Low-vibration energy-saving air distribution camshaft of engine of motor vehicle

A valve cam, engine technology, applied in the direction of machine/engine, engine components, mechanical equipment, etc., can solve the problems of large valve switch vibration, unstable crankshaft valve opening and closing process, high noise, etc., to reduce fuel consumption, valve spring Moderate tightness, reducing vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

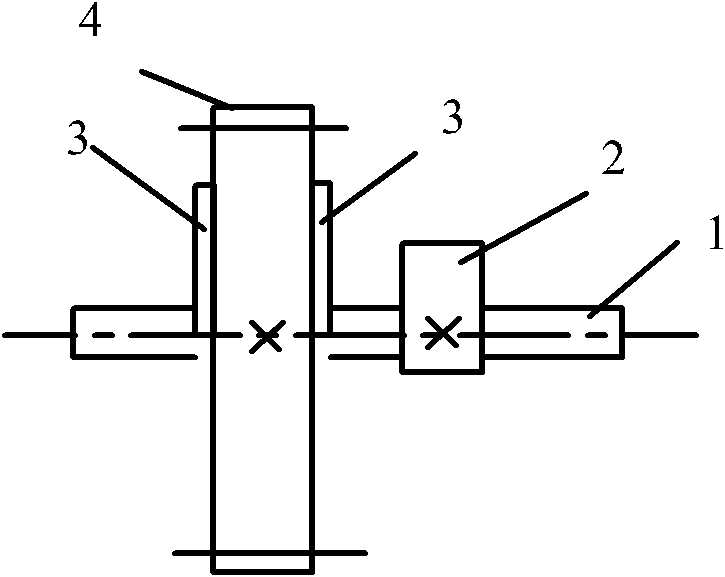

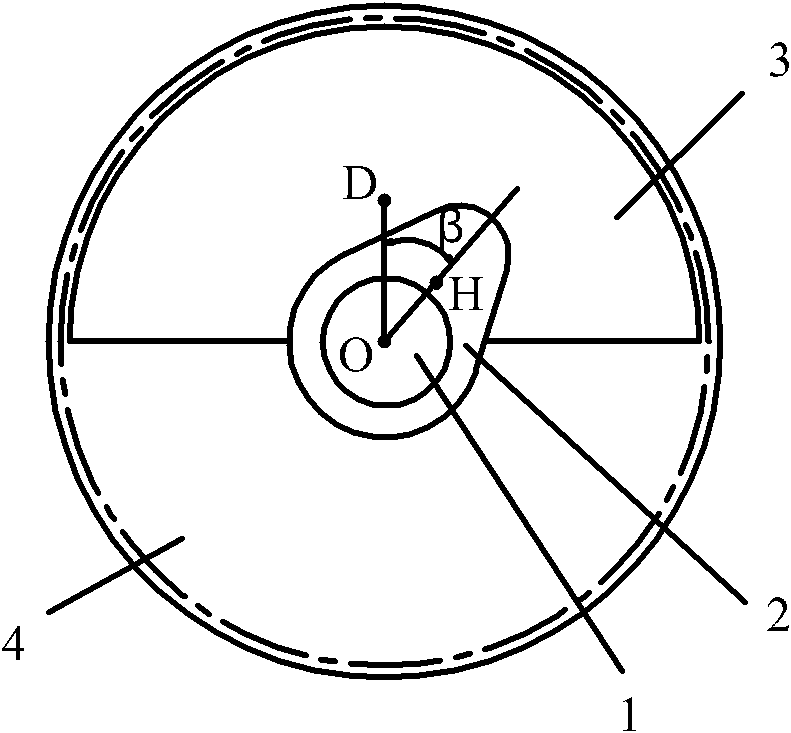

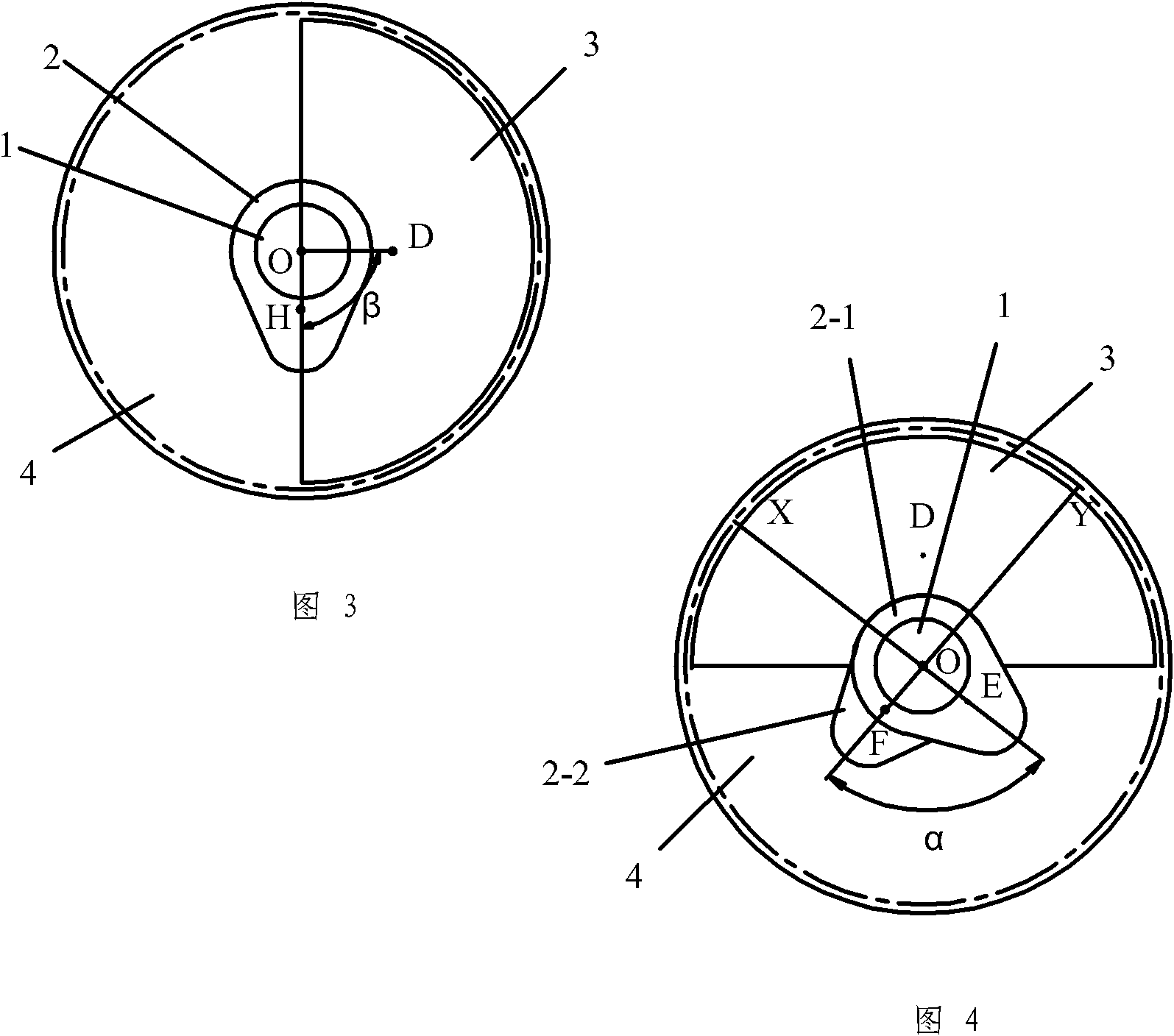

[0006] Specific embodiment one: the following combination figure 1 and figure 2 The present embodiment will be specifically described. This embodiment includes a shaft body 1, a valve cam 2 and a power transmission wheel 4. The valve cam 2 and the power transmission wheel 4 are fixed on the shaft body 1 and the former two rotate coaxially with the shaft body 1. It also includes Eccentric disc body 3, the eccentric disc body 3 is arranged on the shaft body 1 and the disc body surface of the eccentric disc body 3 is perpendicular to the shaft body 1, the mass center D of the eccentric disc body 3 in the circumferential direction of the shaft body 1 The connection line with the shaft body 1 is deviated from the connection line between the mass center H of the valve cam 2 and the shaft body 1 . The power transmission wheel 4 transmits the power from the crankshaft of the internal combustion engine.

specific Embodiment approach 2

[0007] Specific embodiment two: the following combination figure 1 and figure 2 The present embodiment will be specifically described. The difference between this embodiment and the first embodiment is that the eccentric disc body 3 is fixed on one end face of the power transmission wheel 4 . The eccentric disc body 3 of this embodiment is arranged on the shaft body 1 in this way, which not only achieves a compact structure, but also enables the eccentric disc body 3 to be reliably fixed.

specific Embodiment approach 3

[0008] Specific embodiment three: the following combination figure 1 The present embodiment will be specifically described. The difference between this embodiment and the second embodiment is that it further includes another eccentric disc body 3 , and the two eccentric disc bodies 3 are respectively fixed on both end faces of the power transmission wheel 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com