Anti-impact elevator car ceiling guardrail

An anti-shock and car top technology, which is applied to elevators, elevators, transportation and packaging in buildings, etc., can solve the problems of easy failure of joints, insufficient impact resistance, poor impact resistance, etc., and achieve linkage effect Good, good impact resistance, improve the effect of absorbing impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

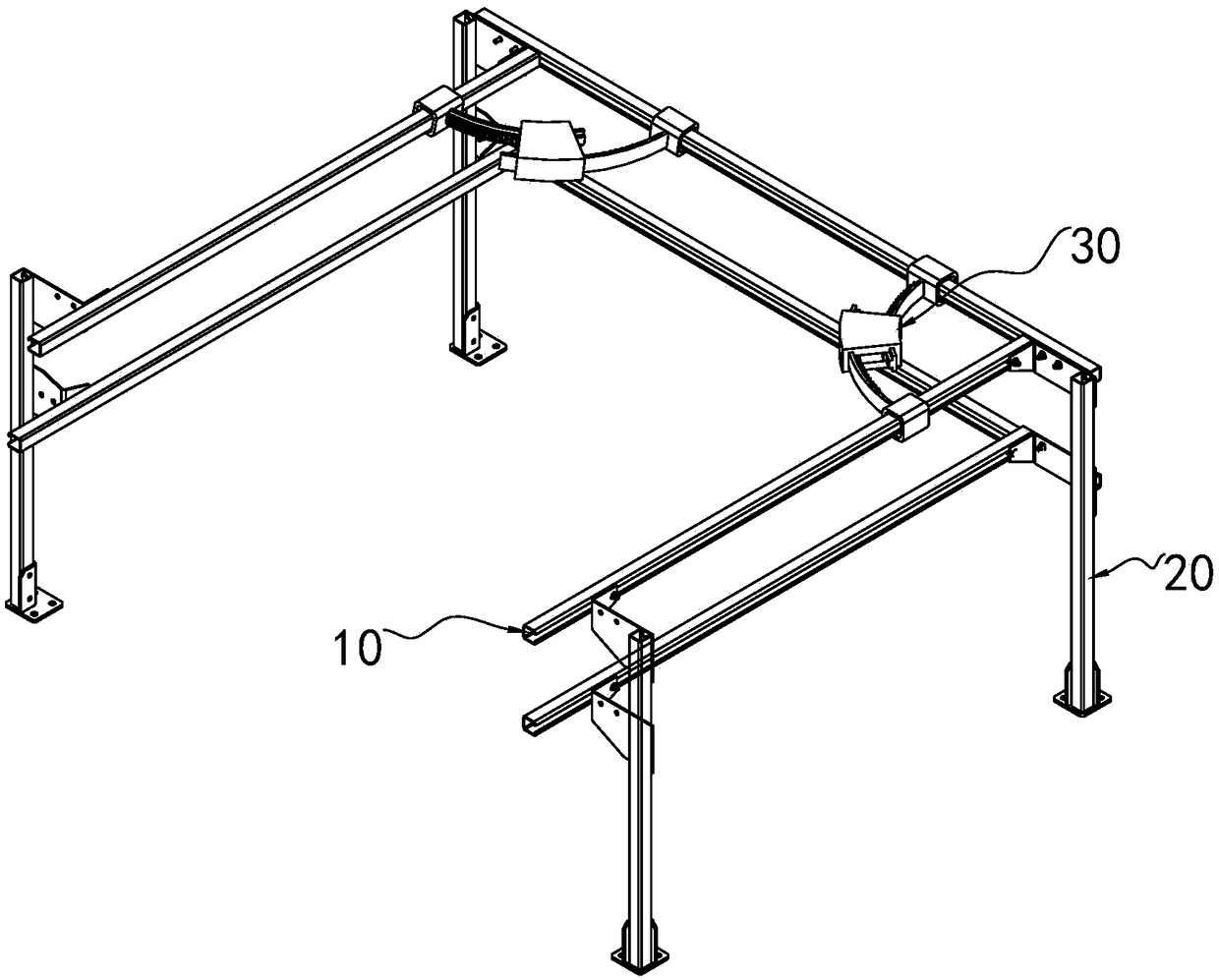

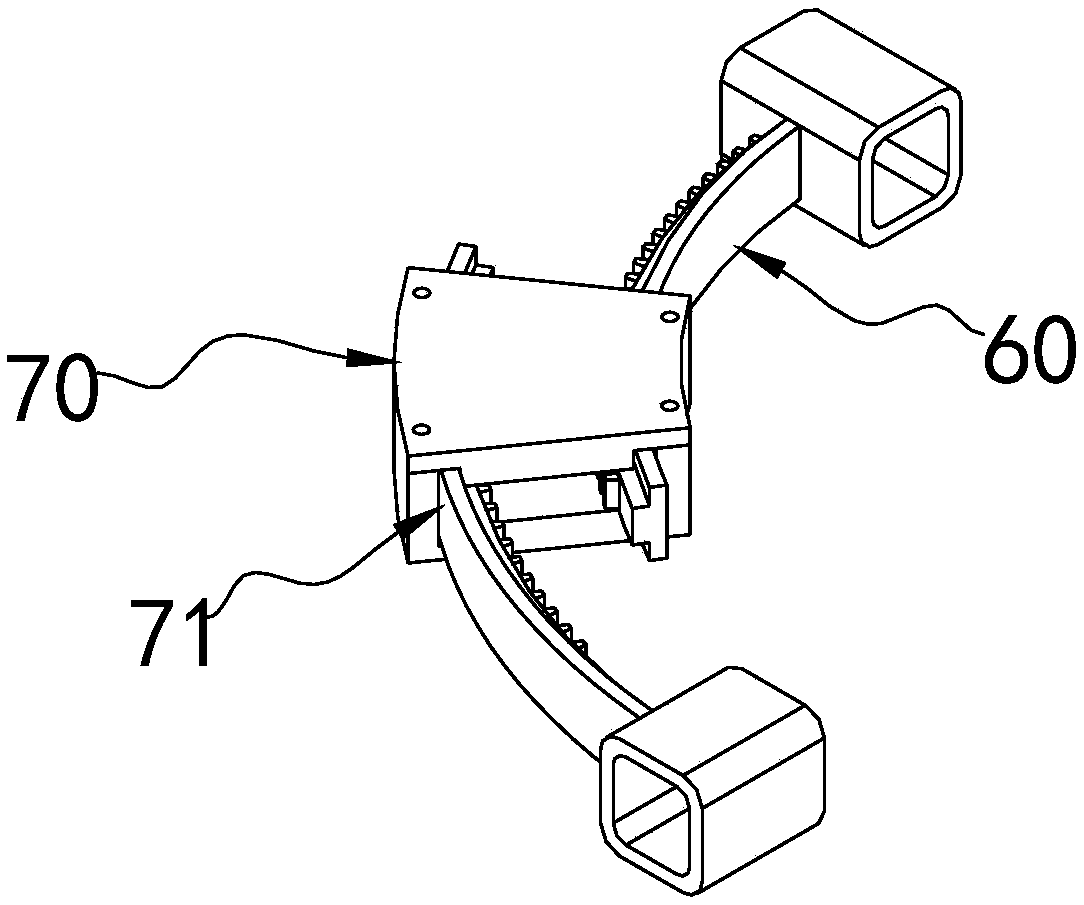

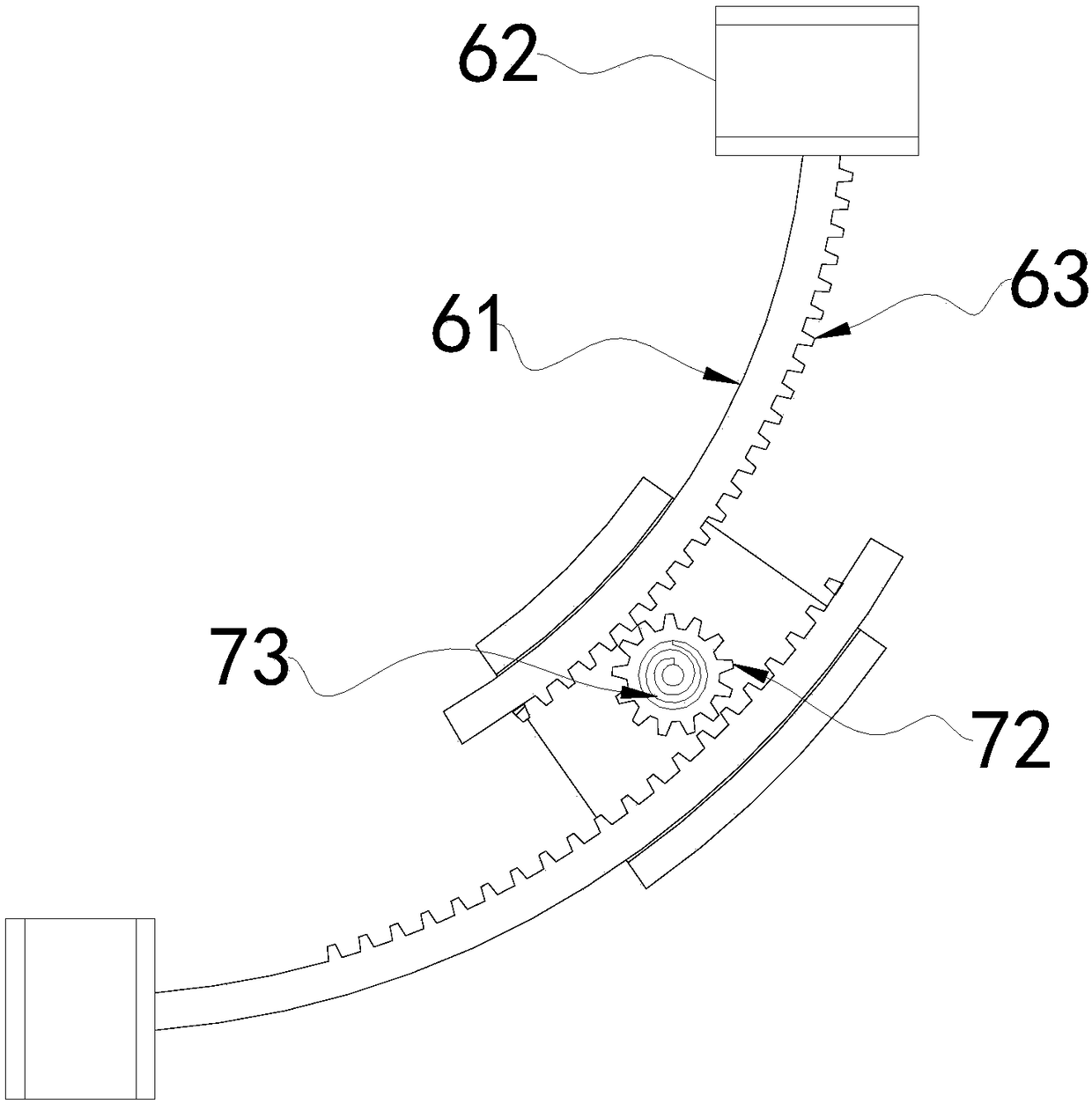

[0017] Embodiment: a kind of anti-shock elevator car top guardrail, comprises the horizontal railing 10 of U-shaped setting, and railing 10 is connected with the upright column 20 that is fixed on the car top; Connecting the joint of two railings 10 is provided with buffering device 30; The buffer device 30 described above includes two oppositely arranged resistance arms 60 and a limit box 70; the resistance arm 60 includes an arc bar 61 with a T-shaped cross section, and the end of the arc bar 61 is provided with a side rail 10 or The sliding sleeve 62 on the rear railing 10 and the arc bar 61 are provided with a rack 63; the limit box 70 is provided with an arc groove 71 slidingly matched with the arc bar 61, and the limit box 70 is provided with A gear 72 cooperating with the rack 63, and a clockwork spring 73 is provided at the joint between the gear 72 and the limiting box 70 .

[0018] The rack 63 is arranged on the opposite surface of the two arc bars 61 , and the gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com