product quality of the lining cloth to achieve undesired results.

Owner:黄艺伟

Surface drilling equipment for household appliance shell production and machining

InactiveCN112355348AFacilitate depositionAvoid inhalationMaintainance and safety accessoriesBoring/drilling machinesPhysical healthEngineering

The invention discloses surface drilling equipment for household appliance shell production and machining, and relates to the technical field of drilling equipment. The surface drilling equipment comprises a bottom plate, a drilling device and a plate, two supporting rods are fixedly connected to the upper surface of the bottom plate, two supporting blocks are fixedly connected to the opposite sides of the two supporting rods, the upper surfaces of the two supporting rods are jointly and fixedly connected with a bearing beam, the upper surface of the bottom plate is fixedly connected with an operation table, and an operation cavity is formed in the operation table. According to the surface drilling equipment, through mutual cooperation of the structures, a plate to be drilled is automatically fixed, the final drilling effect is guaranteed, dust generated during drilling is automatically collected, the effect of a good machining environment is guaranteed, and the problems that a traditional drilling device cannot conveniently fix a plate, dust generated in the drilling process cannot be treated, and the physical health condition of an operator is affected are solved.

Owner:王毛元

Film covering device for bathroom waterproof composite floor production

PendingCN112356433AAvoid problems such as pleatingImprove lamination efficiencyMetal working apparatusElectric machineryStructural engineering

The invention relates to the technical field of floor production, and discloses a film covering for bathroom waterproof composite floor production. The film covering device comprises a conveying belt,a support is fixedly connected to the front side of the conveying belt, a sleeve is fixedly connected to the bottom of the support, a motor support is arranged on the rear side of the conveying belt,a motor is fixedly connected to the top of the motor support, a vibration reducing device is arranged inside the sleeve, and a material pressing device is arranged at the top of the conveying belt. According to the film covering device for the bathroom waterproof composite floor production, materials are placed on the conveying belt during work, when the materials move to a brake switch, the brake switch is started to drive a feeding roller to rotate, the bottom of a floor film moves to the upper surface of a material lifting roller through the feeding roller, through rotation and movement ofthe material pressing roller, the floor film moving to the lower surface of the material pressing roller is subjected to rolling arrangement, and the situation that the floor film pleats and wrinkleswhen moving among the rollers, and consequently material film covering is affected is avoided.

Owner:湖州凯鑫智能家居股份有限公司

Feeder for nylon raw material

PendingCN108529035AAvoid cloggingAffect the quality of the finished productHollow article cleaningLarge containersEngineeringPolycondensation reaction

The invention relates to the technical field of feeding, in particular to a feeder for nylon raw materials. The feeder comprises a feeding pipe and a feeding head, wherein a feeding hopper is connected with one end of the feeding pipe, and the other end of the feeding pipe is a free end, and the feeding head is connected with polycondensation reaction equipment; a vibrator is arranged on the outerside wall of the feeding pipe; the feeding hopper is in a hollow inverted truncated cone shape , a top cover is connected to the top face of the feeding hopper, the top cover is provided with a feeding opening and a cleaning opening, the free end of the feeding pipe is connected with the feeding opening, and the cleaning opening is provided with a cover plate; and a cleaning pipeline is arrangedon the side of the feeding hopper, pure water circulates in the cleaning pipeline, and the cleaning pipeline is connected with the cleaning opening. Through the operation of the vibrator, PTA raw materials adhered to the inner wall of the feeding pipe can be shaken off, and therefore the blockage of the feeding pipe is avoided; and the PTA raw materials adhered to the feeding head can be washed through regular cleaning by matching use of the cleaning pipeline and the cleaning opening to avoid blockage.

Owner:FUJIAN JINJIANG TECH

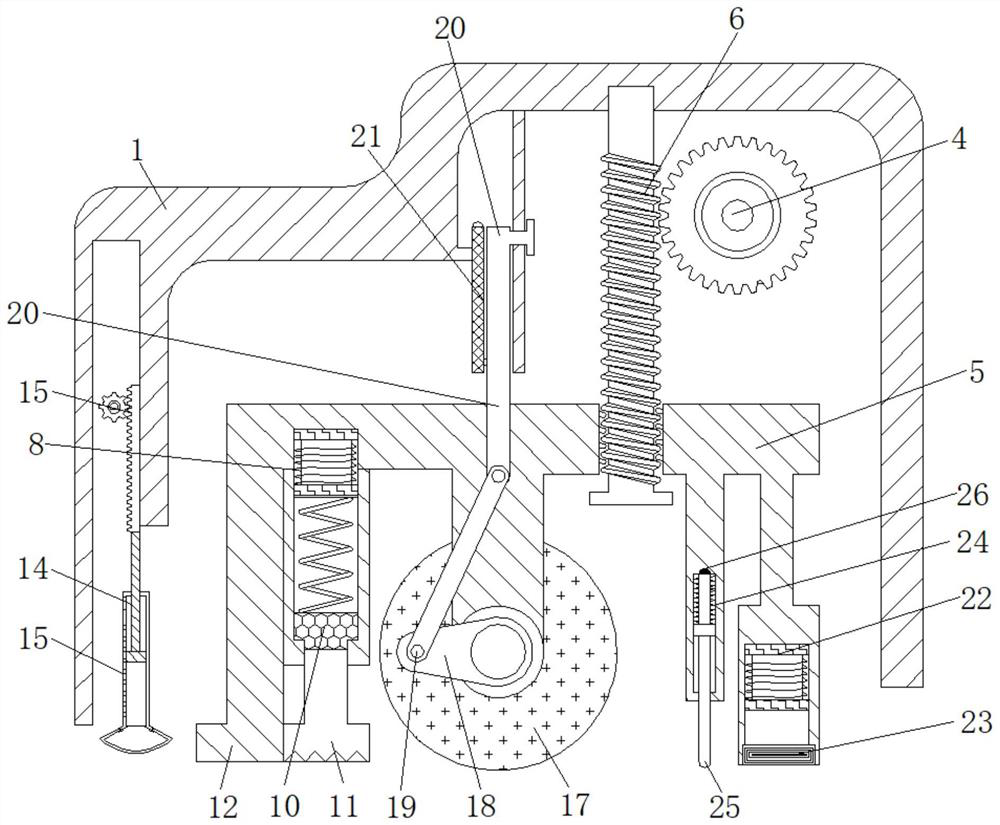

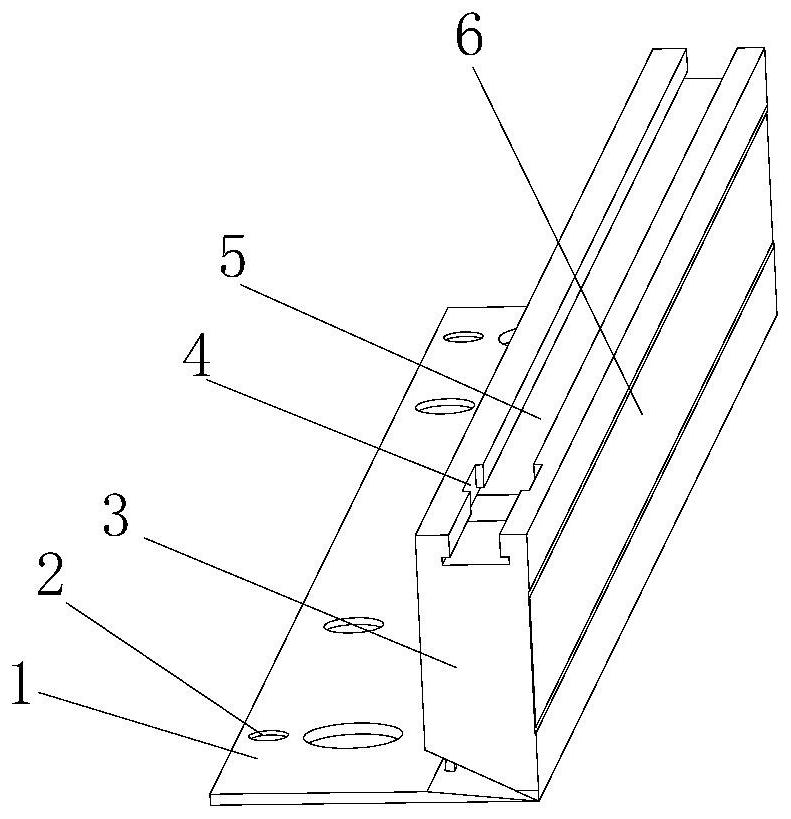

Sizing treatment equipment used for textile fabric

InactiveCN112160085AFully infiltratedPromote infiltrationLiquid/gas/vapor removalTextile treatment by spraying/projectingGear wheelEngineering

The invention relates to the technical field of textile equipment, and discloses sizing treatment equipment used for textile fabric. The equipment comprises an equipment body, the bottom of the equipment body is rotationally connected with a poke rod, the left side of the poke rod is in transmission connection with a first gear through a rotary disc, and the front end and the rear end of the rotary disc are in transmission connection with belt drives. The left side of the first gear is in engaged connection with a screw rod, the exterior of the screw rod is in threaded connection with a sliding block, a first electromagnet is fixedly connected in the left end of the sliding block, and a first magnet is movably connected to the side, close to the center of the equipment body, of the electromagnet through a first reset spring. According to the sizing treatment equipment used for the textile fabric, the fabric soaking effect of size is enhanced, sizing is more uniform, the product qualityis improved, the height of rolled fabric is convenient to adjust, the situation that the quality of a fabric finished product is affected by too large or too small pressing force is avoided, redundant size can be evaporated, the production cost is prevented from being increased or the production period is prevented from being prolonged, and the production efficiency is improved.

Owner:东阳梦凡特时装有限公司

Concrete pouring mold for road

PendingCN114457657AStir wellImprove laying efficiencyAnimal repellantsRoads maintainenceStructural engineeringMechanical engineering

The invention relates to the field of advanced steel materials, in particular to a road concrete pouring mold which comprises two bases, a left mold baffle is arranged at the top end of one base, a right mold baffle is arranged at the top end of the other base, and a fixing hole, a first mounting hole and a second mounting hole are formed in the top ends of the two bases correspondingly. A first mounting frame is mounted on the inner walls of the left mold baffle and the right mold baffle, a stirring assembly used for uniformly mixing concrete is arranged on the inner wall of the first mounting frame, an adjusting assembly used for adjusting the angles of the left mold baffle and the right mold baffle is arranged at the top end of the base, and a defoaming assembly used for eliminating bubbles in the concrete is arranged in the left mold baffle; a warning assembly used for warning and repelling animals is arranged at the top end of the base, and concrete is evenly stirred by arranging the stirring assembly; by arranging the defoaming assembly, bubbles in the concrete are eliminated; by arranging the arc-shaped connecting rods, the inclination angles between the left mold baffle and the right mold baffle and the ground are adjusted; by arranging an alarm and a warning lamp, animals are repelled.

Owner:长沙理工检测咨询有限责任公司 +1

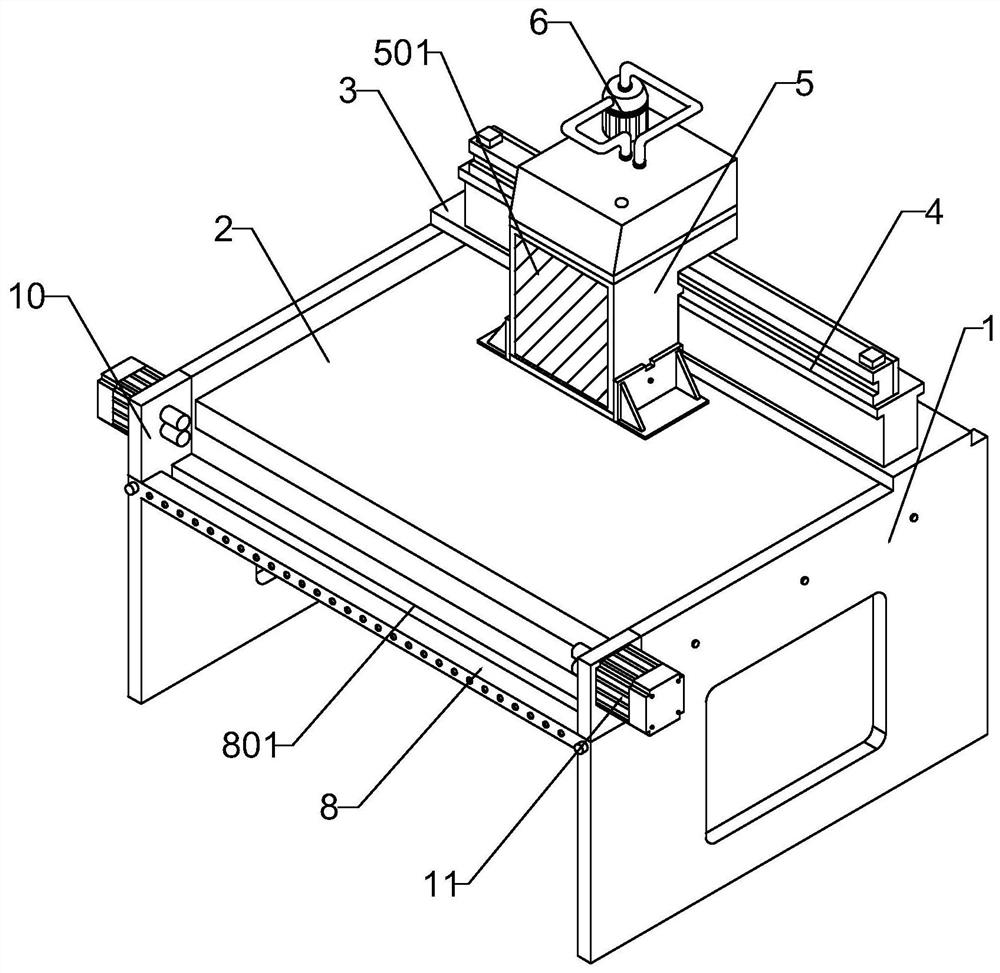

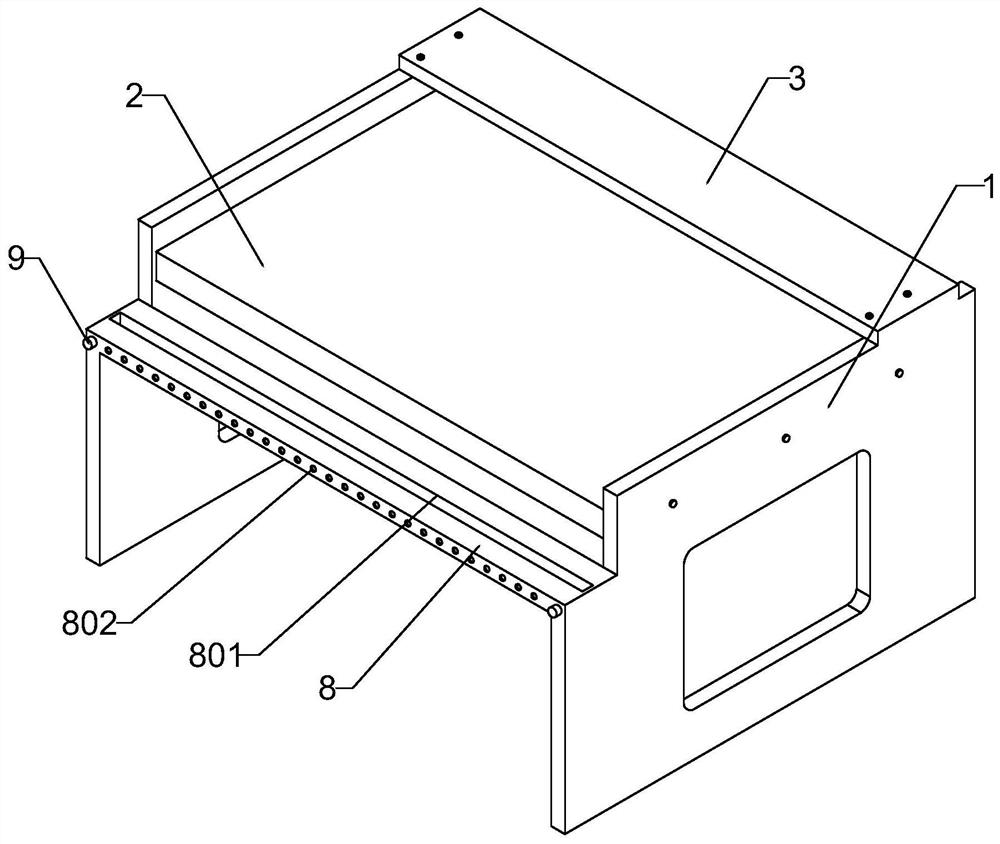

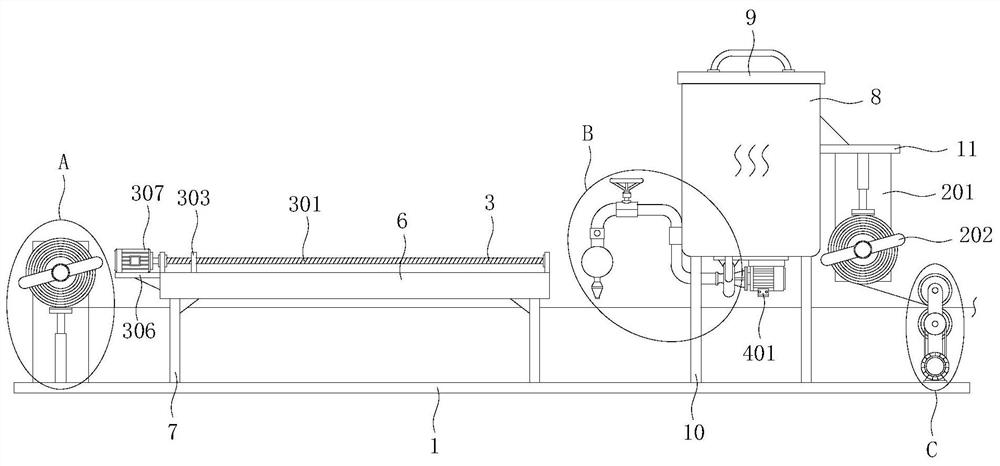

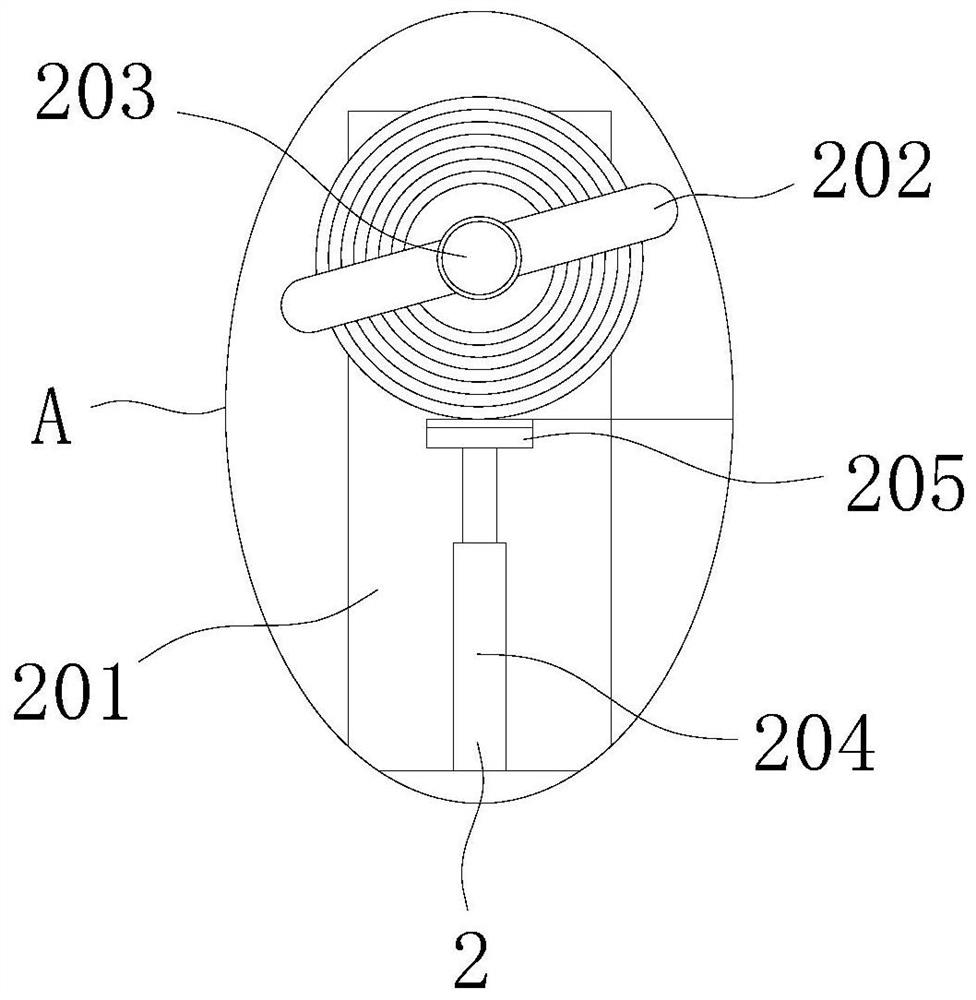

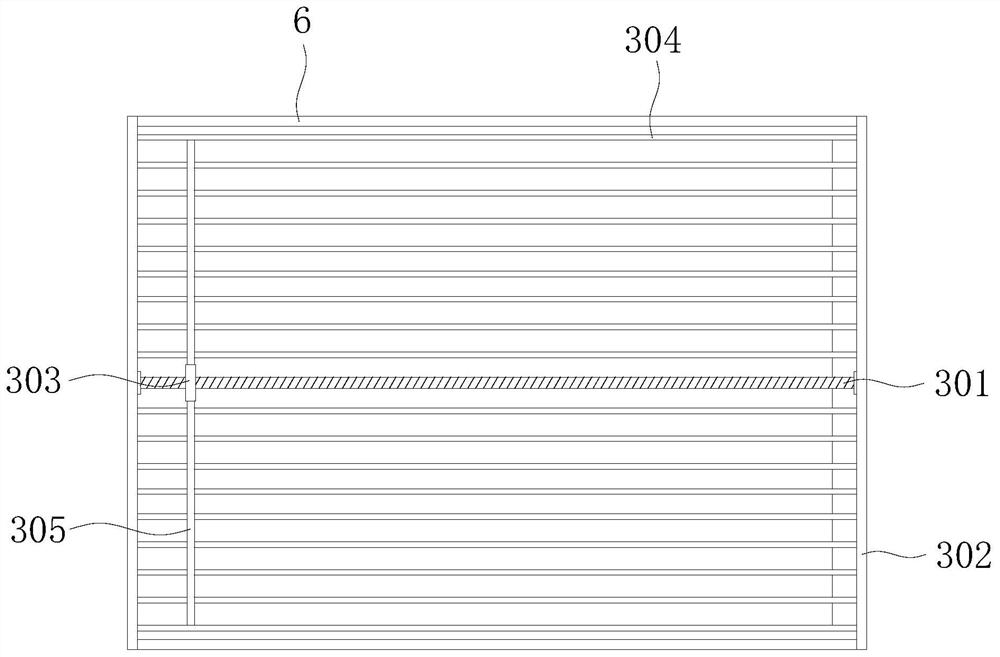

Full-polyester digital printing processing equipment

InactiveCN113715528AAvoid enteringImprove heat transfer efficiencyTypewritersOther printing apparatusPolyesterTextile printer

The invention relates to full-polyester digital printing processing equipment which comprises a supporting frame, a printing table top and a mechanism bottom plate, the printing table top is fixedly installed on the inner side wall of the supporting frame, the mechanism bottom plate is welded to the rear end of the top face of the supporting frame, a transverse moving sliding rail is fixedly installed on the top face of the mechanism bottom plate, and a jet printing mechanism is movably embedded in the front end of the transverse moving sliding rail. A heat absorption head can pump heat in the jet printing mechanism out of the jet printing mechanism through operation of a micro water pump and dissipate the heat, the heat exchange efficiency is high, the heat dissipation effect is excellent, meanwhile, the good sealing performance is achieved, two movable shafts and fixed shafts are matched to clamp the two side edges of a polyester fabric, the fabric is tensioned, the quality of finished products is prevented from being influenced by wrinkles generated in the fabric jet printing process, a printing and dyeing part in the center of the fabric does not make contact with the axial surface, and compared with a traditional roller shaft form tensioning mode, the defect that the surface of the roller shaft is stained with dye to affect the quality of the finished products is effectively overcome.

Owner:绍兴柯桥利冠数码印花科技有限公司

Production method of adhesive-free coated abrasive

The invention discloses a production method of a coated abrasive tool without a complex adhesive. The production method comprises the steps: coating a primer layer, wherein the thickness of the primer is 80+ / -5% of the total thickness of a traditional primer and a complex adhesive layer, and the viscosity of the primer is 1-3 times greater than that of a traditional primer; an abrasive material is glued on the primer layer according to a conventional process, and then is suspended and dried. In order to improve the bonding force between the primer layer and the substrate layer, a pre-coating layer is coated on the substrate layer before the primer layer is coated. The production method provided by the invention has the advantages that the complex adhesive layer which is coated on the surfaces of particles of the abrasive materials, the grinding efficiency of the coated abrasive tool can be greatly improved, the working temperature can be reduced in the process of grinding, and the pollution on a grinding operating surface caused by the complex adhesive layer can be prevented; furthermore, the thickened primer layer can ensure that the abrasive materials can be firmly glued on the primer layer so as to fight against the impact force in the process of grinding; in addition, the viscosity of the primer can be improved to prevent a gumming phenomenon in the production process and affect the end product quality of the coated abrasive tool.

Owner:HENAN WANGPAI ABRASIVE CLOTH MFG

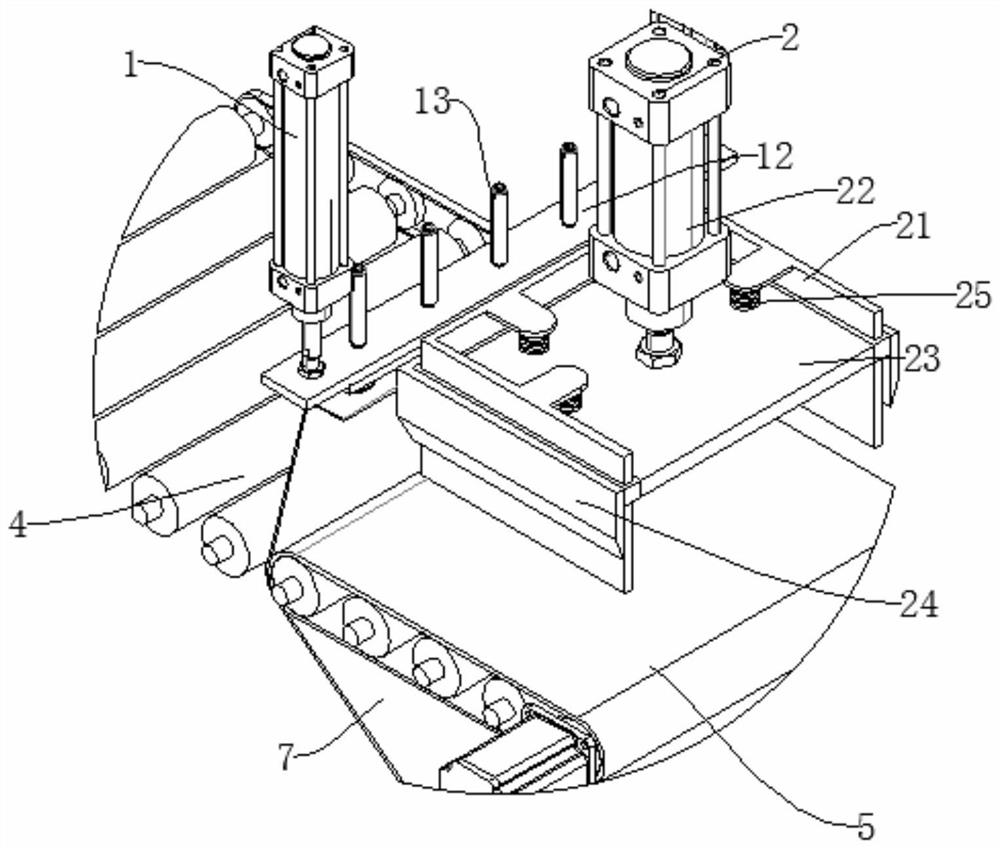

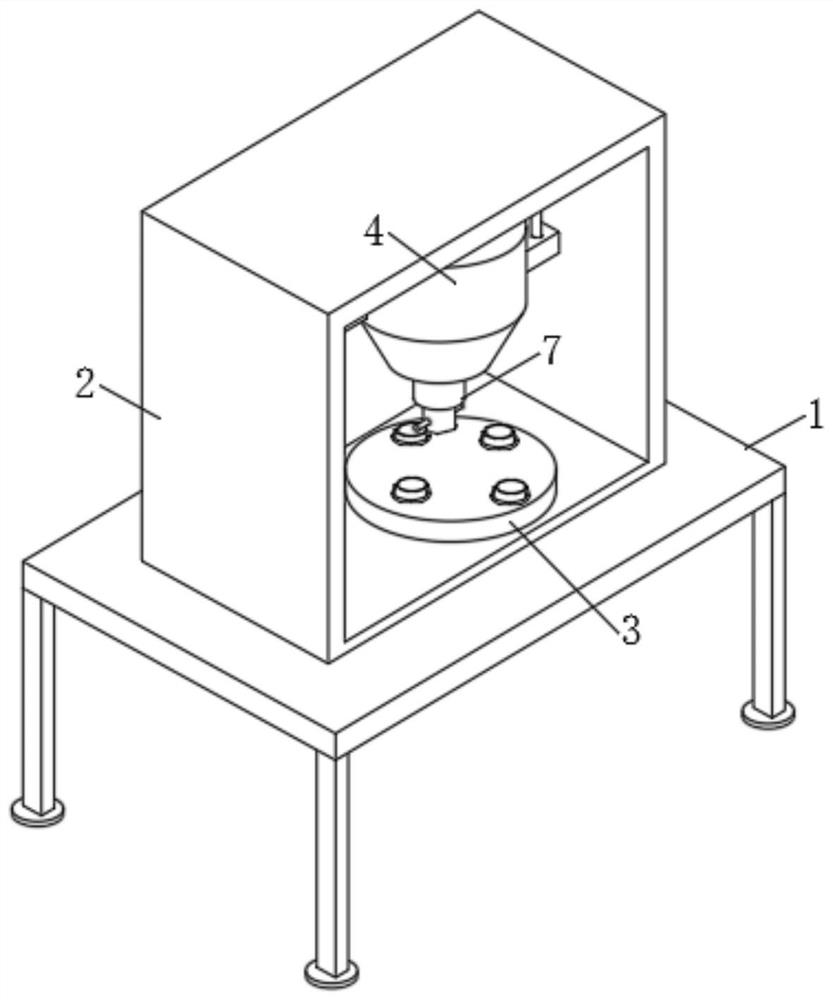

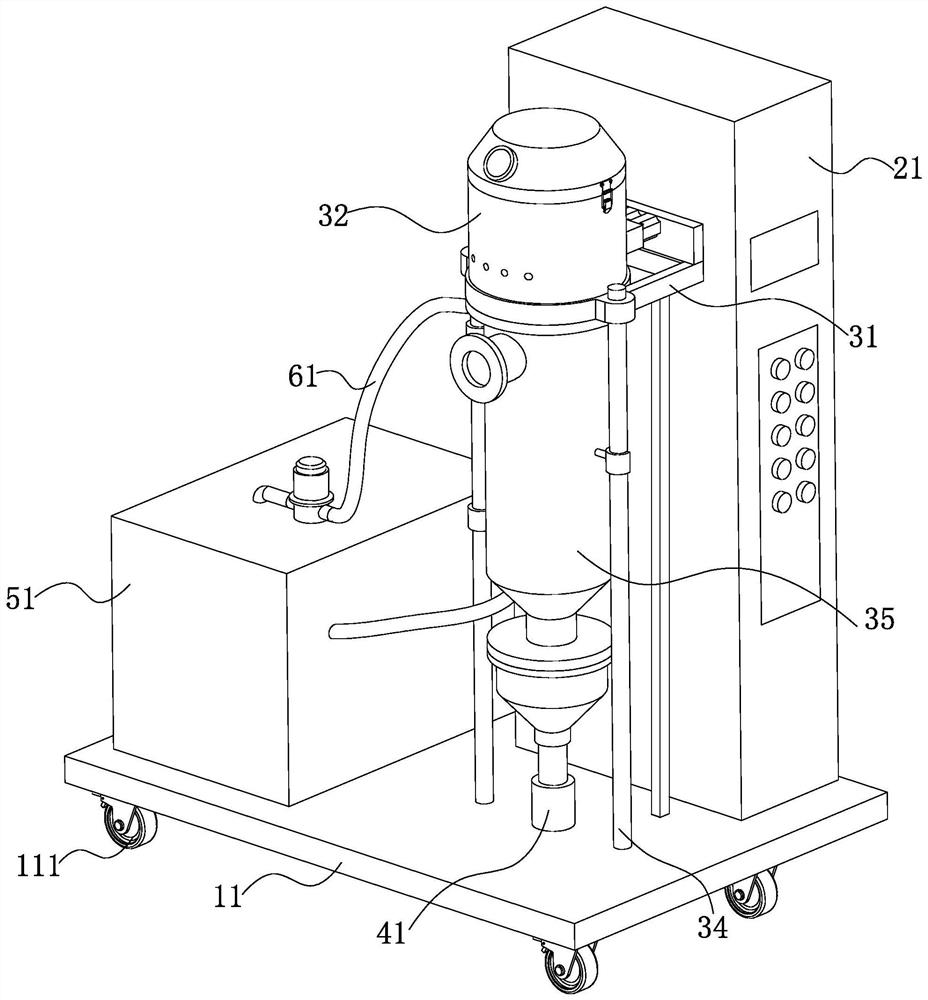

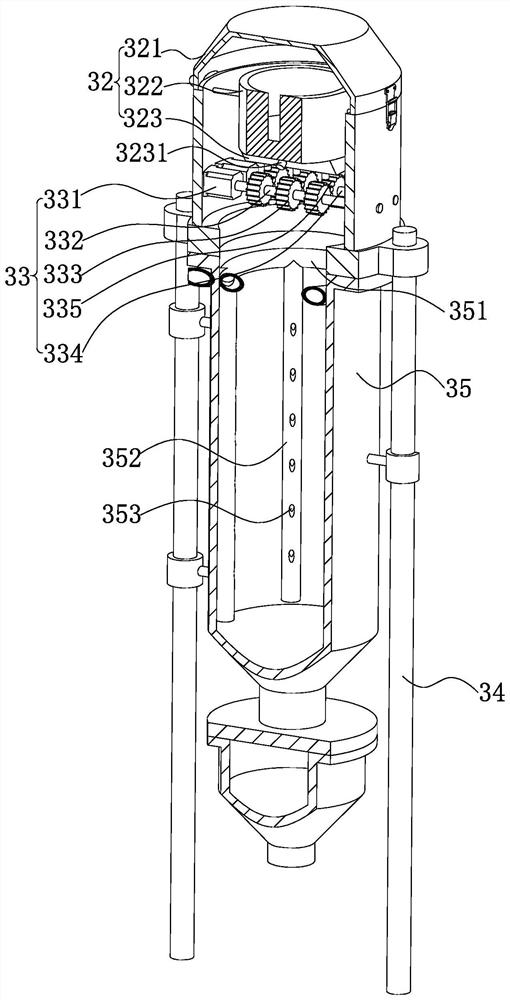

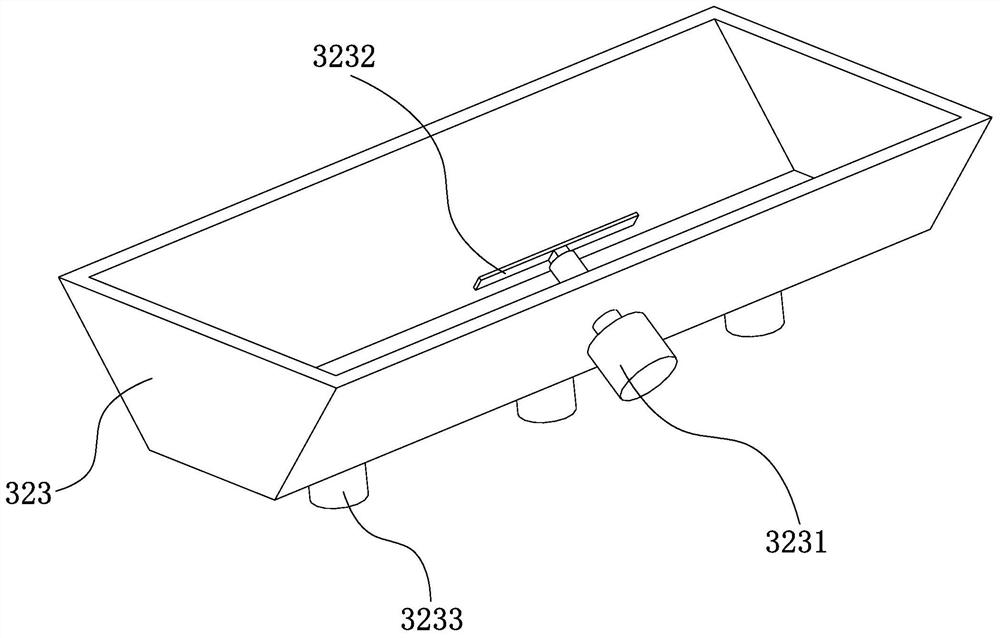

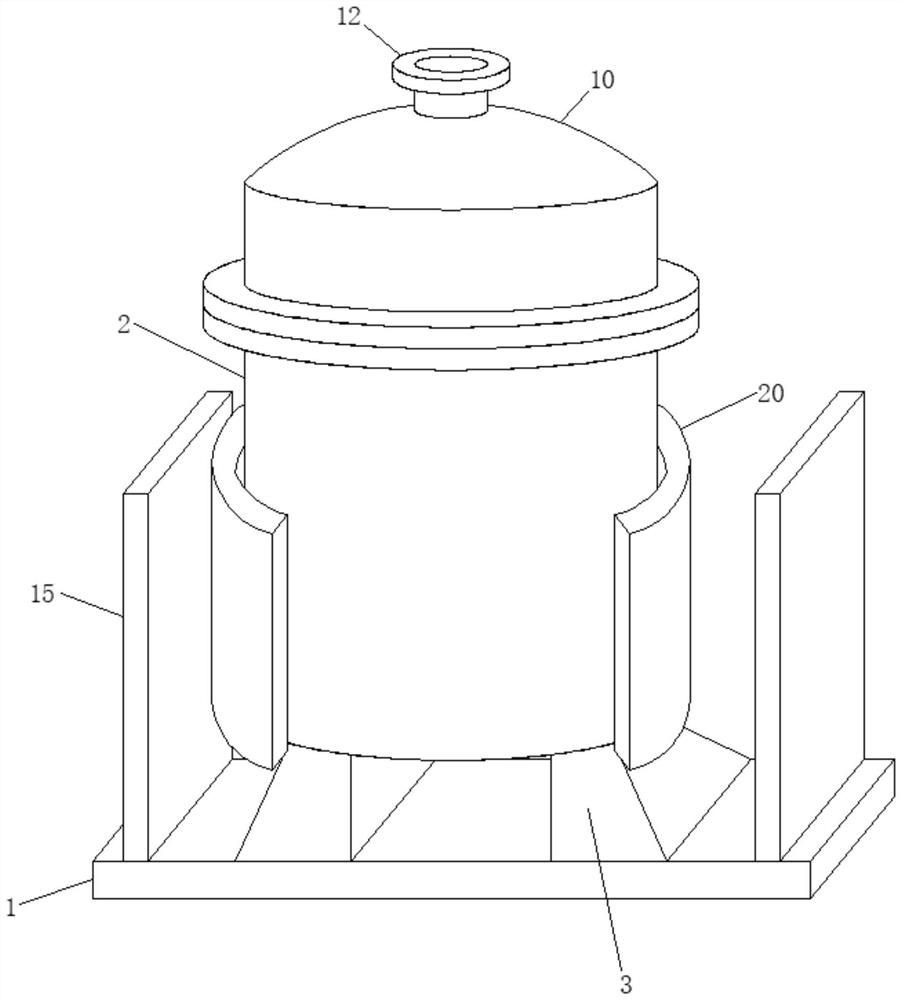

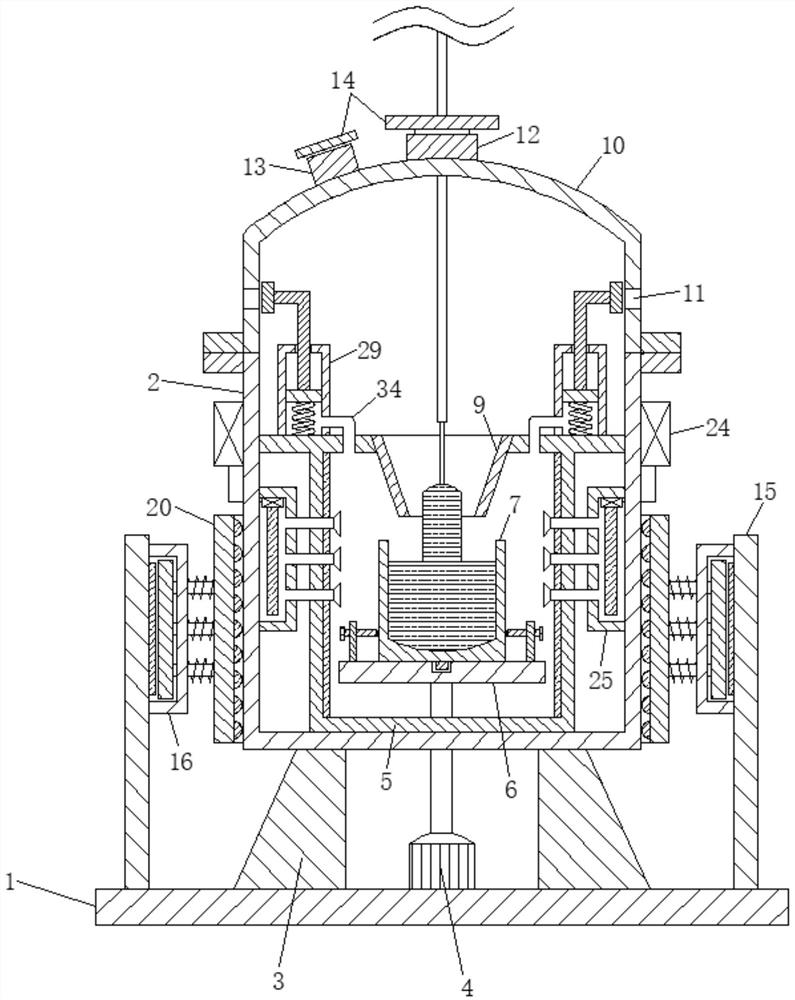

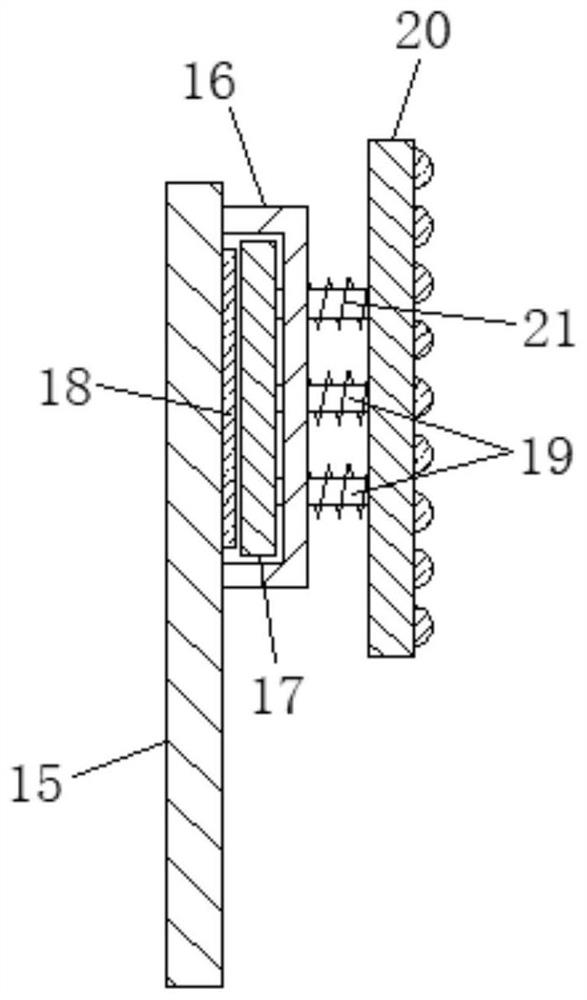

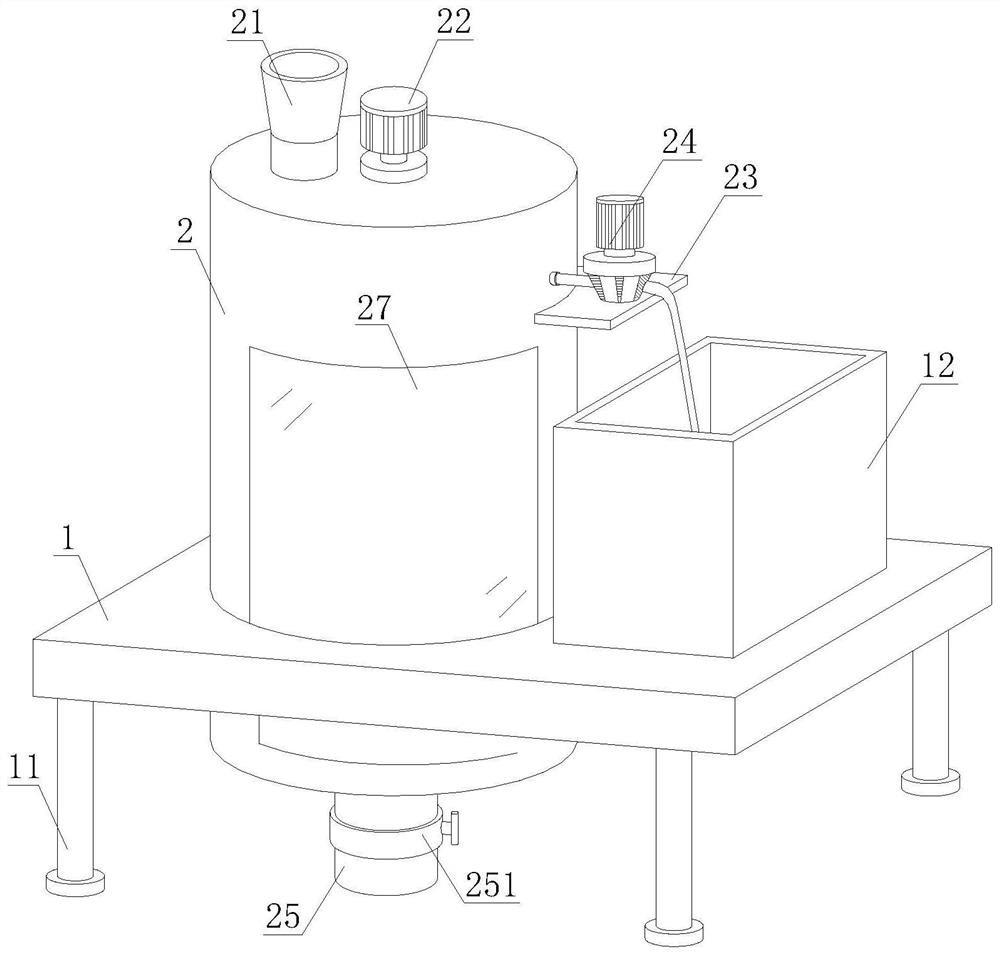

Precious metal vacuum bead scattering machine

InactiveCN113319287AUniform particle sizeAffect the quality of the finished productHydraulic cylinderEngineering

The invention relates to the technical field of jewelry processing equipment, in particular to a precious metal vacuum bead scattering machine. The precious metal vacuum bead scattering machine comprises a base, an electric control cabinet arranged on the base, a mounting frame vertically arranged on the upper surface of the base, a vacuum melting furnace fixedly connected with the top of the mounting frame, a quantitative granulation device arranged in the vacuum melting furnace, a stand column arranged on the mounting frame and located below the vacuum melting furnace, a material receiving barrel with the side edge arranged on the stand column in a sleeved mode, a hydraulic cylinder arranged on the base and used for jacking the material receiving barrel upwards, and a water cooling device arranged on the base and used for supplying circulating cooling water to the material receiving barrel; the material receiving barrel moves upwards under jacking of the hydraulic cylinder and abuts against the lower end face of the vacuum melting furnace; and a liquid outlet of the water cooling device is communicated with a liquid inlet of the material receiving barrel through a water pipe. The precious metal vacuum bead scattering machine provided by the invention has the advantages that produced precious metal beads are uniform in particle size and good in finished product quality.

Owner:杭州升元珠宝有限公司

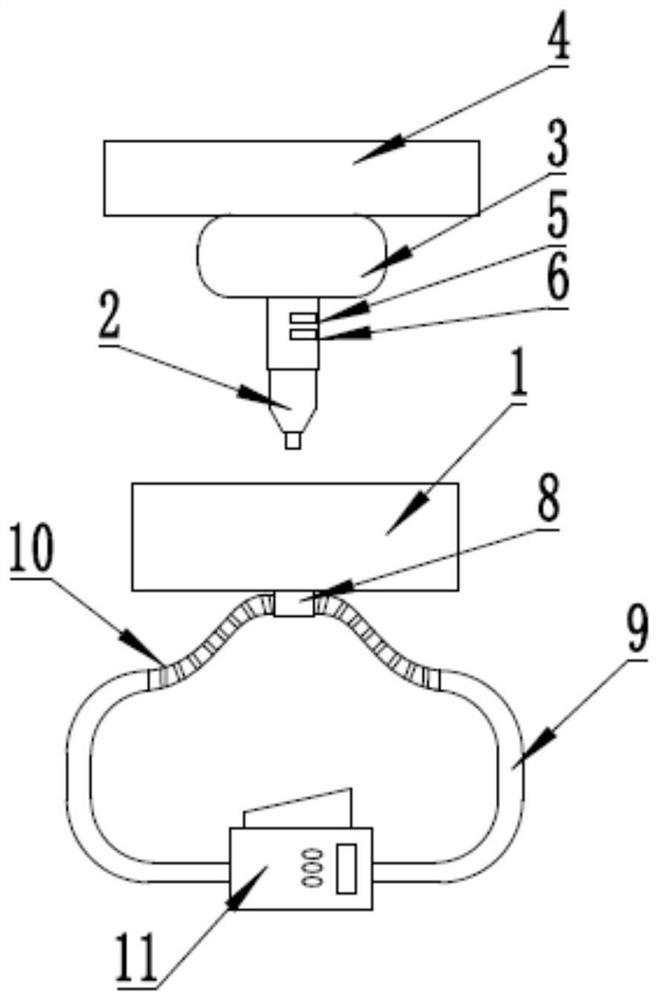

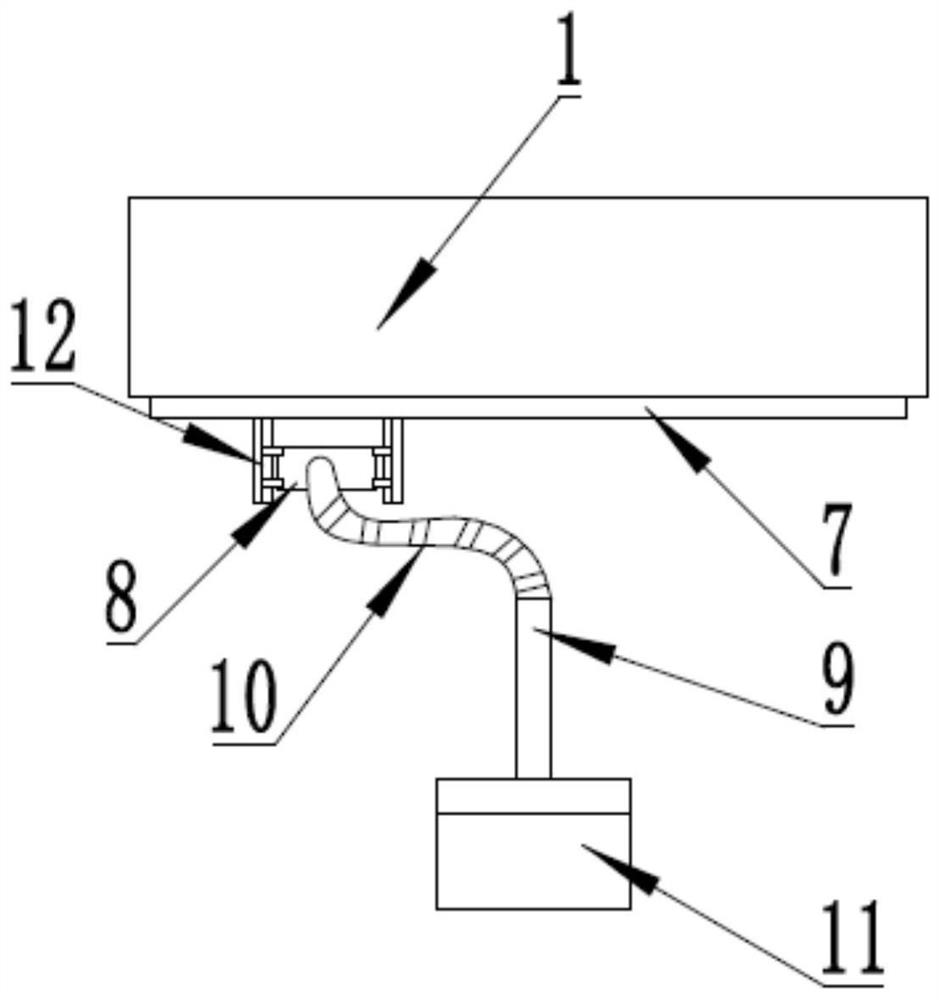

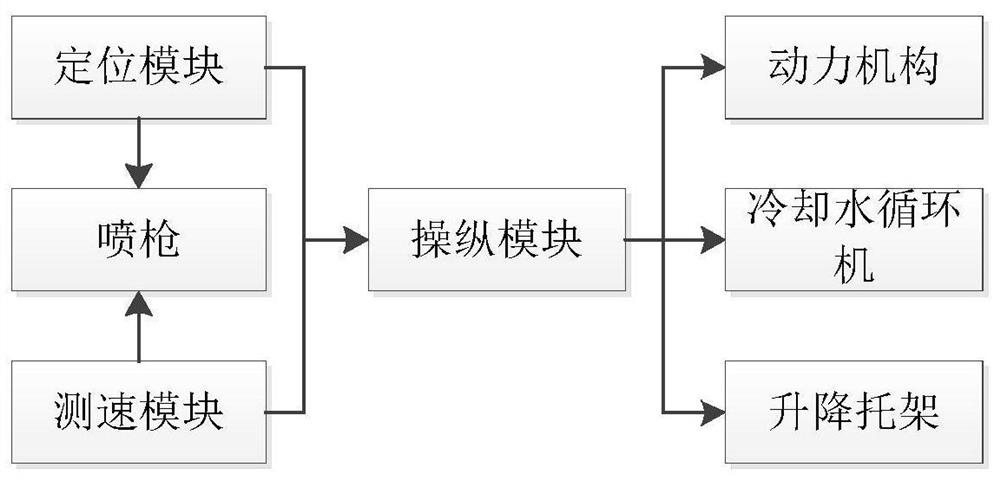

A ceramic coating blade coating spraying device

ActiveCN110465433BAffect the quality of the finished productImprove working powerSpraying apparatusCeramic coatingThermal deformation

The invention discloses a coating spraying device of a ceramic coating scraper. By setting a spraying platform and a plasma spraying mechanism, the coating scraper placed on the spraying platform is sprayed; the moving speed of a spray gun is measured by setting a speed measuring module; the position of the spray gun is measured by setting a positioning module, and a cooling mechanism is set to bemovable; and when a control module obtains the information measured by the speed measuring module and the positioning module, the position and the moving speed of the spray gun are obtained, so thatthe cooling mechanism is moved to the response position under the spray gun to cool the local area of the coating scraper, and the working power of the cooling mechanism is adjusted according to the moving speed of the spray gun. When the moving speed of the spray gun is slower, the working power of the cooling mechanism is improved to balance the temperature rise brought by the contact time of aplasma flame flow, so that the situation that the temperature rise is too high in the local area of the coating scraper so as to result in excessive thermal deformation or thermal stress to affect thefinal product quality of the ceramic coating scraper is avoided.

Owner:MAANSHAN WISDOM NEW NANOMETER MATERIALS

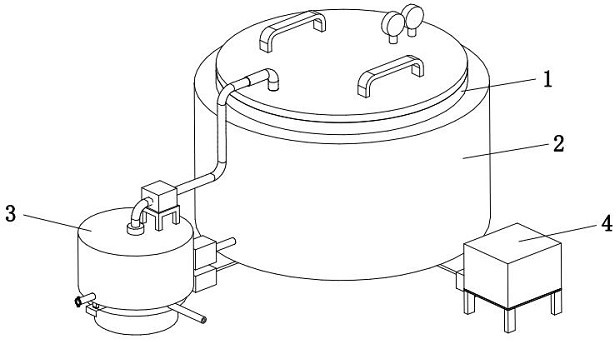

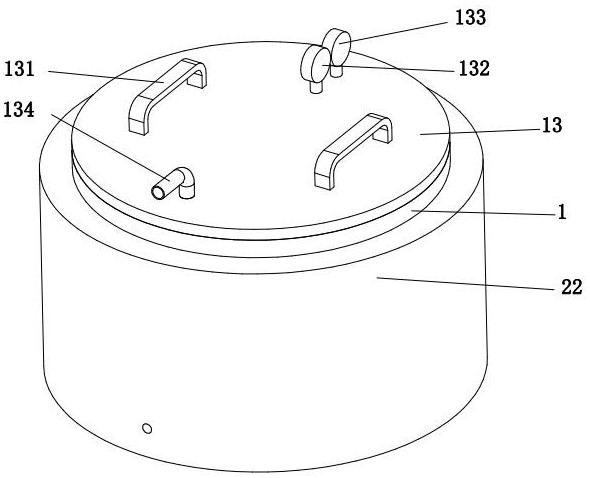

Monocrystalline silicon furnace for processing semiconductor raw material wafer

PendingCN114775038AEnsure air pressure balancePlay the role of automatic pressure reliefPolycrystalline material growthBy pulling from meltElectric machineHeat conservation

The invention relates to a monocrystalline silicon furnace for semiconductor raw material wafer processing, which comprises a base, a furnace body is arranged above the base, damping mechanisms are arranged on both sides of the furnace body, a motor is arranged below the furnace body, the inner wall of the furnace body is fixedly connected with a heat preservation cylinder, and the top end of an output shaft of the motor penetrates through the bottom of the furnace body and is fixedly connected with a turntable; and heating mechanisms are arranged on the two sides of the heat preservation cylinder, pressure relief mechanisms are arranged on the two sides of the top of the heat preservation cylinder, and a furnace cover is installed on the top of the furnace body. According to the single crystal silicon furnace, automatic pressure relief can be achieved to guarantee air pressure balance in the heat preservation barrel, potential safety hazards caused by too large air pressure in the heat preservation barrel are avoided, the quartz crucible can be limited so that the stability of the quartz crucible can be improved, in addition, the damping effect on the furnace body can be achieved so that the working noise of the single crystal silicon furnace can be reduced, and the service life of the single crystal silicon furnace can be prolonged. And meanwhile, parts in the furnace body are effectively prevented from being damaged due to collision caused by vibration.

Owner:赵董生

A tire curing device

Owner:廊坊易砚领创科技有限公司

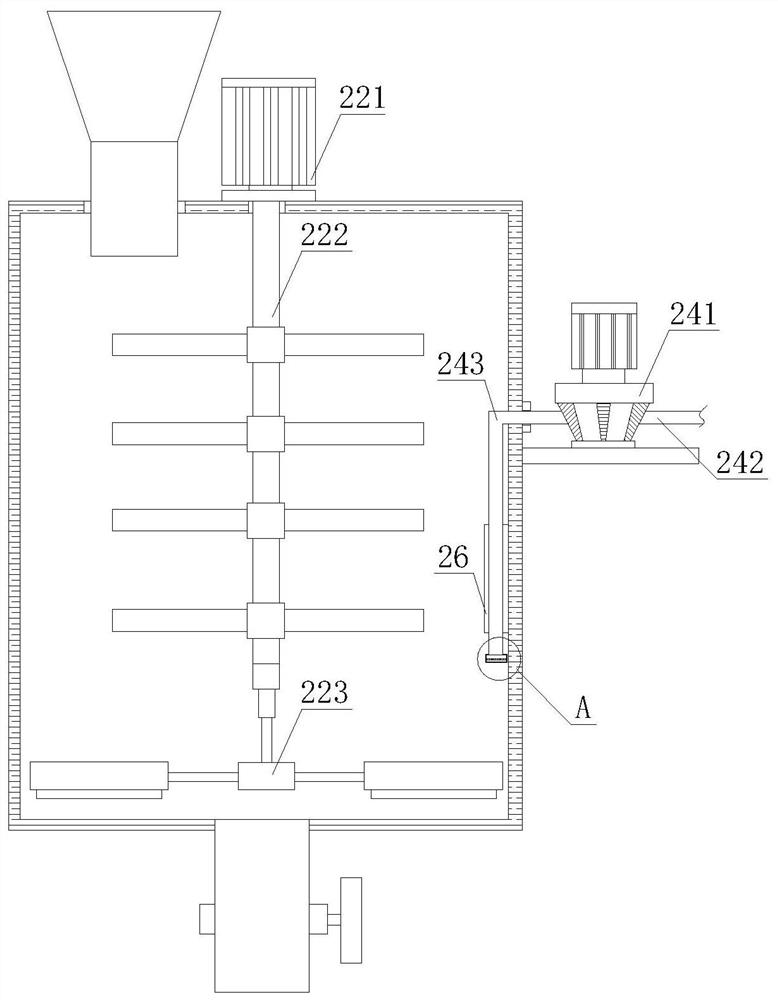

Mortar anti-segregation device

InactiveCN113580372AWell mixedAffect the quality of the finished productCement mixing apparatusStationary filtering element filtersElectric machineMortar

The invention discloses a mortar anti-segregation device. The mortar anti-segregation device comprises a base and a tank body, wherein the tank body is arranged at the upper end of the base; a motor is arranged at the upper end of the tank body; the output end of the motor is connected with a stirring rod; the motor drives the stirring rod to rotate so that mortar can be conveniently mixed; an electric push rod is arranged at the lower end of the stirring rod; a lantern ring is arranged at the lower end of the electric push rod; a connecting rod penetrates through the lantern ring; and lower stirring rods are arranged at the two ends of the connecting rod. The electric push rod pushes the lantern ring to move downwards through a switch, and the lower stirring rods can be driven to stir the bottom of the tank body while the stirring rod rotate, so that the influence on the quality of mortar finished products caused by motor segregation since sand sinks to the bottom is avoided; and a protection pad is arranged at the lower ends of the lower stirring rods, and when the electric push rod pushes the lantern ring and the connecting rod to move downwards, an operator can observe the position of the lower stirring rods through a visual window, so that the situation that the bottoms of the lower stirring rods directly collide with the bottom of the tank body, and consequently the interior of the tank body is damaged is avoided.

Owner:怀化市昌顺建筑工程有限公司

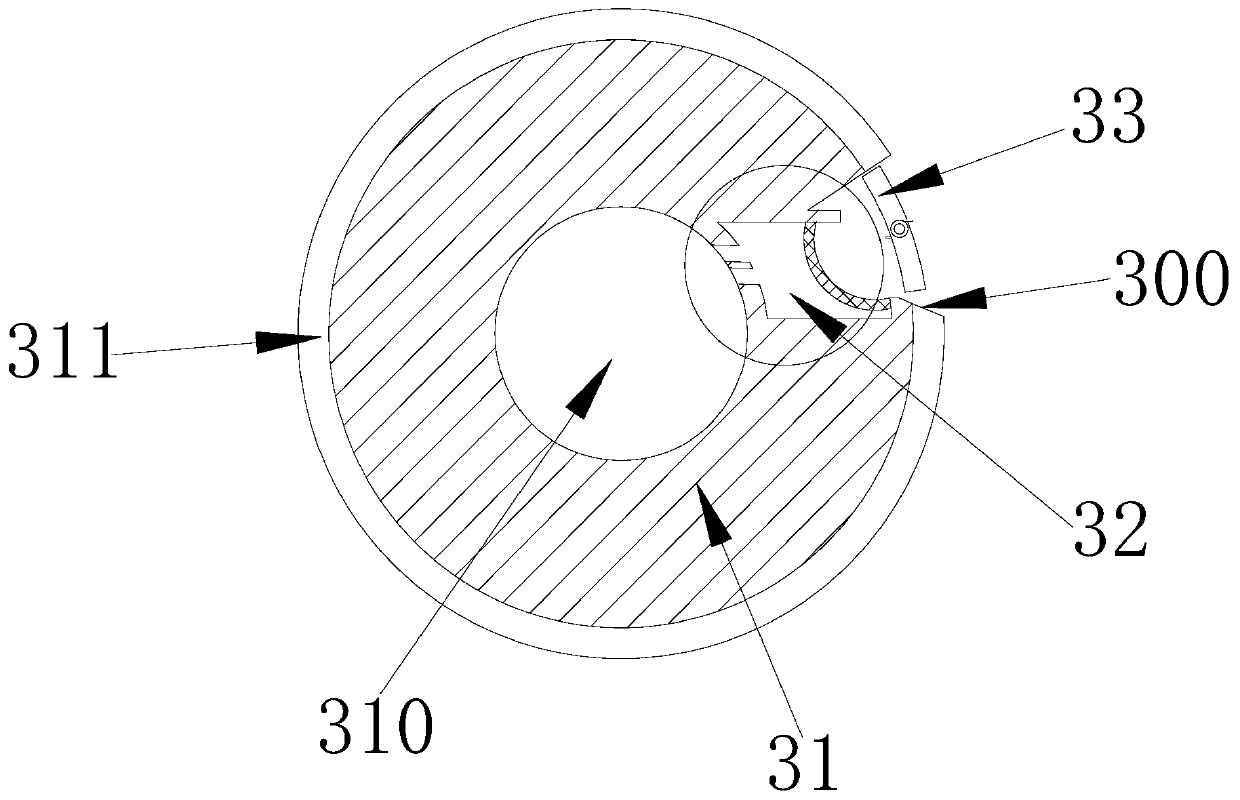

Spraying equipment for spherical parts with auxiliary positioning structure for general machinery

ActiveCN112871512BEasy to limitAffect the quality of the finished productSpraying apparatusElectric machineEngineering

The invention relates to the technical field of mechanical processing, in particular to a spherical part spraying equipment with an auxiliary positioning structure for general machinery, including a base, a hydraulic telescopic rod, a first motor, a second motor, a third motor, a fourth motor, a pneumatic telescopic Rod and the fifth motor, a hydraulic telescopic rod is fixedly installed on the top side of the base, and a first connecting rod is fixedly connected to the end of the hydraulic telescopic rod away from the base. The present invention is provided with a clamping rod, and by starting the fourth motor, the fourth motor drives the oblique rotation rod to rotate, so that the oblique rotation rod drives the rocker to take the first connecting shaft as the axis, so that the bottom end and the top end of the rocker are circular The movement makes it easy for the rocker to drive the spherical parts to shake inside the limit barrel, and it is convenient to spray the surface of the clamping rod comprehensively, avoiding uneven spraying on the surface of the spherical parts and affecting the quality of the spraying, and at the same time improving the spraying efficiency of the spherical parts.

Owner:HUANGHE JIAOTONG UNIV

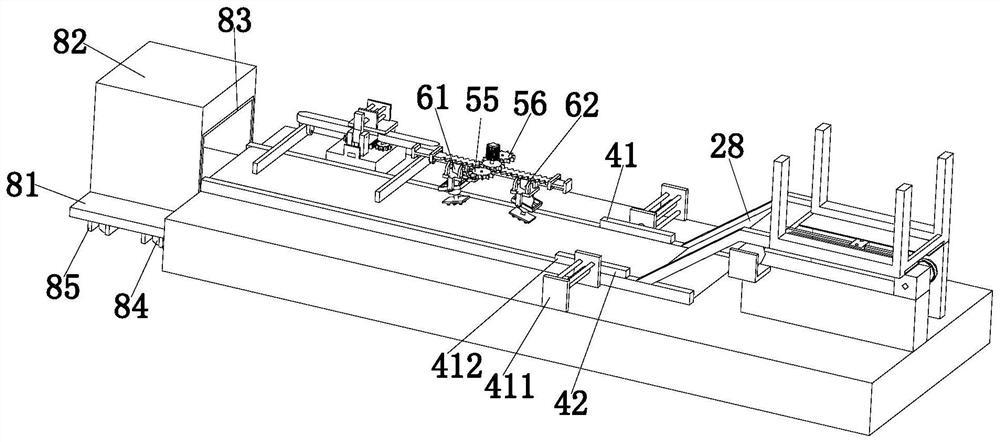

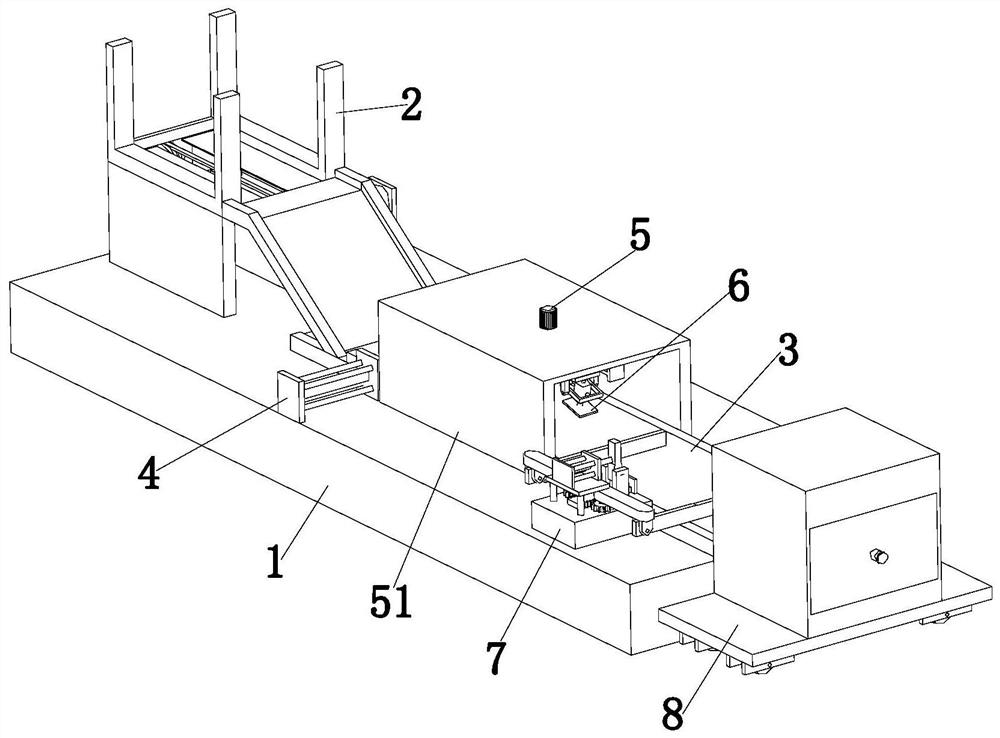

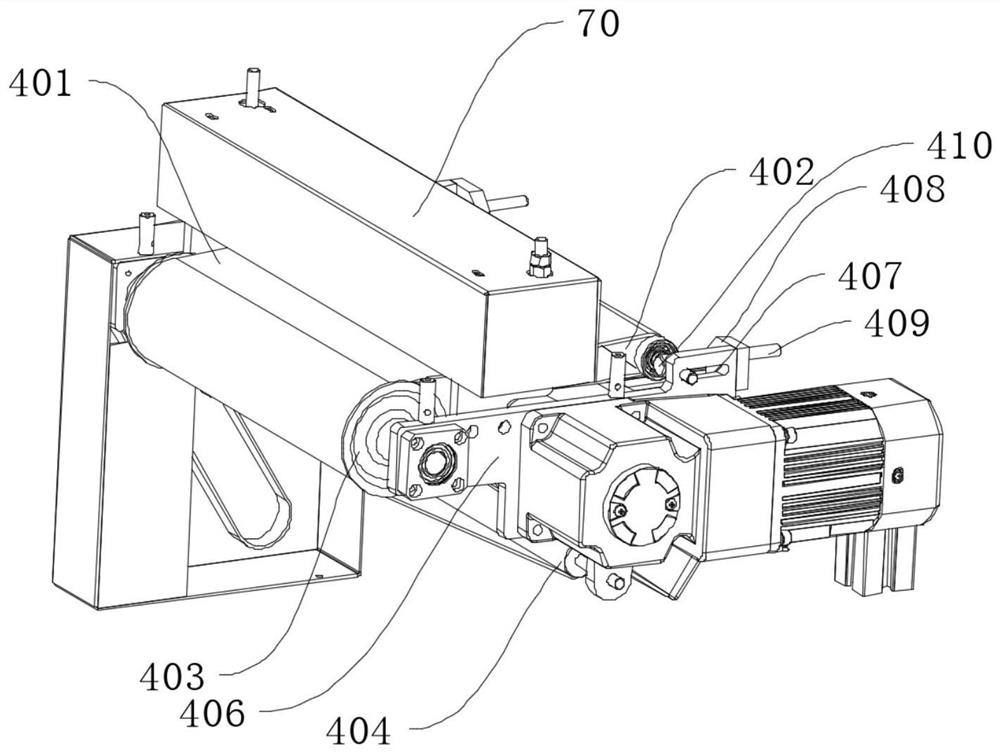

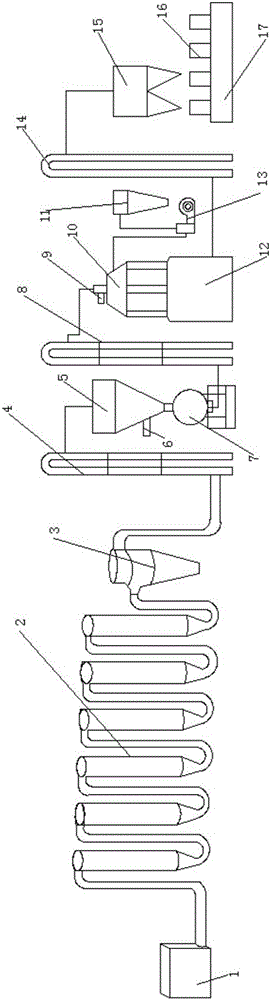

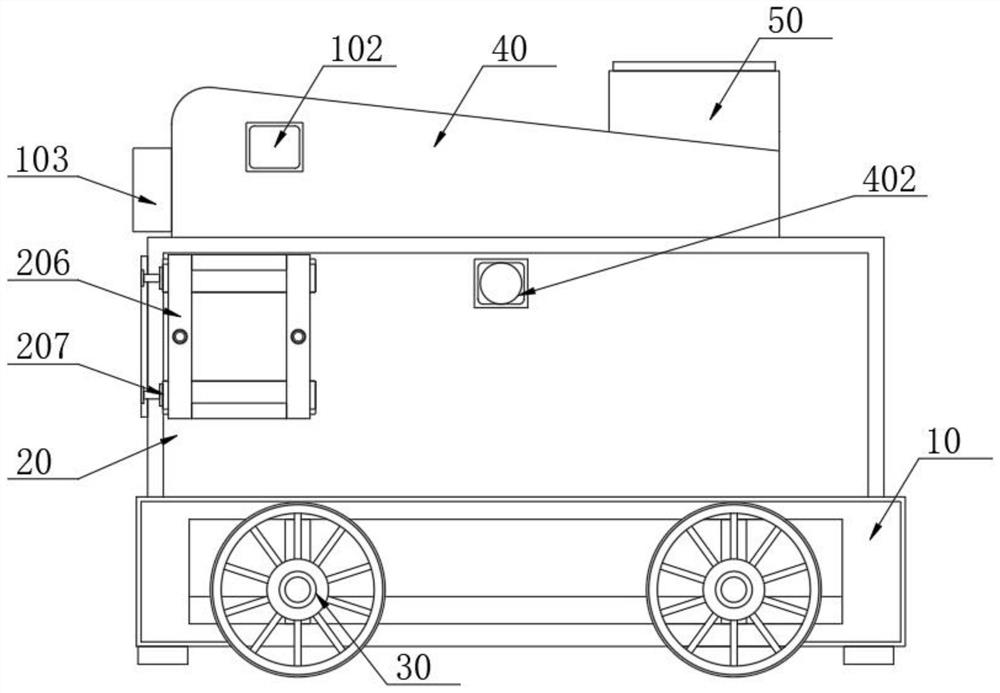

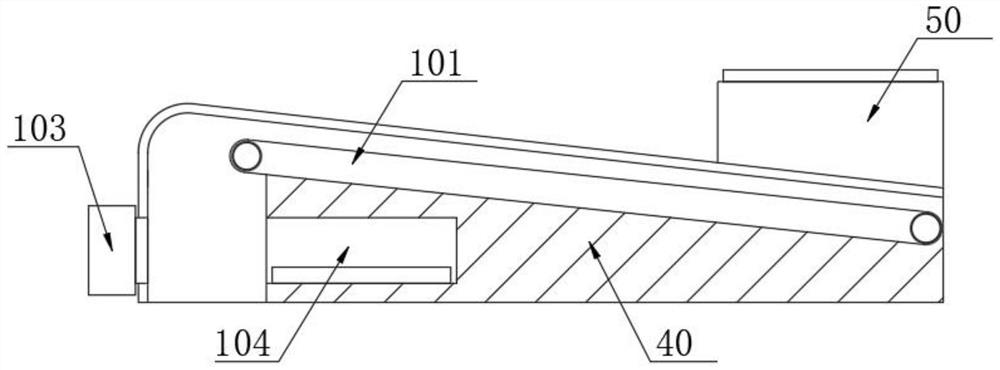

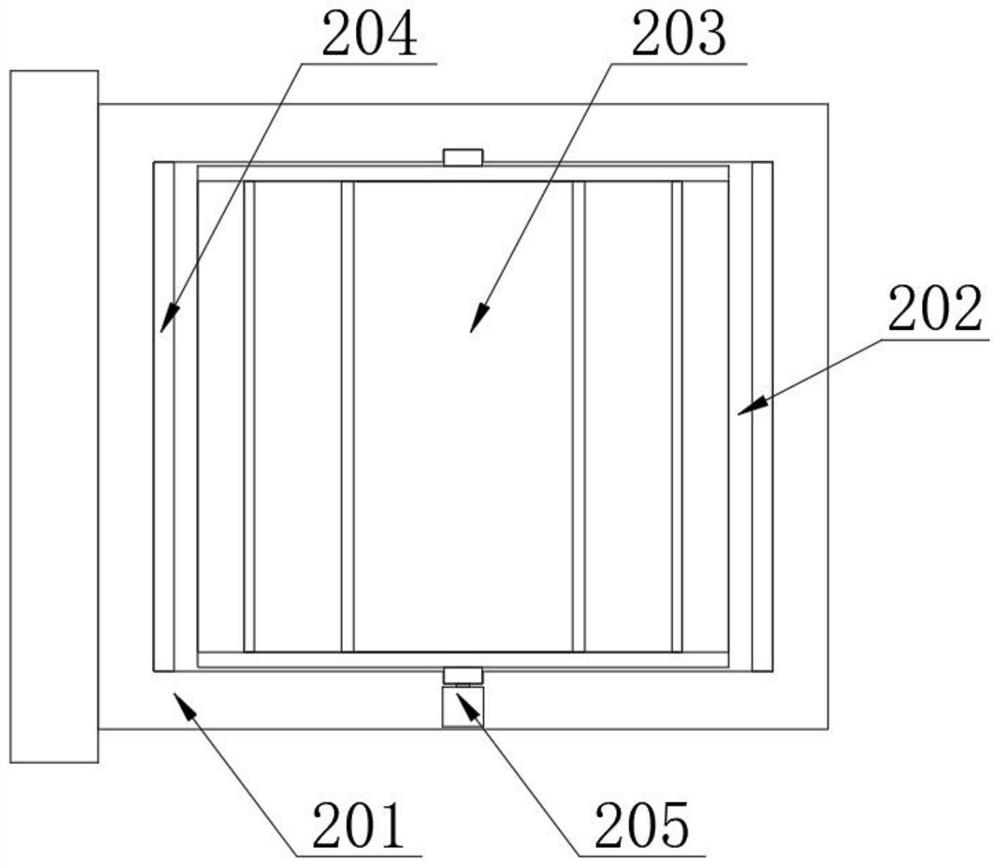

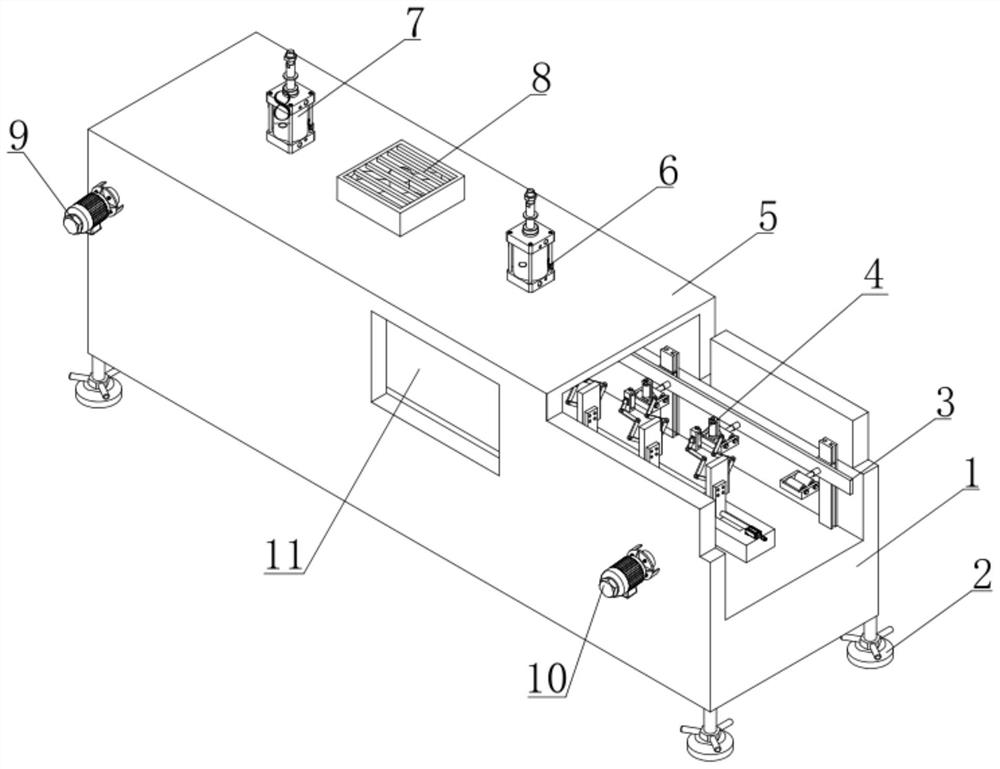

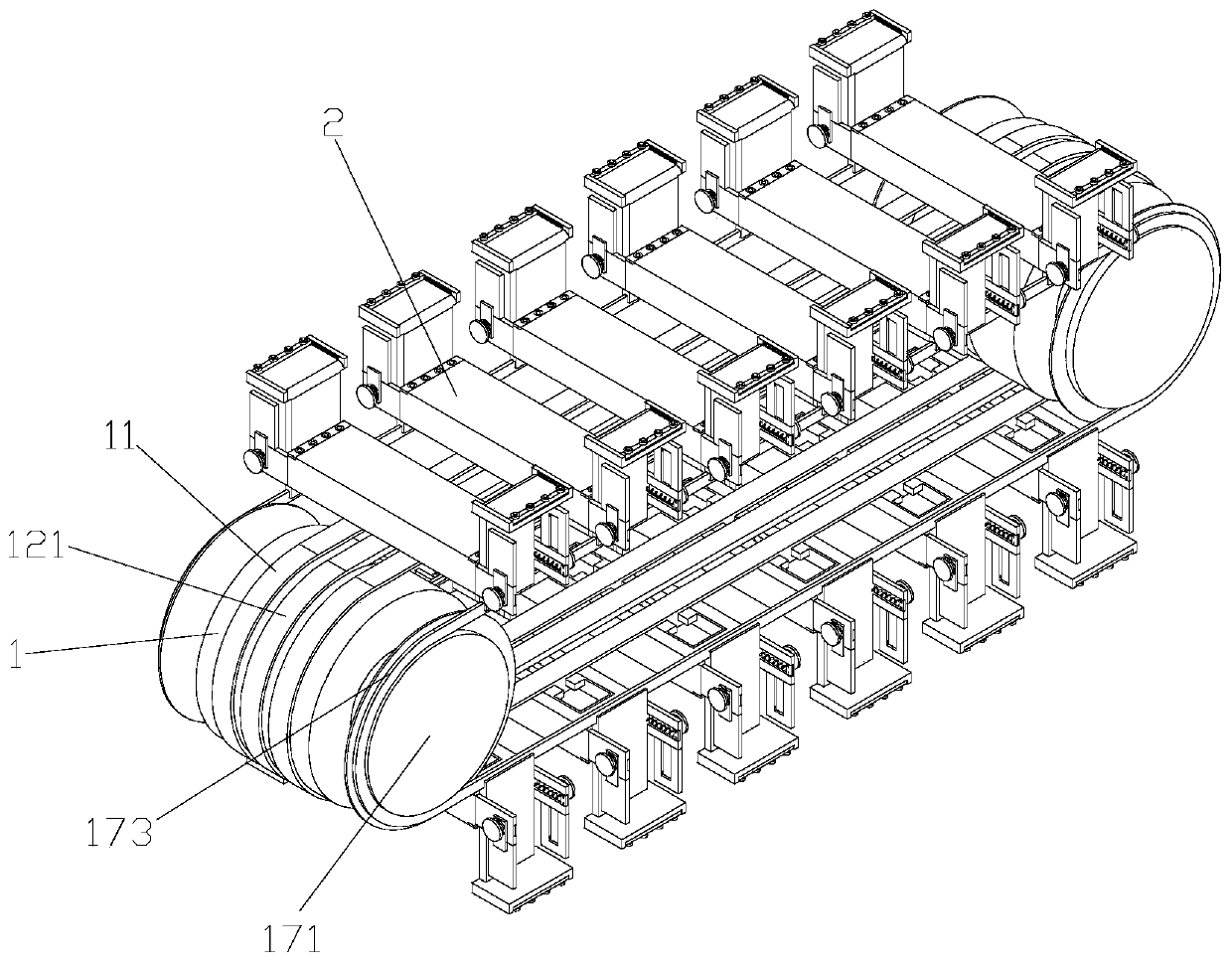

Processing system for performing biomass fuel production

InactiveCN106433842AIncrease productivityAvoid pollutionBiofuelsSolid fuelsProcess engineeringAir cooling system

The invention discloses a processing system for performing biomass fuel production. The processing system is provided with a drying system, a pelletizing system, an air cooling system and a filling system, wherein the drying system is connected with the pelletizing system; the pelletizing system is connected with the air cooling system; the air cooling system is connected with the filling system; a raw material lifting machine and a pelletizing host machine are arranged in the pelletizing system; the pelletizing host machine is arranged on a host machine rack; a storage bin is arranged on the pelletizing host machine; the drying system is connected with a feed port of the raw material lifting machine; a discharge port of the raw material lifting machine is connected with a feed port of the storage bin; a discharge port of the storage bin is connected with a feed port of the pelletizing host machine; and a discharge port of the pelletizing host machine is connected with a feed port of the air cooling system. The processing system is used for performing flow line production operation of a biomass fuel, and can avoid environmental pollution as much as possible while effectively improving the production efficiency of the biomass fuel, and the whole structure has the characteristics of scientific design, reasonability in use, energy conservation and environmental protection.

Owner:CHONGQING HUAWANLUN BIOLOGICAL NEW ENERGY TECH CO LTD

Efficient-cleaning combined type grain cleaning machine

ActiveCN113798186AEasy to cleanAffect the quality of the finished productSievingGas current separationMetallurgyMetal impurities

The invention relates to the technical field of grain processing machinery, in particular to an efficient-cleaning combined type grain cleaning machine. The efficient-cleaning combined type grain cleaning machine comprises a feeding mechanism, a primary cleaning mechanism, a screening mechanism, a guiding mechanism and a secondary cleaning mechanism. According to the grain cleaning machine, the primary cleaning mechanism cleans metal impurities in grains, metal impurities are effectively prevented from being mixed in grains to affect the quality of finished products of the grains, cleaning operation on different grains is achieved by adjusting the hole diameter of screening holes in the screening mechanism, the application range of the grain cleaning machine is further widened, flexible impurity screening adjustment can be conducted according to the impurity condition of the grains, and then the cleaning efficiency of the grains is improved; and the grains are dried through the secondary cleaning mechanism, dust attached to the surfaces of the grains is separated from the grains, then the dust generated in the grain cleaning process is collected in a centralized mode, the situation that the dust escapes out of a cleaning box and pollutes the environment is avoided, and meanwhile the body health of workers can be effectively guaranteed.

Owner:界首市粮食机械有限责任公司

Aluminum profile straightening machine with gradient detection mechanism and operation method

InactiveCN114178350AImprove yieldEasy to operateMetal working apparatusStructural engineeringMachine

The invention discloses an aluminum profile straightening machine with an inclination detection mechanism and an operation method.The aluminum profile straightening machine comprises a supporting base, anti-skid pads are fixedly installed at the four corners of the bottom of the supporting base, a cover plate is arranged at the top of the supporting base, a first straightening mechanism is arranged on the left side of the supporting base, and the inclination detection mechanism is arranged on the right side of the first straightening mechanism; a fixing mechanism is arranged on the right side of the gradient detection mechanism, and second straightening mechanisms are installed on the two sides of the fixing mechanism and installed on the inner side wall of the supporting base. According to the aluminum profile straightening machine with the inclination detection mechanism and the operation method of the aluminum profile straightening machine, operation is easy, the straightening quality of the initial end of an aluminum profile is improved, the yield of the aluminum profile is improved, the detection process is simple, visual and high in accuracy, the aluminum profile is fixed through the clamping rollers, it is avoided that in the straightening process, the aluminum profile deviates, and the quality of the aluminum profile is improved. And the finished product quality of the aluminum profile is affected, the straightening quality of the aluminum profile is guaranteed, the working efficiency is improved, and high practicability is achieved.

Owner:黄娇

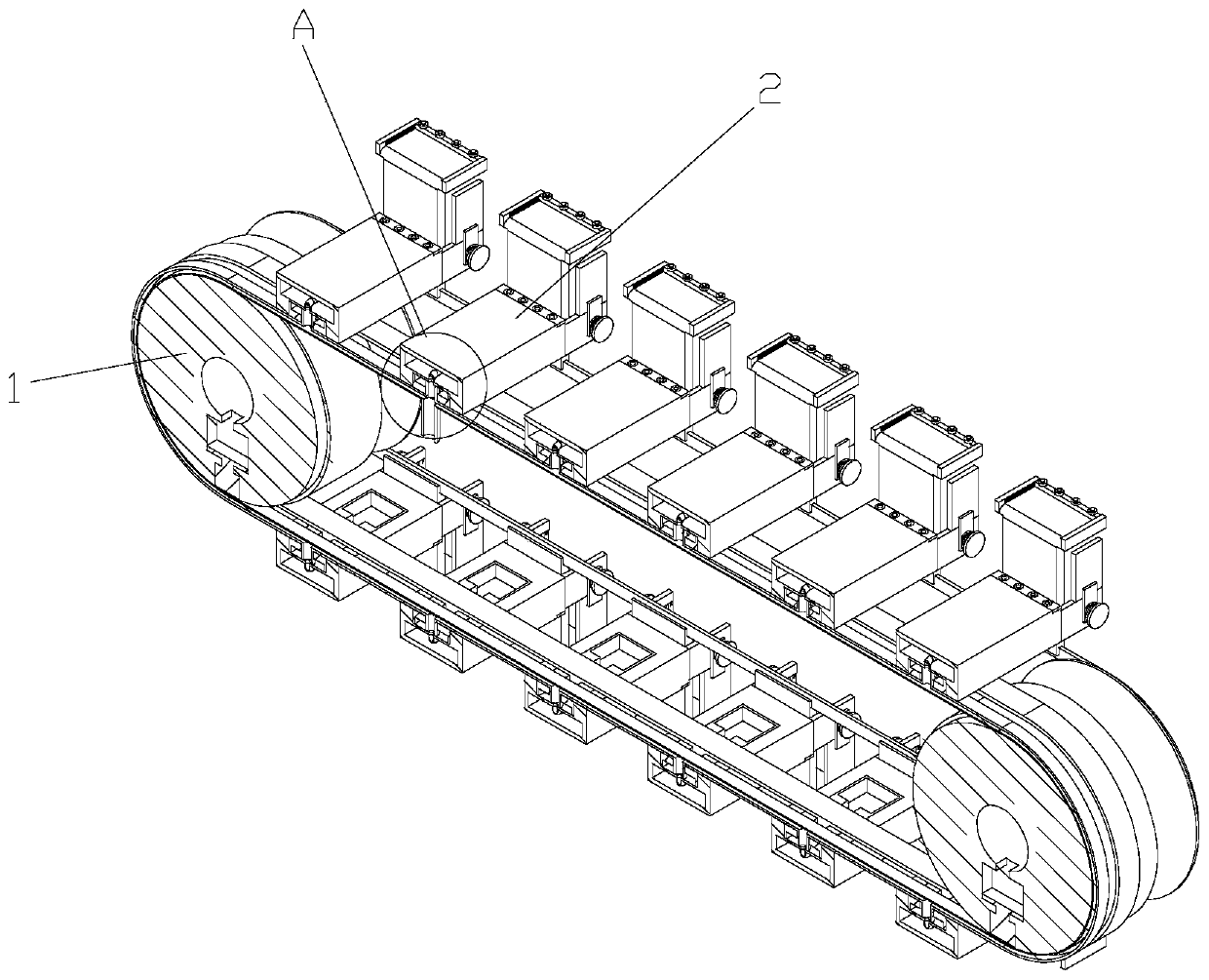

Operation stabilized continuous sponge foaming machine

The invention discloses an operation stabilized continuous sponge foaming machine. The operation stabilized continuous sponge foaming machine comprises rotary rollers, first transmission chains arranged on the rotary rollers and multiple sets of supporting plates arranged on the first transmission chains. The supporting plates are uniformly laid on the first transmission chains. The sidewalls of the supporting plates are provided with baffles. The supporting plates and the baffle are paved with sulfate paper. The bottom of each supporting plate is provided with a second mounting groove. A third connecting block is mounted in each second mounting groove. Each third connecting block is provided with a limiting groove. The first transmission chains are provided with third limiting plates matched with the limiting grooves. When the supporting plates need maintaining, the limiting grooves and the third limiting plates are combined to push the supporting plates to enable the third limiting plates to move along the inner walls of the limiting grooves, and the third limiting plates are taken out from one sides of the limiting grooves. Through the operation stabilized continuous sponge foaming machine, the supporting plates can be taken down conveniently from the transmission chains to facilitate maintaining, and the maintaining difficulty of the supporting plates is reduced.

Owner:方文韬

A winding device for a printing machine

ActiveCN110526012BAffect the printing effectImprove printing effectPrinting press partsWebs handlingProcess engineeringPrinting press

The invention discloses a rewinding device for a printing machine, comprising a rewinding roller, limit plates are movably installed at both ends of the rewind roller, and a rewinding pretreatment device with the function of drying paper is fixed on the outside of the two limit plates , the outer side of the winding roller is provided with a size adjustment assembly with a deviation correcting function, and the product of the present invention uses a winding pretreatment device with a paper drying function to dry the surface of the rolled paper to avoid that the ink printed on the surface of the paper is not dry , Squeezing contact with the back of the inner paper will affect the printing effect, thereby improving the printing effect of the paper. At the same time, through the size adjustment component, it can meet the winding of paper of different sizes, and avoid wrinkles at both ends of the paper, which will affect the quality of the finished paper.

Owner:JI LONG MACHINERY CO LTD

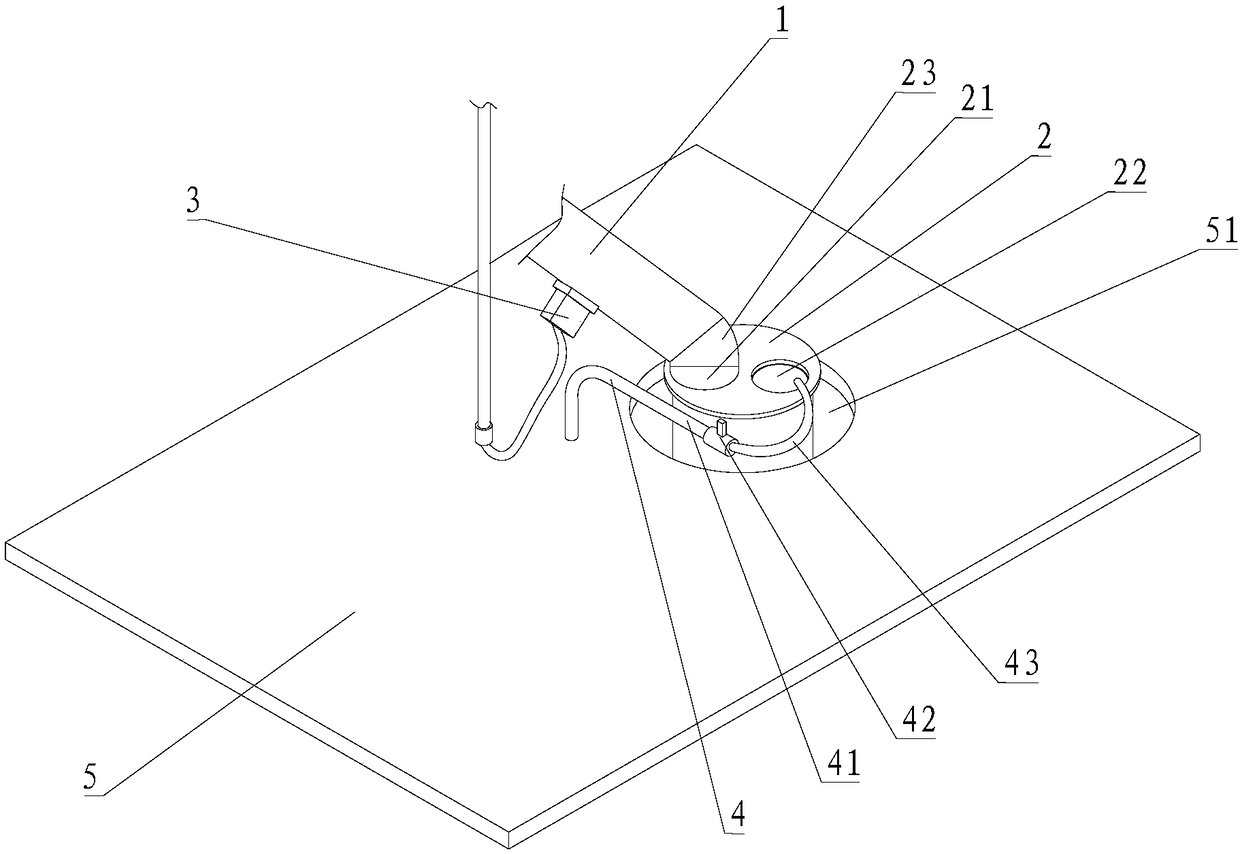

Preparation method and preparation device for preparing polyurethane foam wound dressing

PendingCN113752601AAvoid the risk of reduced effectivenessQuality assuranceAbsorbent padsFlat articlesPolymer scienceWound dressing

The invention discloses a preparation method and a preparation device for preparing a polyurethane foam wound dressing, and relates to the technical field of polyurethane foam dressings. The preparation method for preparing the polyurethane foam wound dressing comprises three steps of mixing, cutting and pressing. The preparation device for preparing the polyurethane foam wound dressing comprises a base, and a sleeving coiling mechanism, a feeding mechanism, a material injection mechanism, a pressing mechanism, a feeding box and a material storage barrel are arranged on the base. According to the preparation method for the polyurethane foam wound dressing, the dressing is designed in a split type structure, the dressing is integrally formed in a pasting and pressing manner in the preparing process, the steps are simplified, operation is convenient, and the shape and specification of the dressing can be correspondingly adjusted according to production requirements. According to the preparation device for the polyurethane foam wound dressing, batch operation can be achieved, the processing time consumption is shortened, machine automatic operation is achieved, manpower input is reduced, and the labor burden of operators is relieved.

Owner:南昌智产科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com