Simple multifunctional assembly line workbench

An assembly line and multi-functional technology, applied to workbenches, manufacturing tools, metal processing equipment, etc., can solve problems that affect work efficiency, time-consuming and labor-intensive, and achieve the effect of process switching and easy product movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

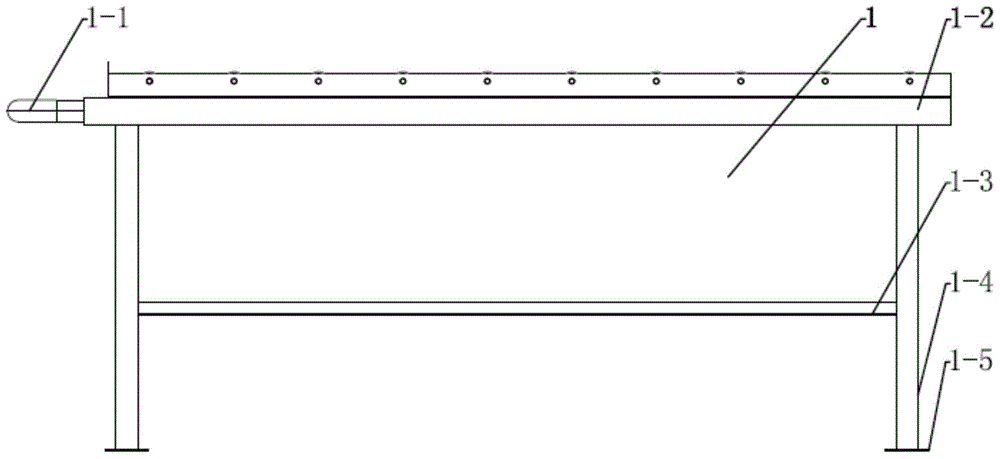

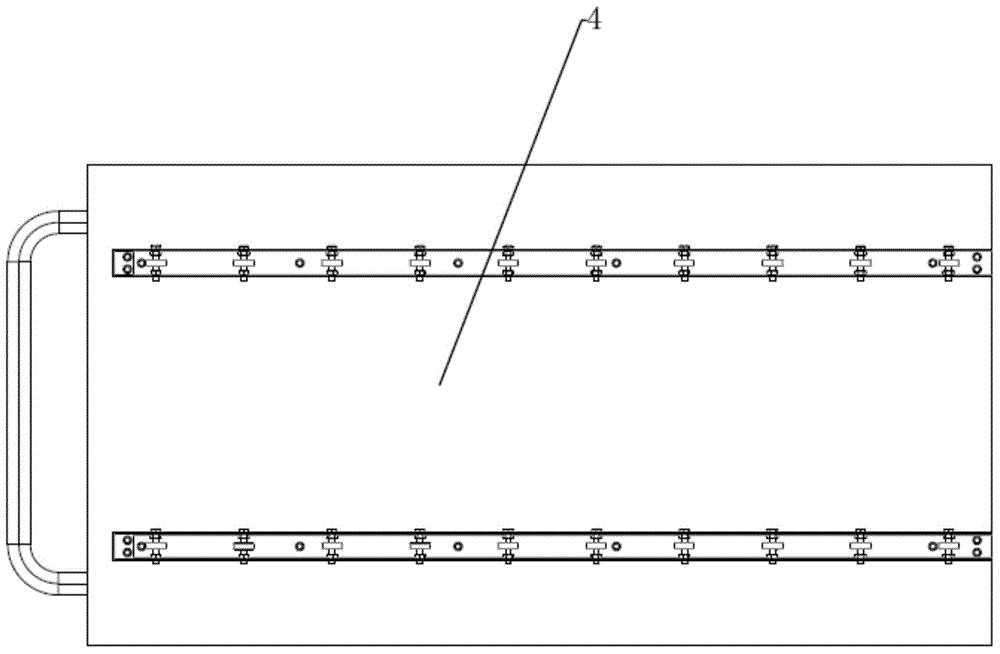

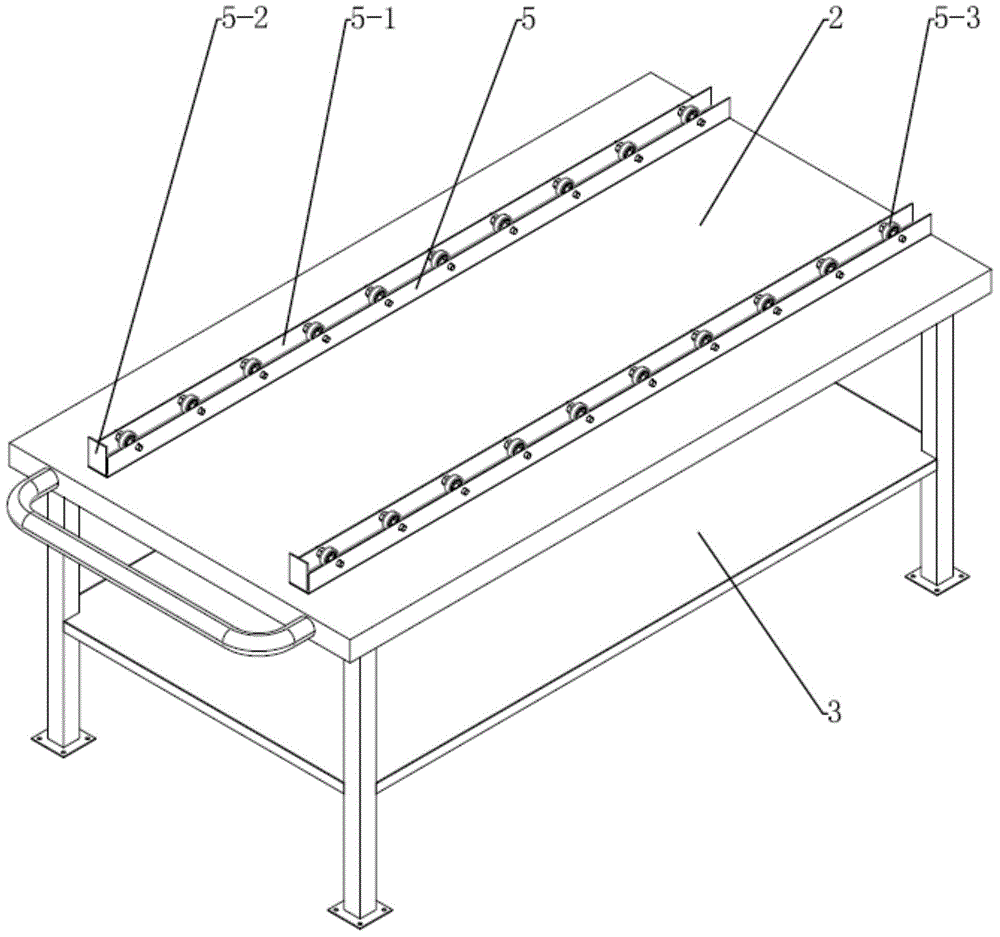

[0019] Such as Figure 1 ~ Figure 3 As shown, a simple multifunctional assembly line workbench of the present invention includes a console frame 1 , an upper console 2 , a lower console 3 , an insulating pad 4 and a sliding guide rail 5 .

[0020] The console frame 1 includes a handle 1-1, an upper console frame 1-2, a lower console frame 1-3, a leg 1-4 and a leg fixing surface 1-5, and is the carrier of the entire assembly line workbench. All components are constructed by welding, and the structure is firm. The handle 1-1 is a φ25×2 steel pipe, made of Q235A, with a length of 700mm, bent at 100mm at both ends, with a bending radius of 50mm, and welded to the left frame of the upper operating table 2. The frame 1-2 of the upper operating table is a 2mm thick stainless steel L-shaped angle bracket, which is welded in sections into a rectangular shape, with a length of 1600mm and a width of 850mm. The lower console frame 1-3 is a 2mm thick stainless steel L-shaped angle bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com