Full-polyester digital printing processing equipment

A technology of digital printing and processing equipment, applied in printing, printing devices, typewriters, etc., can solve problems such as affecting the quality of finished products, affecting printing effects, low heat dissipation efficiency, etc., to improve work efficiency and work quality, and prevent dust from entering jet printing Mechanism, excellent heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

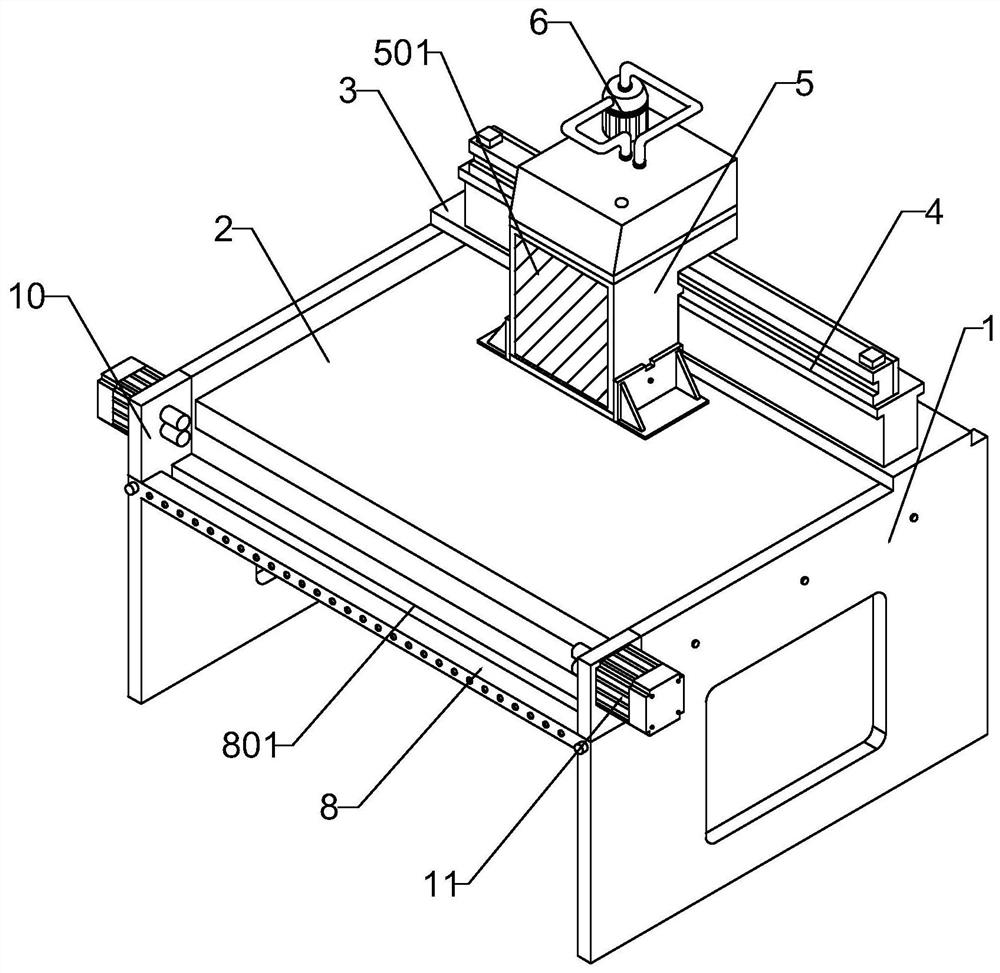

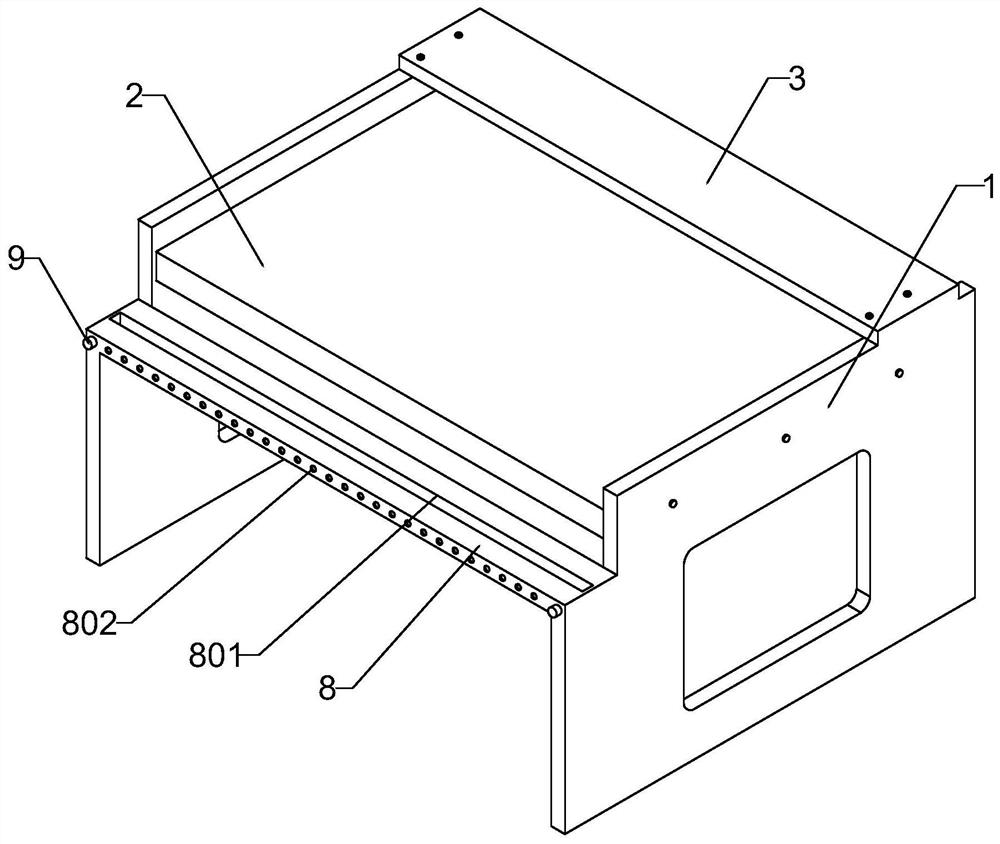

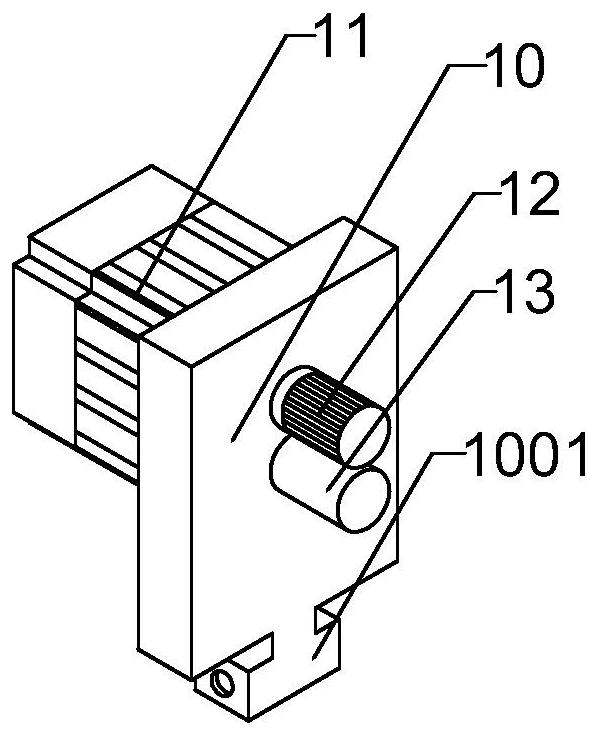

[0024] refer to figure 1 , figure 2 , image 3 and Figure 4 , the present invention provides the following technical solutions: a full polyester digital printing processing equipment, including a support frame 1, a printing table 2 and a mechanism bottom plate 3, the printing table 2 is fixedly installed on the inner side wall of the support frame 1, and the mechanism bottom plate 3 is welded and arranged on the support The rear end position of the top surface of the frame 1, the top surface of the mechanism bottom plate 3 is fixedly equipped with a traverse slide rail 4, and the front end of the traverse slide rail 4 is movably fitted with a spray printing mechanism 5, and the top surface of the spray print mechanism 5 is fixedly installed with a A micro-water pump 6, and a heat-absorbing head 7 is inlaid inside the spray printing mechanism 5, and a mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com