Dusty flue gas conveying reversing pipeline and dry desulfurization system

A reversing tube and flue gas technology, applied in the direction of tube elements, separation methods, chemical instruments and methods, etc., can solve the problems of accumulation of dust, inability to operate stably, affecting the normal transportation of dust-laden flue gas, etc., to avoid accumulation and elimination. The effect of accumulating dead spots on the side and reducing the possibility of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

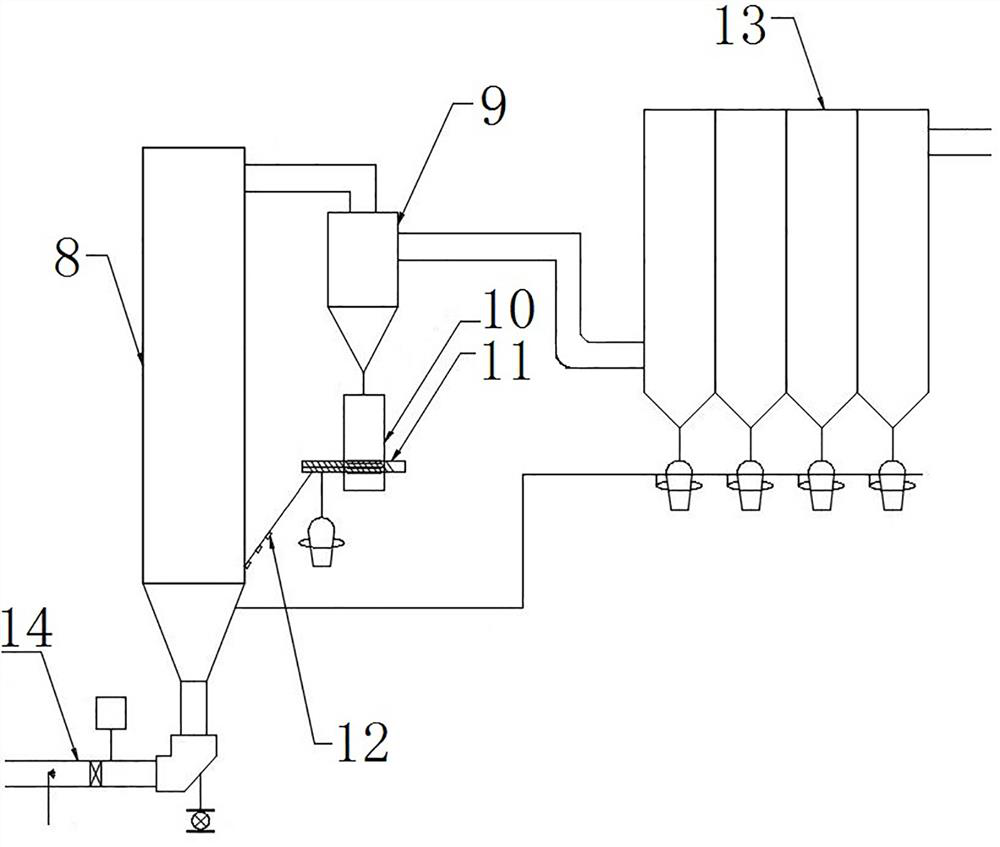

[0050] Such as figure 1 As shown, it includes a desulfurization reaction tower 8, a front dust collector 9, a circulation hopper 10, a lower screw conveyor 11, a circulation ash conveying pipe 12 and a rear dust collector 13. Wherein, the bottom of the desulfurization reaction tower 8 is provided with an air inlet, the air inlet is connected with the air intake flue 14, and the sulfur-containing tail gas is passed into the desulfurization reaction tower 8 through the intake flue gas flue 14, and the sulfur-containing tail gas is desulfurized A high-speed airflow from bottom to top is formed in the reaction tower 8 . The upper part of the front dust collector 9 has an air inlet, and the lower part has a discharge port. The gas outlet of the desulfurization reaction tower 8 communicates with the air inlet of the front dust collector 9. The hopper 10 has a feed inlet and a discharge port. The front dust collector 9 The discharge port of the circular hopper is communicated with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com