Medium-high pressure natural gas flow path switching device and using method

A switching device, natural gas technology, applied in the valve device for absorbing fluid energy, valve device, valve operation/release device, etc. The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

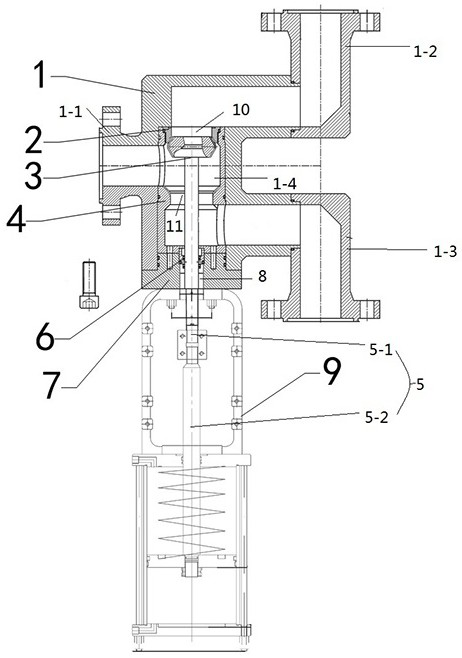

[0020] Such as figure 1 As shown, a medium-high pressure natural gas process switching device includes a valve body 1 and a pneumatic device connected to the valve body 1, and the valve body 1 includes an inlet 1-1, a first outlet 1-2, and a second outlet 1-3 And the separation chamber 1-4, the inlet 1-1, the first outlet 1-2 and the second outlet 1-3 all communicate with the separation chamber 1-4 through passages, the first outlet 1-2 and the second outlet 1 -3 Connected with the separation chamber 1-4 are the first interface 10 and the second interface 11 respectively, the pneumatic device includes a pneumatic driver 9 and a valve stem 5 connected to the pneumatic driver 9, the pneumatic driver 9 is connected to the valve body 1, the valve The stem extends into the separation chamber 1-4 through the second interface 11, and the top end of the valve stem 5 is connected with a valve stem disc 3, which matches the first outlet 1-2 and the second outlet 1-3.

[0021] The valve...

Embodiment 2

[0025] Such as figure 1 As shown, on the basis of Embodiment 1, flanges are provided at the inlet 1-1, the first outlet 1-2 and the second outlet 1-3. The inlet 1-1, the first outlet 1-2 and the second outlet 1-3 are all arranged in a flange shape, and are connected with upstream and downstream pipelines through flanges and screws.

[0026] The valve seat 2 is connected to the first interface 10 .

[0027] The valve stem sleeve 4 is connected to the second interface 11 .

[0028] A valve seat 2 is connected to the inner wall of the channel at the first interface 10 , so that the valve seat 2 is in contact with the valve stem disc 3 to form a seal. The valve stem sleeve 4 is also connected to the second interface 11 , so that the valve stem sleeve 4 forms a seal with the valve stem disc 3 .

[0029] The valve body 1 is connected with an end cover 7, and the other side of the end cover 7 is connected with a pneumatic driver 9, and the valve stem 5 passes through the end cover...

Embodiment 3

[0042] Such as figure 1As shown, on the basis of Example 2, a method of using a medium-high pressure natural gas process switching device, when in the metering process, the pneumatic driver 9 is activated to push the valve stem 5 upward until the valve stem disc 3 contacts the valve seat 2 And seal, block the first interface 10, the gas entering from the inlet 1-1 passes through the separation chamber 1-4, the second interface 11, and finally discharges from the second outlet 1-3; when in the production process, the pneumatic drive 9 Close, the valve stem 5 goes down until the lower end of the valve stem disc 3 contacts with the valve stem sleeve 4 and forms a seal, forming a seal for the second interface 11, and the gas entering from the inlet 1-1 is discharged from the first outlet 1-2.

[0043] There are two types of processes, metering process and production process. During the metering process, there is little gas from the inlet 1-1, and generally only one upstream pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com