Operation stabilized continuous sponge foaming machine

A technology of stable operation and foaming machine, applied in the field of sponge production, can solve the problems of inconvenient maintenance of chain plates, inconvenient removal, affecting the service life of the foaming machine, etc., to increase the scope of application, reduce waste, and reduce equipment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

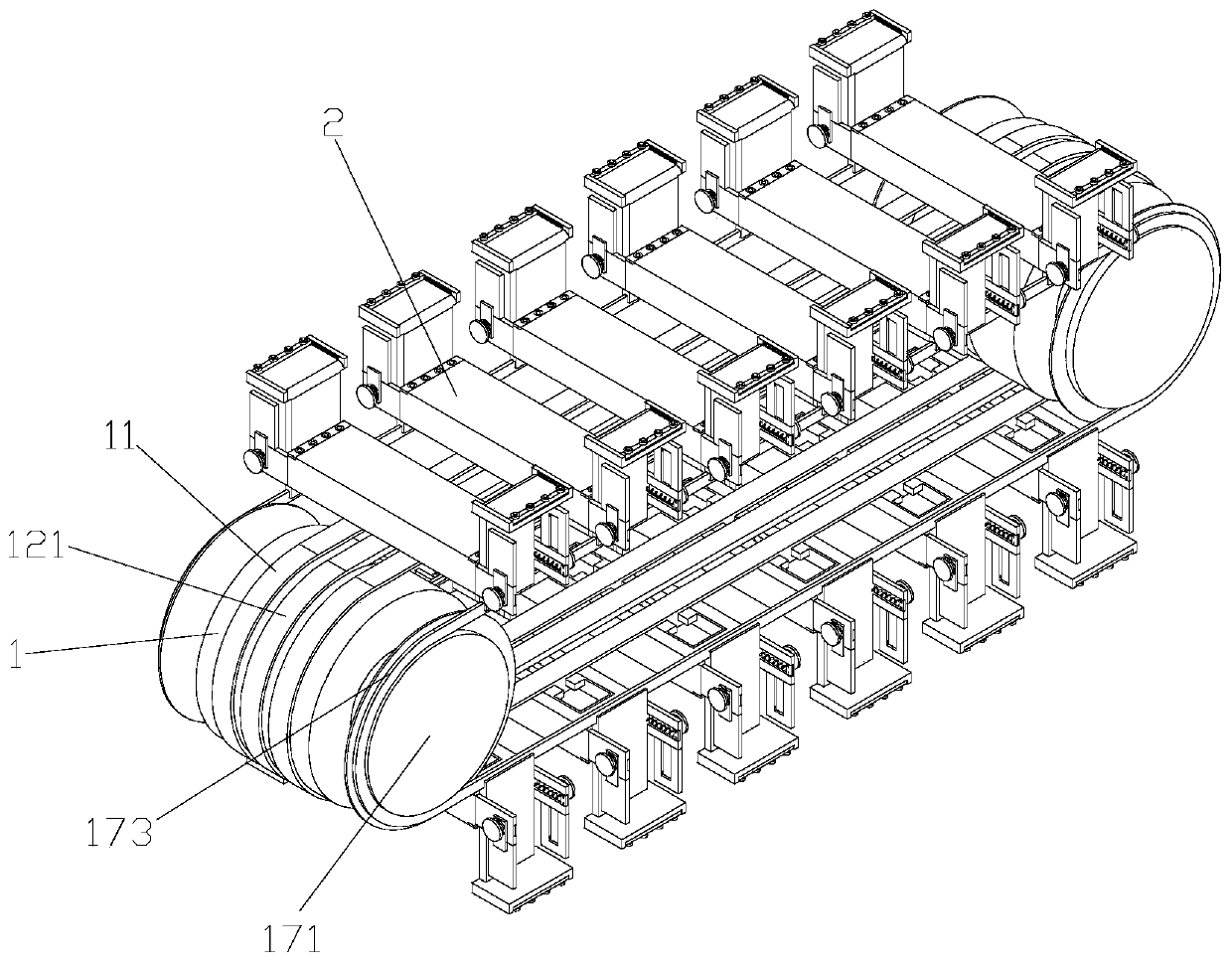

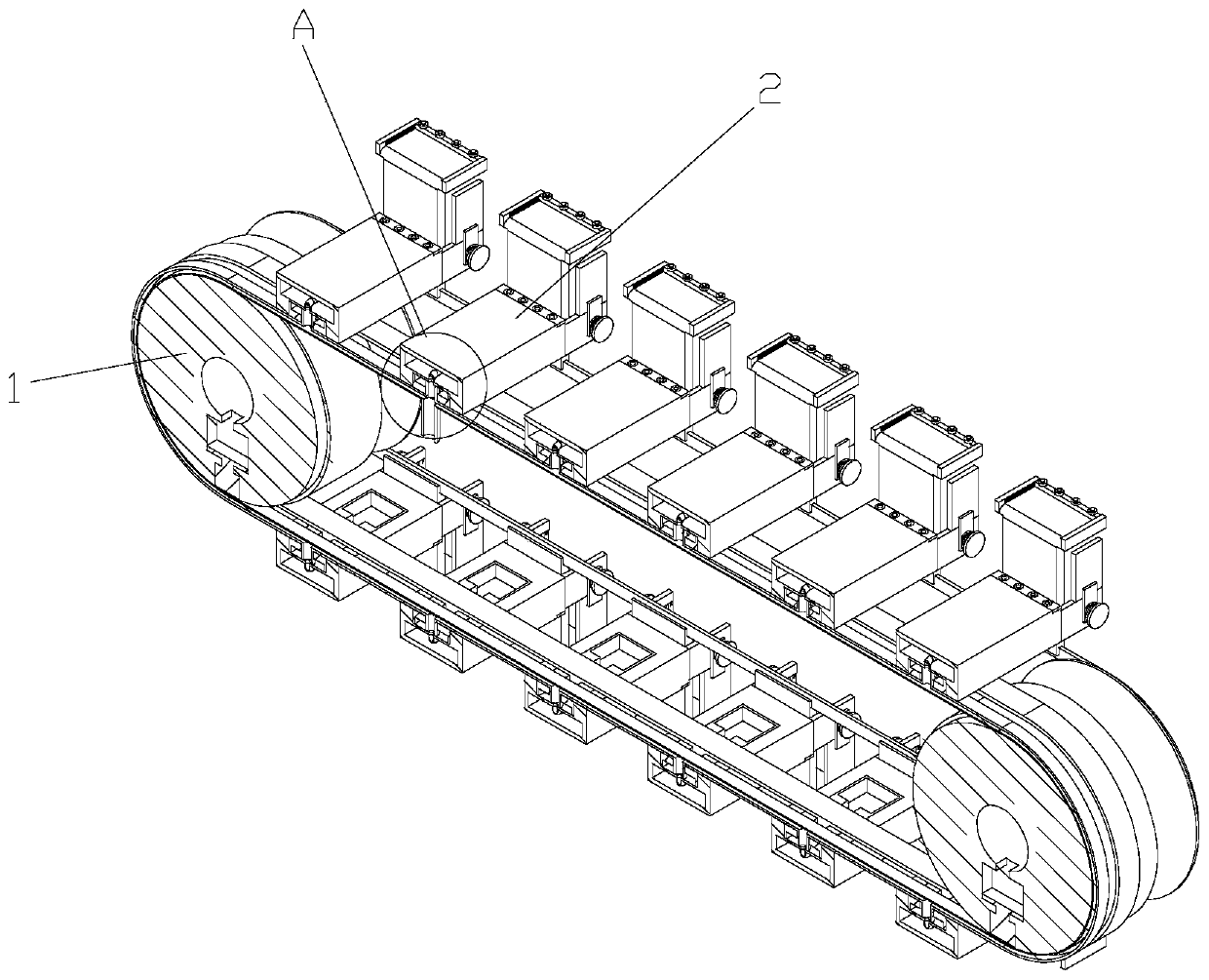

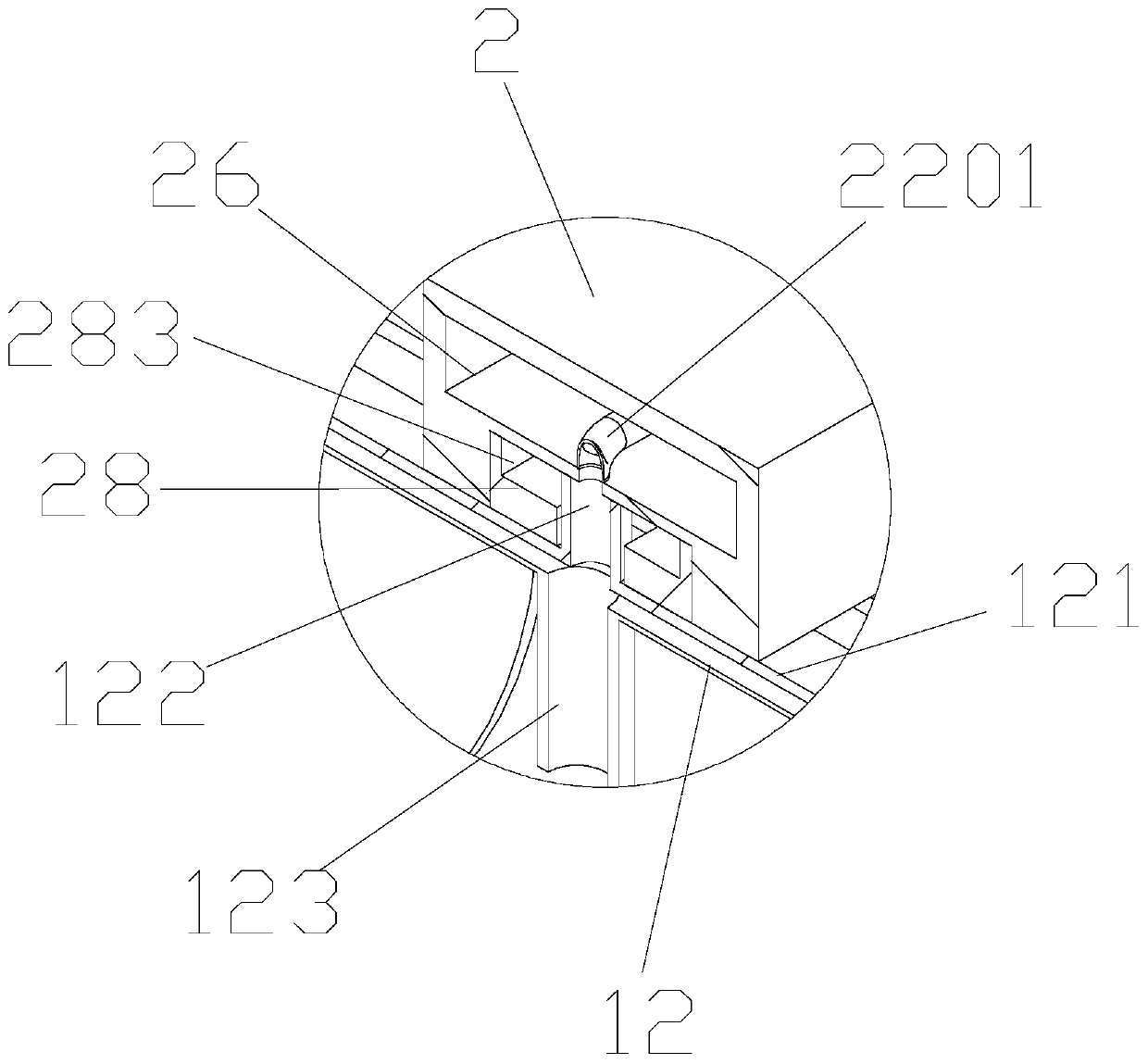

[0037] Such as Figure 1-25As shown, a continuous sponge foaming machine with stable operation includes a rotating roller 1, a first transmission chain 11 arranged on the rotating roller 1 and a support plate 2 arranged on the first transmission chain 11, The support plates 2 are in multiple groups, and are evenly laid on the first transmission chain 11. The first transmission chain is two groups, which are symmetrically arranged on the rollers, so as to improve the stability of the support plates and increase the connection between the support plates and the transmission. Cooperating effect of the chain; the side wall of the support plate 2 is provided with a baffle plate 21, the support plate 2 and the baffle plate 21 are covered with kraft paper, and the side wall of the support plate 2 is provided with a first connecting plate 23 , the first connecting plate 23 is provided with a first chute, and the side wall of the baffle 21 is provided with a first slider matching the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com