Automatic on-line analysis electrophoresis tank

An electrophoresis tank and automatic technology, used in electrophoresis plating, electrolytic paint, coating and other directions, can solve the problems of the electrophoresis production line being unable to run continuously for a long time, costing labor costs, affecting production efficiency, etc., to achieve fully automatic operation, The effect of reducing labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

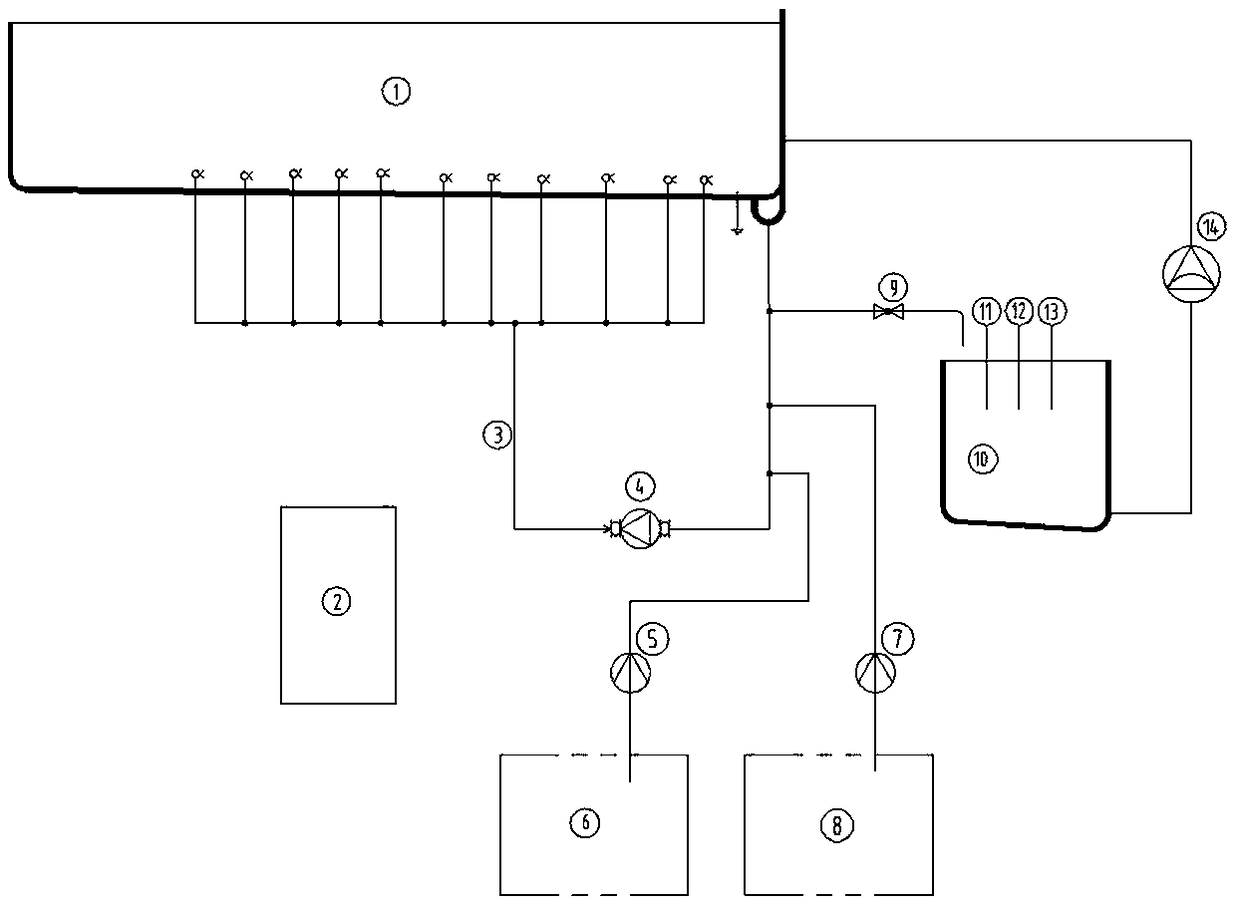

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] like figure 1 As shown, the automatic online analysis electrophoresis tank of the present invention comprises a main tank 1, a liquid outlet and a liquid return port are arranged on the main tank 1, and a circulation pipeline 3 connecting the liquid outlet and the liquid return port is arranged outside the main tank 1, and the circulation pipe Circulation stirring pump 4 is arranged on road 3. The main tank 1 is provided with an assay analysis tank 10 , an electrophoretic paint base liquid storage tank 8 and a neutralizing liquid storage tank 6 .

[0024] A liquid outlet pipeline is connected between the assay analysis tank 10 and the main tank 1, and a solenoid valve 9 is arranged on the liquid outlet pipeline. A liquid return pipeline is also connected between the assay analysis tank 10 and the main tank 1 , and a diaphragm pump 14 is provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com