A Hydraulic Cylinder Control Valve Without Unloading Shock Resonance

A technology of hydraulic cylinders and control valves, which is applied in mining equipment, earthwork drilling, pillars/brackets, etc., and can solve problems such as weld cracking, cylinder overload expansion, and hydraulic control stop valve spring force that cannot be adjusted according to needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

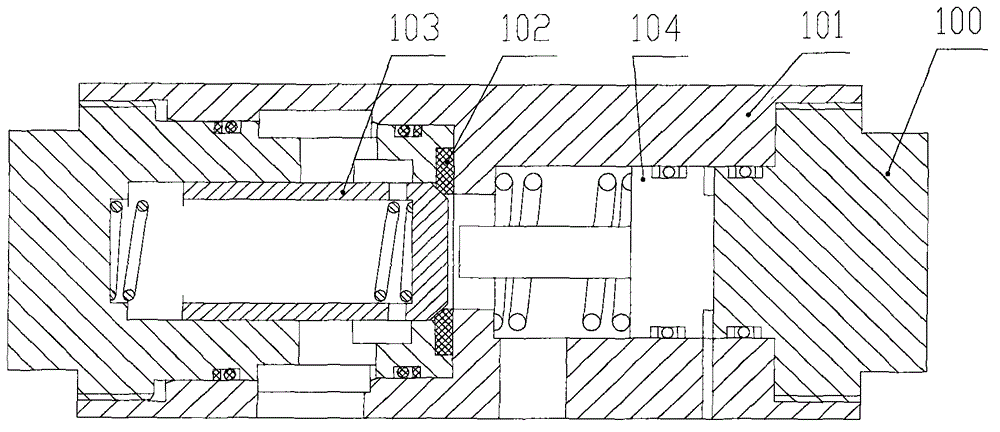

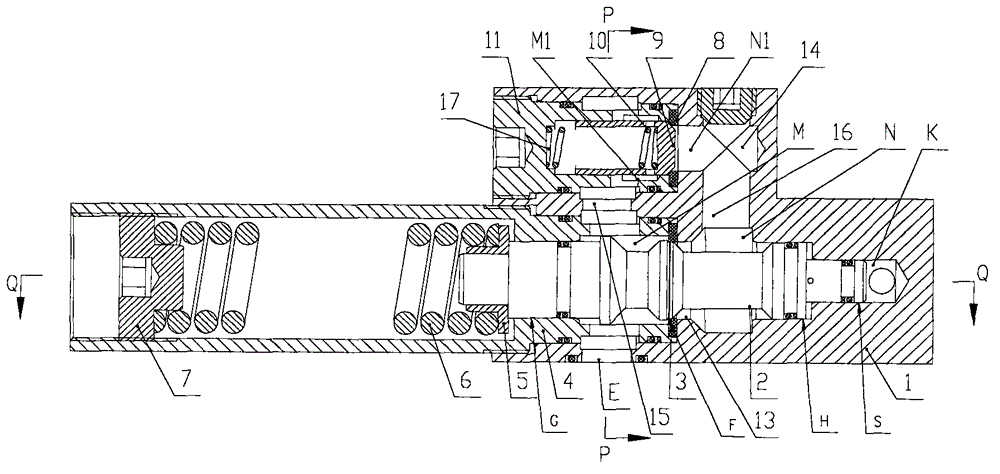

[0058] Such as Figure 3 ~ Figure 5 As shown, the technical solution adopted in the present invention includes a valve body 1, in which a valve body main hole 13, a valve body auxiliary hole 14, a first communication hole 15 and a second communication hole 16 are processed, and in the valve body Install the first valve seat 3, the first valve core 2, the sleeve 4 and the sealing member in the main hole 13, and install the spring seat 5, the first spring 6 and the pressure regulating screw in the sleeve 4. 7. Install the first spool 2, the sleeve 4 and the seal in the main hole 13 of the valve body to form the main hole sealing chamber M, the main hole liquid return chamber N and the control chamber K. The first spool 2 includes In addition to the diameter G of the sealing section of the same diameter as the sealing diameter F of the valve port and the diameter H of the liquid return section, there is also a diameter S of the control section with a smaller diameter. The diamet...

specific Embodiment approach 2

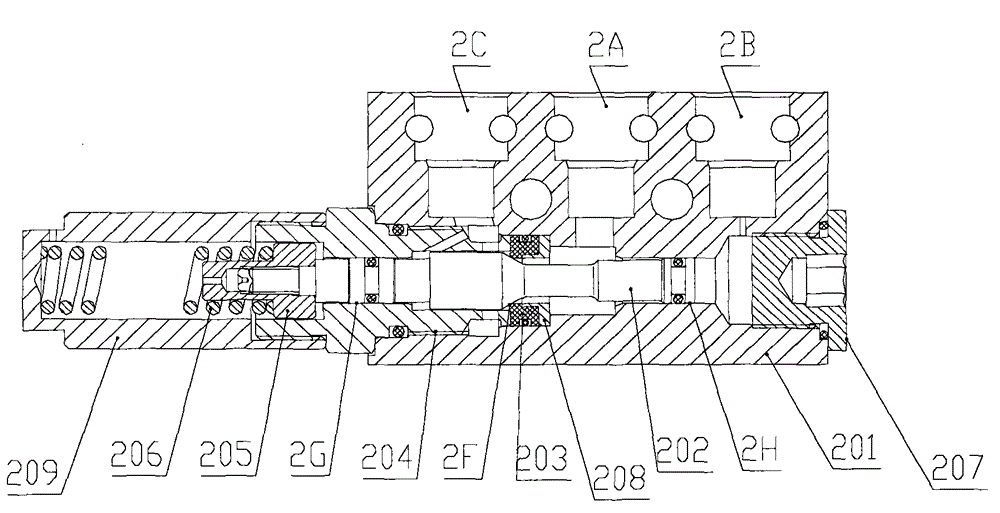

[0060] Such as Figure 6 As shown, the technical solution adopted in Embodiment 2 of the present invention is the same as that in Embodiment 1, the difference is that the valve body 1 is connected with a plate-type connection check valve 601 that communicates with it in place of the auxiliary hole check valve 601 in the valve body 1. The one-way valve 17 has a plate-type connection check valve sealing cavity 6M2 and a plate-type connection check valve liquid inlet chamber 6N2 in the valve body of the plate-type connection check valve 601, and the main hole seal chamber M and the plate-type connection check valve seal cavity 6M2 It communicates with the plate connection, and leads to the plate connection interface E, and communicates with the fifth interface C and the sixth interface C1. The main hole liquid return chamber N communicates with the plate connection check valve inlet chamber 6N2 during the plate connection. , and communicate with the first interface A and the seco...

specific Embodiment approach 3

[0061] Such as Figure 7 As shown, the technical solution adopted in Embodiment 3 of the present invention is the same as that in Embodiment 1, the difference is that the pipe connection check valve 701 connected to the valve body 1 outside the valve body 1 replaces the auxiliary valve 701 in the valve body 1. The hole check valve 17, in the valve body of the pipe type connection check valve 701, has a pipe type connection check valve sealing chamber 7M2 and a pipe type connection check valve inlet chamber 7N2, the main hole sealing chamber M and the pipe type Connect the check valve sealing chamber 7M2 to communicate with the pipe connection, and communicate with the plate connection interface E, the fifth interface C and the sixth interface C1, the first interface A, the second interface A1, the main hole liquid return chamber N It communicates with the liquid inlet cavity 7N2 of the pipe connection check valve 701 by installing a tee 702 and a section of communication pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com