Low-fat yogurt fermentation inoculant taking lactobacillus paracasei and lactic acid bacteria as main components

A technology of yogurt fermentation bacteria and Lactobacillus, applied in the direction of bacteria, dairy products, milk preparations, etc., can solve the problems affecting the quality of yogurt products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of low-fat type yoghurt fermenting bacterial agent with Lactobacillus paracasei and lactic acid bacteria as main components, is made by following raw materials, and described parts are weight parts:

[0047] Skimmed milk powder 90 parts

[0048] Lactobacillus bulgaricus 1 part

[0049] Streptococcus thermophilus 1 part

[0050] Lactobacillus paracasei 1 part

[0051] Add skimmed milk powder, Lactobacillus bulgaricus, Streptococcus thermophilus and Lactobacillus paracasei in proportion through a quantitative feeder, dry mix evenly, and carry out subpackaging.

Embodiment 2

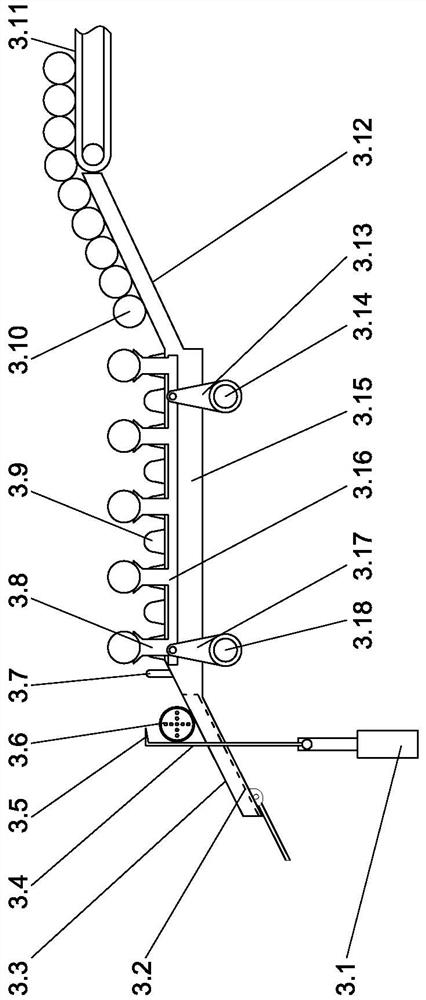

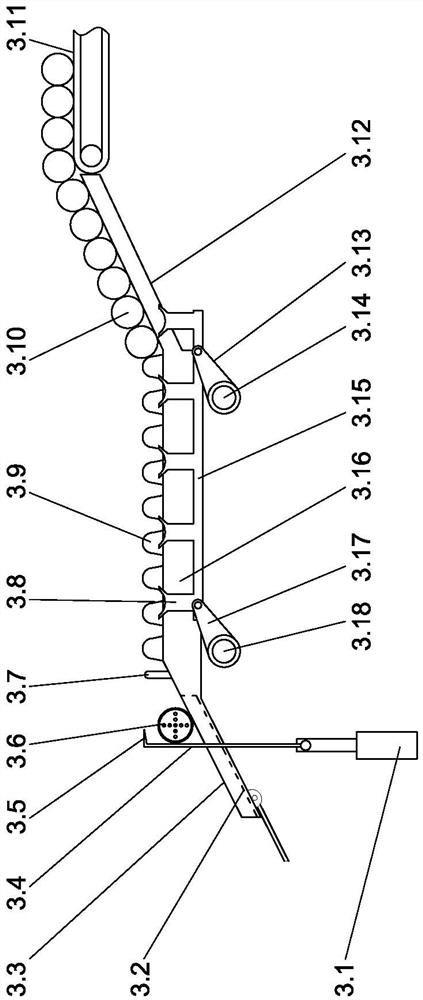

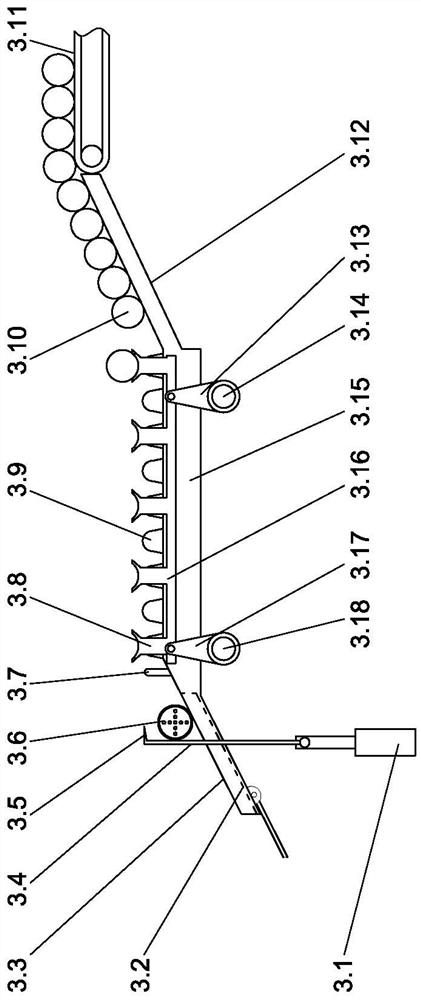

[0053] Such as Figure 1-3 As shown, the quantitative feeder includes a bacteria bag conveyor belt and a quantitative delivery device, and the cylindrical film bag is conveyed on the bacteria bag conveyor belt, and bacteria are wrapped in the cylindrical film bag, and the lower end of the bacteria bag conveyor belt is connected to the quantitative delivery device. material device.

[0054] The quantitative delivery device includes a horizontal support platform, a front slope material guide platform and a rear slope material guide platform, the front end of the horizontal support platform connects the lower end of the bacteria bag conveyor belt through the front slope material guide platform, and the rear end of the horizontal support platform Connect the upper end of the rear slope guide platform; set a number of stopper rubber blocks perpendicular to the conveying direction on the horizontal support platform; install the left front and left rear rotation rollers on the left f...

Embodiment 3

[0061] Such as Figure 4-6 As shown, the dry-mix quantitative conveyor includes a dry-mix quantitative conveyor base, a feed barrel and a quantitative barrel, and a groove is provided in the middle of the dry-mix quantitative conveyor base, and the left and right sides of the dry-mix quantitative conveyor base There are frame support columns on both sides, and a feed barrel is arranged between the upper ends of the frame support columns on both sides. A telescopic rod is arranged on both sides of the feed barrel, and the other end of the telescopic rod is arranged on the machine. The inner wall of the frame support column, a No. 1 motor is arranged in the middle of the upper surface of the feeding barrel, and a feed inlet is arranged on the right side of the No. 1 motor. The inner side of the discharge port at the lower end of the material barrel is provided with a solenoid valve, the lower end of the feed barrel is provided with a quantitative barrel, and the outer side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com