Immersion nozzle for casting central point of ultrathin special-shaped blank

An immersion, special-shaped blank technology, applied in casting equipment, casting melt containers, metal processing equipment, etc., can solve the problems of many defects in ultra-thin shaped blanks and affect the pass rate, etc. The effect of flow field and temperature field stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

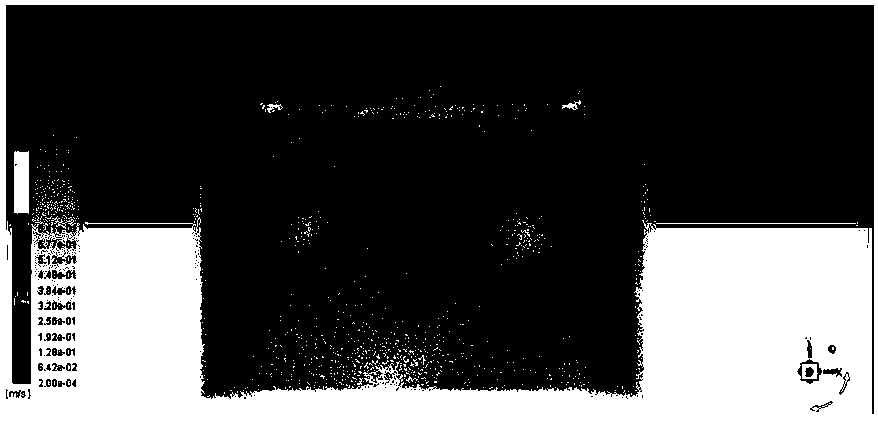

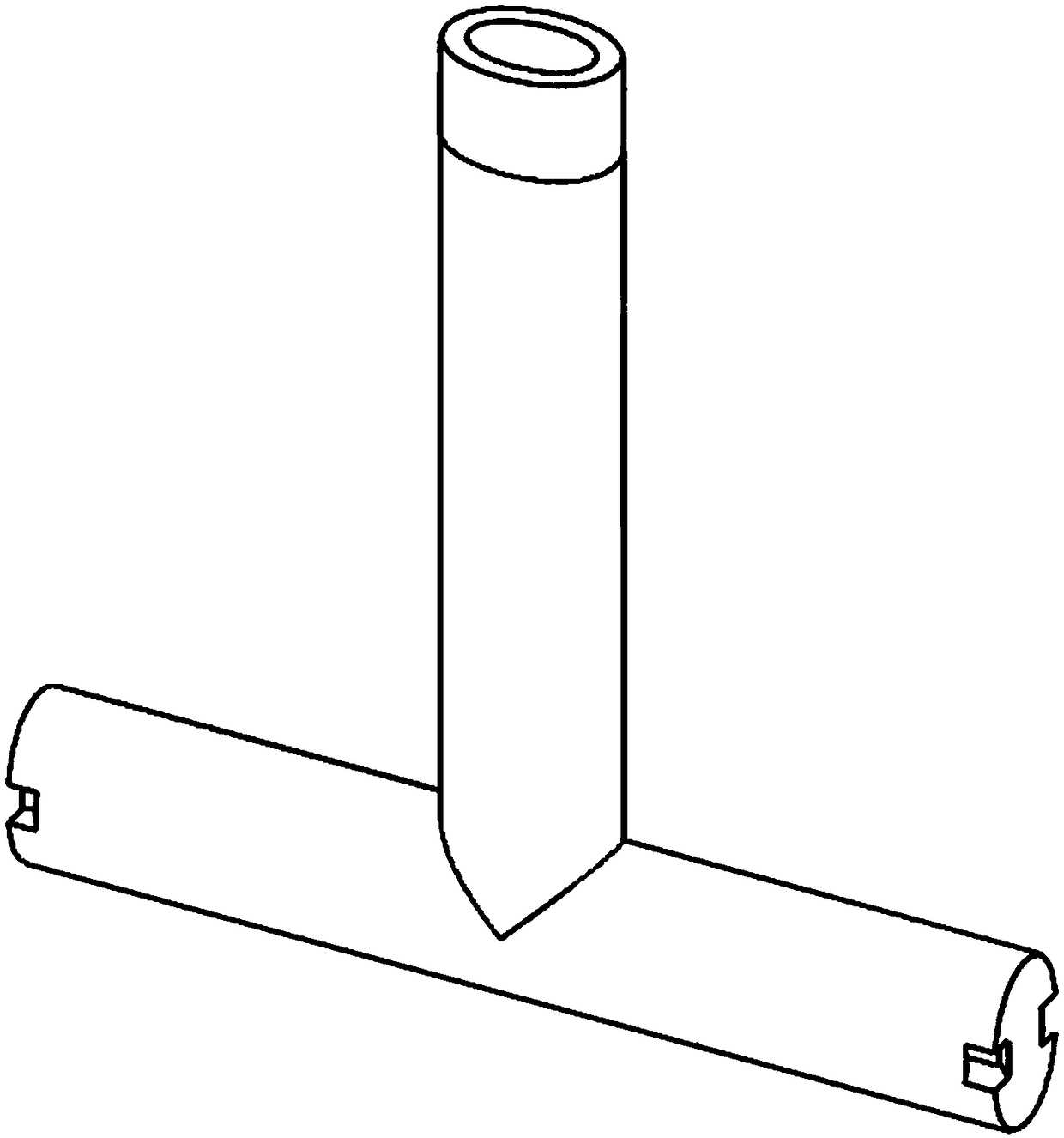

[0057] image 3 The section size of the special-shaped blank shown is 900mm×450mm, the length of the web 10 of the special-shaped blank is 600mm, and the width is 100mm; the radius of the first rounded corner 12 at the flange 11 of the special-shaped blank is 80mm, and the second rounded corner is 13 round The arc radius is 50mm.

[0058] against image 3 The special-shaped billet shown corresponds to the crystallizer used. This embodiment provides a submerged nozzle for casting at the center of the ultra-thin special-shaped billet. The specific structure is as follows figure 1 , figure 2 As shown, the length of the mouth portion 4 of the vertical section of the submerged nozzle is 100 mm, the angle between the extension line of the mouth portion 4 and the center line of the vertical section 2 is 15°, and the mouth portion 4 is connected to the upper nozzle of the tundish. The connection is protected by inert gas, the length of the vertical section 2 is 500mm, the length o...

Embodiment 2

[0061] The structure of this embodiment is the same as that of Embodiment 1, except that submerged nozzles of different sizes and specifications are provided. image 3 The crystallizer required for the production of the profiled billet is shown, and this embodiment provides a submerged nozzle for casting at the center of the ultra-thin profiled billet.

[0062] The length of the bowl mouth 4 of the vertical section of the submerged nozzle is 80mm, and the angle between the extension line of the bowl mouth 4 and the center line of the vertical section 2 is 30°. Protected by inert gas, the length of the vertical section 2 is 450mm, the length of the horizontal section 3 is 360mm, and the oval cross-sectional area c is 1000mm 2 . A pair of circular through-holes 7 are symmetrically arranged at both ends of the horizontal section 3 along the central point of the elliptical cross-section, and the sum b of the cross-sectional areas of the two circular through-holes 7 is 300mm 2 , ...

Embodiment 3

[0065] The structure of this embodiment is the same as that of Embodiment 1, except that submerged nozzles of different sizes and specifications are provided. image 3 The crystallizer required for the production of the profiled billet is shown, and this embodiment provides a submerged nozzle for casting at the center of the ultra-thin profiled billet.

[0066] The length of the bowl mouth 4 of the vertical section of the submerged nozzle is 110mm, and the angle between the inner extension line of the bowl mouth 4 and the center line of the vertical section 2 is 20°. Protected by gas, the length of the vertical section 2 is 500mm, the length of the horizontal section 3 is 720mm, and the elliptical cross-sectional area c is 900mm 2 . A pair of elliptical through-holes 7 are arranged symmetrically along the lower end of the short axis of the elliptical cross-section in the horizontal section 3, and the sum b of the cross-sectional areas of the two elliptical through-holes 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com