Patents

Literature

37results about How to "Shock won't" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

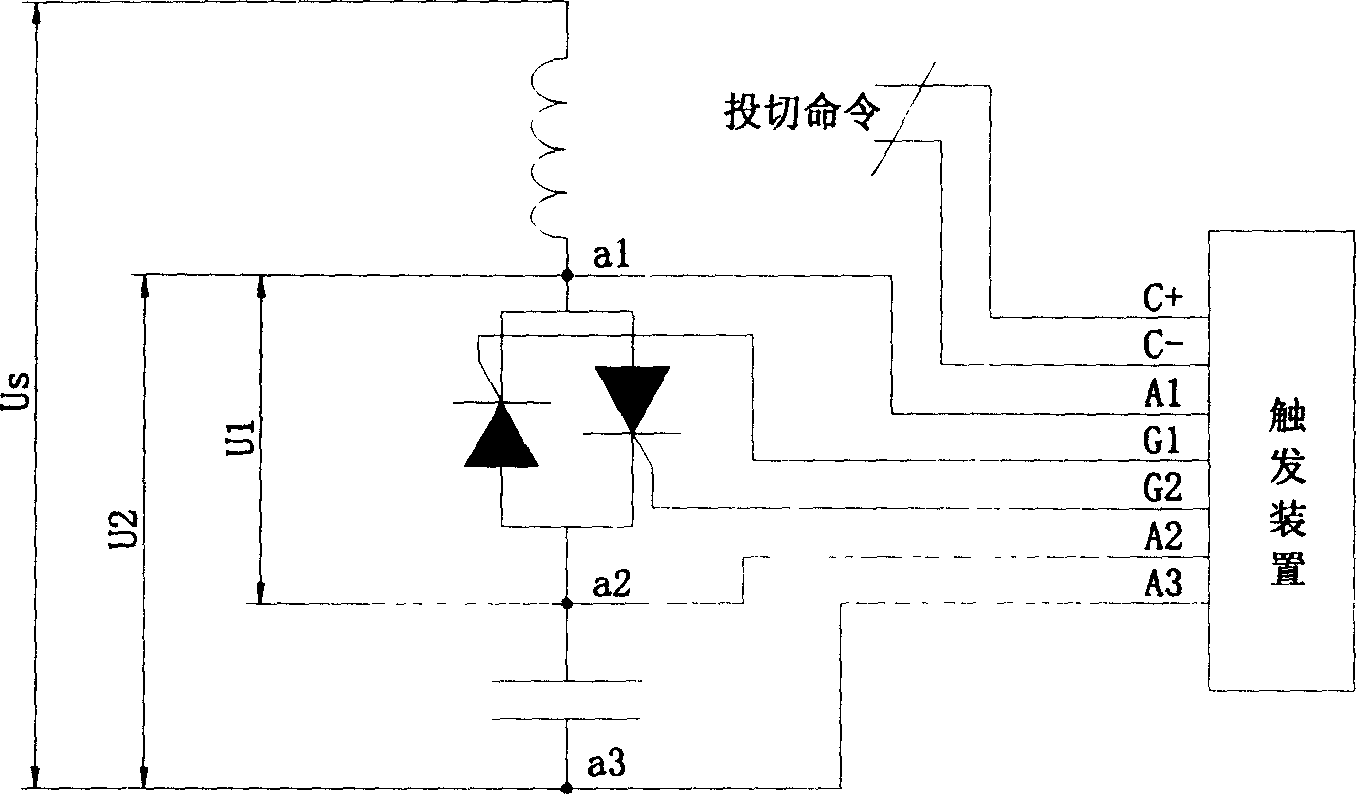

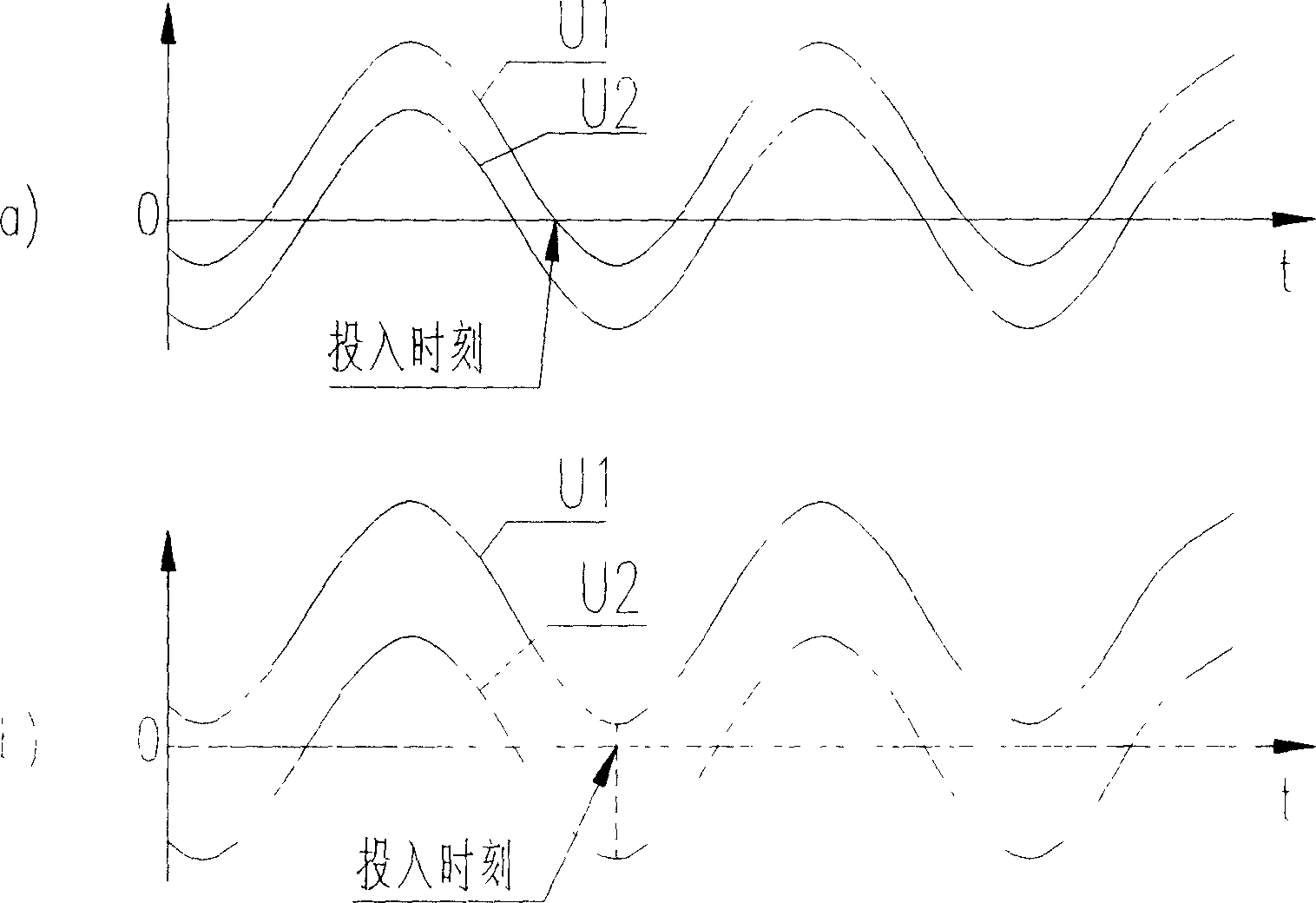

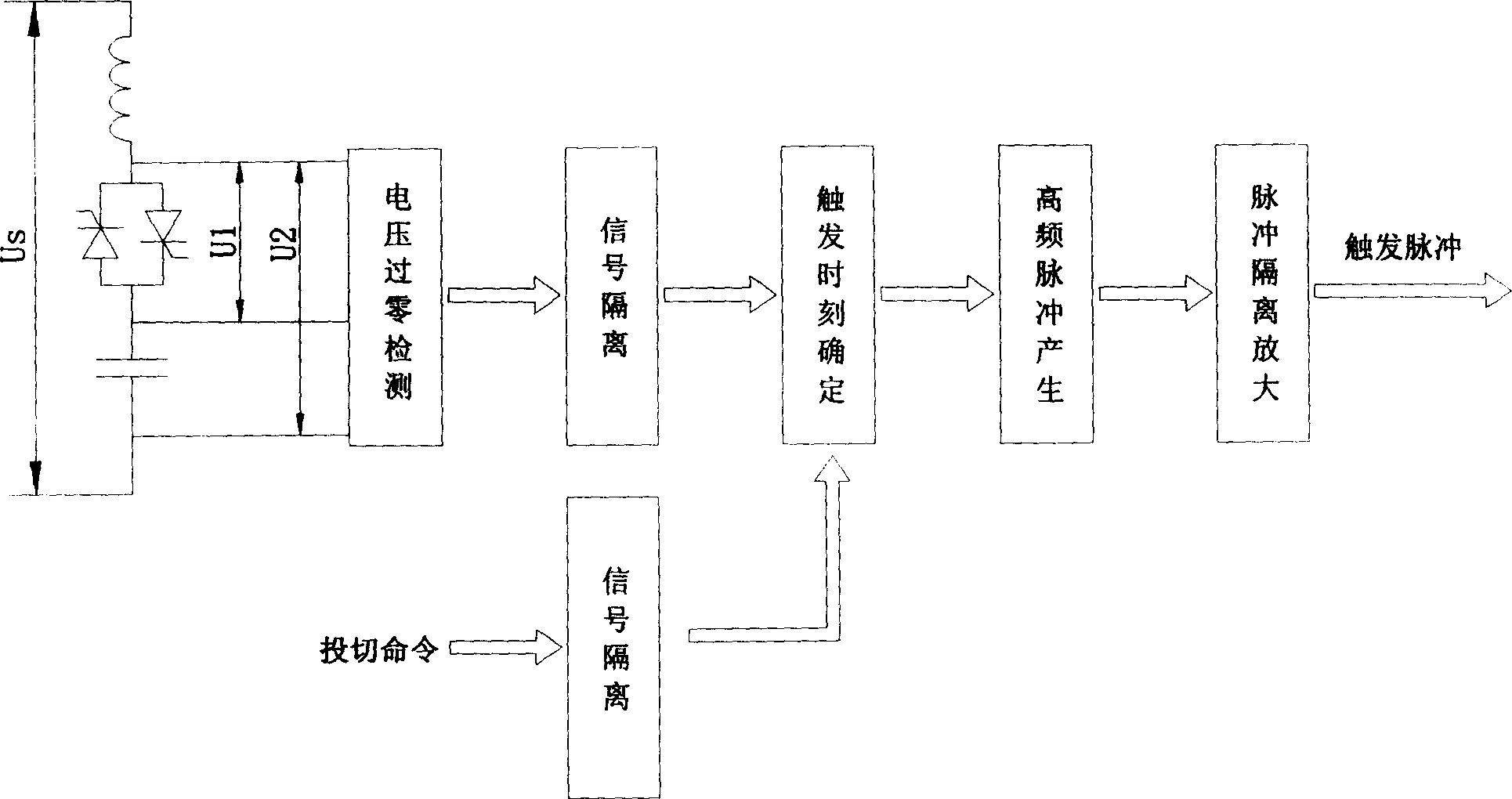

Thyristor triggered control method and device for dynamic reactive compensation

InactiveCN1858956AGood application prospectQuick switchReactive power adjustment/elimination/compensationReactive power compensationCapacitancePeak value

This invention relates to a thyristor trigger control method for dynamic reactive compensation characterizing in collecting voltage U1 at both ends of a reversed parallel thyristor and voltage U2 at both ends of the thyristor and a capacitor to take U1 and U2 as the base to determine the throw-in time of the entire capacitor branch, in which, U1 is the voltage at both ends of the thyristor and U2 is the sum of the voltage of thethyristor and the capacitor, when the thyristor is not turned on, U2 is equal to the system voltage US, U1 is equal to the system voltage deducting the residual voltage of the capacitor, when it is smaller than the peak value of the US and U1 has over-zero point, then the point is taken as the trigger time of the thyristor.

Owner:顺特电气有限公司

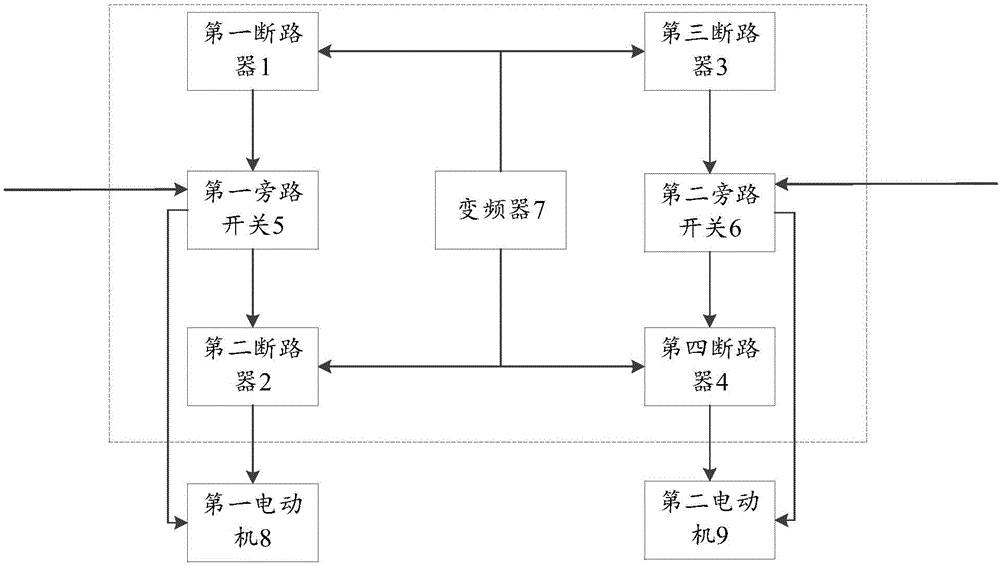

Frequency-conversion soft starter

InactiveCN104158445AShock won'tReduce manufacturing costMultiple dynamo-motor startersFrequency changerFrequency conversion

The invention discloses a frequency-conversion soft starter. The on-off sequence of breakers is controlled by a controller so that a frequency converter can start two motors at different time, and after one motor is started, the corresponding frequency converter bypass can be switched on. Thus, the frequency-conversion soft starter can be stably switched to a power-frequency power source without current impact after starting is finished, the starting current can be effectively reduced, ships cannot be impacted, and the frequency-conversion soft starter has obvious advantages in the aspects of structures and control. In addition, it is not needed to equip frequency converters for all the motors, and therefore the manufacturing cost of the ships is saved.

Owner:CSIC WUHAN SHIP & MARINE ENG EQUIP DESIGN

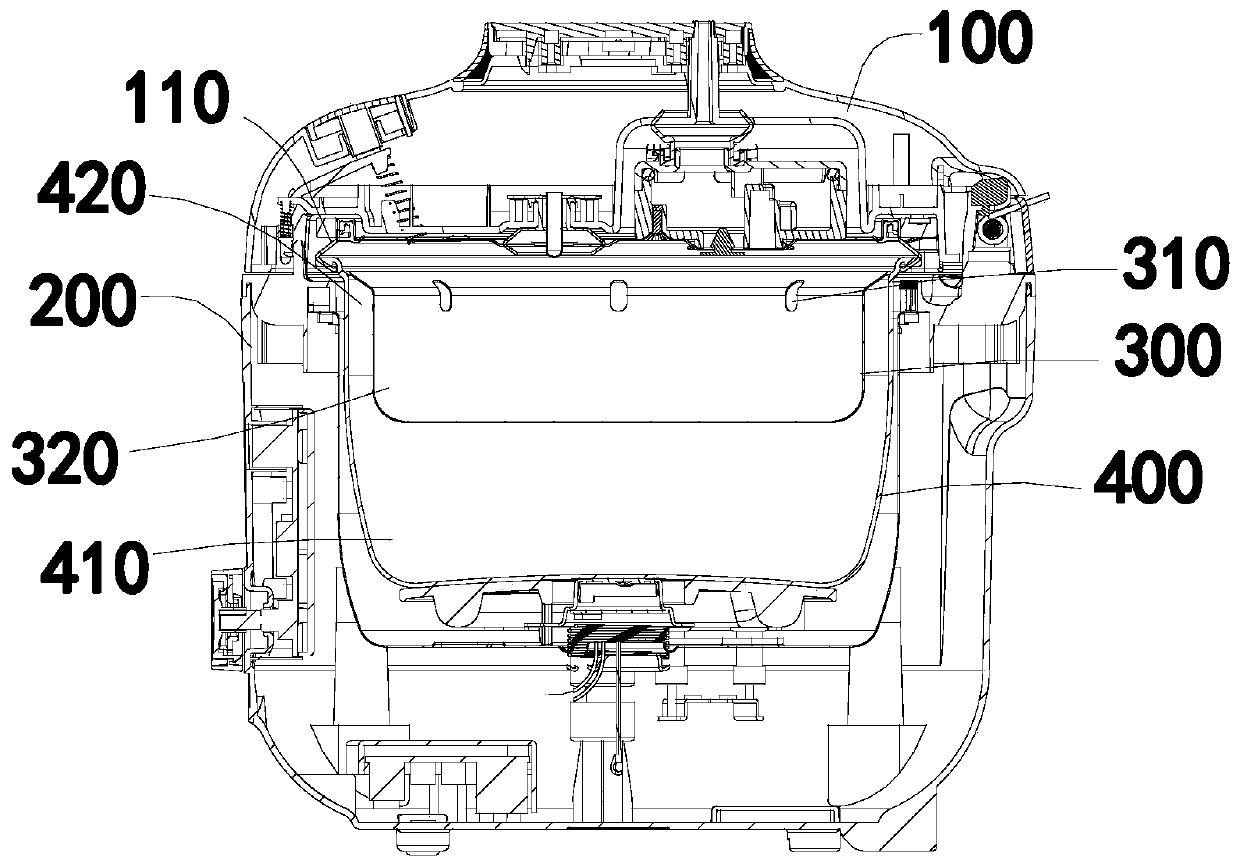

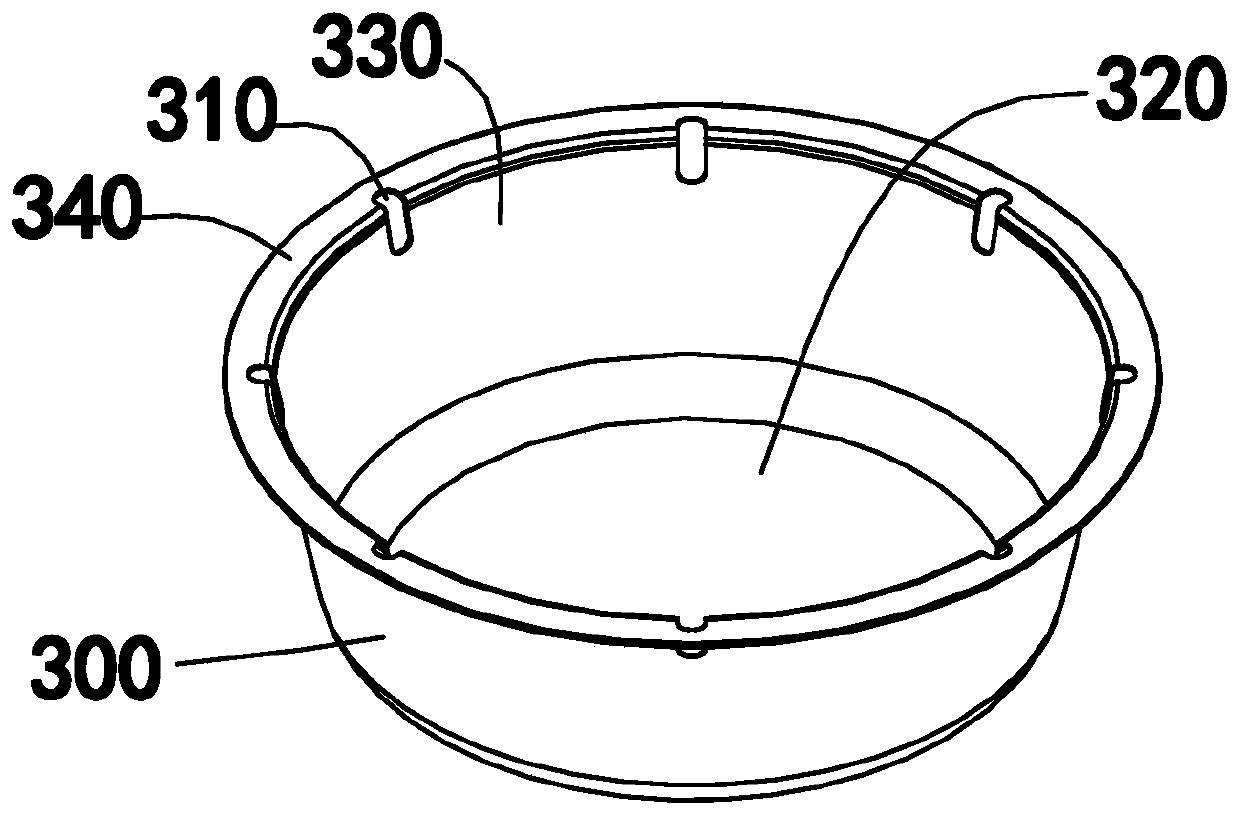

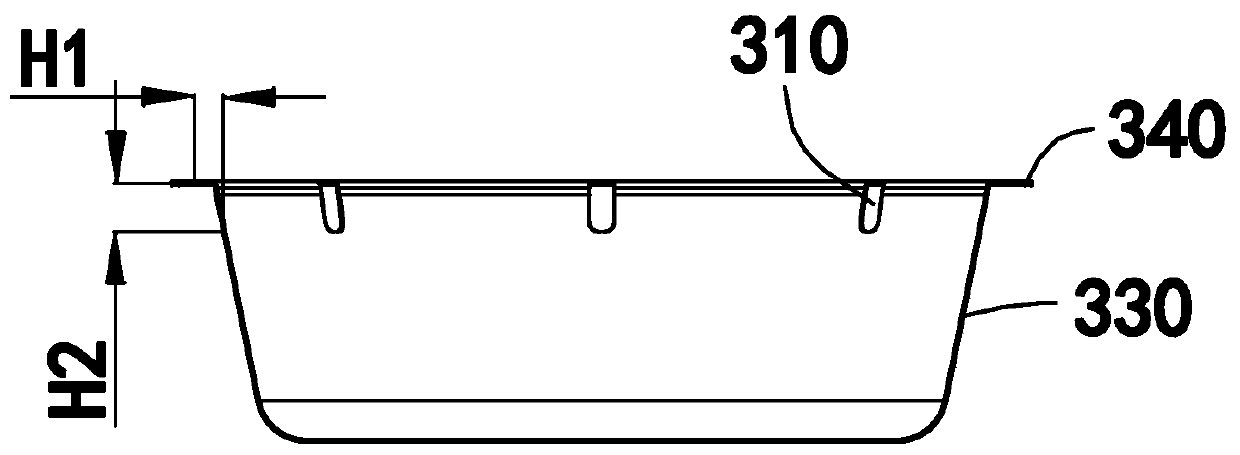

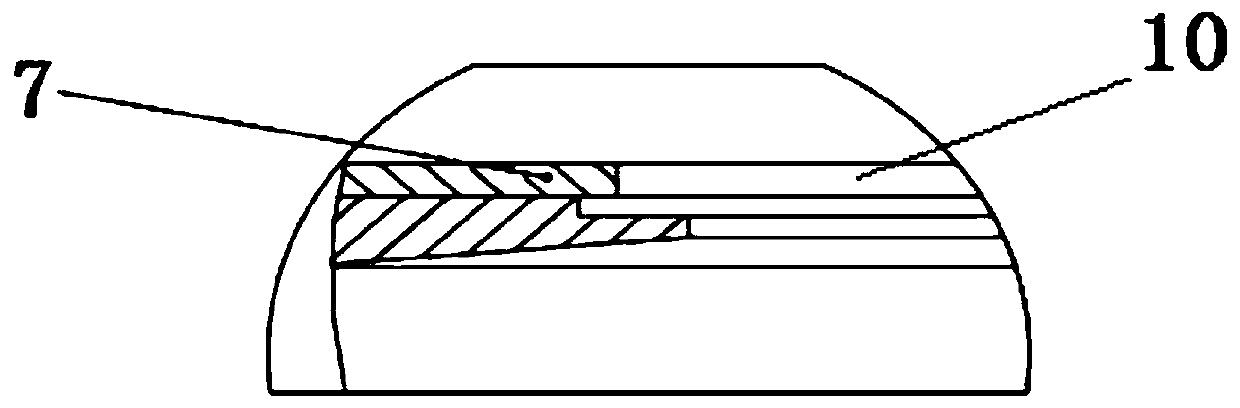

Cooking utensil

PendingCN110353509ASimple structureLow manufacturing costCooking insertsVessels with intergral heatingEngineeringFlange

The present invention provides a cooking utensil. The cooking utensil comprises a pot body and a pot cover; the pot body comprises an outer pot and an inner container placed in the outer pot; the upper half zone of the inner container is provided with a rice soup collector; the rice soup collector is internally provided with a collecting cavity for collecting rice soup; the lower half zone of theinner container forms a rice cooking cavity; anopening of the rice soup collector is provided with a flange; the side wall of the rice soup collector is provided with a plurality of through holes; thethrough holes extend from the side wall of the rice soup collector to the flange; the collecting cavity is in communicationwith the rice cooking cavity via the through holes; and the length of the through holes in the height direction of the side wall is larger than the length of the through holes in the outward extending direction of the flange. According to the technical scheme of the present invention, the through holes are arranged in the side wall of the rice soup collector, the through holes extend to the flange of the rice soup collector, and the length of the through holes in the height direction of the side wall is larger than the length of the through holes in the outward extending direction of the flange, so that the amount of soup in the rice soup collector is effectively improved, and the effect of lowering the sugar is better.

Owner:JOYOUNG CO LTD

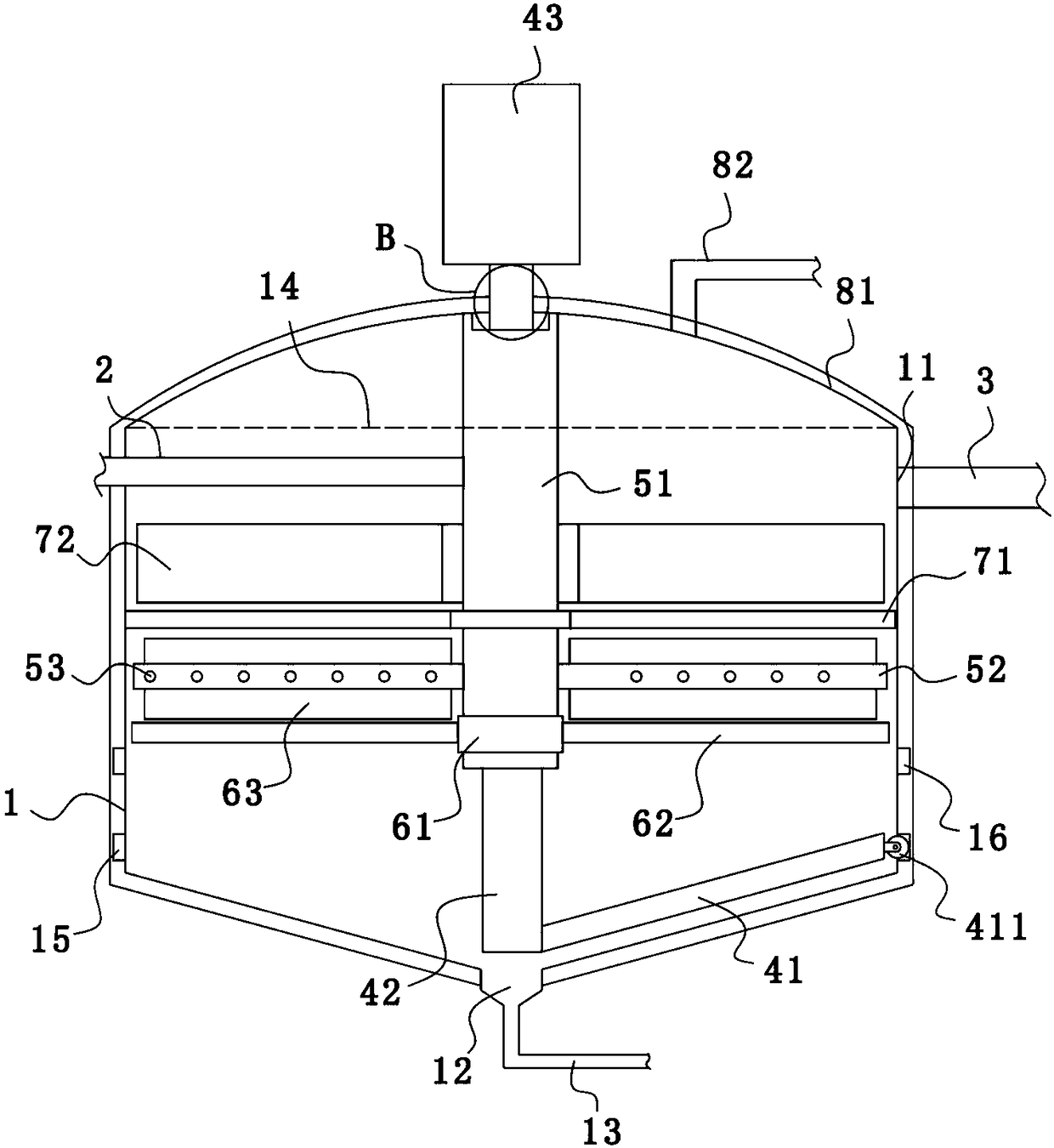

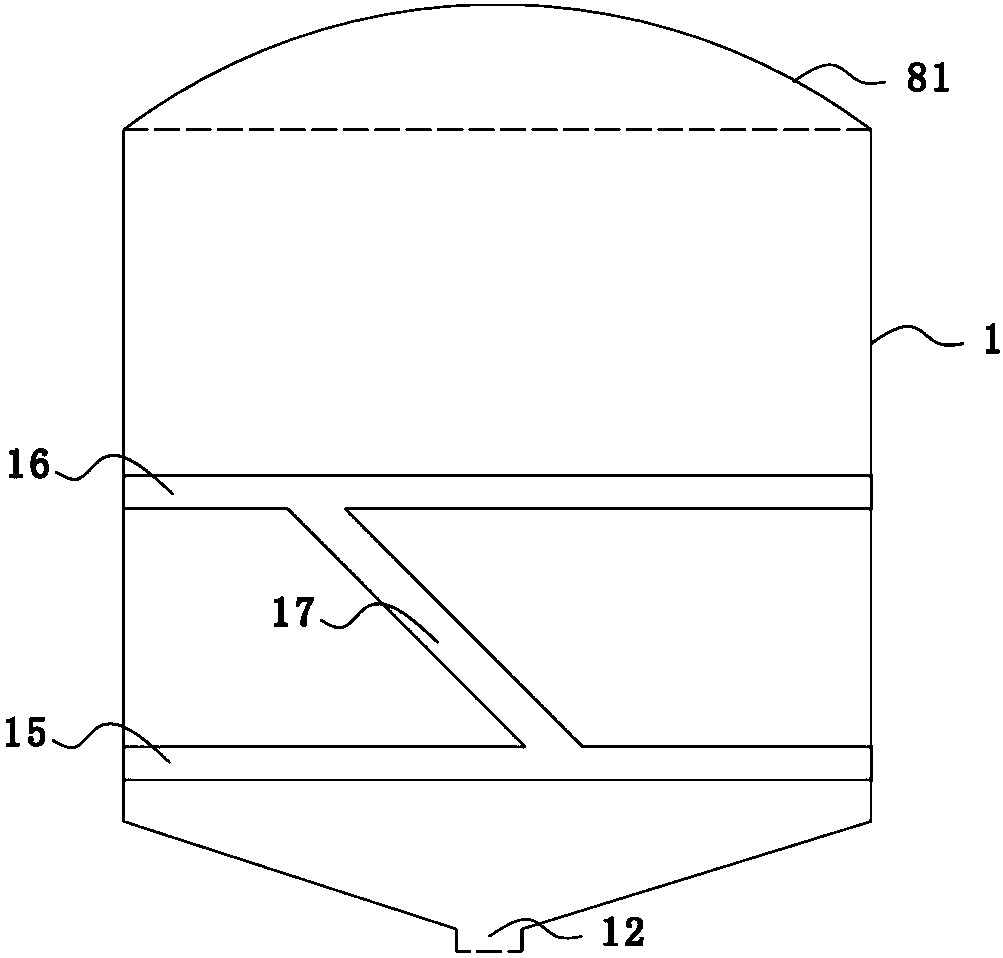

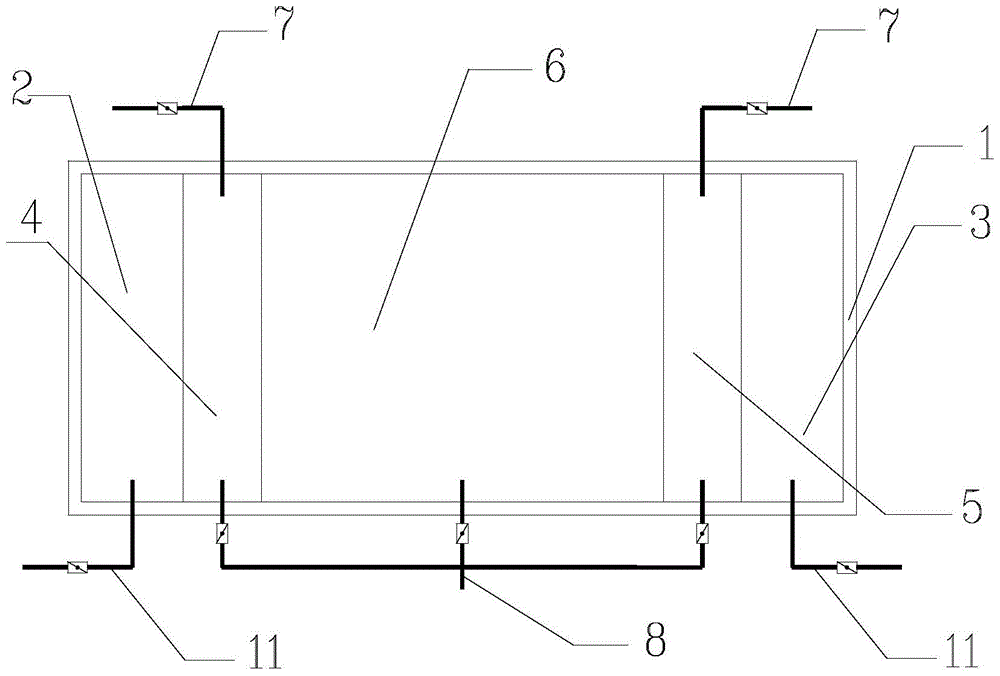

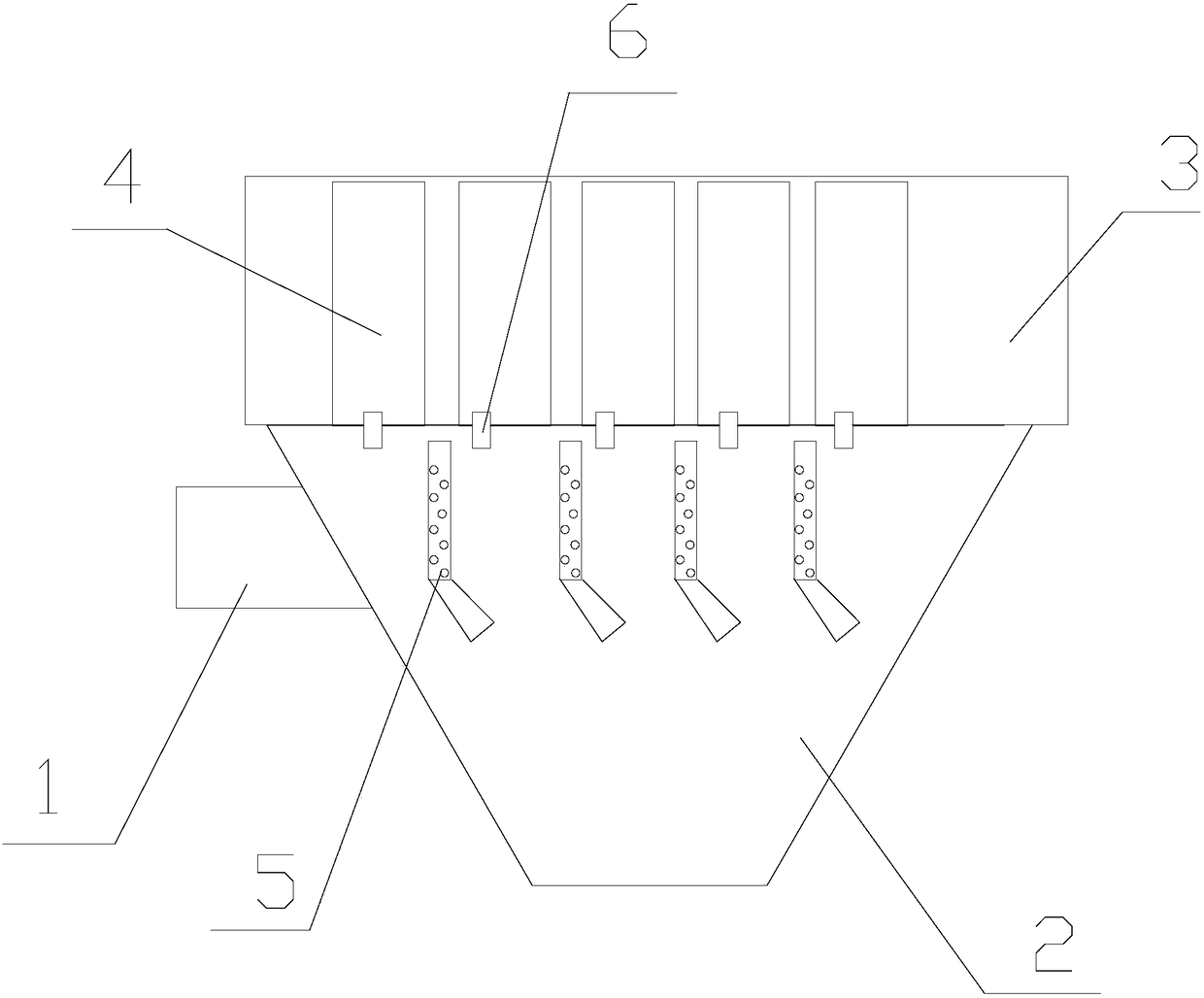

Novel sedimentation pool for sewage plant

ActiveCN108503135AAnaerobic digestion works wellFully contactedWater contaminantsTreatment with anaerobic digestion processesFirst FillFilling materials

The invention discloses a novel sedimentation pool for a sewage plant. The novel sedimentation pool comprises a pool body, a water inlet pipe, a water distribution unit, a biological filling materialunit, a mud scraping device, a gas recovery device and a water outlet pipe, wherein the water distribution unit, the biological filling material unit, the mud scraping device, the gas recovery deviceand the water outlet pipe are arranged in the pool body; the mud scraping device comprises a mud scraping rod arranged at the bottom surface of the pool body, a driving rod fixedly connected with themud scraping rod, a rotating driving element used for driving the driving rod to rotate and a second driving element used for driving the driving rod to vertically act; the water distribution unit comprises a center pipe, a plurality of water distribution pipes and spray heads arranged on the water distribution pipe; the biological filling material unit comprises a first filling material assembly;the first filling material assembly comprises a fixing sleeve, a plurality of filling material frames and a biological filling material; the filling material frames are distributed at intervals in the peripheral direction of the fixing sleeve; the biological filling material is arranged on the filling material frame. The sewage is in sufficient contact with the biological filling; the biologicalfilling has a good anaerobic digestion treatment effect on the sewage; the sewage deposition quantity is reduced; the frequent mud scraping operation is not needed; the energy is saved; the environment is protected; the abrasion of the mud scraping component is small; the service life is long.

Owner:SHAOXING HEQIAO JIANGBIN WATER TREATMENT

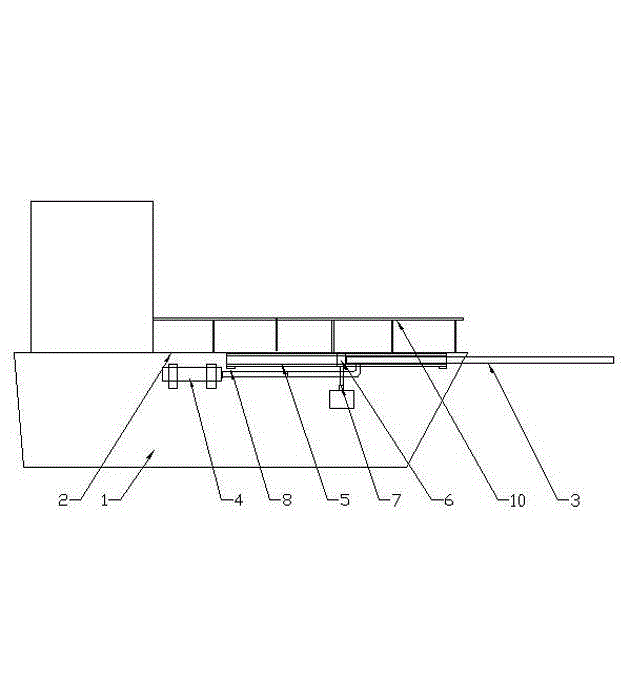

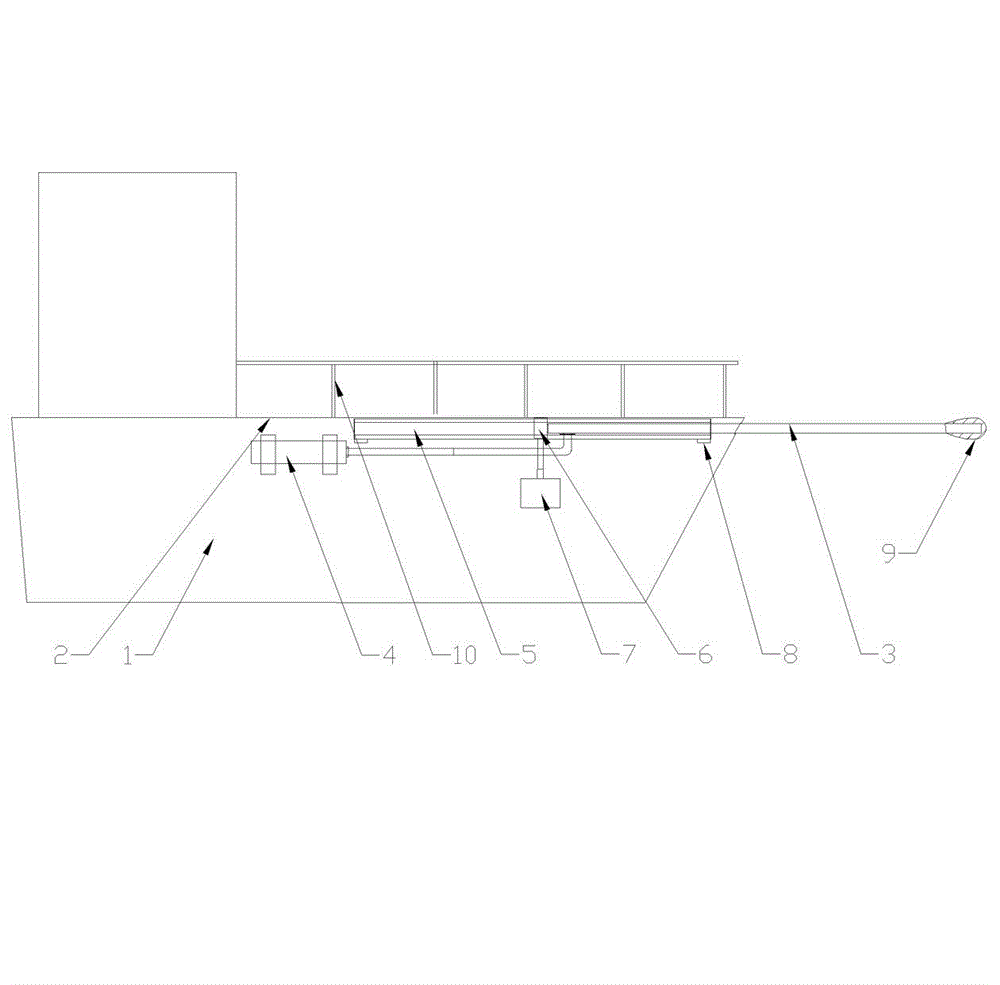

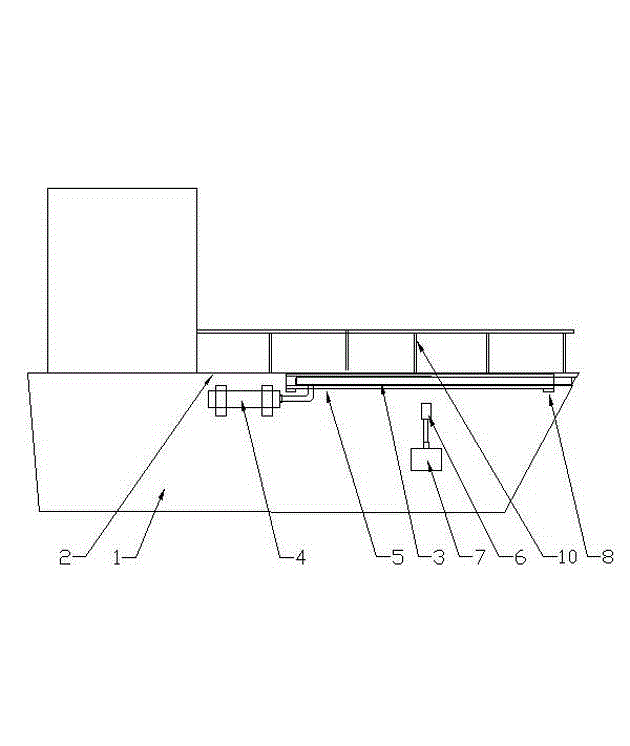

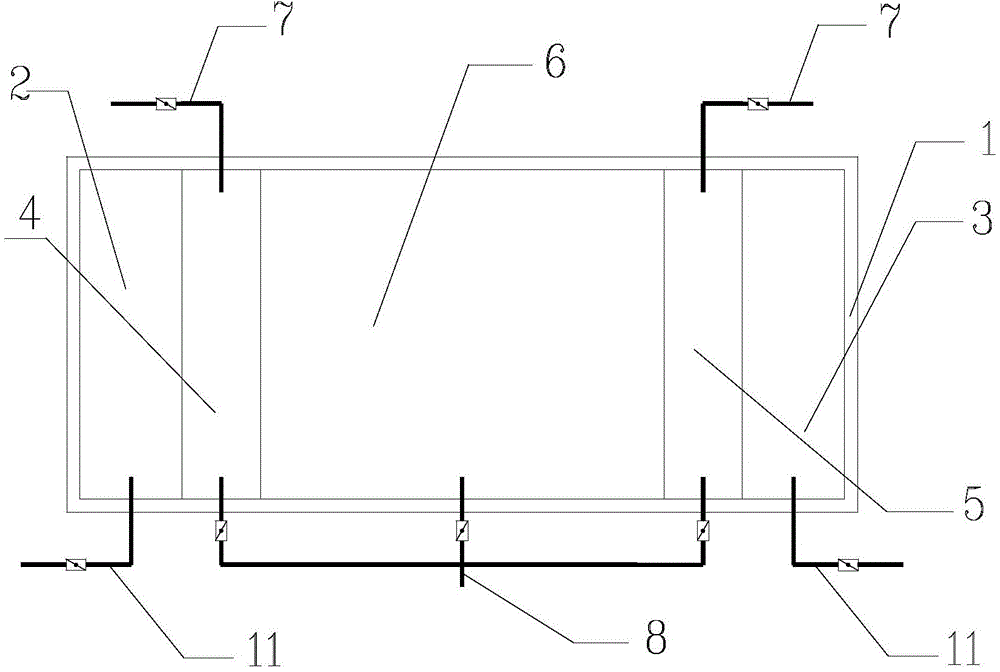

Ship with retractable installation

The invention discloses a ship with a retractable installation, the appearance of which can be kept attractive and which is safe to use and convenient to operate. The ship with the retractable installation comprises a ship body (1) and a deck (2), the retractable installation is arranged at a position upon and under the deck (2) and clings to the deck (2), the retractable installation comprises a retractable plate (3) and a push-pull mechanism (4), and the retractable plate (3) comprises a working station and a retracted station; at the working station, the push-pull mechanism (4) drives the retractable plate (3) to extend out of the ship body (1); and at the retracted station, the retractable plate (3) is retracted and located upon or under the deck (2). The invention can be applied to the field of ships.

Owner:ZHUHAI TIANYUE TECH

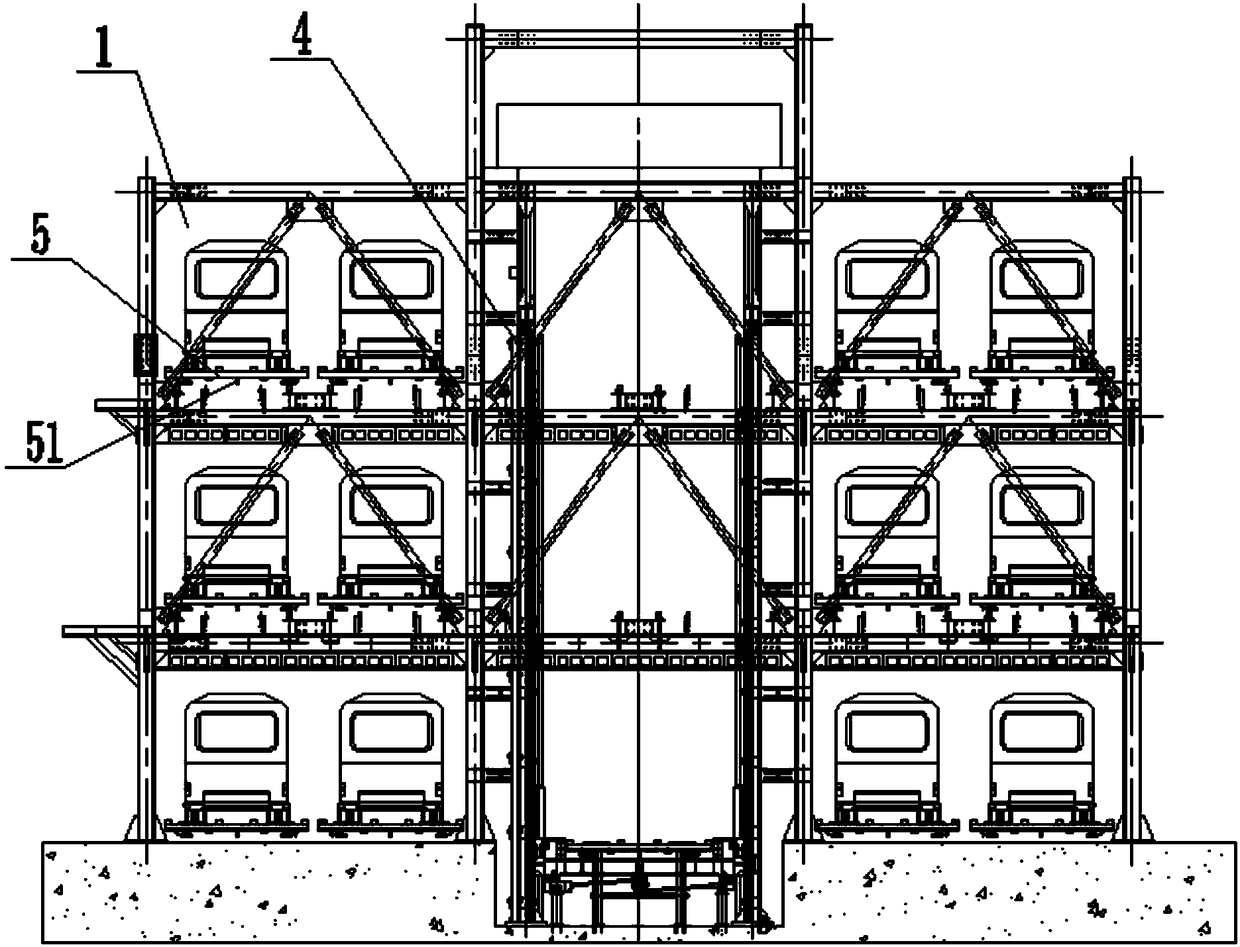

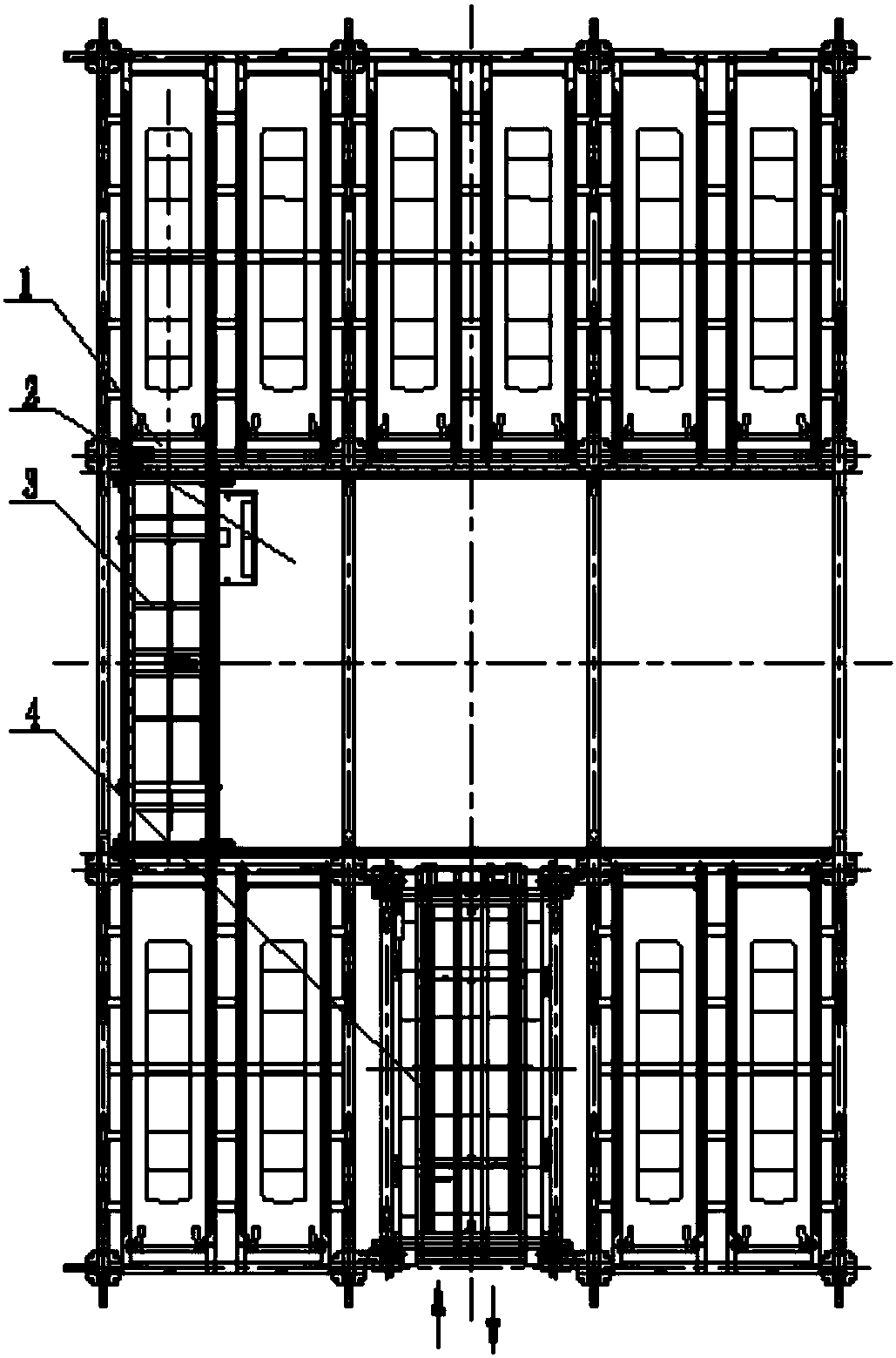

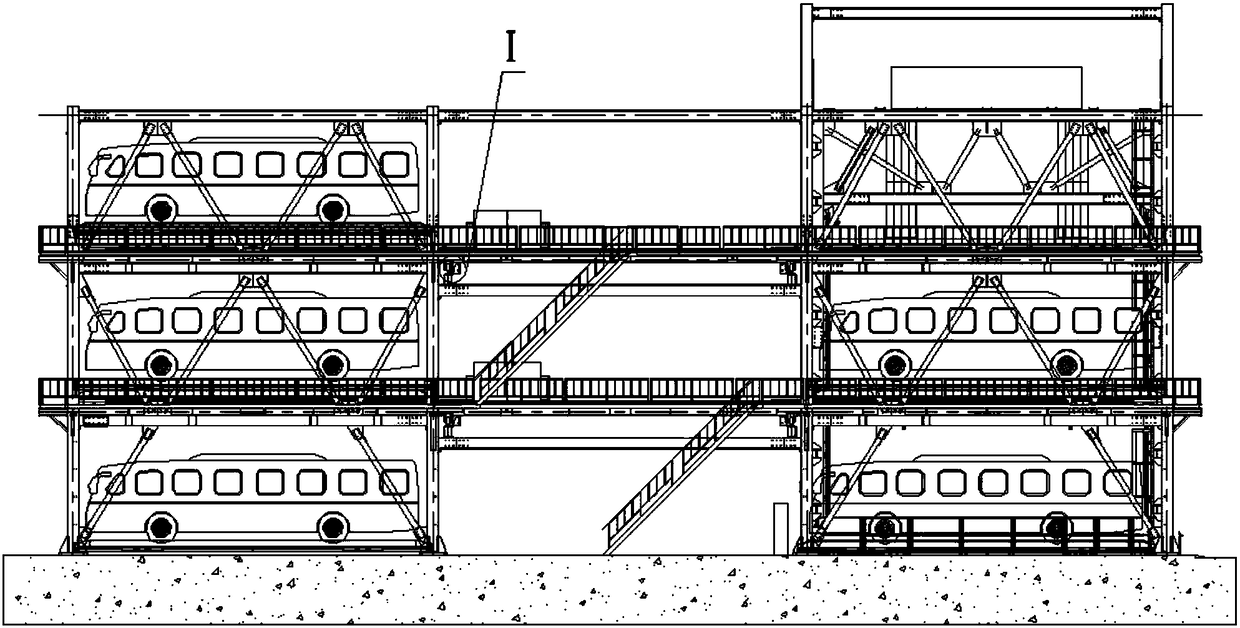

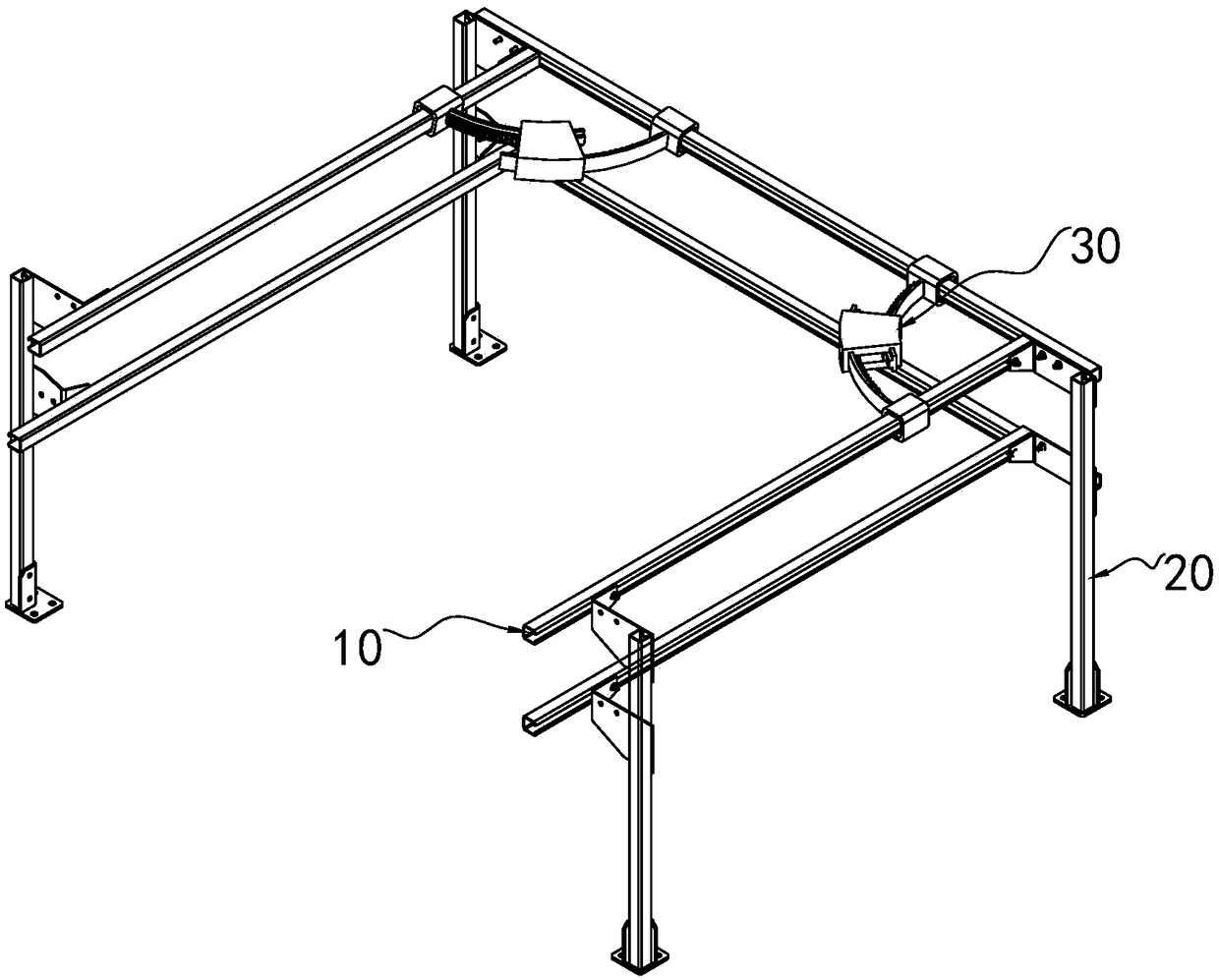

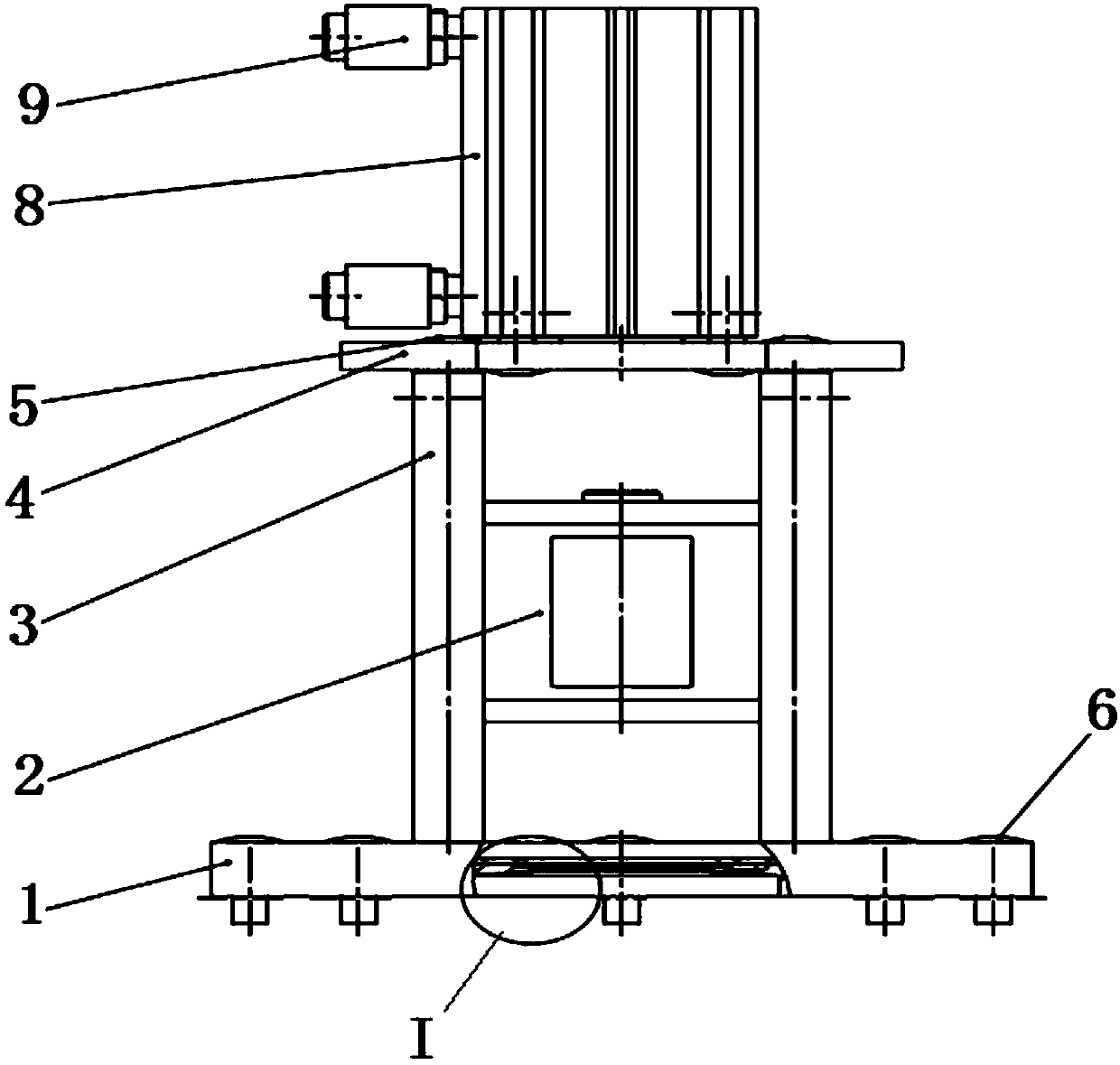

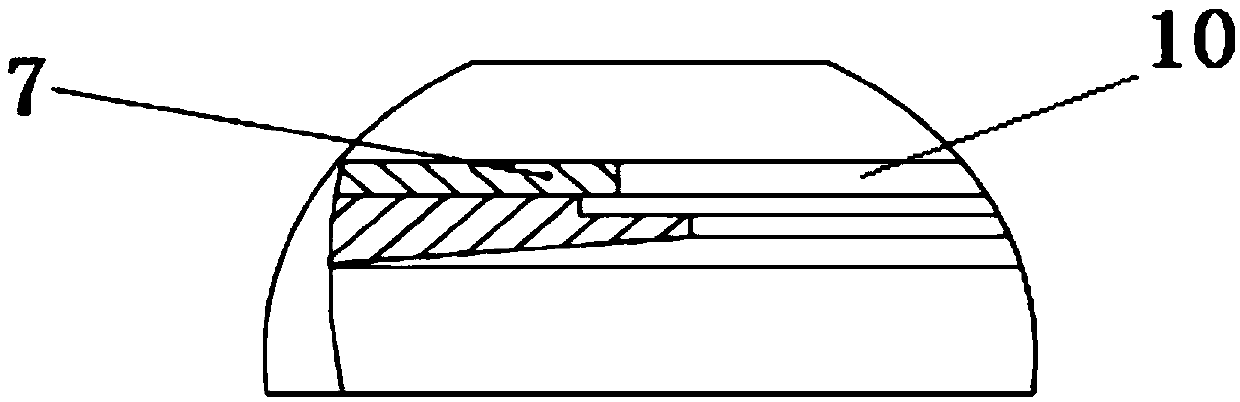

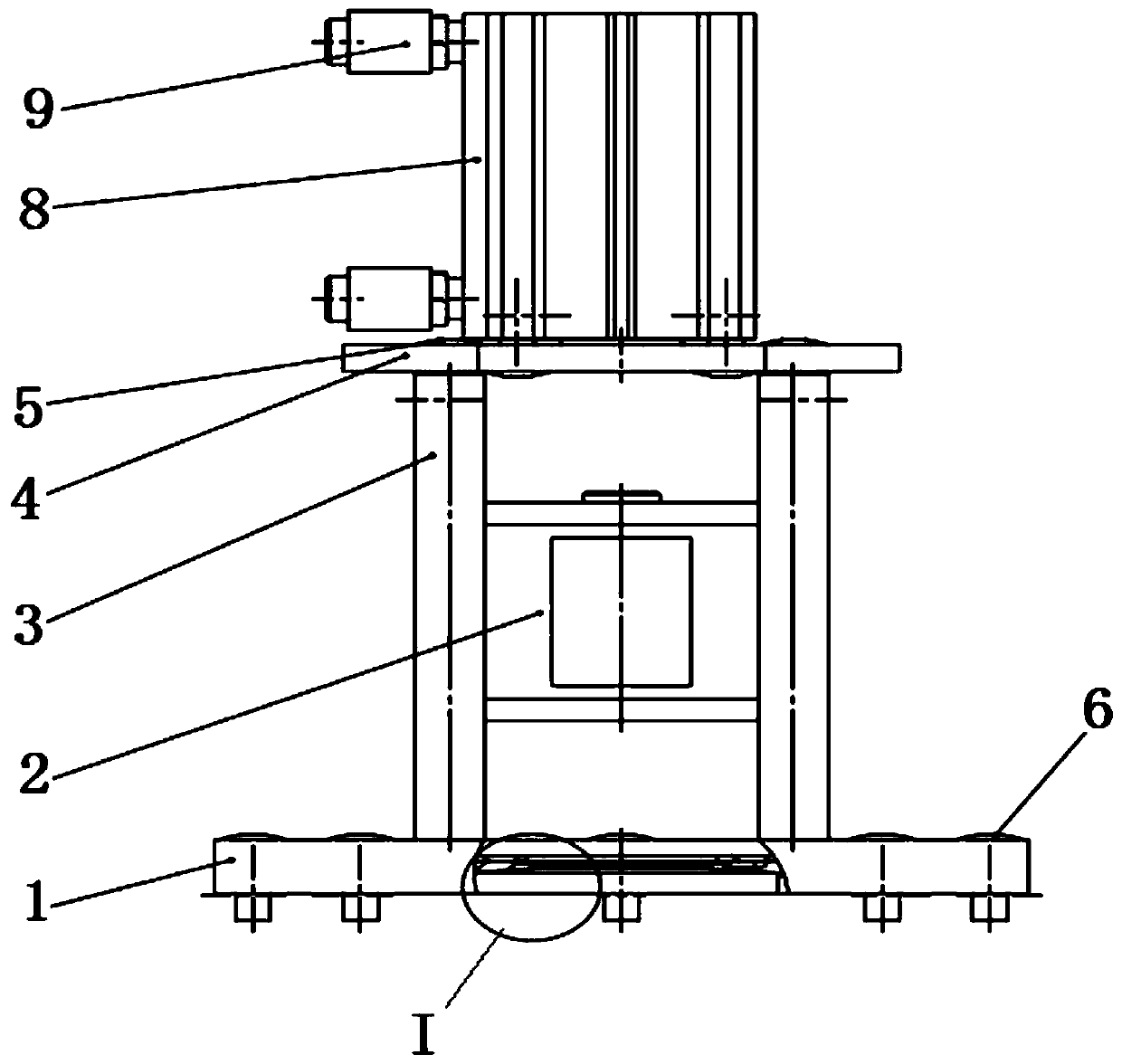

Mechanical three-dimensional parking garage

PendingCN108487749AEasy accessImprove shipping efficiencyCharging stationsElectric vehicle charging technologyAutomotive engineeringEngineering

The invention belongs to the technical field of parking equipment, and relates to a mechanical three-dimensional parking garage. The problems that an existing parking garage cannot meet the requirements that vehicle parking and charging at the same time, or the parking and taking efficiency is low, and the vehicle has great impact on a lifter are solved. The garage comprises a garage control system and a plurality of parking units. The parking units are of floor structures. Each floor above a second floor comprises a conveyor and two rows of parallel parking spaces. The conveyor is located ina lane between the two rows of parking spaces. The layout of a first floor is the same as that of the second floor, or is a plane parking space. Each parking unit further comprises lifters, vehicle-carrying boards and a vehicle entrance and exit, wherein the lifters are arranged in each row of parking spaces; the number of the vehicle-carrying boards is equal to the number of parking spaces; and the vehicle entrance and exit are arranged at the position of the lifter on the first floor. The conveyor comprises a frame, a walking device and a parking and taking device, wherein the walking deviceenables the conveyor to move in the length direction of the lane, and the parking and taking device is used for carrying the vehicle-carrying boards and the vehicles. Charging mother parts are arranged on the parking spaces, charging son parts are arranged on the vehicle-carrying boards, the charging son parts are connected with charging guns; and a pit is arranged under the lifter, and supporting columns of the vehicle-carrying boards are arranged in the pit.

Owner:陕西隆翔特来电充电科技有限公司

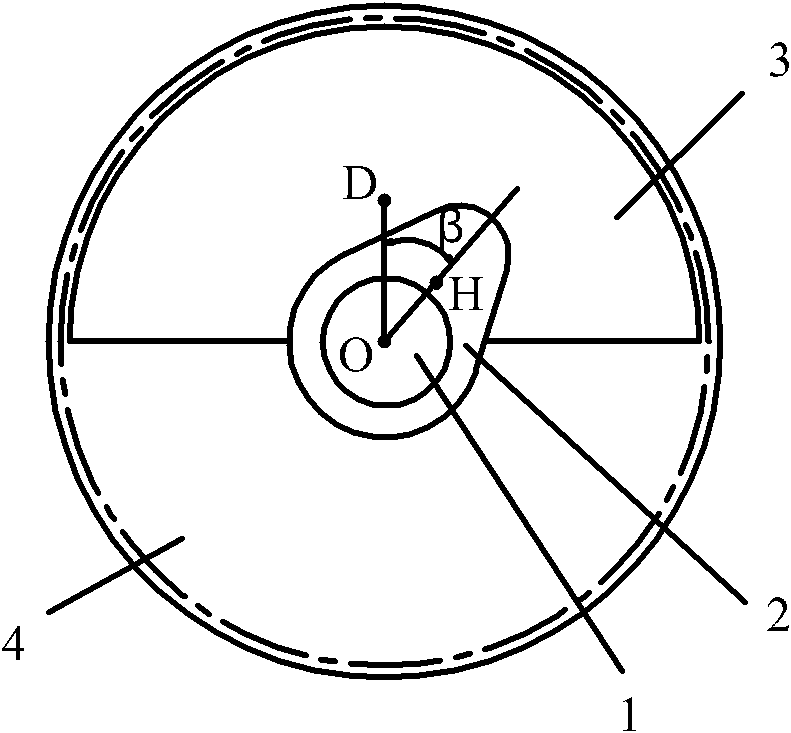

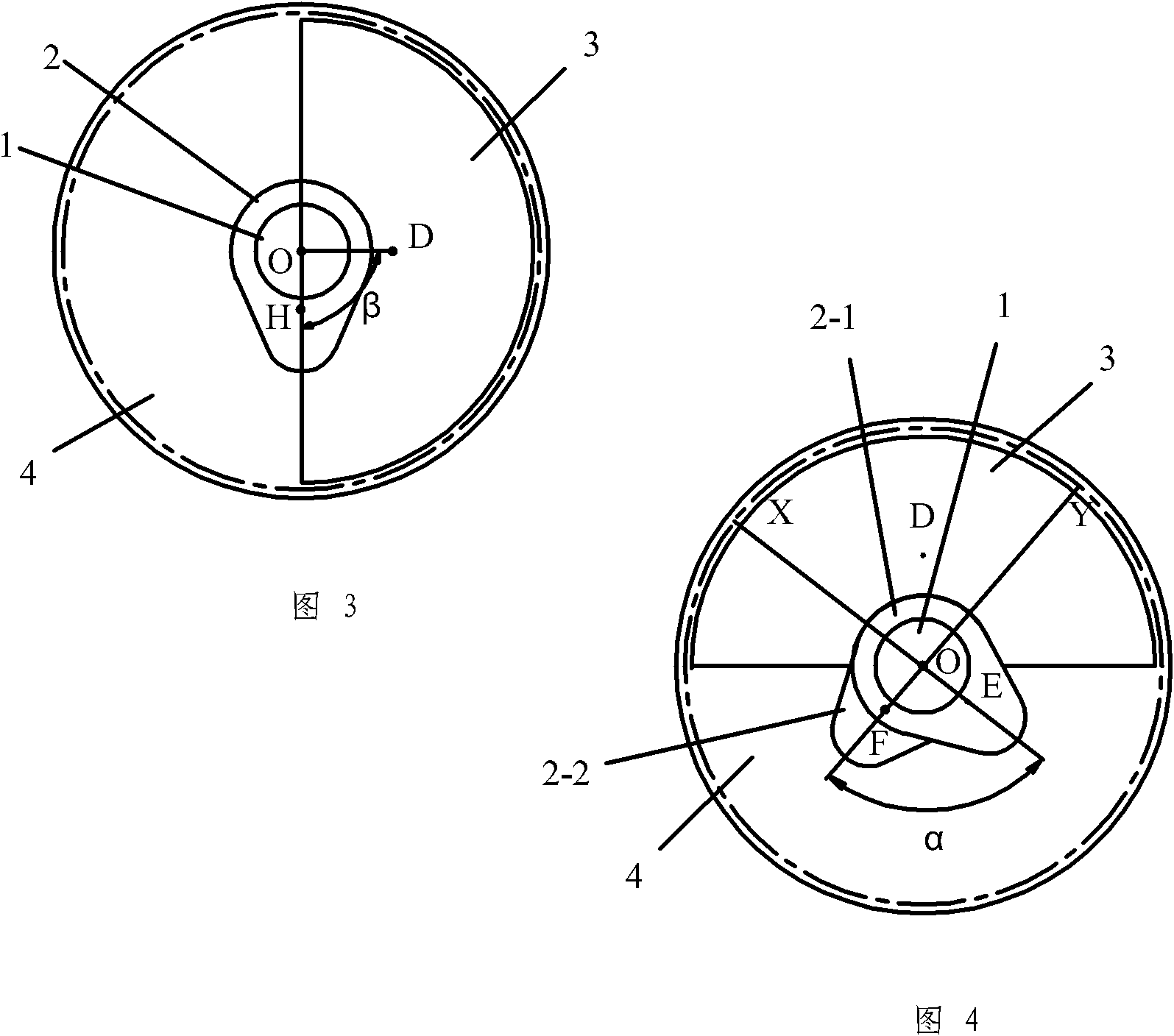

Low-vibration energy-saving air distribution camshaft of engine of motor vehicle

InactiveCN102032007AIncrease the moment of inertiaOpen and close smoothlyValve arrangementsMachines/enginesInternal combustion engineCam

The invention discloses a low-vibration energy-saving air distribution camshaft of an engine of a motor vehicle, and relates to an air distribution camshaft of an internal combustion engine of a motor vehicle. The camshaft is used for the engine of the motor vehicle. The camshaft overcomes the defects of high air valve switching vibration and high noise caused by unsmooth entrance in the air valve switching process due to the variable acceleration rotation of a crankshaft. The camshaft comprises a shaft body, an air distribution cam and a power transmission wheel; the air distribution cam and the power transmission wheel are fixed on the shaft body and coaxially rotate with the shaft body; the camshaft also comprises an eccentric disc body; the eccentric disc body is arranged on the shaft body, and the surface of the eccentric disc body is vertical to the shaft body; and in the circumference direction of the shaft body, the connecting line of the mass center of the eccentric disc body and the shaft body deviates from the connecting line of the mass center of the air distribution cam and the shaft body. The tension of an air valve spring can be adjusted to be better moderate so as to facilitate the reduction of power consumption of the engine and achieve the effects of saving oil, balancing the impact force of the crankshaft, reducing the vibration of the engine and improving the output torque and power.

Owner:李云合

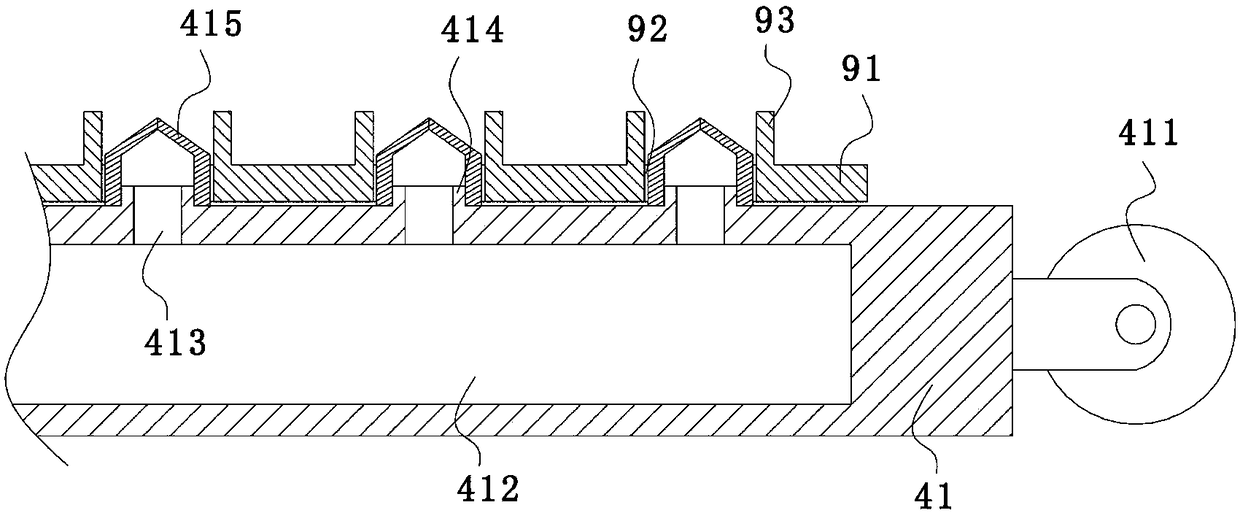

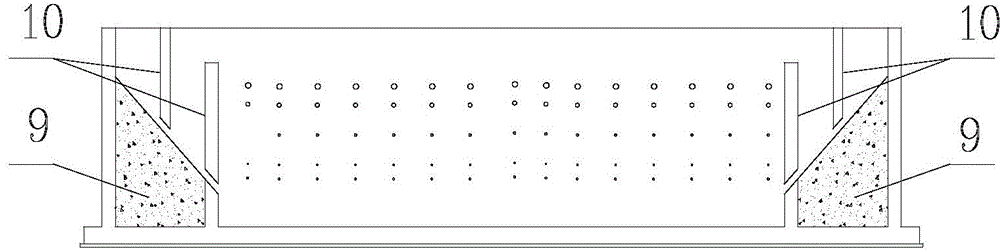

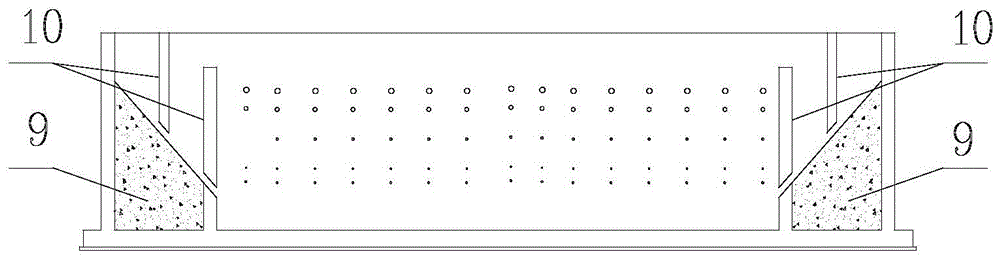

Alternate plug flow aerobic biological fluidized bed reactor

ActiveCN104876326ACause blockageIncrease contact surfaceTreatment using aerobic processesSustainable biological treatmentFluidized bedDistribution system

The invention discloses an alternate plug flow aerobic biological fluidized bed reactor which comprises a reaction tank, wherein the interior of the reaction tank is divided into a settling zone A and a settling zone B propped against two side walls, a multifunctional zone A close to the settling zone A, a multifunctional zone B close to the settling zone B, and an aerobic fluidized bed reaction zone between the multifunctional zone A and the multifunctional zone B; aerating systems are arranged at the bottoms of the interiors of the multifunctional zone A and the multifunctional zone B; water distribution systems are arranged at the tops of the interiors of the multifunctional zone A and the multifunctional zone B; another aerating system is arranged at the bottom of the aerobic fluidized bed reaction zone, and a biocarrier loaded with aerobic bacteria is distributed in the aerobic fluidized bed reaction zone; a mud guard wall and fenders are arranged in each of the settling zone A and the settling zone B; a water outlet is formed in the bottom of each of the settling zone A and the settling zone B. The alternate plug flow aerobic biological fluidized bed reactor increases the contact area between microorganism and waste water, and is excellent in treatment effect, small in occupied area and low in energy consumption.

Owner:JIANGSU ZHONGMEI HUACHAO SCI & TECH ENVIRONMENTAL PROTECTION CO LTD

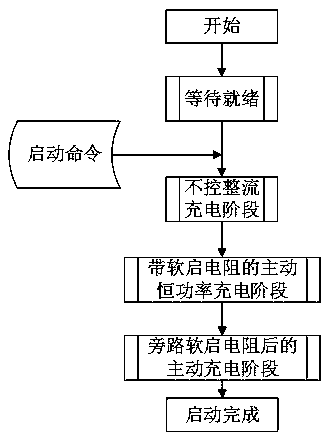

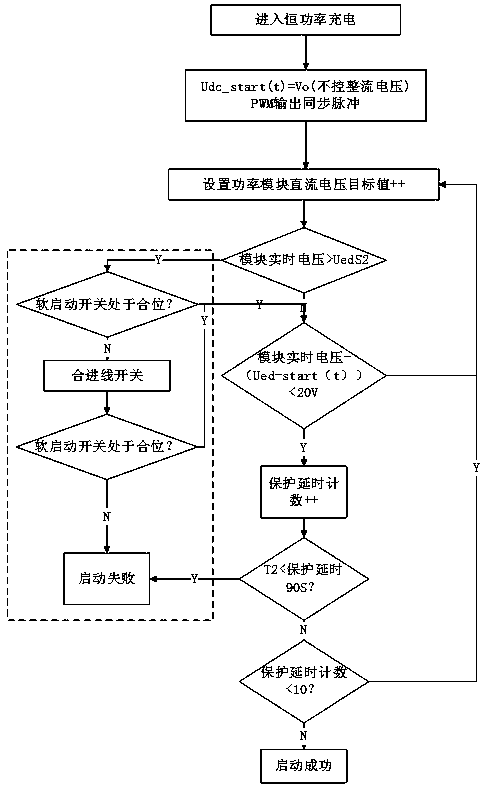

Method for starting high-voltage SVG and ice melting device with low impact current

ActiveCN108667038AReduce the impact of starting currentReduce shockOverhead installationFlexible AC transmissionElectrical resistance and conductanceConstant power

The invention relates to a method for starting a high-voltage SVG and ice melting device with low impact current. The method is characterized by comprising three stages of (1) an uncontrolled rectifying stage; (2) an active constant-power charging stage with a starting resistor; and (3) an active charging stage after bypassing a soft starting resistor. According to the method, the current limitingfunction of the starting resistor of a soft starting switch cabinet is fully utilized under the condition of not changing original hardware equipment, starting current impact of the high-voltage SVGand ice melting device is reduced, the starting time is shortened and the stability of a power grid is improved.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

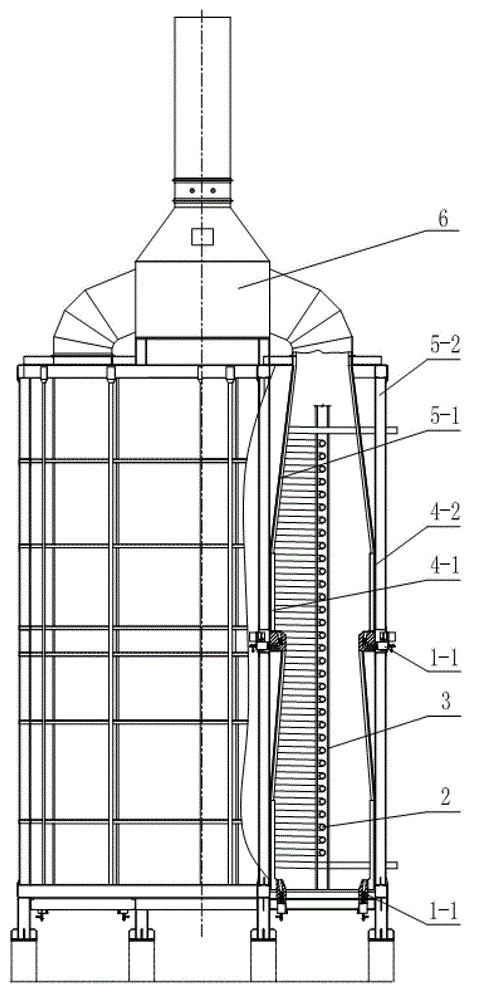

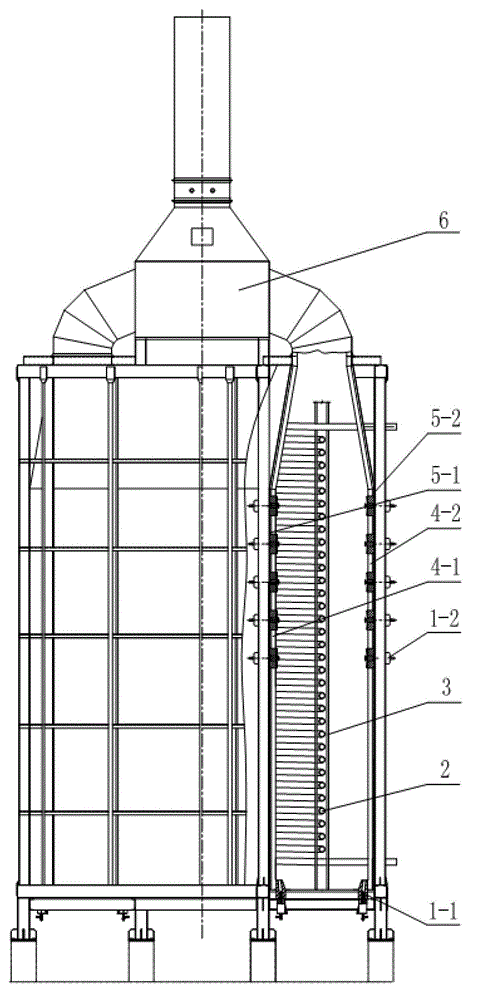

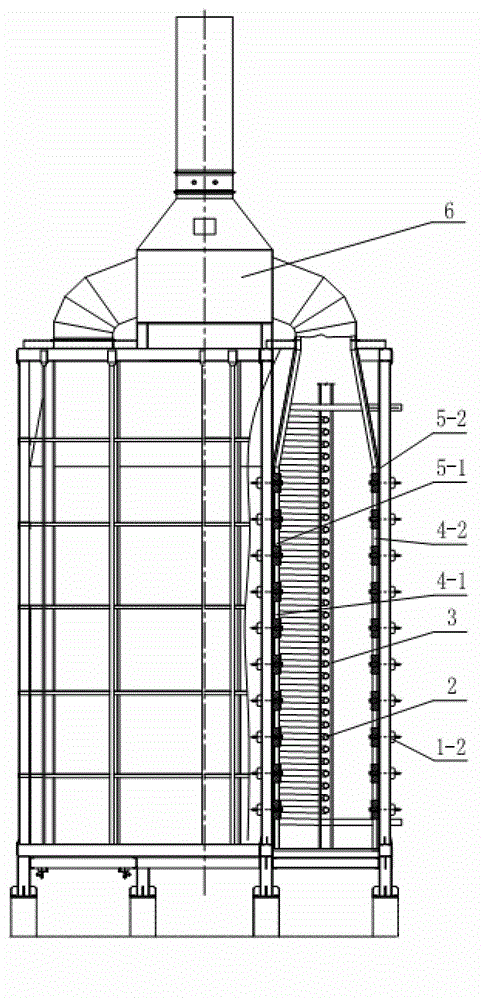

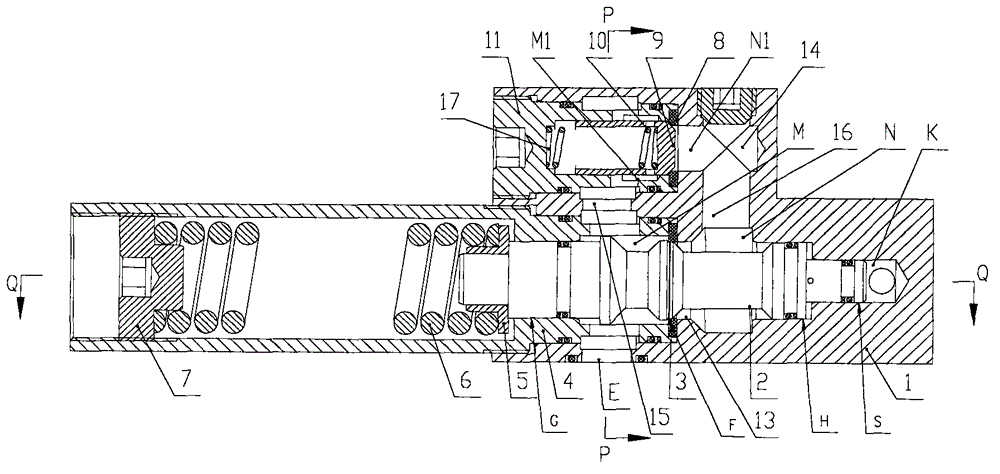

Double-sided radiation spiral pipe heating furnace

The invention relates to the technical field of tube heating furnaces for petroleum refining, petrochemical industry and coal chemical industry, particularly to a double-sided radiation spiral pipe heating furnace which comprises a steel framework, an outer ring radiation wall, a spiral pipe, an inner ring radiation wall and a flame combustor, wherein the outer ring radiation wall is attached inside the steel frame, the spiral pipe is positioned on the inner side of the outer ring radiation wall; the inner ring radiation wall is positioned on the inner side of the spiral pipe; and the flame combustor heats for enabling the inner ring radiation wall and the outer ring radiation wall to reach a high temperature to form radiations, and then the inner ring radiation wall and the outer ring radiation wall supply heat to the spiral pipe in a double-sided radiation mode. The double-sided radiation spiral pipe heating furnace can heat furnace pipes evenly, improve average heat strength of radiations of the furnace pipes, save cost, shorten the hydraulic length of the furnace pipe, increase the flow speed of medium inside the pipes, and avoid cock inside the pipes. Meanwhile, abrasions caused by high solid content medium inside the pipes to the inner walls of bending pipes can be avoided, and potential risks caused by the abrasions can be eliminated.

Owner:BEIJING PETROCHEM ENG

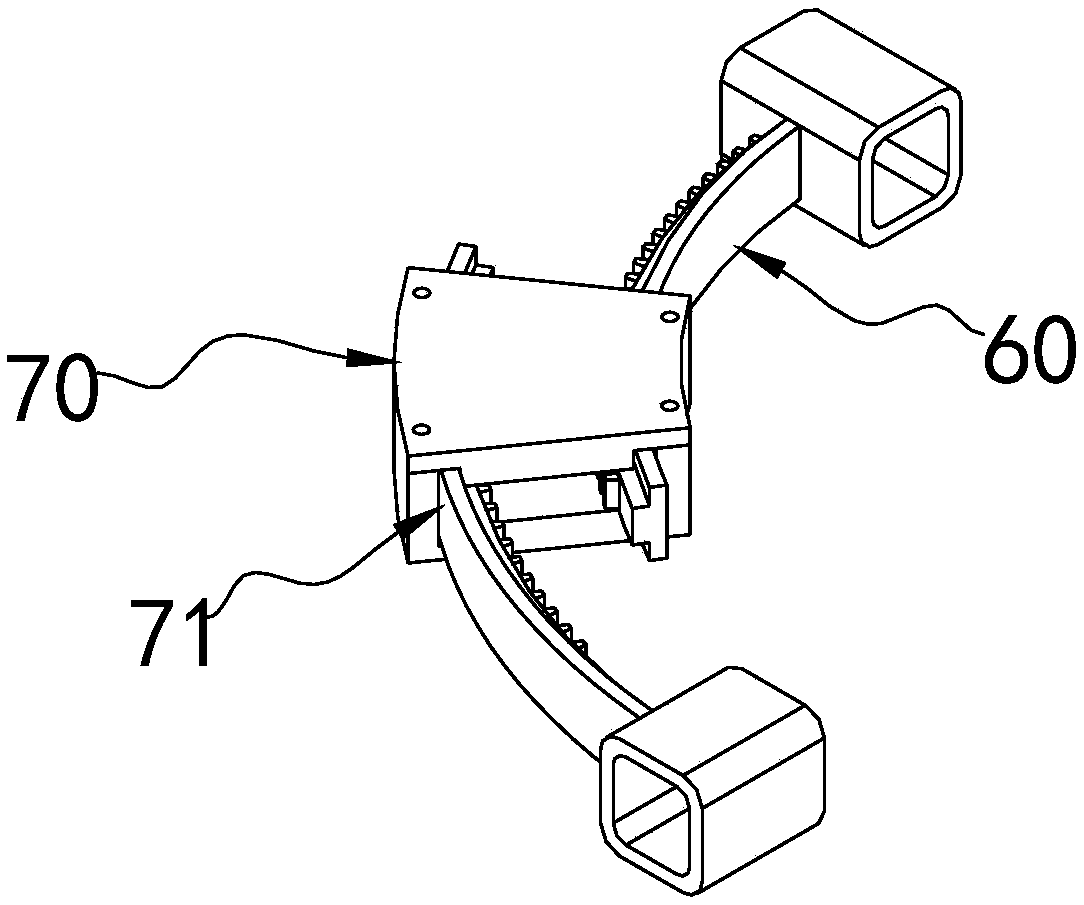

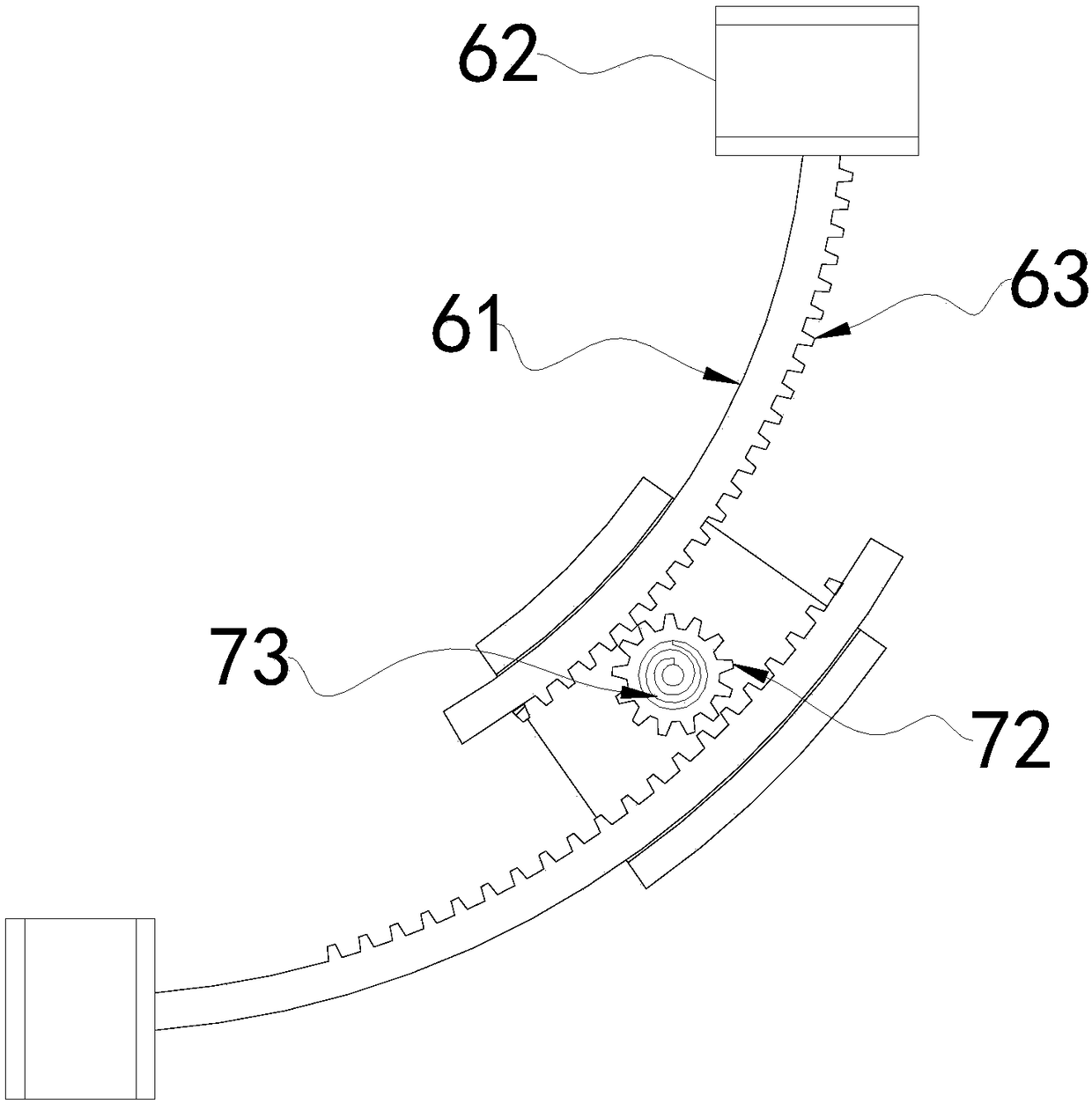

Anti-impact elevator car ceiling guardrail

The invention discloses an anti-impact elevator car ceiling guardrail. The anti-impact elevator car ceiling guardrail comprises U-shaped horizontal guard bars. The guard bars are connected with standcolumns fixed to a car ceiling. A buffer device is arranged at the joint of every two guard bars. Each buffer device comprises two resisting arms and a limiting box. Each resisting arm comprises an arc-shaped strip with the T-shaped cross section, the end of the arc-shaped strip is provided with a sliding sleeve arranged on one side guard bar or the rear guard bar in a sleeving mode, and the arc-shaped strip is provided with a rack. Each limiting box is provided with an arc-shaped groove in sliding fit with the corresponding arc-shaped strip. Each limiting box is internally provided with a gear matched with the corresponding racks. A clockwork spring is arranged at the junction between each gear and the corresponding limiting box. The anti-impact elevator car ceiling guardrail has the characteristics of being high in structural strength and good in impact resistance. Besides, the anti-impact elevator car ceiling guardrail is concise and stable in structure, simple in manufacturing process and low in cost.

Owner:湖州安讯达电梯科技有限公司

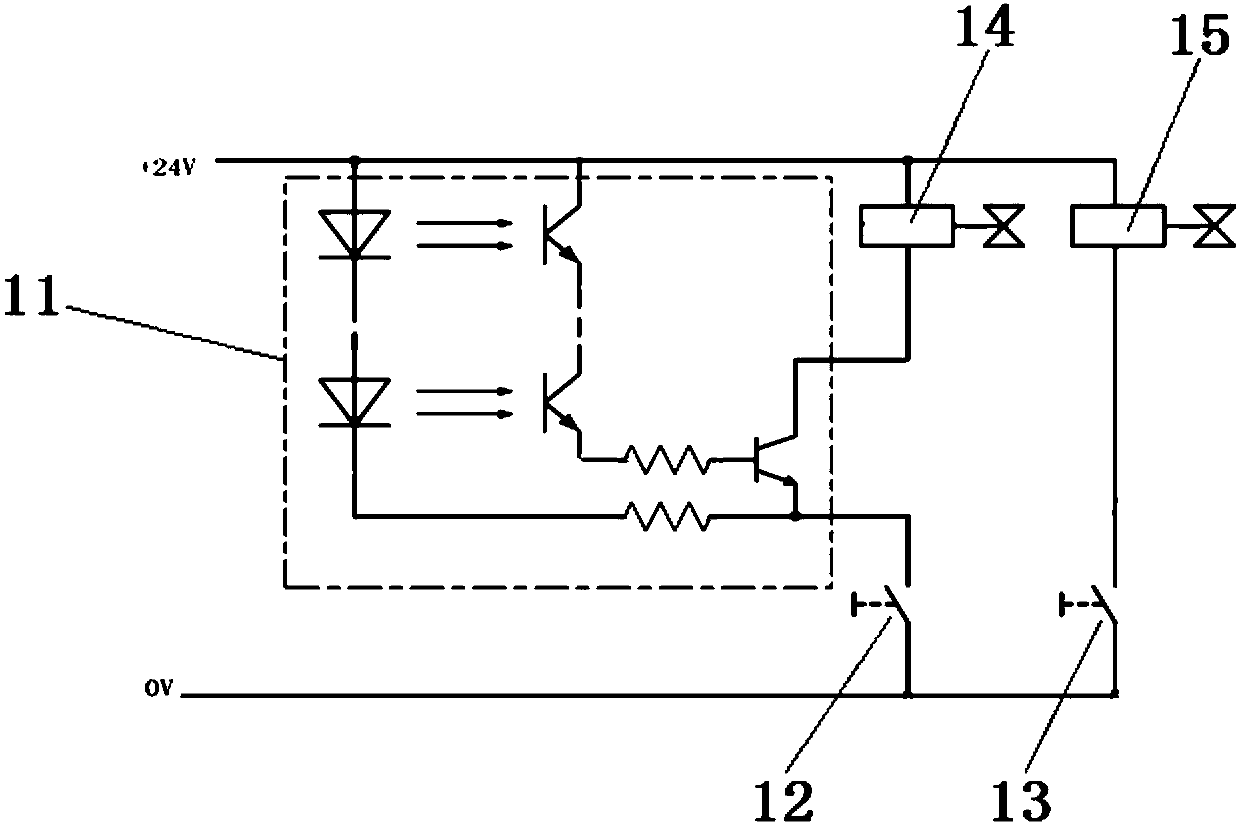

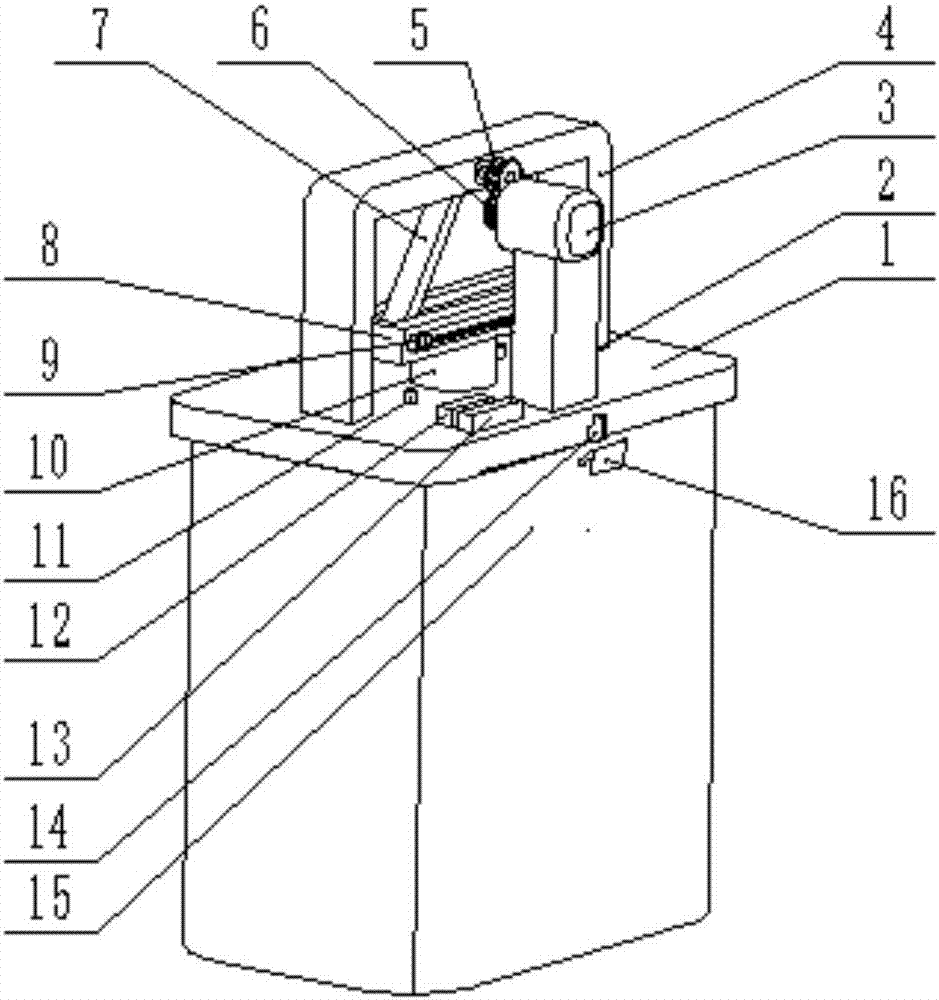

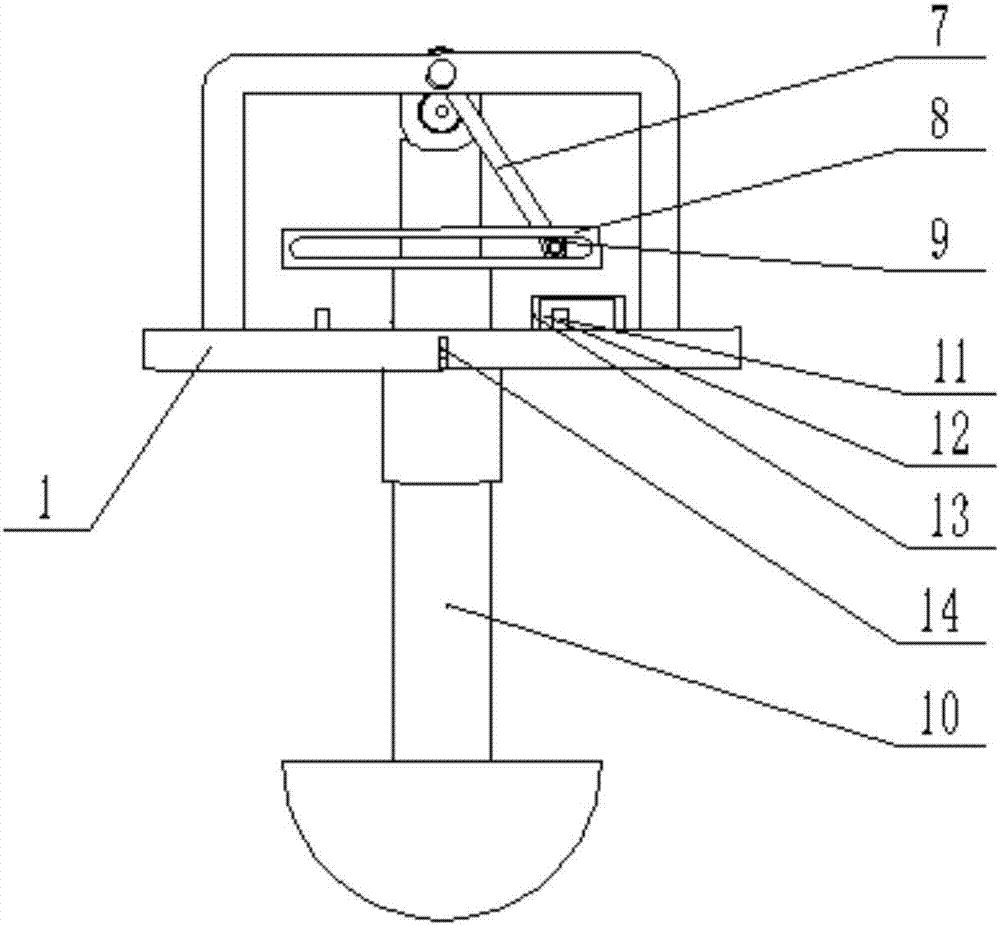

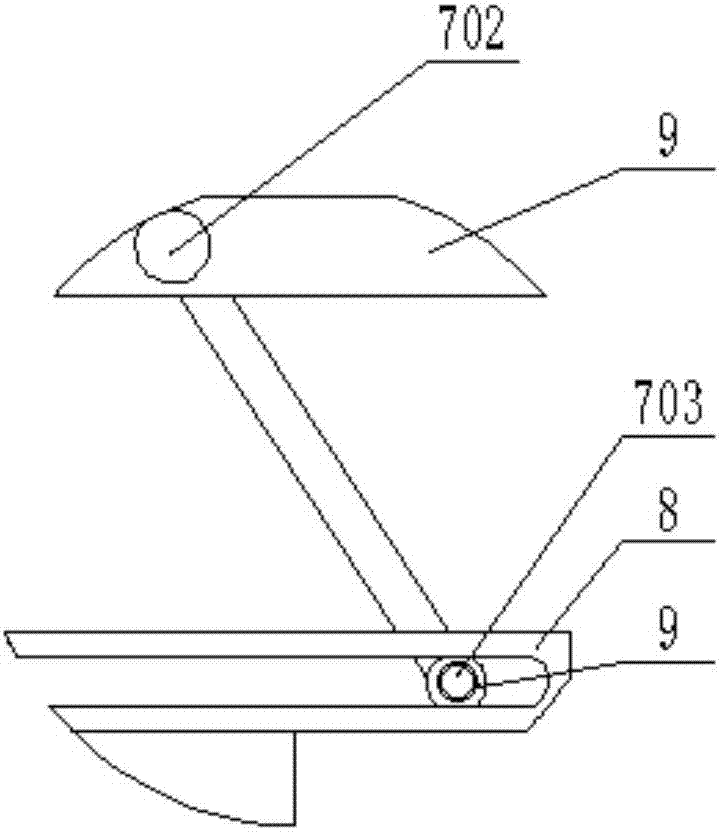

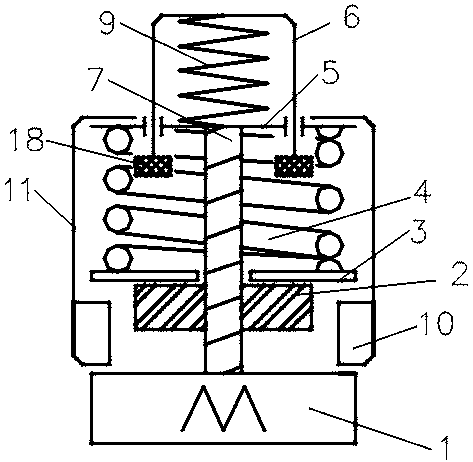

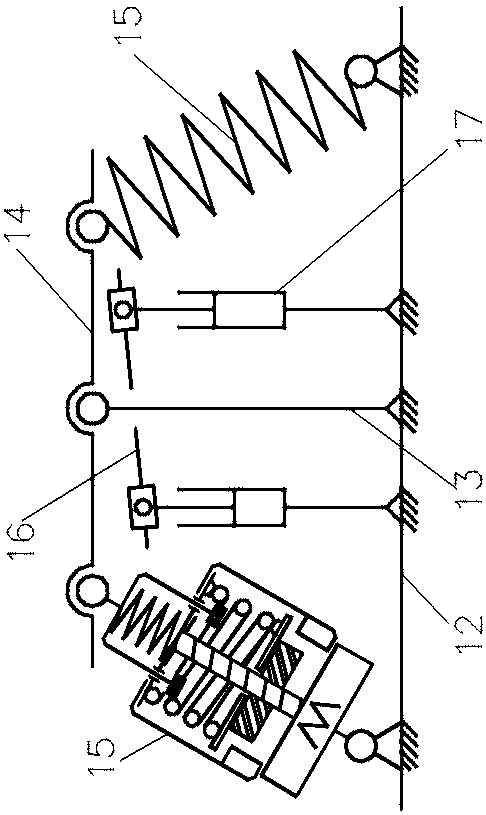

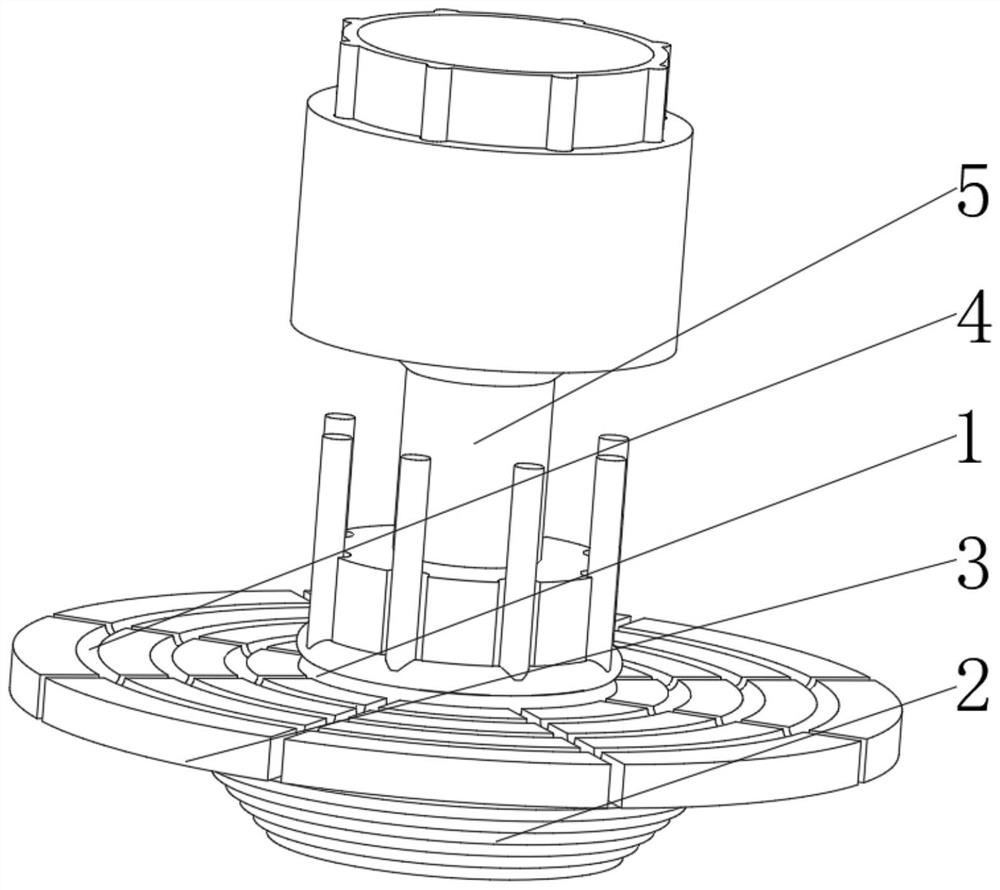

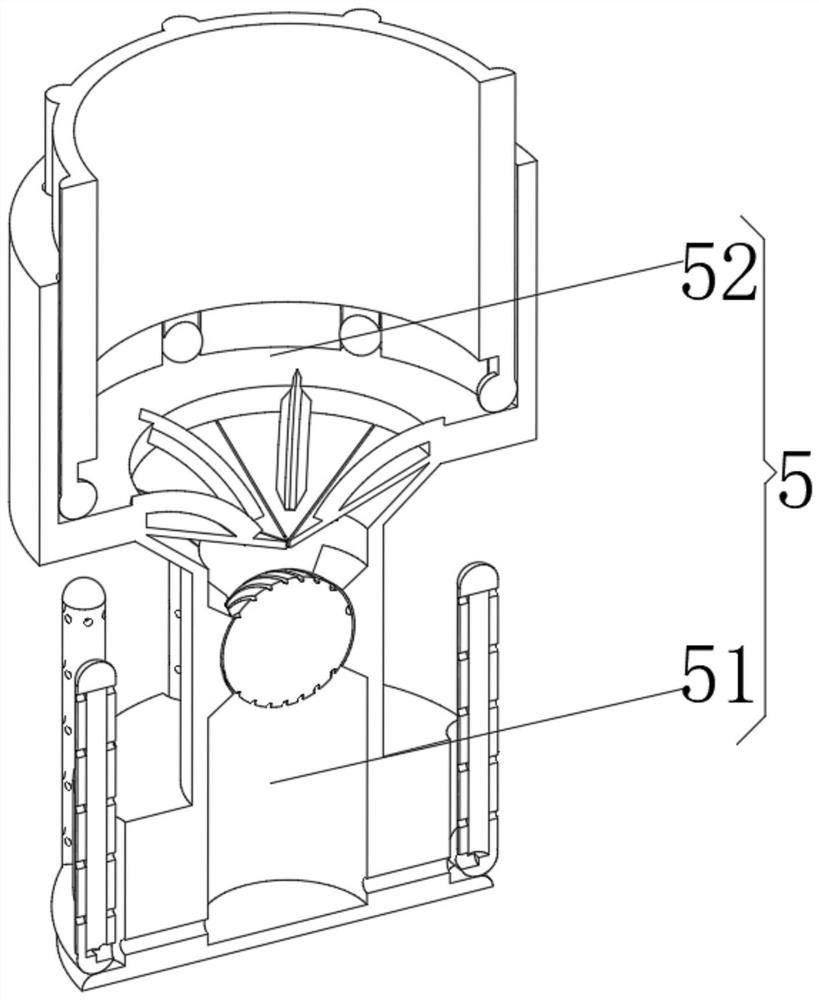

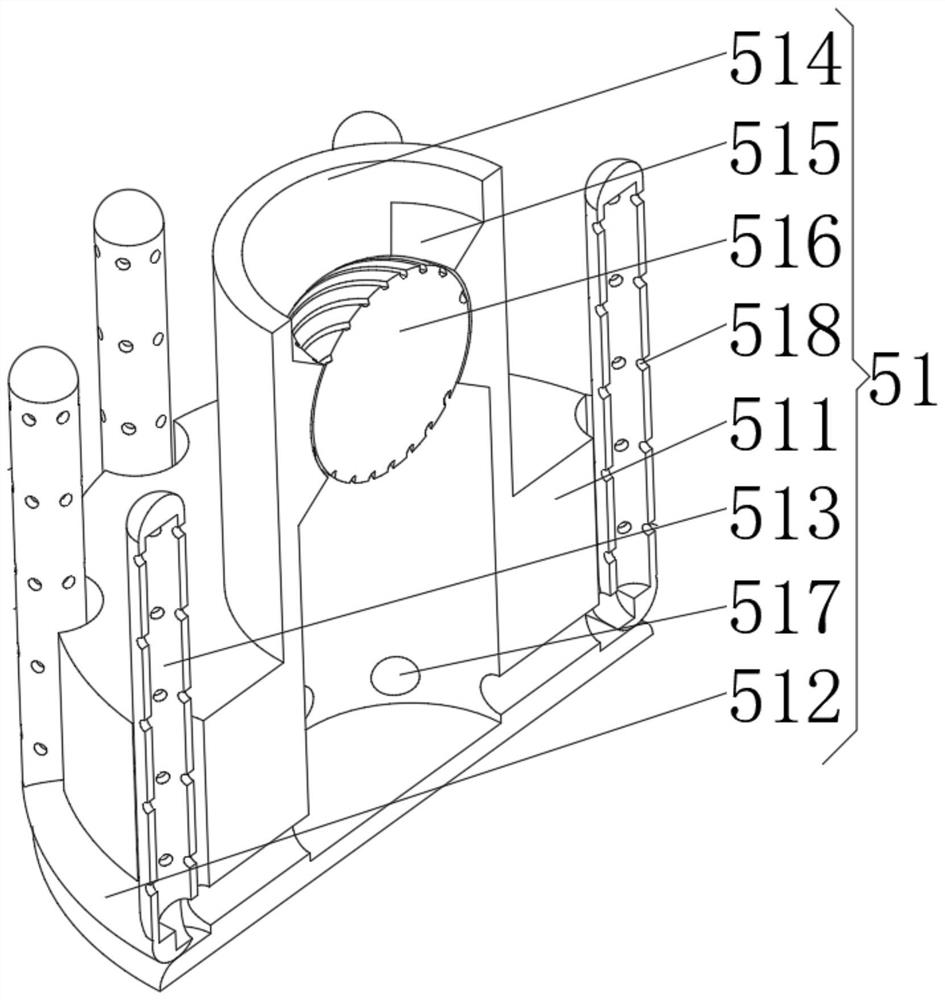

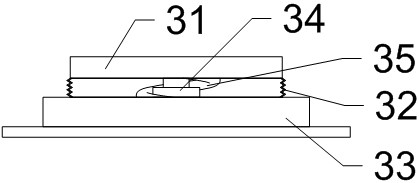

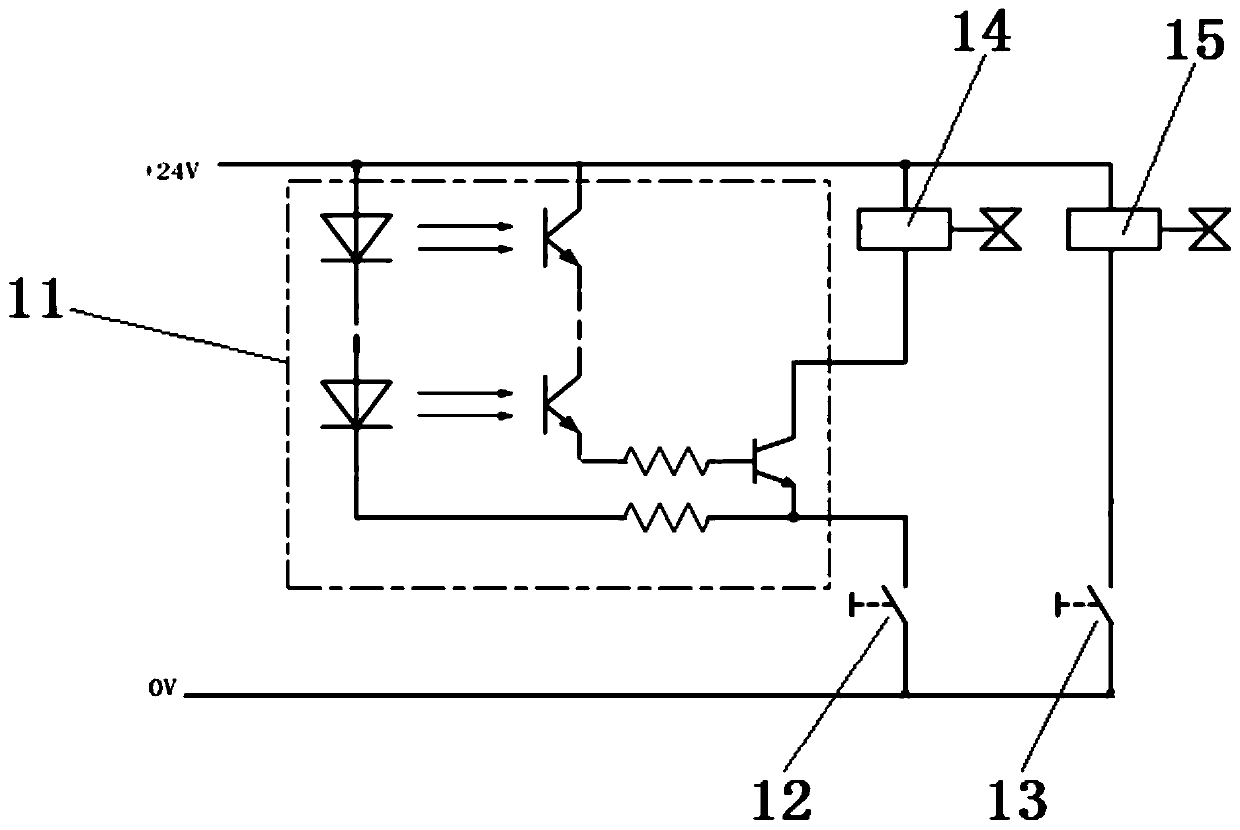

Swirler airflow test tool holddown gear

ActiveCN107782544ACompact structureTight controlMachine part testingEngine testingAirflowEngineering

The invention discloses a swirler airflow test tool holddown gear comprising a tool mount body with a disc structure; the middle of the tool mount body is provided with a cavity used for mounting thetest tool; a seal pad is arranged in the cavity; the tool mount body is connected with a cylinder bearer through a plurality of poles; a cylinder is arranged on the cylinder bearer; a compact cavity is arranged between the plurality of poles, and arranged right above tool mount body cavity; a control circuit controlling the cylinder to open / close is provided, and comprises a compact switch controlling the cylinder to move downwards, and a first solenoid valve connected with the compact switch; the control circuit also comprises a loose switch used for controlling the cylinder to move upwards,and a second solenoid valve connected with the loose switch; the first and second solenoid valves are respectively connected with the air inlet of the cylinder through a cylinder current limiter; thedevice is reliable in sealing, can conveniently and fast clamp the test tool, and safe and reliable, thus preventing the experiment data inaccurate problems caused by gas leakage.

Owner:AECC AVIATION POWER CO LTD

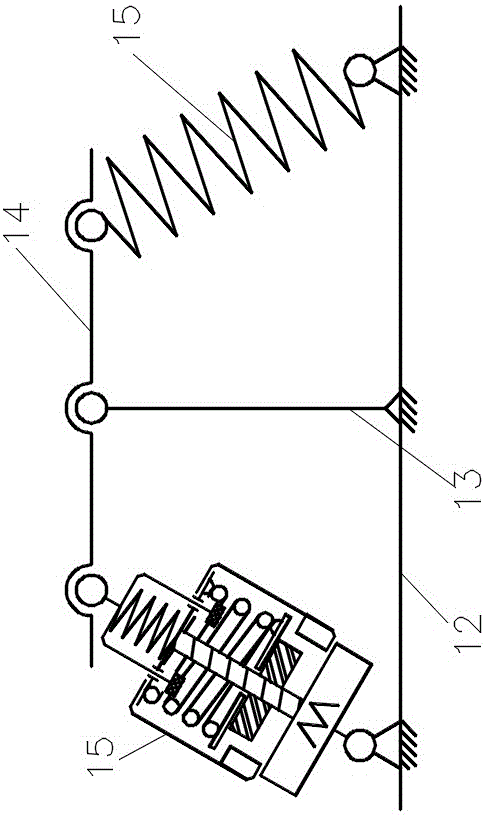

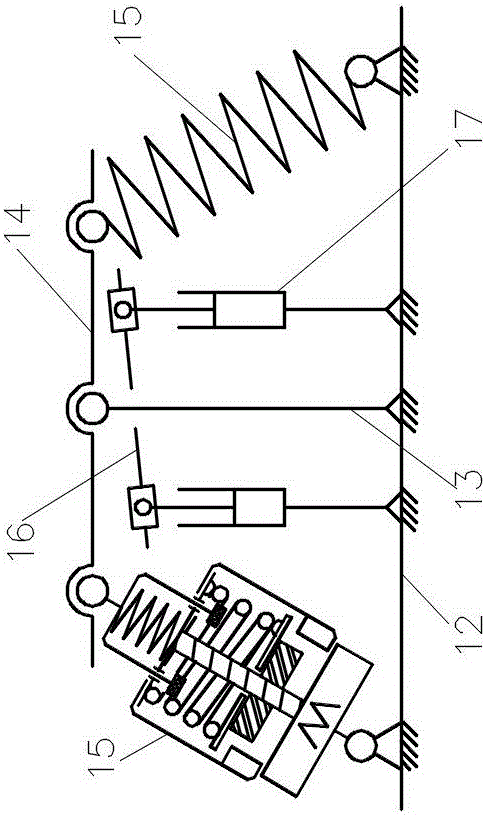

Garlic mashing device

The invention discloses a garlic mashing device belonging to the field of kitchen utensils. The garlic mashing device is composed of a bearing device, a movement mechanism, a control part, a power device and a storage device. A mechanical structure is controlled to complete a mashed garlic making operation by an electric actuator, the manual labor is replaced, and the efficiency is improved; by adopting a rocker-slider mechanism, garlic flakes can be smashed twice in an operating stroke, and the motion frequency is high, so that the whole device has high working efficiency; a stepping motor serves as a drive motor and is electrically connected with a single chip microcomputer, so that the positive and negative rotation and swing angle of the crank can be accurately controlled; and the rocker and the chute are indirectly connected by a roller, the roller is matched with the rocker chute, and the inner diameter of the roller is larger than that of a rocker shaft III, so that friction between the rocker and the rocker chute can be reduced, and the conversion of efficiency is efficiently realized.

Owner:曾正扬

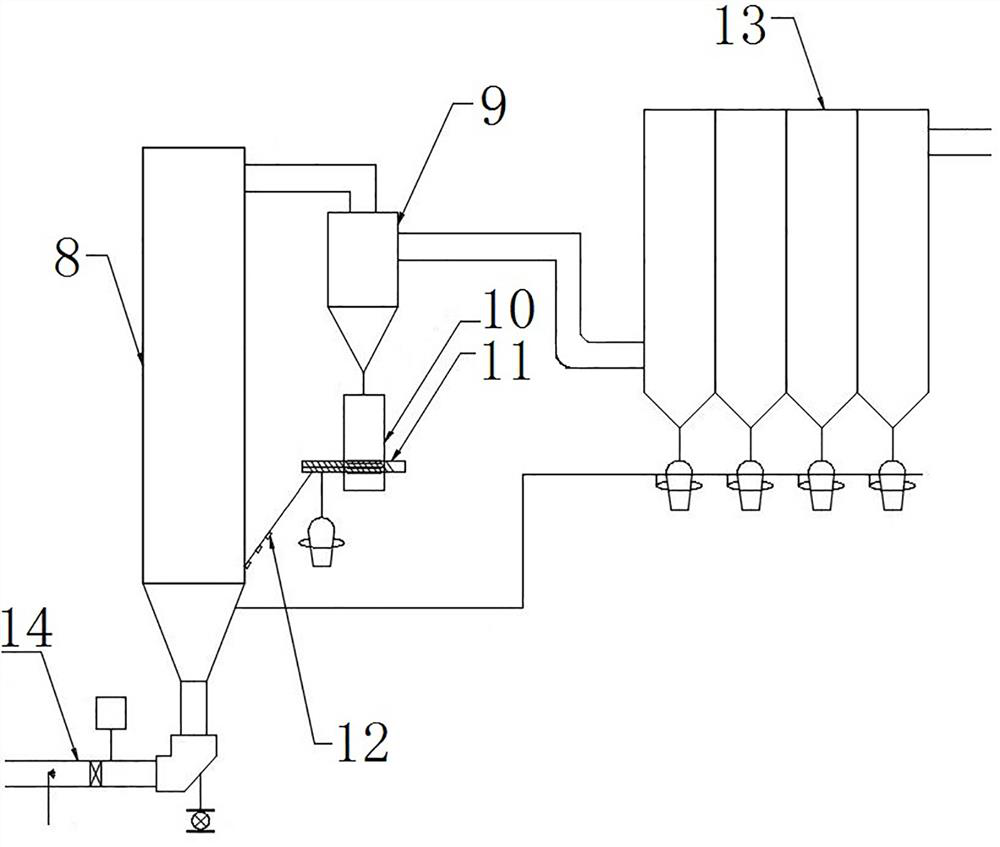

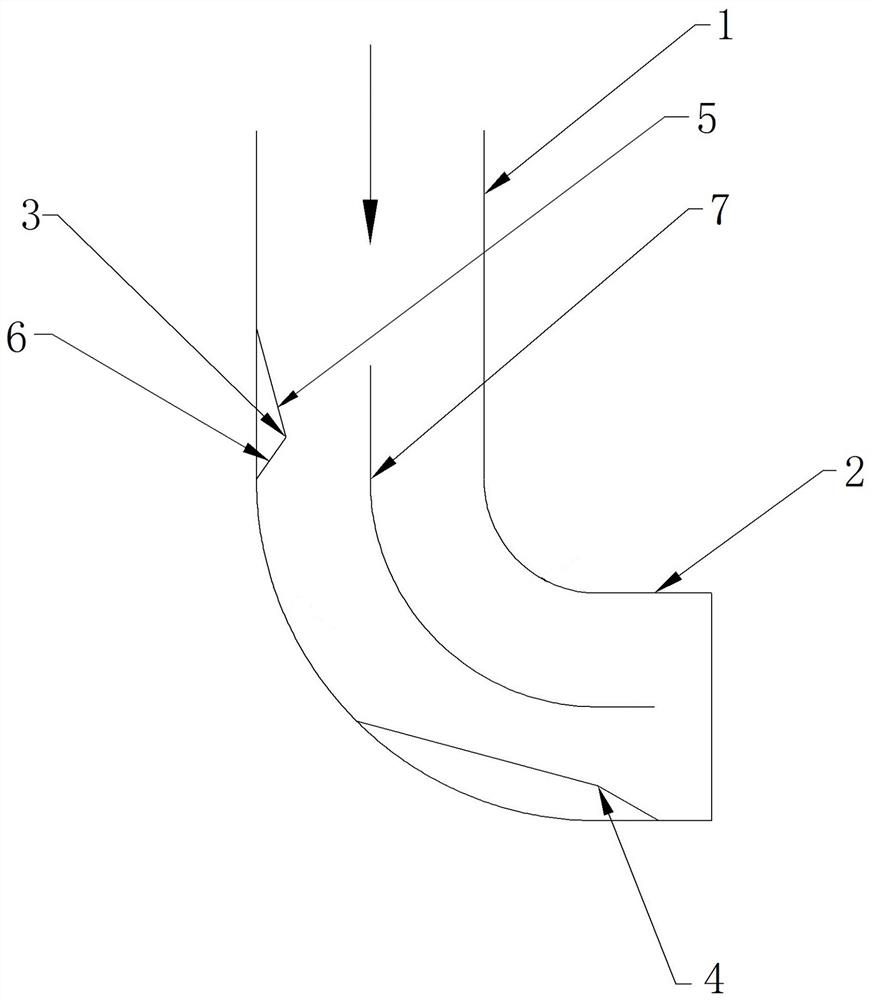

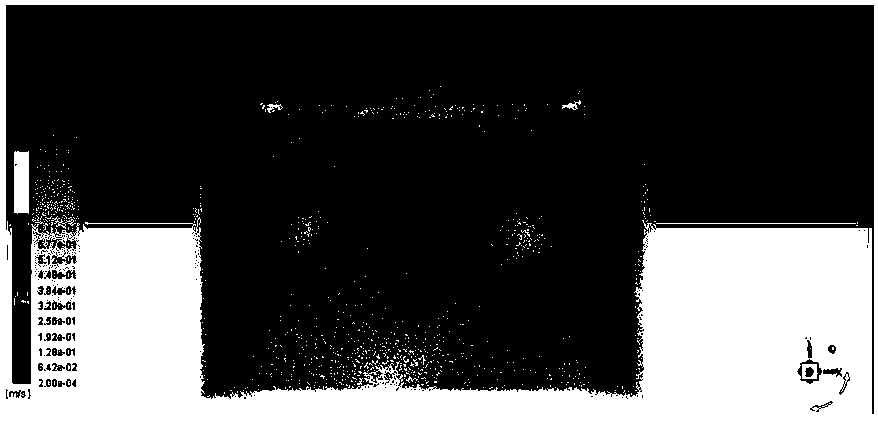

Dusty flue gas conveying reversing pipeline and dry desulfurization system

ActiveCN112569774AAvoid stockpilingEliminate side accumulation dead angleDispersed particle separationPipe elementsThermodynamicsFlue gas

The invention relates to a dusty flue gas conveying reversing pipeline and a dry desulfurization system. The dusty flue gas conveying reversing pipeline comprises a front side flue and a rear side flue; smoke flows into the rear side flue from the front side flue to achieve reversing of the flow direction, a flow guide piece is arranged on the inner wall of the outer side of the front side flue and / or the inner wall of the outer side of the rear side flue and provided with a flow guide face, and the flow guide face extends from the inner wall of the outer side of the flue to the middle of theflue in the flow direction of the dusty smoke to guide the middle of the flue. Under the guidance of the flow guide part, dust-containing flue gas flows along a path close to the inner side of the pipeline, and the flow speed of the flue gas close to the middle of the flue is higher than that of the flue gas at the inner wall of the outer side of the flue, so that dust in the flue gas can be takenaway by the flue gas, and the dust in the flue gas is prevented from being accumulated at the corner of the flue or the downstream of the corner.

Owner:ZHENGZHOU TIDYLAND ENVIRONMENTAL TECH CO LTD

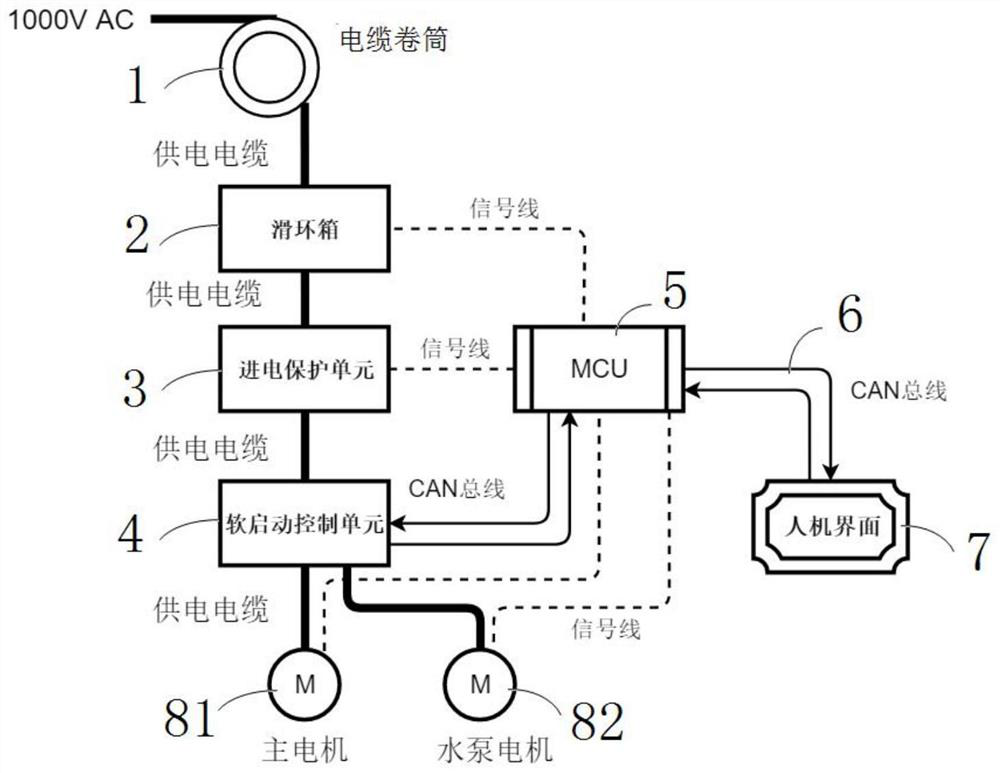

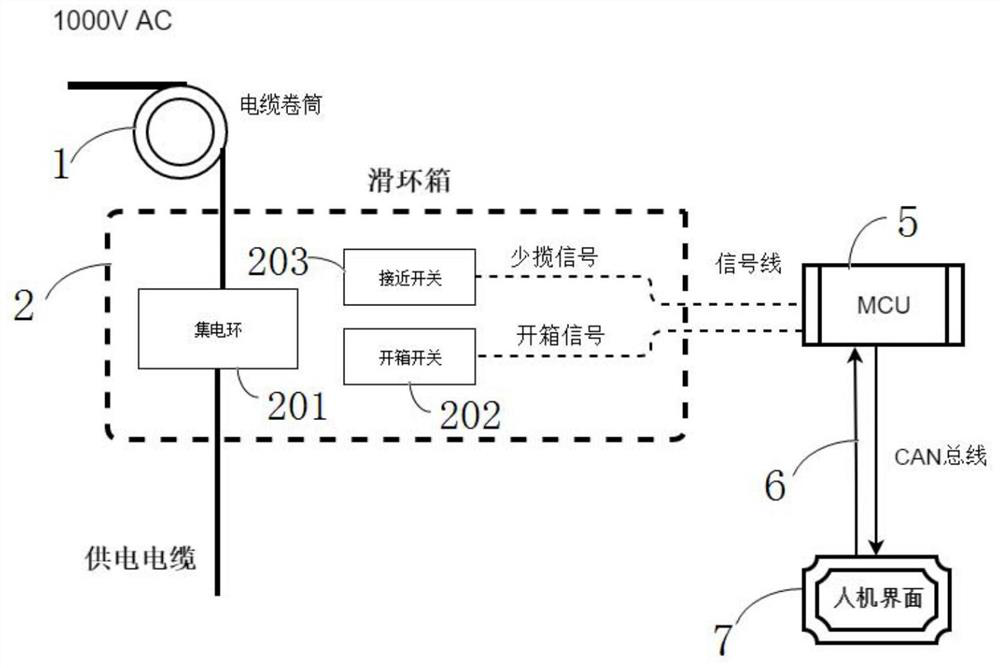

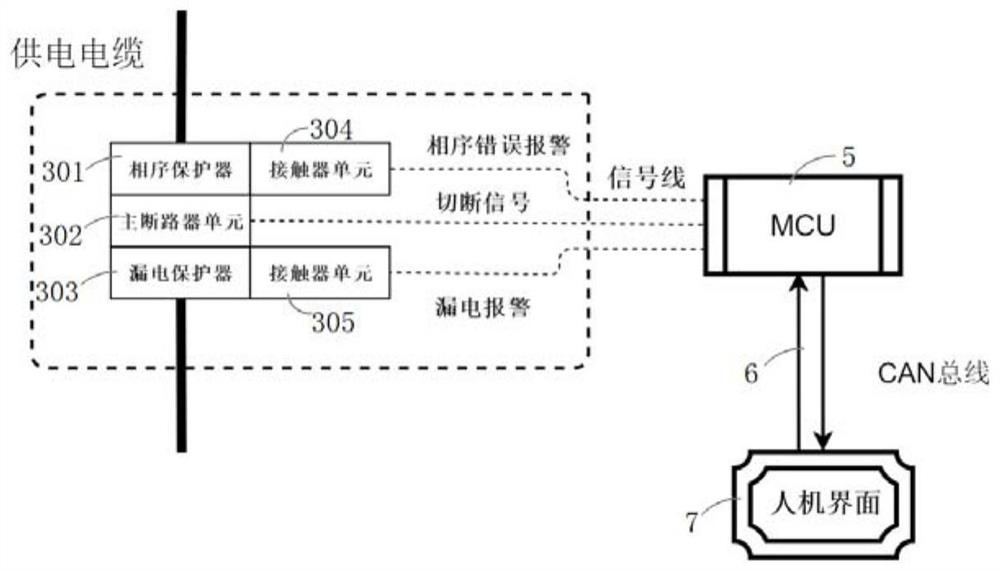

Safety control system and method for drill jambo power unit

PendingCN111786599ANot easy to damage insulationExtend your lifeElectric motor controlMultiple dynamo-motor startersHuman–machine interfaceSafety control

The invention discloses a safety control system and method for a drill jambo power unit, and belongs to the technical field of drill jambo control. The system comprises a cable drum, a slip ring box,a motor unit, a power inlet protection unit, a soft start control unit, an MCU, a CAN bus and a human-computer interface. A power supply cable is connected with the wire inlet end of the slip ring boxthrough a cable drum; the wire outlet end of the slip ring box is connected with the motor unit through the power inlet protection unit and the soft start control unit in sequence, the MCU is connected with the slip ring box, the power inlet protection unit and the motor unit, the MCU is connected with the soft start control unit and the human-computer interface through a CAN bus, and a motor monitoring unit is arranged in the motor unit. Impact-free soft start of the motor can be realized, the service life of the motor is prolonged, and impact of current on a power grid is avoided; the safety of the system is improved by monitoring the states of different parts and giving an alarm in real time.

Owner:ATLAS COPCO (NANJING) CONSTR & MINING EQUIP CO LTD

An Alternating Plug Flow Aerobic Biological Fluidized Bed Reactor

ActiveCN104876326BShock won'tCause blockageTreatment using aerobic processesSustainable biological treatmentFluidized bedWastewater

Owner:JIANGSU ZHONGMEI HUACHAO SCI & TECH ENVIRONMENTAL PROTECTION CO LTD

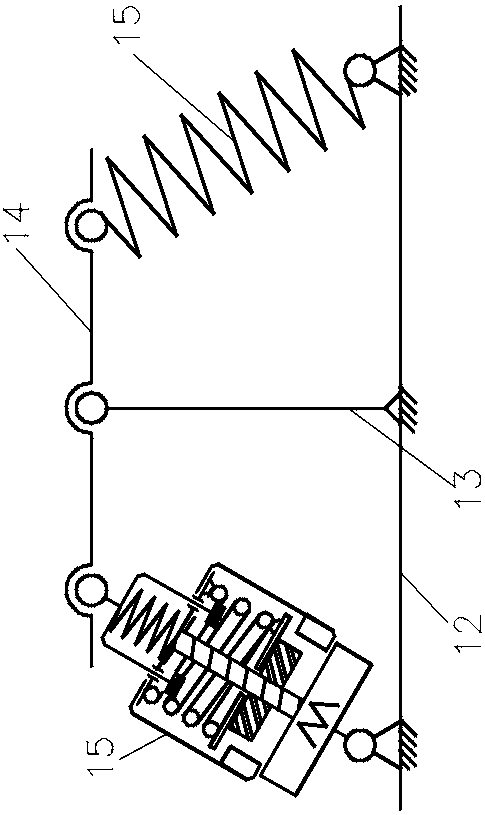

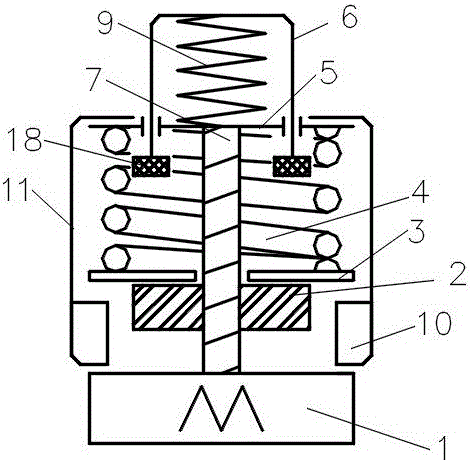

Explosion storage mechanism and cooking device using same

InactiveCN106361129BRealize the purpose of fully automatic cookingEnsure safetyCooking vessel supportElectric machineEngineering

The invention, based on an existing cooking device, is improved, and provides a detonation accumulation mechanism and a cooking device adopting the same. The detonation accumulation mechanism comprises a motor, a first magnetic connecting plate, a magnetic conductive metal plate, a detonation accumulation spring, a detonation accumulation limiting device and an output connecting piece, wherein a thread output shaft is arranged on the motor, the first magnetic connecting plate is arranged on the thread output shaft, and the magnetic conductive metal plate penetrates through the thread output shaft. By removal of a redundant structure and continuous improvement and optimization, the detonation accumulation mechanism can realize more cooking functions, and achieve a better cooking effect, thereby improving the automation degree of cooking. By virtue of a working mode of accumulating and then releasing mechanical energy, the detonation accumulation mechanism provided by the invention can provide energy output by using a power source with higher power, smaller volume and smaller mass, strengthen the action effect greatly by virtue of this power source, achieve an effect of outputting a same equivalent weight with higher power source energy, and replace an execute component (such as an electromagnet) acting directly in the prior art.

Owner:麦维文

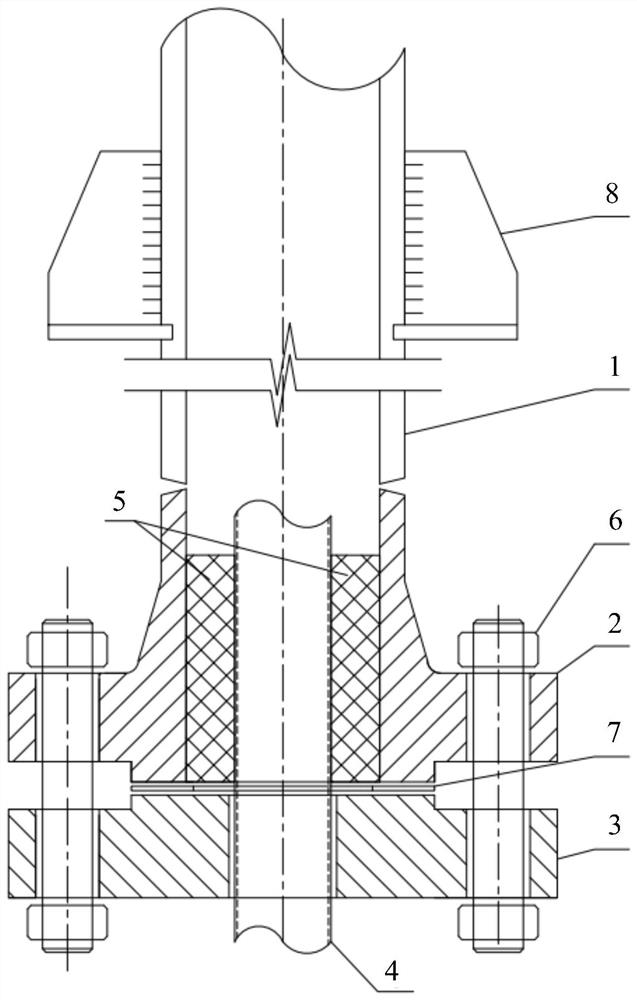

Pipeline connecting structure and EVA production device using connecting structure

PendingCN113669523AExtended service lifeSimple structureSleeve/socket jointsFlanged jointsEngineeringWelding

The invention provides a connecting structure used for connecting a high-pressure pipeline and a low-pressure pipeline. The connecting structure comprises a low-pressure side connecting piece connected with the low-pressure pipeline and a high-pressure side connecting piece connected with the low-pressure side connecting piece. The high-pressure pipeline penetrates through the high-pressure side connecting piece and the low-pressure side connecting piece. A cavity is formed among the low-pressure side connecting piece, the high-pressure pipeline and the high-pressure side connecting piece, and filler is contained in the cavity. According to the connecting structure, welding-free sealed type connection between the high-pressure pipeline and the low-pressure pipeline is achieved, the connecting structure can bear large impact force, and therefore the connecting pieces and the low-pressure pipeline cannot be damaged, and the service life of the connecting pieces and the service life of the low-pressure pipeline are prolonged. In addition, the connecting structure is simple in structure, convenient to install, easy to maintain and low in investment cost. In addition, the invention also provides an EVA production device using the connecting structure.

Owner:DAQING PETROCHEM ENG

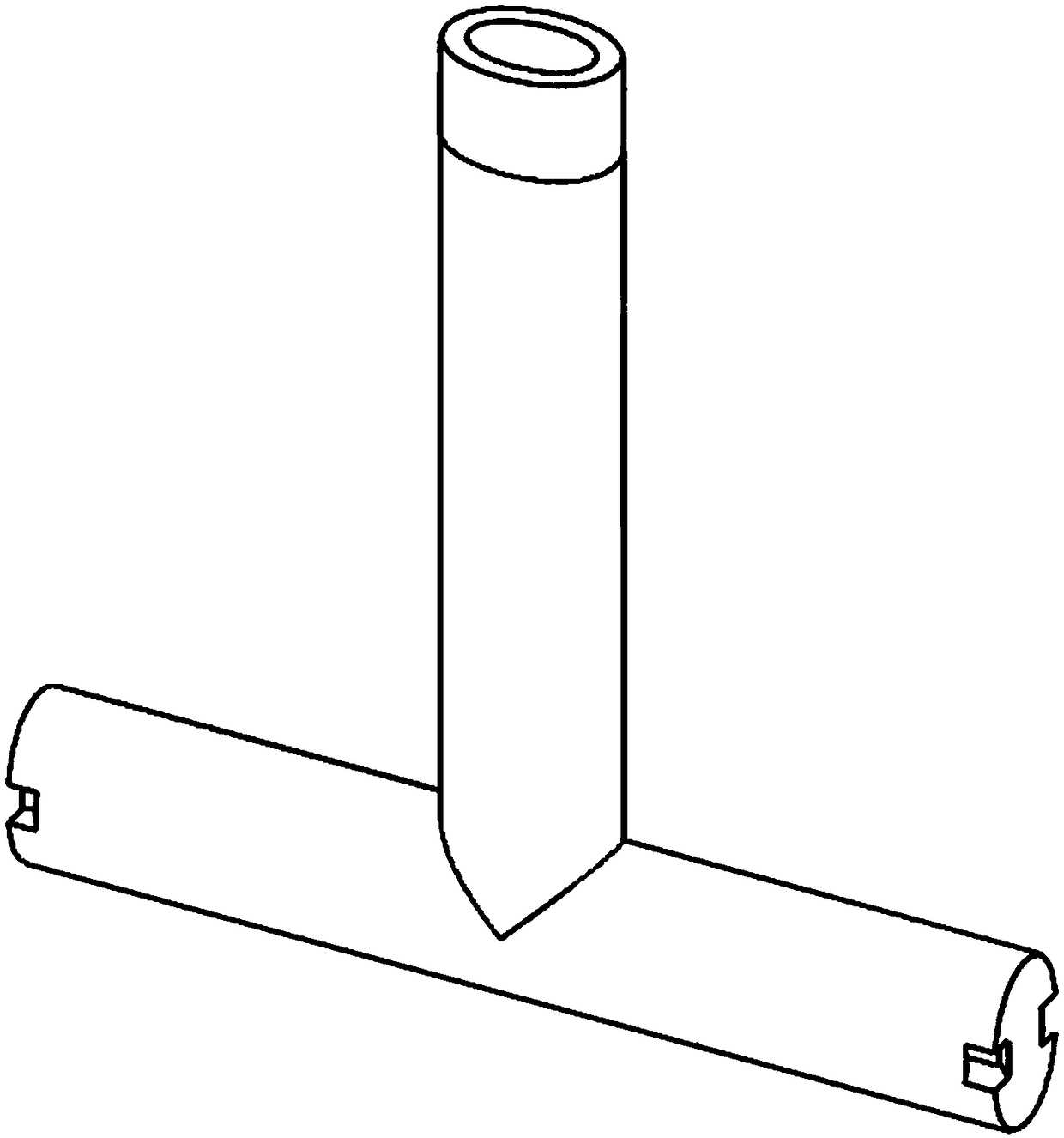

Immersion nozzle for casting central point of ultrathin special-shaped blank

The invention discloses an immersion nozzle for casting a central point of an ultrathin special-shaped blank, and belongs to the technical field of continuous casting of special-shaped blanks. The immersion nozzle comprises an immersion nozzle body, wherein the immersion nozzle body comprises a vertical section and a horizontal section, the vertical section and the central position of the horizontal section are integrally connected, the vertical section comprises a bowl part and an equal-diameter section, the bowl part is positioned at the upper end of the equal-diameter section, the inner cross section of the equal-diameter section is oval, and the long axis of the oval cross section is parallel to the central line of the horizontal section; the inner diameters of the horizontal section are equal and are symmetrical about the symmetrical surface of the vertical section, the shape of the inner vertical section is elliptic, the elliptic section is parallel to the central line of the vertical section, and through holes are arranged at the two ends of the horizontal section; and at least two downward inclined water holes are symmetrically arranged at the bottom end of the horizontal section. The structure of the immersion nozzle can be optimized, the temperature field and the flow field in the mold are stable, the flowing uniformity of molten steel is improved, the defects causedby continuous casting are reduced, the quality of ultra-thin special-shaped blank continuous casting is improved, and the immersion nozzle has the advantages of simple structure, reasonable design andeasiness in manufacturing.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

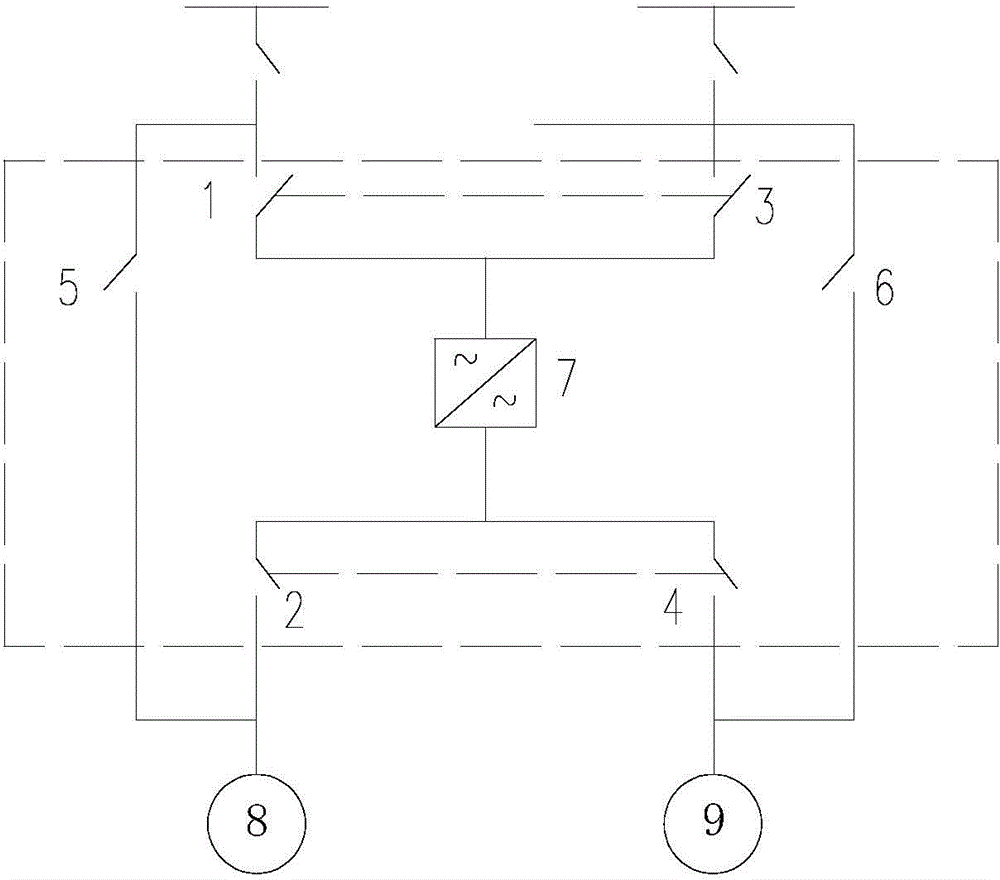

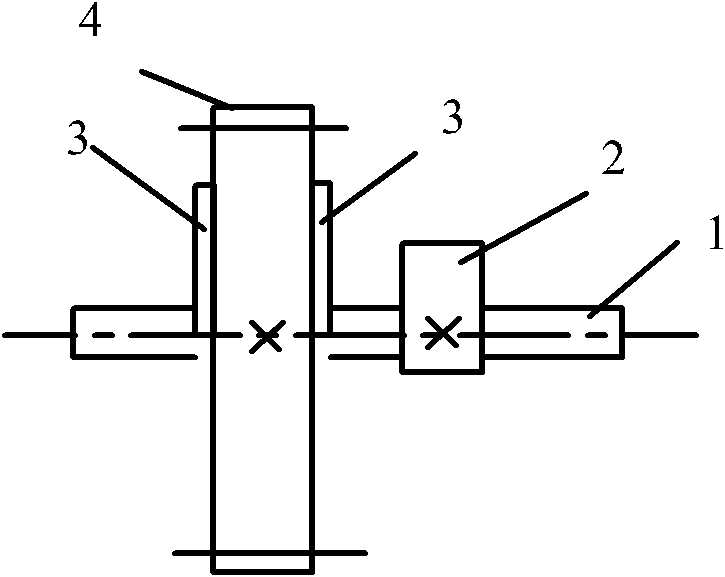

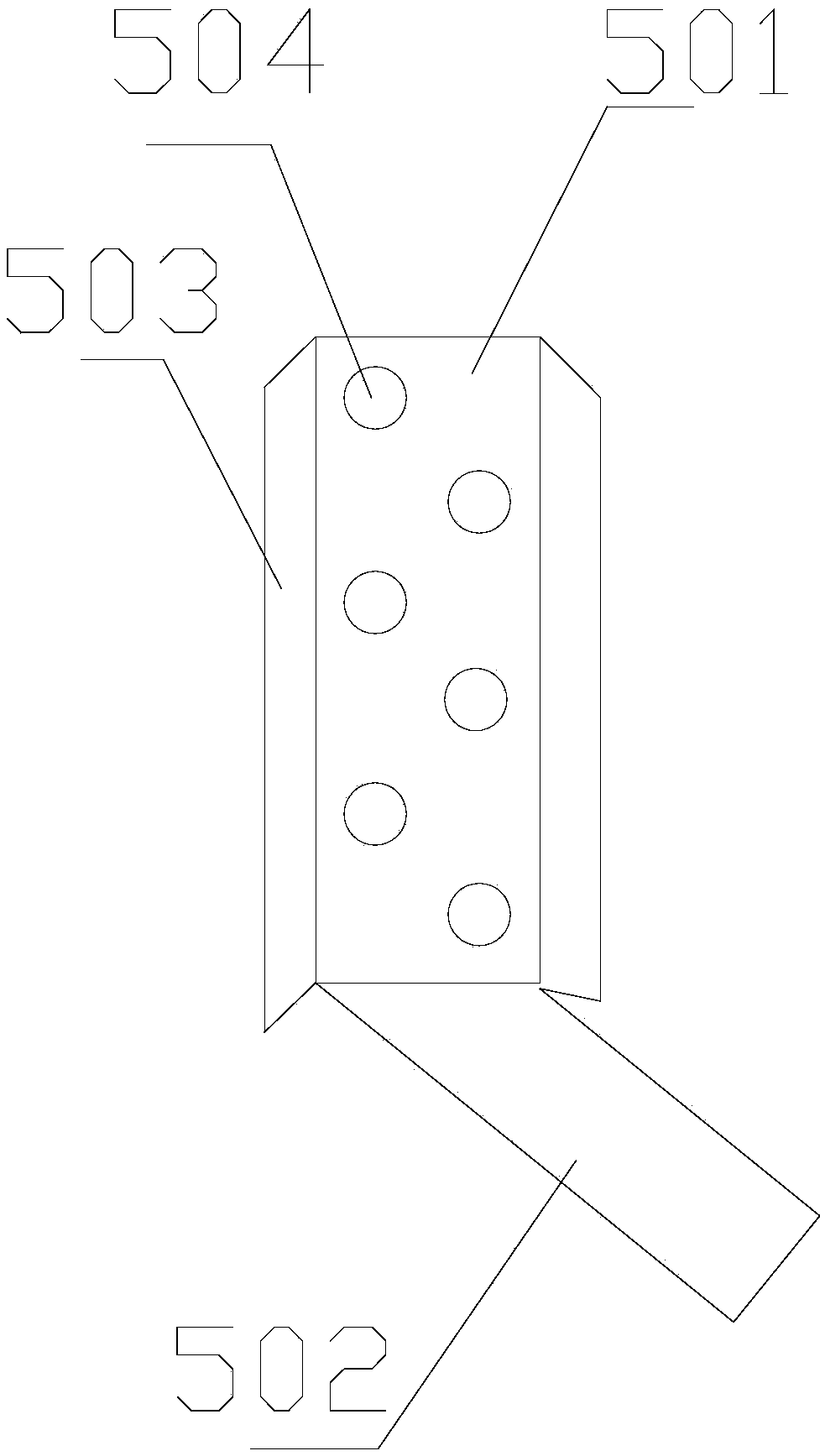

Exhaust bypass device for protecting engine turbocharger

PendingCN109505695AExtended service lifeShock won'tInternal combustion piston enginesTurbochargerMain channel

The invention provides an exhaust bypass device for protecting an engine turbocharger and belongs to the technical field of engine turbocharger parts. One end of a main channel (2) of a device shell body (1) of the exhaust bypass device for protecting the engine turbocharger communicates with an exhaust manifold, and the other end of the main channel (2) communicates with a supercharger; a by-passpipeline (3) communicates with an exhaust tail pipe; a driving valve (5) is arranged on an executing rod I (4) in the main channel (2); a driven valve (7) is arranged on an executing rod II (6) in the by-pass pipeline (3); the executing rod I (4) is connected with a driving motor I (8); and the executing rod II (6) is connected with a driving motor II (9). According to the exhaust bypass device for protecting the engine turbocharger, the structure is simple, circulating paths for exhaust gas entering the turbocharger can be switched conveniently and reliably in different working conditions, the supercharger system can be protected from being affected by particle impact, and the service life of the supercharger is prolonged.

Owner:JIANGXI TENHLE POWER CO LTD

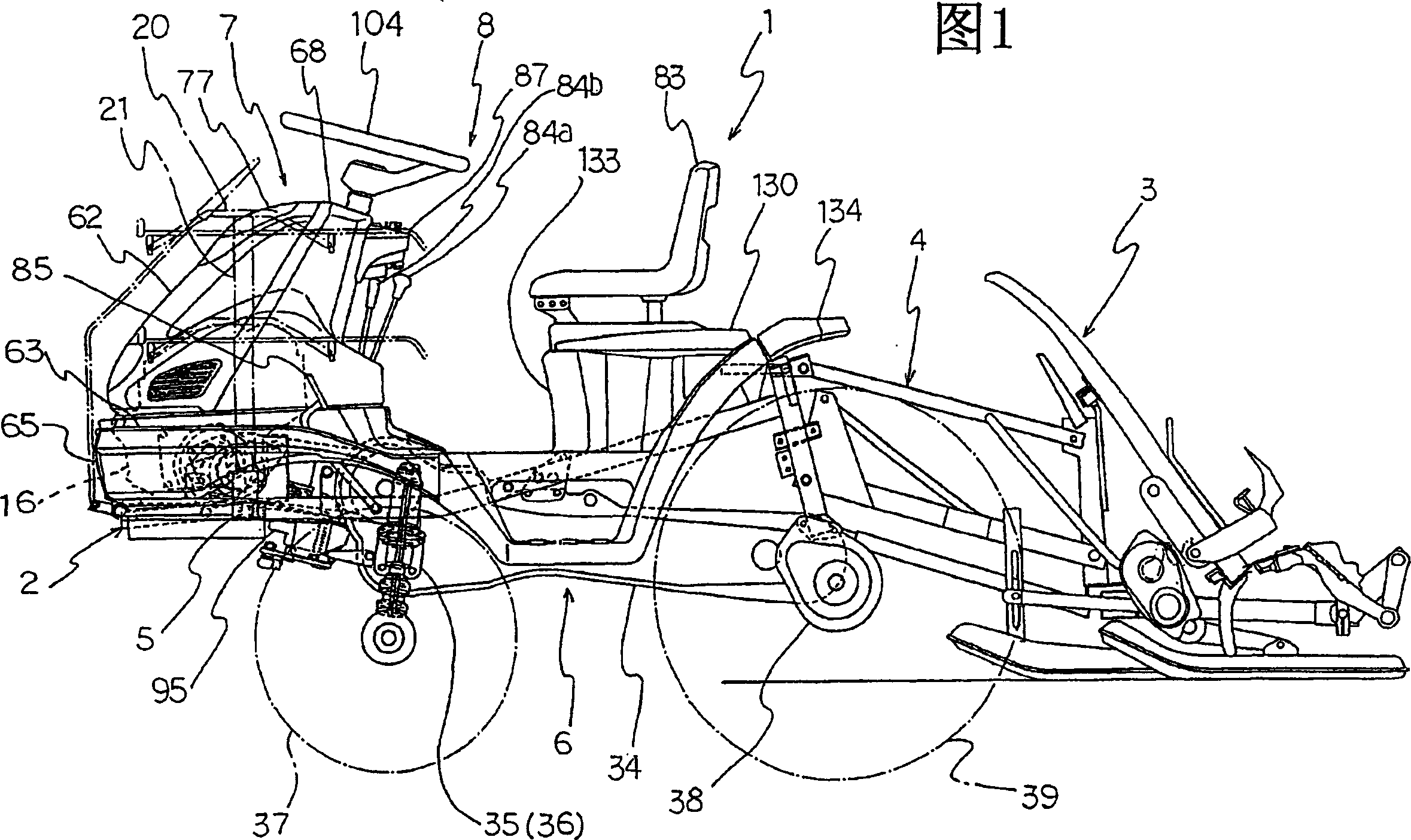

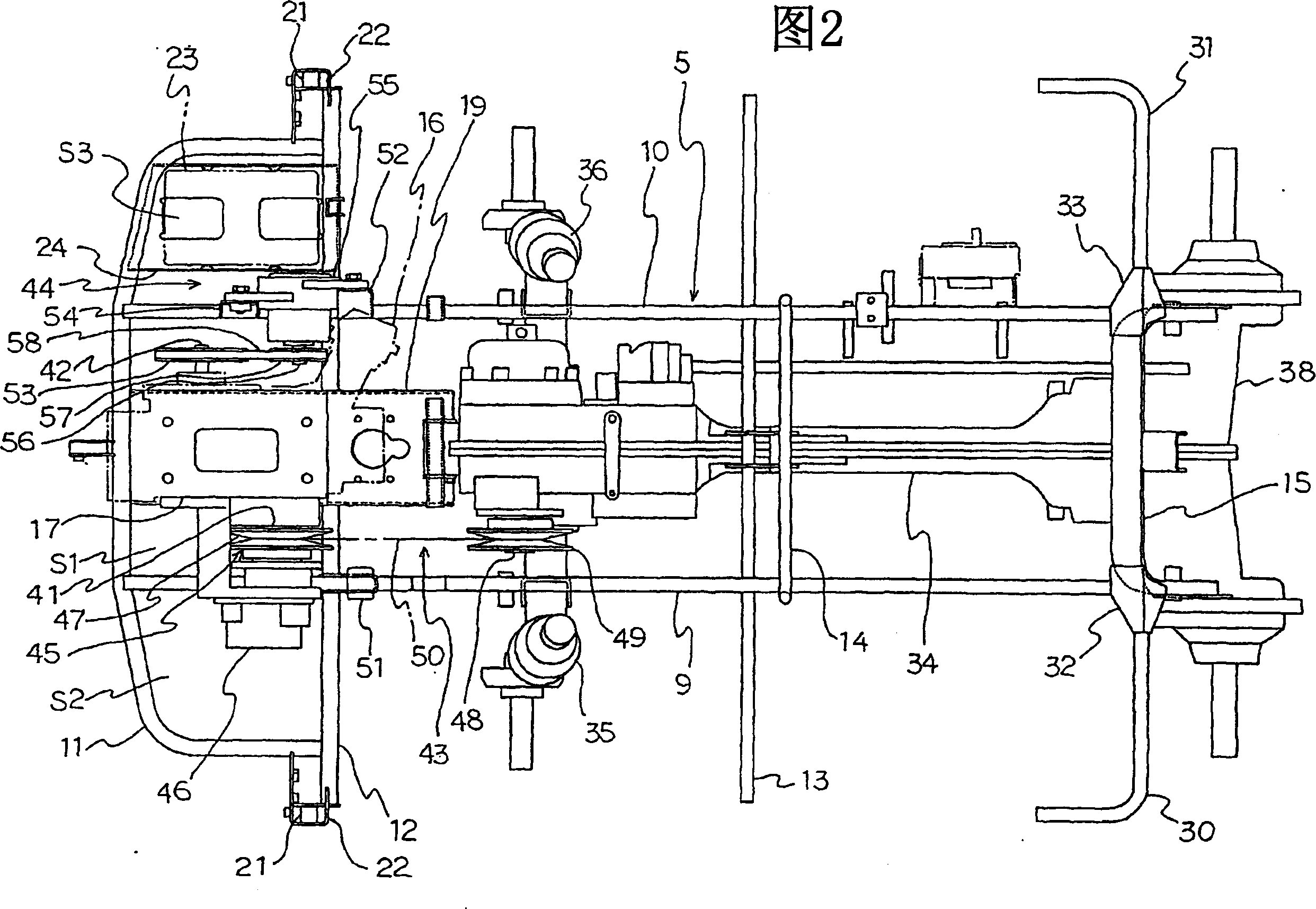

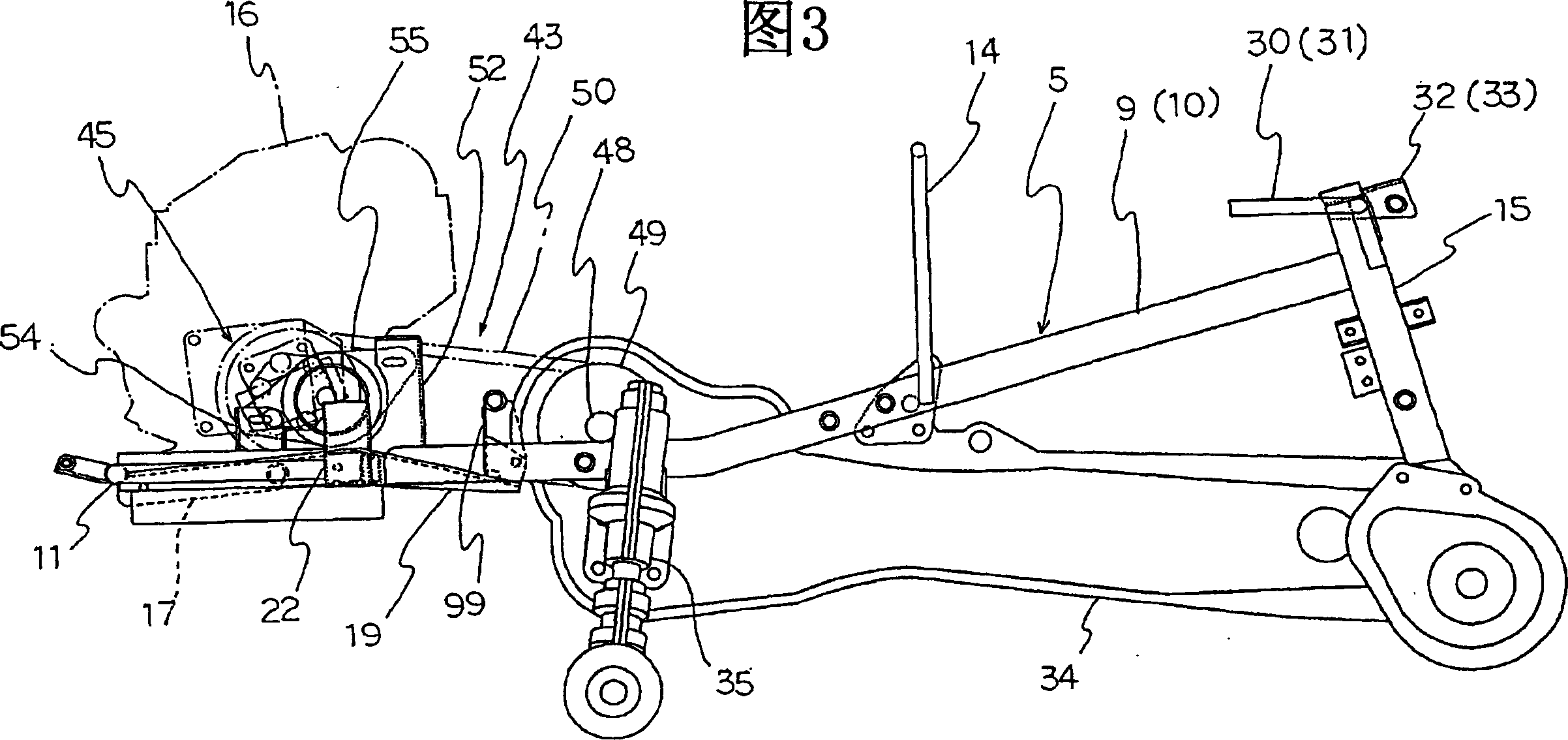

Agricultural machine

InactiveCN1275504CEconomic realizationShock won'tSuperstructure subunitsTransplantingAgricultural engineering

An agricultural machine in which in order to reduce the weight of the agricultural machine, installed on the front of a pair of right and left center frame structures extending longitudinally to constitute a machine frame is a reserve seedling mount support frame structure extending in the direction of the width, and a reserve seedling mount is supported on the right and left sides of the reserve seedling mount support frame structure, wherein a front frame structure is transversely installed on the front of the pair of right and left center frame structures, and the front frame structure is connected at its right and left sides to the right and left sides of the reserve seedling mount support frame structure.

Owner:YANMAR CO LTD

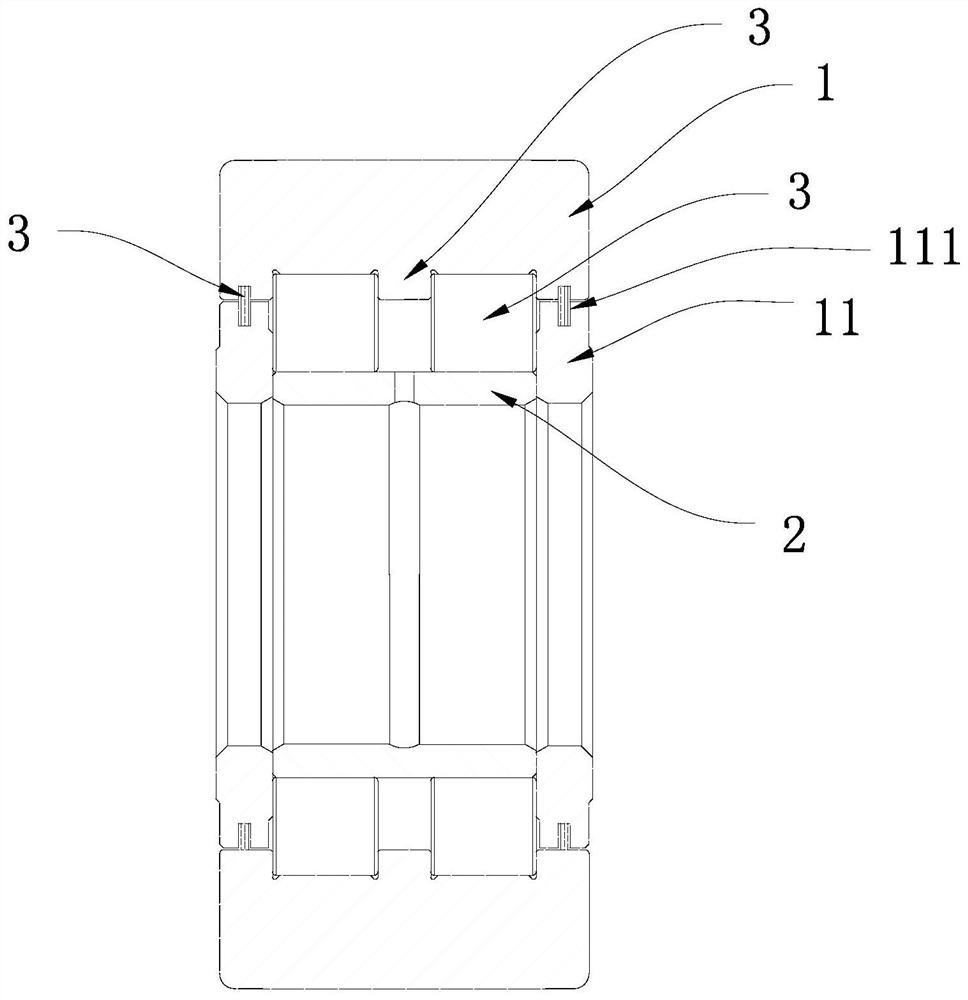

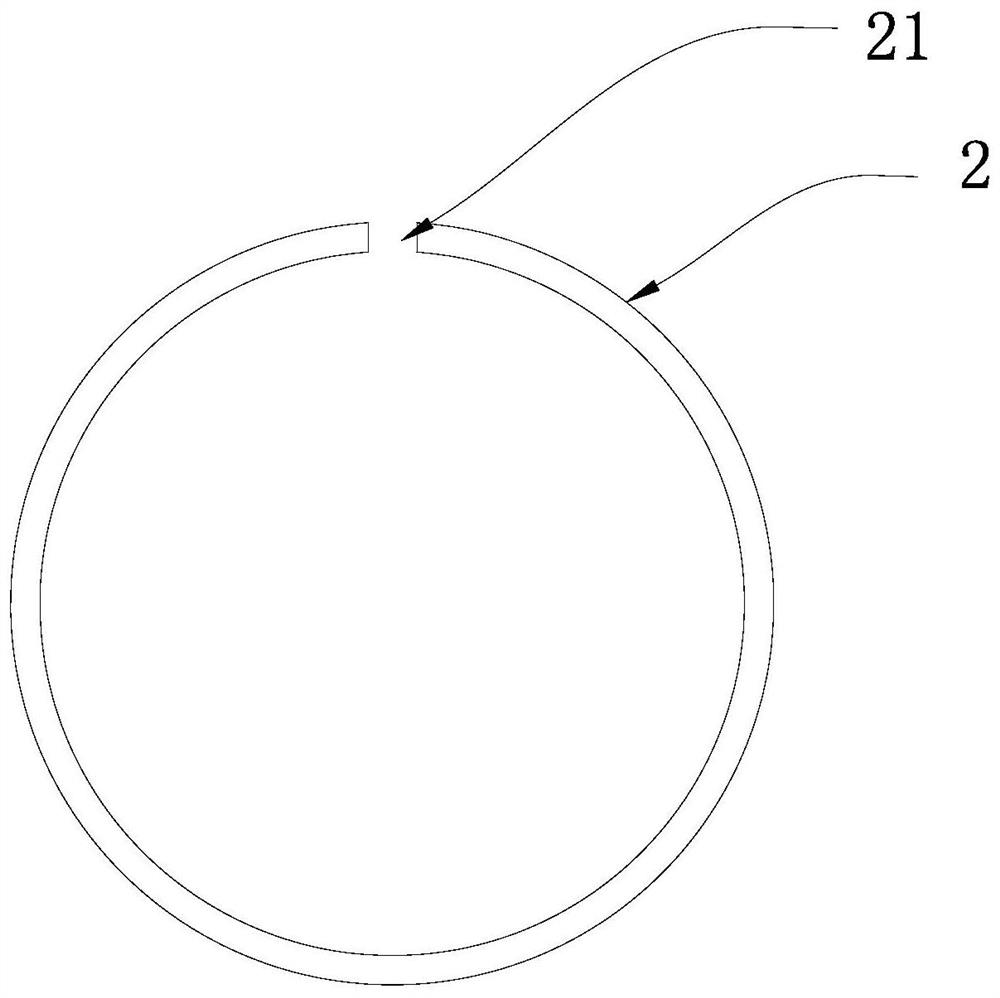

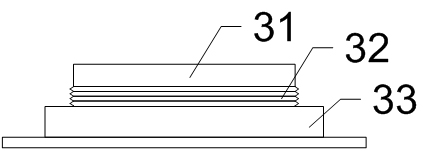

Sealing structure of cylindrical roller

InactiveCN112610597ADoes not affect speedImprove work efficiencyRoller bearingsBearing componentsStructural engineeringMechanical engineering

Owner:C&U CO LTD +1

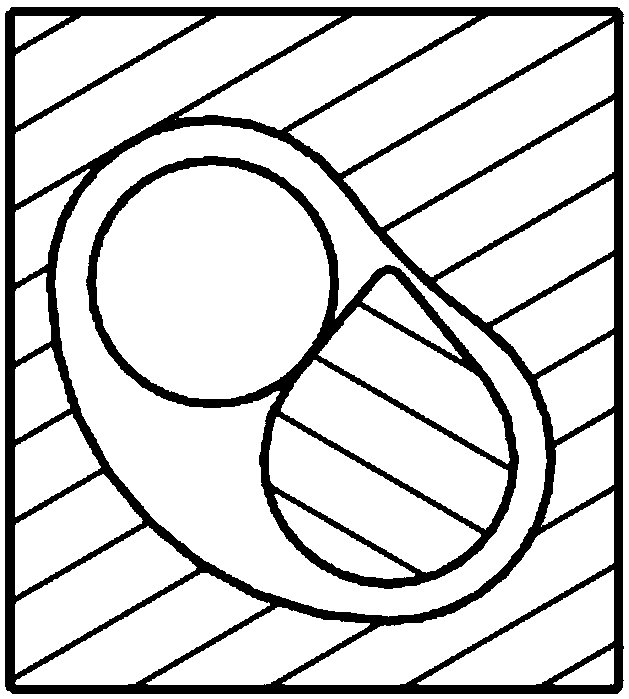

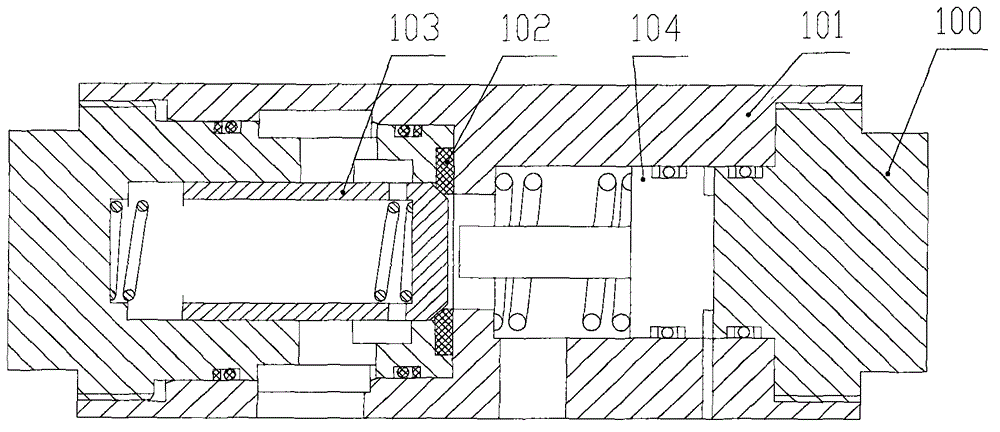

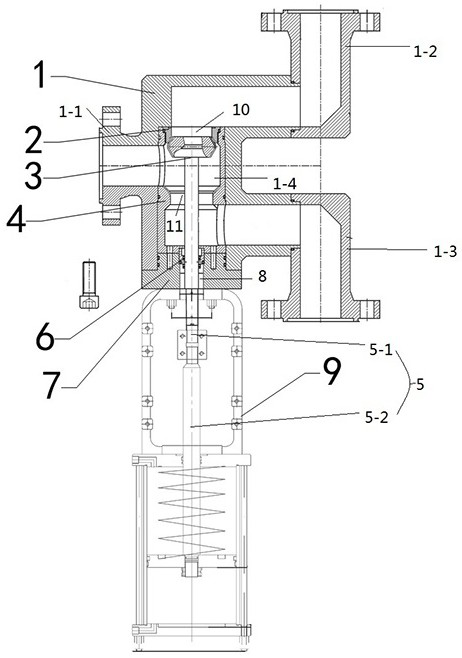

A Hydraulic Cylinder Control Valve Without Unloading Shock Resonance

ActiveCN103244155BSolve unloading shock resonance problemShock won'tMine roof supportsProps/chocksHydraulic cylinderResonance problem

The invention discloses a hydraulic cylinder control valve without unloading impact resonance, which overcomes the problem that impact resonance is generated by the unloading of a hydraulic control one-way valve of a conventional hydraulic cylinder. The hydraulic cylinder control valve without unloading impact resonance is characterized in that: a sealing diameter of a valve opening of a first valve core inside a valve body is same as a diameter of a sealing section and a diameter of a liquid return section; and the diameter of a control section is smaller than the diameter of a liquid return section. The beneficial effects are that: as the sealing diameter of the valve opening of a first valve core is same as the diameter of the sealing section and the diameter of the liquid return section, the unloading impact resonance problem of the control valve of the hydraulic cylinder is solved; as the sealing diameter of the valve opening, the diameter of the sealing section and the diameter of the liquid return section can be increased equivalently, and the diameter of the control section can be reduced at will based on a need, the control pressure is unlikely too low, and no false operation is generated; and a secondary-hole one-way valve arranged in a secondary hole inside the valve body or a plate-shaped connecting one-way valve or a tubular one-way valve outside the valve body are used for raising a column, so that needs of big channel for dropping the column, a small channel for raising the column, and joint control of a balancing jack and a lifting jack while the column is raised are satisfied.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD

New energy power generation device

PendingCN113595492AGuaranteed cleanlinessAvoid accumulationPhotovoltaic supportsMechanical energy handlingEnergy technologyWater storage

A new energy power generation device disclosed by the invention comprises a central bottom column, wherein the bottom part of the outer surface of the central bottom column is movably connected with a stepped supporting frame plate, the side, away from the central bottom column, of the stepped supporting frame plate is movably connected with a solar power generation panel, an arc-shaped guide groove is formed in the side, away from the stepped supporting frame plate, of the solar power generation panel, and the top part of the central bottom column is movably connected with an auxiliary mechanism; and the auxiliary mechanism comprises a cleaning mechanism, the side, away from the center bottom column, of the cleaning mechanism is movably connected with a water storage mechanism, the bottom part of the outer surface of the cleaning mechanism is movably connected with the solar power generation panel, and the bottom part of the cleaning mechanism is movably connected with the center bottom column. The new energy power generation device relates to the technical field of new energy sources. The new energy power generation device collects external moisture, and the surface of the solar power generation panel is cleaned by using the collected water flow, so that the surface of the solar power generation panel is kept clean, dust and other sundries are prevented from being accumulated, normal contact of light is ensured, and normal operation of the power generation capacity of the solar power generation panel is ensured.

Owner:李泽亮

Flow guide device for bag filter

ActiveCN105999889BReduce workloadReduce operating loadDispersed particle filtrationEngineeringElectrical and Electronics engineering

The invention discloses a flow guide device of a cloth bag type dust remover. The flow guide device of the cloth bag type dust remover comprises a dust hopper, a box body, cloth bags and n flow guide plates, wherein the dust hopper is arranged under a bottom plate of the box body; openings of the cloth bags are formed in the bottom plate of the box body; n+1 groups of ventilation holes are formed in the bottom plate of the box body; the positions of the openings of the cloth bags correspond to the ventilation holes; the ventilation holes are used for communicating the dust hopper with the cloth bags; the flow guide plates are arranged on the inner side wall of the dust hopper and are located between two adjacent groups of ventilation holes; the flow guide plates comprise air shielding plates and air inducing plates; the air guiding plates are located at the bottoms of the air shielding plates; an included angles between each air shielding plate and each air inducing plate is 120-150 degrees; side plates are arranged on two sides of the air shielding plates adjacent to the air inducing plates; an air inlet is formed in the wall of the dust hopper; the plate sides of the air shielding plates are opposite to the air inlet; staggered protrusions are formed in the plate sides of the air shielding plates; n is a natural number being greater than or equal to 1. Through the flow guide device, the airflow distribution uniformity of the dust remover can improved; the re-entrainment of the dust of the dust hopper can be reduced; the operation resistance of the equipment can be reduced; meanwhile, the service life of the cloth bags can be prolonged.

Owner:安徽贝特滤材有限公司

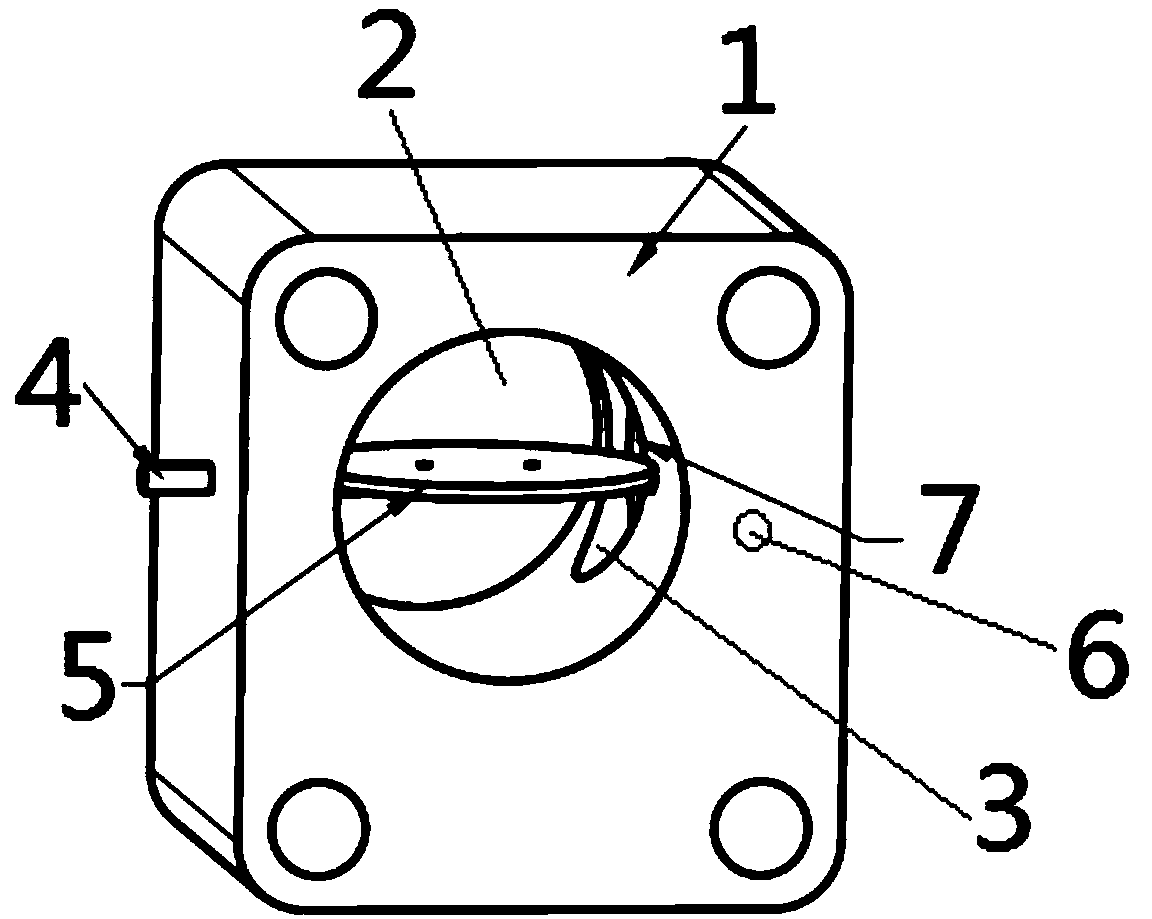

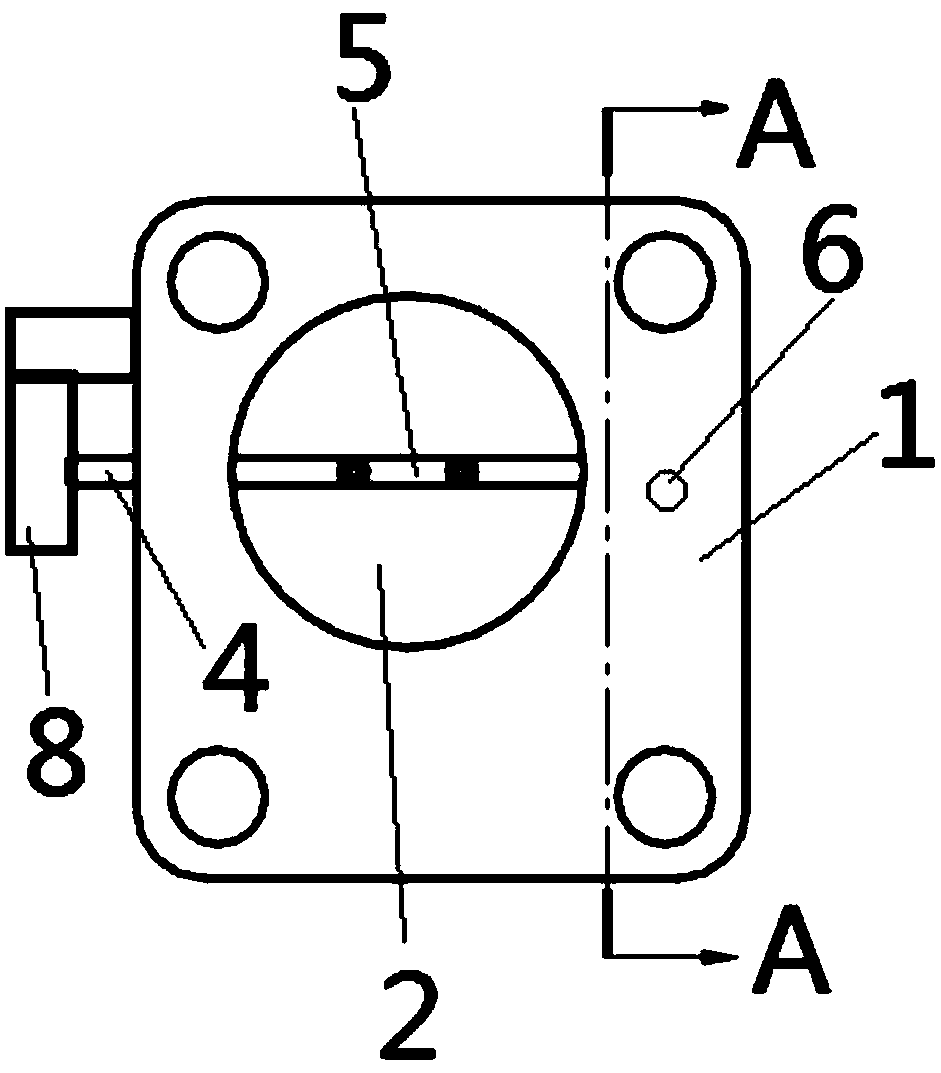

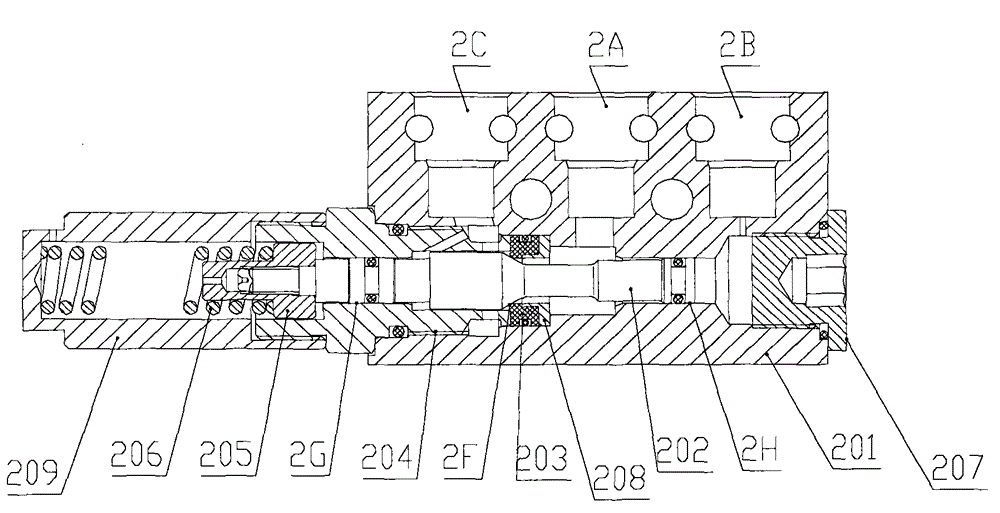

Medium-high pressure natural gas flow path switching device and using method

InactiveCN112610723ARealize process switchingReduce shockOperating means/releasing devices for valvesValve members for absorbing fluid energyEngineeringControl valves

The invention discloses a middle-high pressure natural gas flow path switching device and a using method. The middle-high pressure natural gas flow path switching device comprises a valve body and a pneumatic device connected with the valve body, the valve body comprises an inlet, a first outlet, a second outlet and a separation cavity, the inlet, the first outlet and the second outlet communicate with the separation cavity through channels, a first connector and a second connector are arranged at the joint of the first outlet and the separation cavity and the joint of the second outlet and the separation cavity separately, the pneumatic device comprises a pneumatic driver and a valve rod connected with the pneumatic driver, the pneumatic driver is connected to the valve body, the valve rod penetrates through the second connector to extend into the separation cavity, the top end of the valve rod is connected with a valve rod valve clack, and the valve rod valve clack is matched with the first outlet and the second outlet. The valve rod and the valve rod valve clack are controlled to move through the pneumatic driver, so that the first connector or the second connector is blocked, process switching is achieved, and remote process switching can be achieved by remotely controlling the pneumatic driver.

Owner:PETROCHINA CO LTD

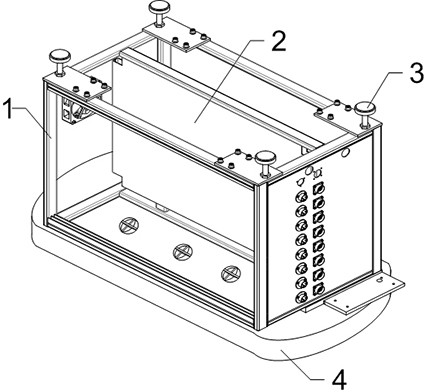

avionics bay with lrm

The invention discloses an avionics cabin equipped with an LRM, which includes a cabin body, a vertically fixed avionics equipment fixing plate is arranged in the cabin body, and several top fixing legs are fixed above the cabin body. The top fixing feet are used for: fixedly connecting the cabin body with the aircraft body, and buffering the cabin body from the vibration of the aircraft body; below the cabin body, a vibration-reducing and heat-dissipating air cushion is fixed, and the vibration-damping and heat-dissipating air cushion Several exhaust ports are opened on the upper surface, and pressure relief valves are arranged in the exhaust ports, and an air injection pipe is fixed below the vibration-reducing and heat-dissipating air cushion. The invention realizes the functions of fixing, shock absorption and enhancing heat dissipation at the same time by using the same placement compartment, so that the space in the aircraft is saved, and at the same time, the damage to the avionics equipment caused by vibration and temperature changes can be avoided.

Owner:四川省安道速博科技有限公司

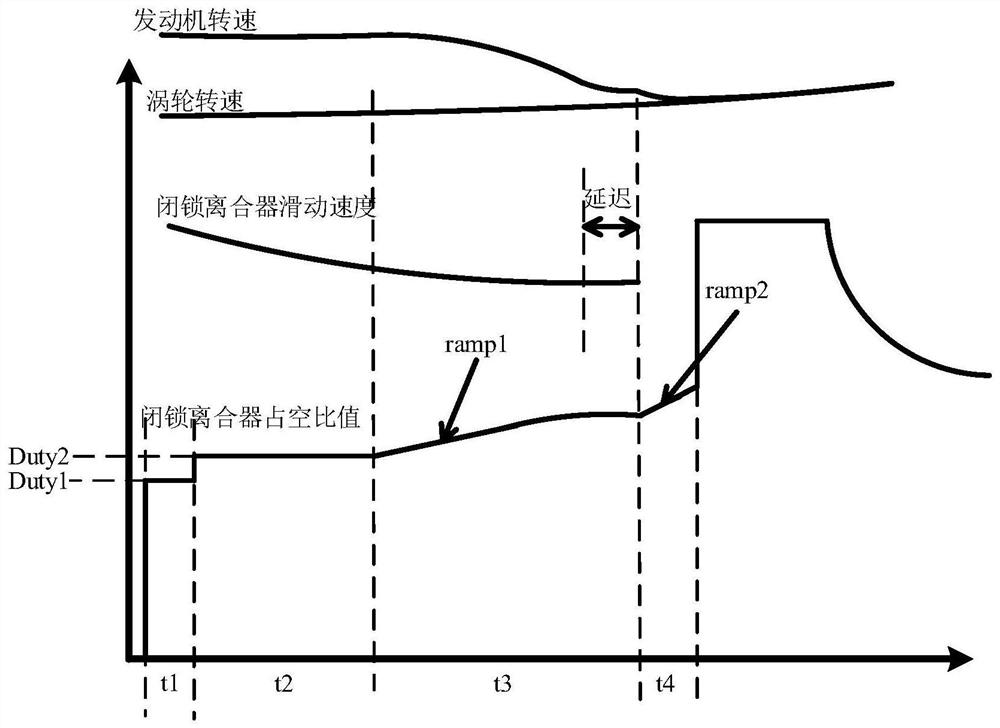

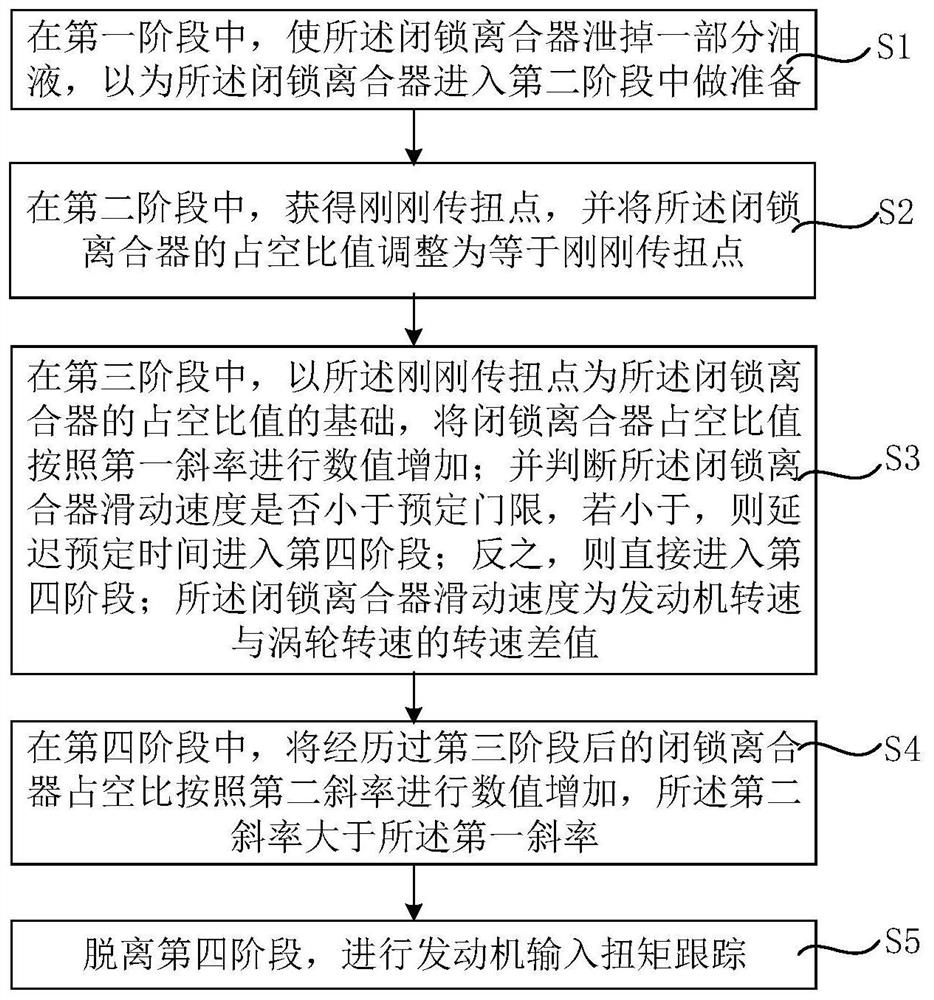

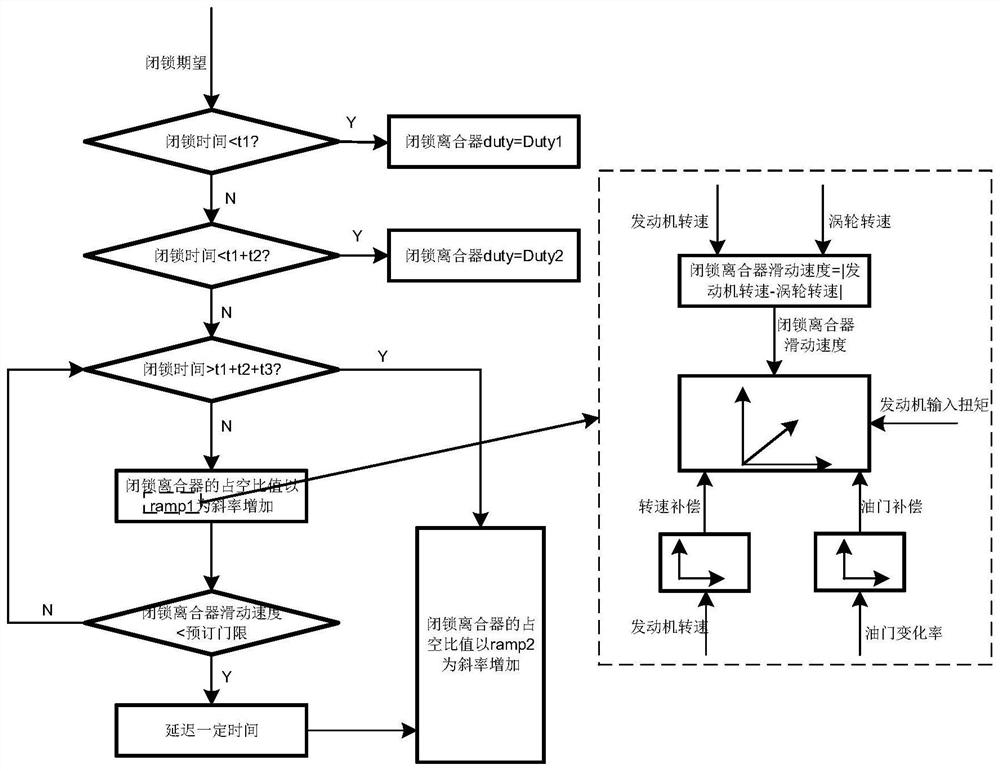

Lockup Pressure Control Method of Lockup Clutch in Torque Converter

ActiveCN111473068BReduce shockImprove robustnessClutchesGearing controlControl theoryPressure controlled method

The present invention provides a lockup pressure control method of a lockup clutch in a hydraulic torque converter. In the third stage, the lockup clutch duty ratio is set to The ratio increases numerically according to the first slope; and it is judged whether the slipping speed of the lock-up clutch is less than a predetermined threshold, and if it is less, then delay the predetermined time to enter the fourth stage; otherwise, directly enter the fourth stage. In the third stage, the first slope adapts to the sliding speed of the lock-up clutch and the input torque of the engine, so that the lock-up clutch can be smoothly transitioned before being pressed, reaching a stable state, which reduces the impact caused by the fixed-slope pressing; in addition, with the second The torque transmission point just in the stage is based on the duty cycle value of the lock-up clutch to sweep the point to realize the locking control, which does not rely on the self-learning of the torque transmission point and has high robustness.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

Detonation accumulation mechanism and cooking device adopting same

InactiveCN106361129ARealize the purpose of fully automatic cookingEnsure safetyCooking vessel supportDetonationMechanical energy

The invention, based on an existing cooking device, is improved, and provides a detonation accumulation mechanism and a cooking device adopting the same. The detonation accumulation mechanism comprises a motor, a first magnetic connecting plate, a magnetic conductive metal plate, a detonation accumulation spring, a detonation accumulation limiting device and an output connecting piece, wherein a thread output shaft is arranged on the motor, the first magnetic connecting plate is arranged on the thread output shaft, and the magnetic conductive metal plate penetrates through the thread output shaft. By removal of a redundant structure and continuous improvement and optimization, the detonation accumulation mechanism can realize more cooking functions, and achieve a better cooking effect, thereby improving the automation degree of cooking. By virtue of a working mode of accumulating and then releasing mechanical energy, the detonation accumulation mechanism provided by the invention can provide energy output by using a power source with higher power, smaller volume and smaller mass, strengthen the action effect greatly by virtue of this power source, achieve an effect of outputting a same equivalent weight with higher power source energy, and replace an execute component (such as an electromagnet) acting directly in the prior art.

Owner:麦维文

A compression device for vortex air flow test tooling

ActiveCN107782544BPrevent rotational displacementAchieve compactionMachine part testingEngine testingSolenoid valveCompression device

The invention discloses a swirler airflow test tool holddown gear comprising a tool mount body with a disc structure; the middle of the tool mount body is provided with a cavity used for mounting thetest tool; a seal pad is arranged in the cavity; the tool mount body is connected with a cylinder bearer through a plurality of poles; a cylinder is arranged on the cylinder bearer; a compact cavity is arranged between the plurality of poles, and arranged right above tool mount body cavity; a control circuit controlling the cylinder to open / close is provided, and comprises a compact switch controlling the cylinder to move downwards, and a first solenoid valve connected with the compact switch; the control circuit also comprises a loose switch used for controlling the cylinder to move upwards,and a second solenoid valve connected with the loose switch; the first and second solenoid valves are respectively connected with the air inlet of the cylinder through a cylinder current limiter; thedevice is reliable in sealing, can conveniently and fast clamp the test tool, and safe and reliable, thus preventing the experiment data inaccurate problems caused by gas leakage.

Owner:AECC AVIATION POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com