Processing system for performing biomass fuel production

A biomass fuel and processing system technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problem of unclear synthesis mechanism, and achieve the effect of rational use, scientific design, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

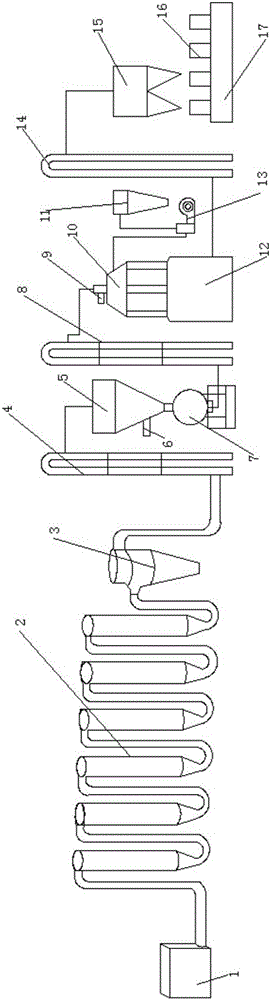

[0028] A processing system for biomass fuel production, which adopts a drying system, granulation system, air cooling system and filling system designed with drying, granulation, air cooling and filling processes, and can be used for biofuel production The assembly line production operation of material fuel can effectively improve the production efficiency of biomass fuel and at the same time avoid environmental pollution as much as possible. The whole structure has the characteristics of scientific design, reasonable use, energy saving and environmental protection, such as figure 1 As shown, the following configuration structure is particularly adopted: a drying system, a granulation system, an air cooling system and a filling system are provided, the drying system is connected to the granulation system, the granulation system is connected to the air cooling system, and the The air-cooling system is connected with the filling system; a raw material hoist 4 and a granulation ma...

Embodiment 2

[0031]This embodiment is further optimized on the basis of the above embodiments, further to better realize the present invention, avoiding the congestion of materials in the silo and affecting the saturation operation of the granulator, such as figure 1 As shown, the following arrangement structure is particularly adopted: the arch breaker 6 is also provided on the silo 5 to avoid the congestion of raw materials, and the arch breaker 6 is arranged at the middle and lower part of the silo 5. When in use, when the silo In the case of congestion in 5, the arch breaker 6 will break up the congested materials, so that the discharge port of the silo 5 will not be blocked, so as to avoid the situation that the material cannot be obtained in time in the granulator 7, which will affect the entire assembly line working process.

Embodiment 3

[0033] This embodiment is further optimized on the basis of any of the above-mentioned embodiments. Further, in order to better realize the present invention, the granulated biomass fuel can be cooled by air-cooling technology, and products that meet the specifications can be screened out so that Filling later, such as figure 1 As shown, the following arrangement structure is adopted in particular: the first elevator 8, the cooling fan 9, the cooling machine 10 and the vibrating screen 12 are arranged in the air-cooling system, and the discharge port of the granulation host 7 is connected to the first elevator The feed port of the machine 8, the discharge port of the first elevator 8 is connected with the vibrating screen 12 through the cooling machine 10, the air outlet of the cooling fan 9 is connected with the air inlet of the cooling machine 10, and the vibrating screen 12 The material output port of the filling system is connected with the material inlet of the filling sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com