New process for producing firedamp by syngas

A synthesis gas and coal-based synthesis gas technology, which is applied in the chemical industry, climate sustainability, sustainable manufacturing/processing, etc., can solve problems such as economic loss, harsh process conditions, and insufficient energy utilization, so as to improve economic benefits , strong competitive advantage, effective use of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

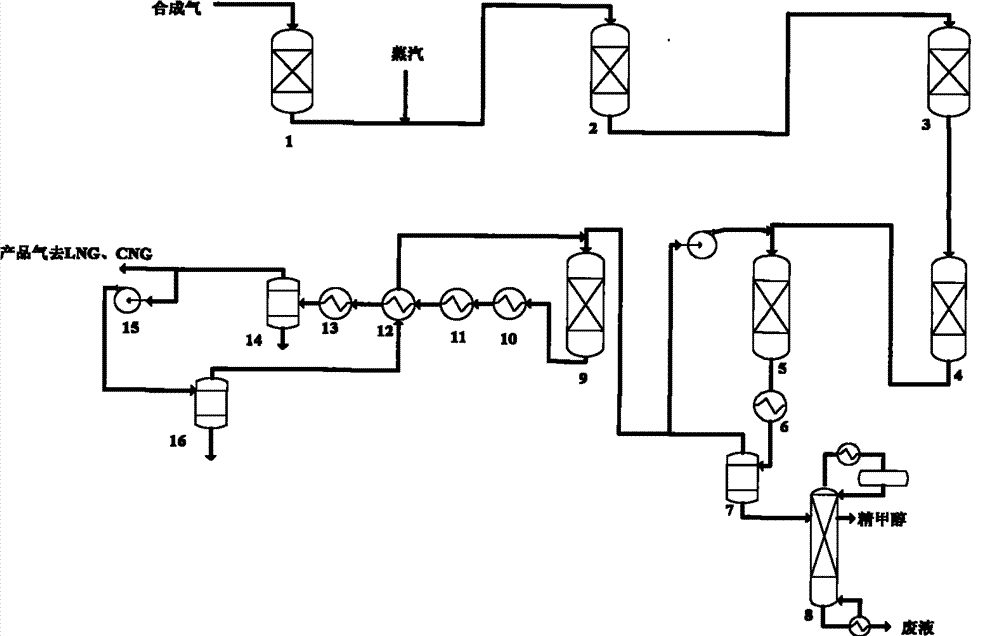

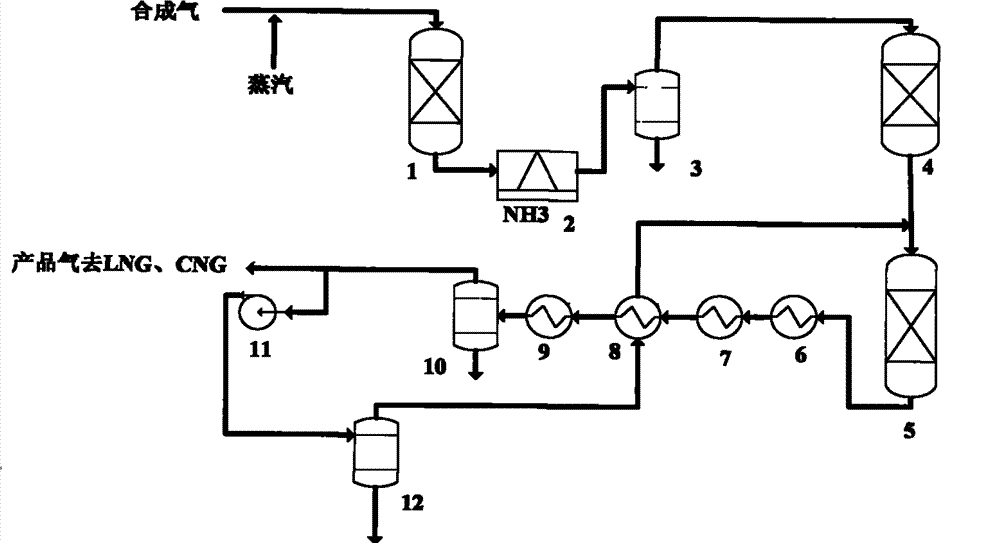

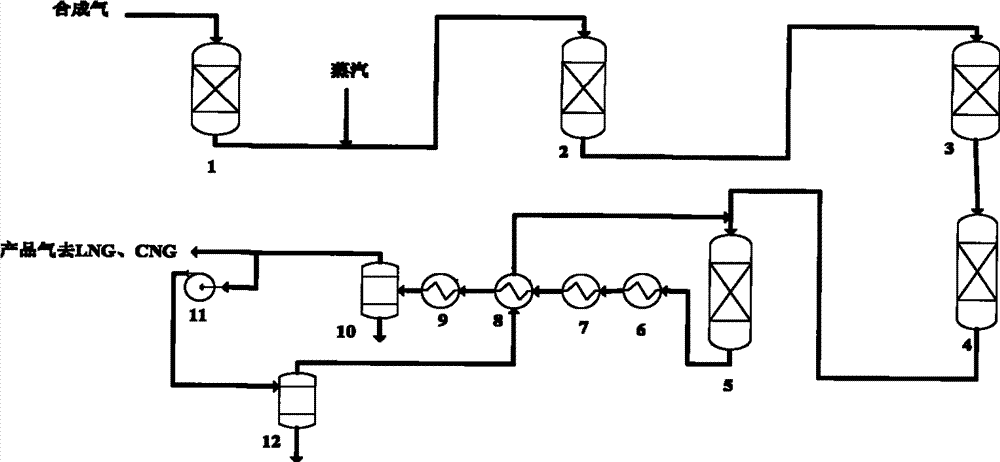

Method used

Image

Examples

Embodiment 1

[0045] To produce 200,000 tons / year of methanol, low-temperature catalytic gasification crude gas is rich in methane 20.0%, using a certain amount of cobalt phthalocyanine and containing 0.5mol / LNa 2 CO 3 Desulfurization in alkaline solution, the H in the gas 2 S off to below 40ppm. After adjusting the ratio of hydrogen to carbon through the full low shift process of 0.8MPa, it enters the decarburization system with a pressure of 2.70MPa for decarburization, and the purified gas is further passed through Co-Mo / γ-Al 2 o 3 Catalyst hydroconversion and zinc oxide refined desulfurization enter into methanol synthesis, with a daily output of 667 tons of methanol and 16,000Nm 3 / h Relax gas.

[0046] The composition of low temperature catalytic gasification crude gas is as follows:

[0047]

[0048] The relaxed gas consists of:

[0049]

[0050] The release gas from methanol synthesis passes through the methanation system with a pressure of 1.0MPa, a temperature of 200-3...

Embodiment 2

[0054] Texaco gasification synthesis gas production is 100,000Nm 3 / d, the composition contains 0.1% methane, and the synthesis gas enters the sulfur-tolerant shift reactor. The sulfur-tolerant shift catalyst generally uses a Co-Mo sulfur-tolerant catalyst, and the H 2 / CO is in the appropriate ratio range of 3.05. The converted gas is cooled to about -27°C by the ammonia cooler, and the condensate is separated. The gas enters the low-temperature methanol elution sulfur decarburization tower. The reaction pressure is 3~8MPa and the temperature is -20~— 60°C, remove acid gas. Then directly enter the methanation system, the pressure is 10.0MPa, the temperature is 300-350℃, and the space velocity is 8000-12000h -1 , so that CO and H 2 Synthesize methane, the product gas pressure after methane synthesis is 10.0MPa. According to the description in the national standard GB / T18047-2000, the high calorific value of CNG is ≥31.4MJ / m 3 , the product complies with the national standa...

Embodiment 3

[0060] Syngas production of 150,000Nm 3 / d, the composition contains 28.5% methane, using a certain amount of cobalt phthalocyanine and containing 0.5mol / LNa 2 CO 3 The solution is desulfurized, and the H in the gas 2 S off to below 40ppm. After adjusting the ratio of hydrogen to carbon through the full low conversion process of 0.8MPa, it enters the decarburization system with a pressure of 2.70MPa, and the purified gas is further passed through Co-Mo / γ-Al 2 o 3 Catalyst hydrogenation conversion and zinc oxide fine desulfurization enter the methanation system, the pressure is 20.0MPa, the temperature is 350-400℃, and the space velocity is 9000-12500h -1 , so that CO and H 2 Synthesize methane, the product gas pressure after methane synthesis is 20.0MPa. According to the description in the national standard GB / T18047-2000, the high calorific value of CNG is ≥31.4MJ / m 3 , the product complies with the national standard GB / T18047-2000, this gas can The CNG production un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com