Thyristor triggered control method and device for dynamic reactive compensation

A technology of trigger control and thyristor, applied in reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve problems such as lack of real-time performance, response speed limitation, etc., and achieve good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

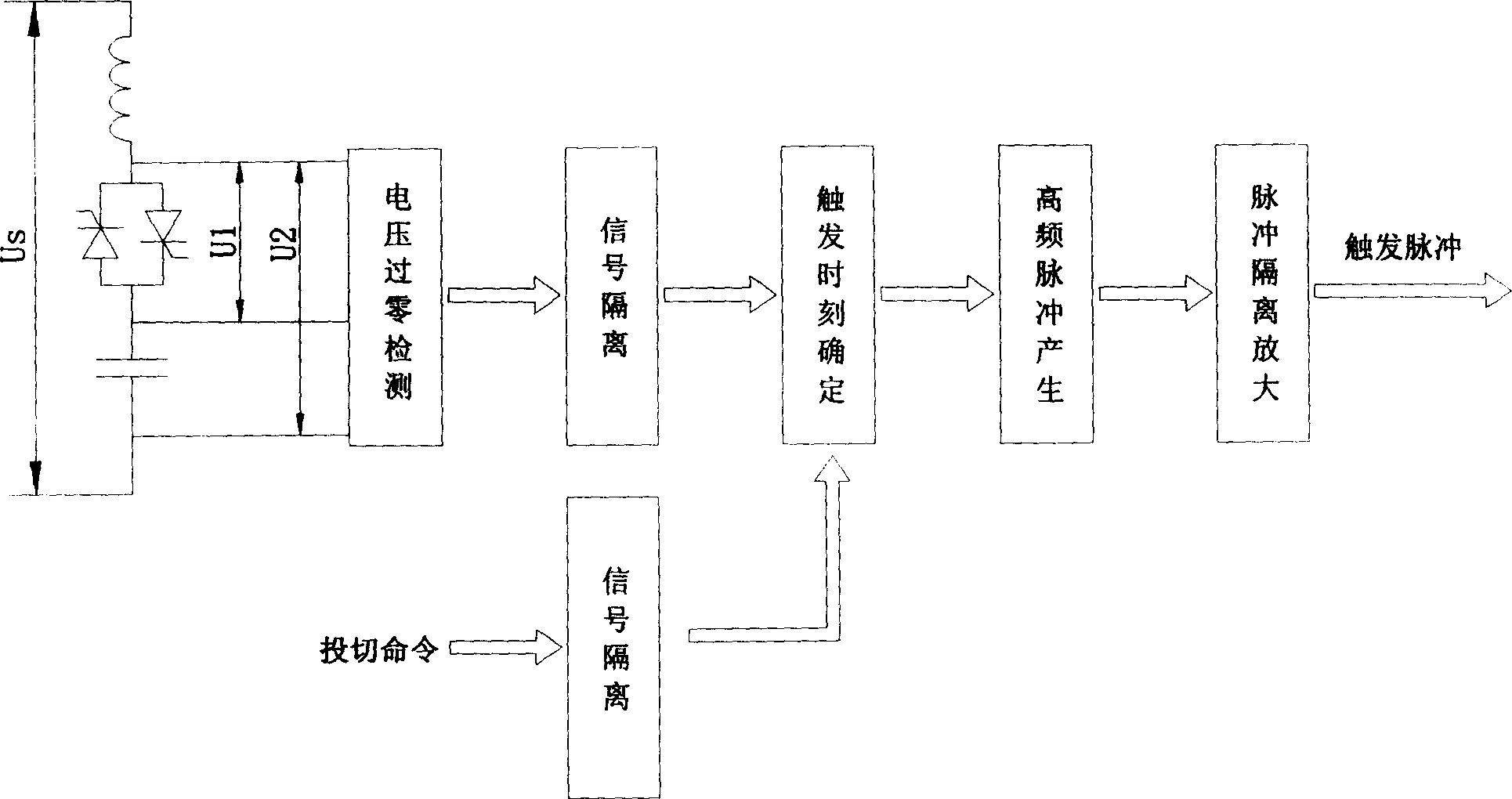

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

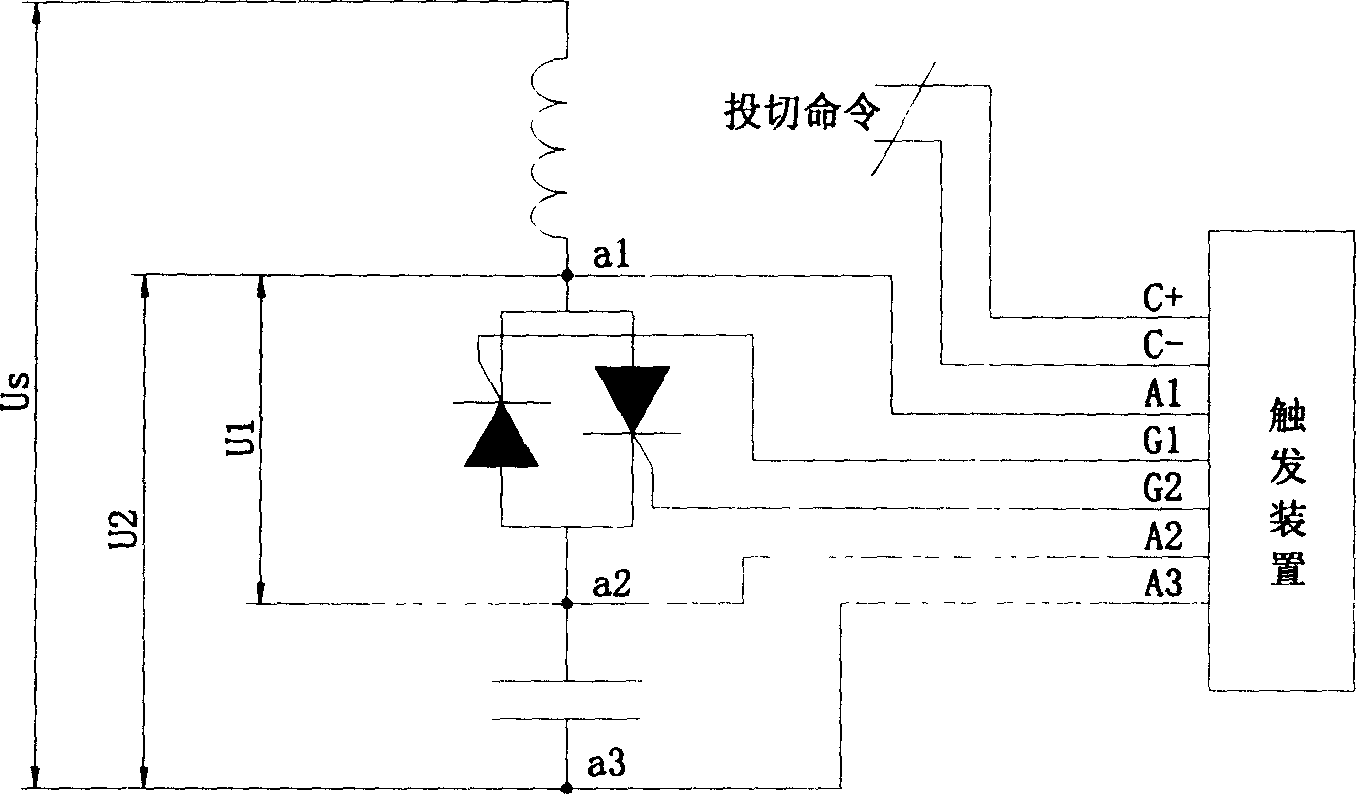

[0049] see Figure 1-Figure 3 , the thyristor trigger control method used for dynamic reactive power compensation timely collects the voltage U1 at both ends a1 and a2 of the thyristor connected in reverse parallel, collects the voltage U2 at both ends a1 and a3 of the thyristor connected in reverse parallel and the capacitor at both ends, and converts the voltage U1 and The voltage U2 is used as the basis for determining the input time of the entire capacitor branch; among them, the voltage U1 is the voltage across the thyristor, and the voltage U2 is the voltage sum of the thyristor and the capacitor;

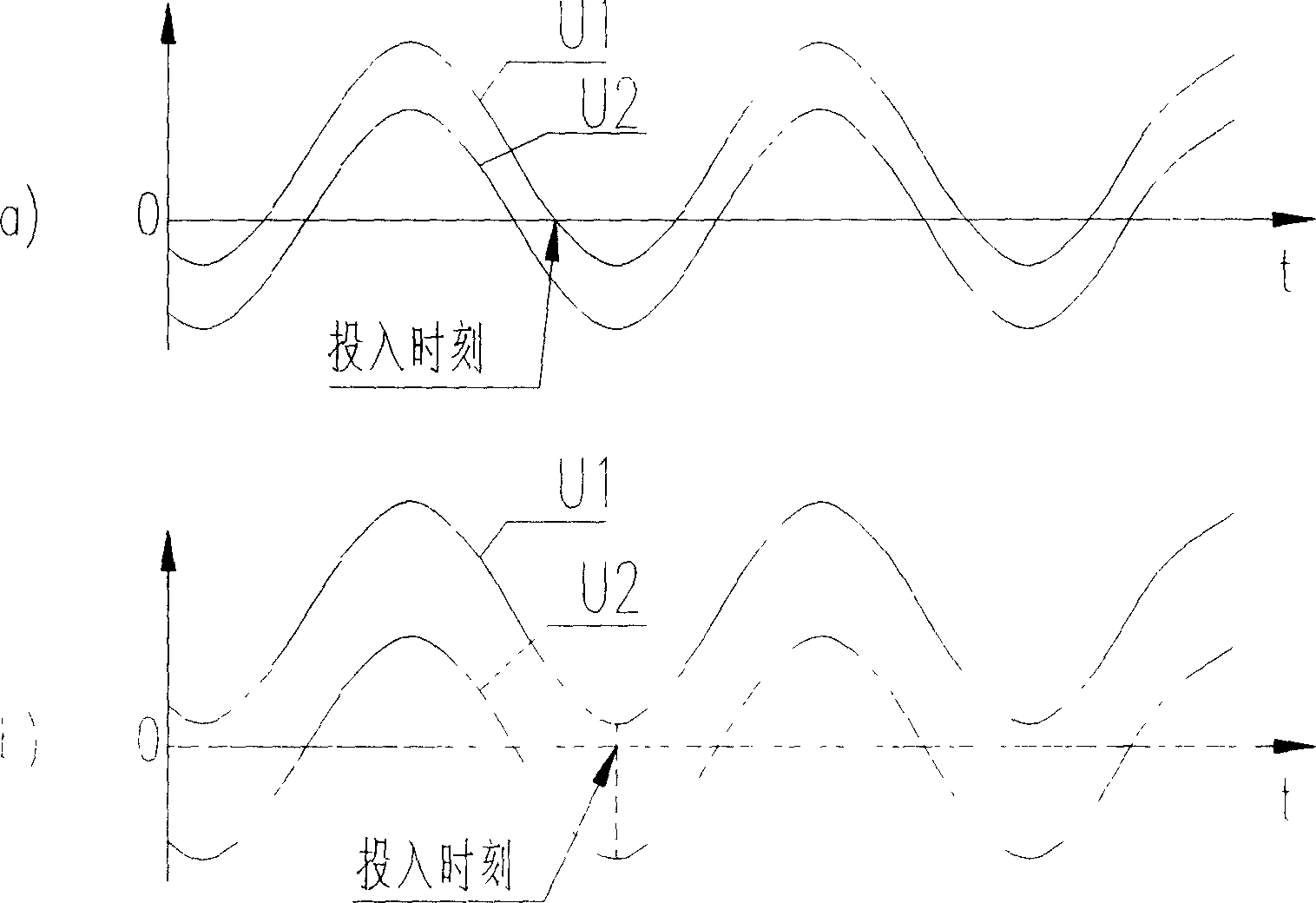

[0050] When the thyristor is not conducting, the voltage U2 is equal to the system voltage U S , the voltage U1 is equal to the system voltage minus the capacitor residual voltage,

[0051] (1) When the capacitor residual voltage is less than the sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com