Device for detecting inner and outer rubbing resistance of steel pipe piles

A technology of steel pipe piles and frictional resistance, which is applied in foundation structure testing, construction, foundational structure engineering, etc., can solve problems such as immature frictional resistance in soil plug sections, and achieve the advantages of convenient application, wide application prospects, and quick operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

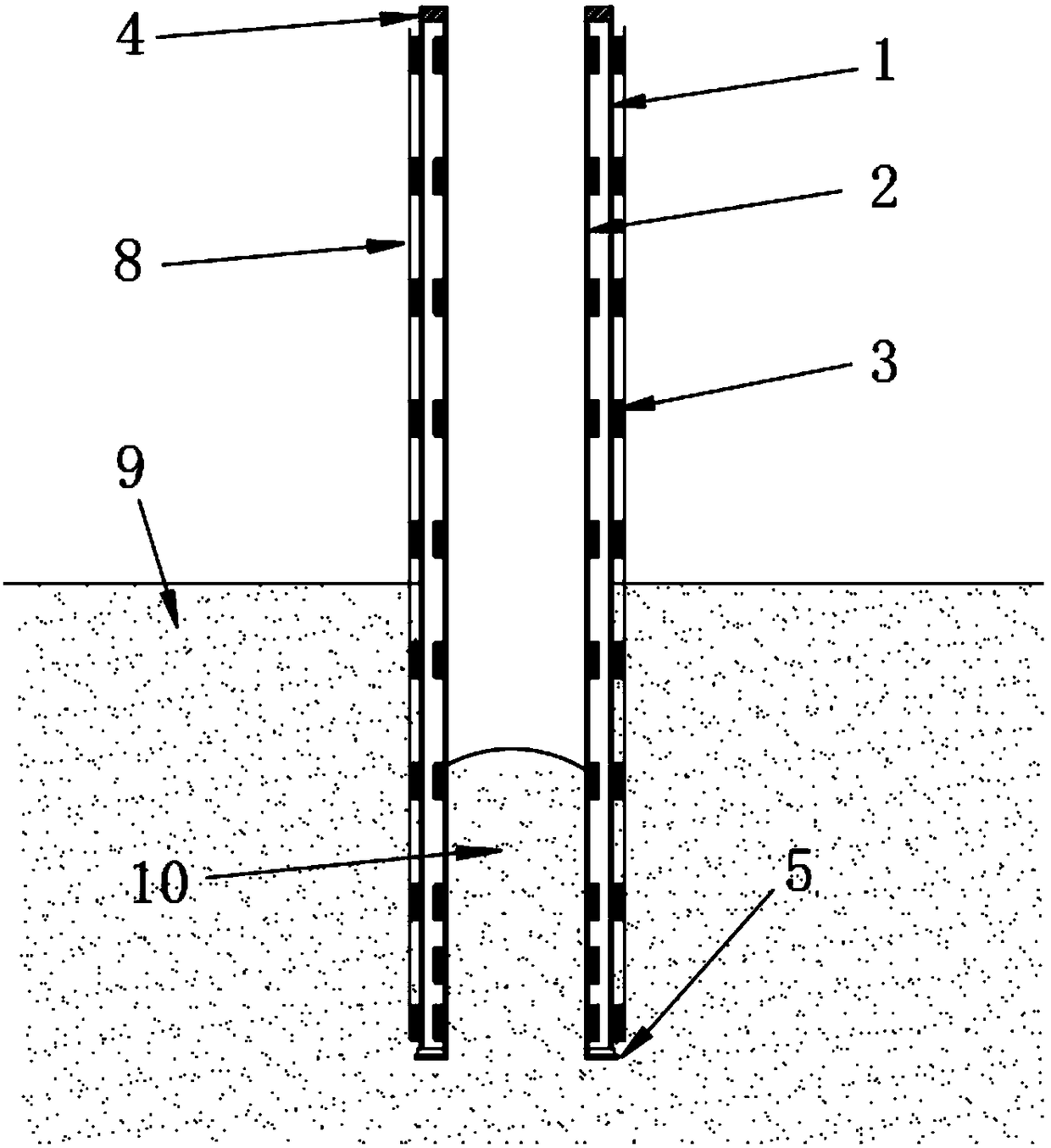

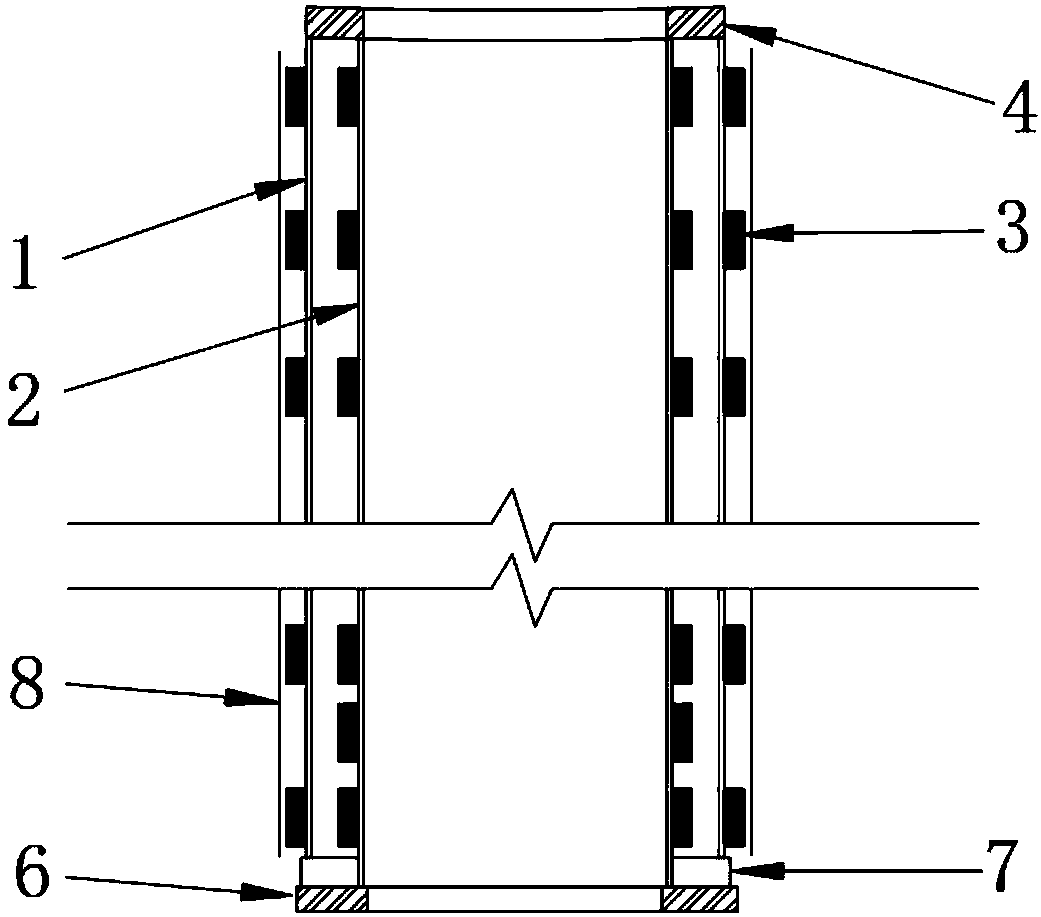

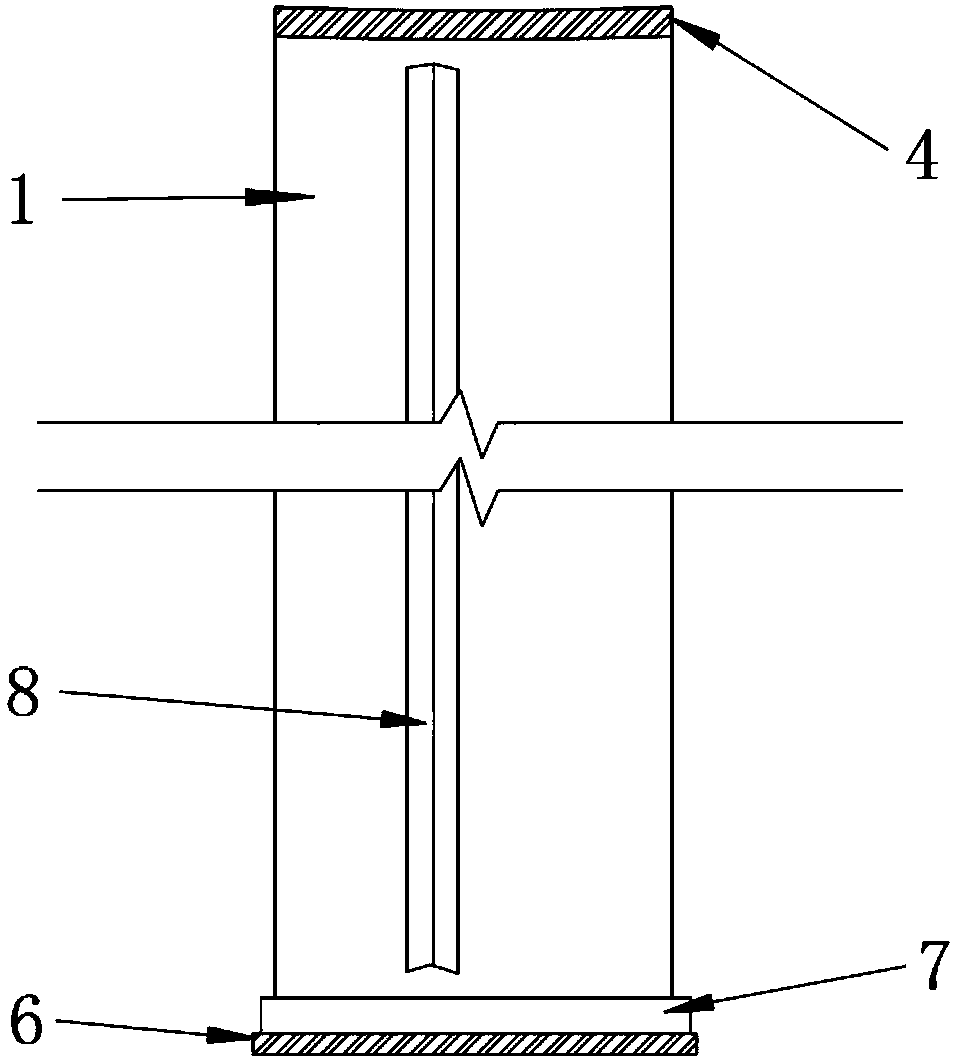

[0031] Such as Figure 1-6 As shown, a device for detecting internal and external frictional resistance of steel pipe piles, said steel pipe piles include outer steel pipe piles 1 and inner steel pipe piles 2 concentrically nested together, outer steel pipe piles 1 and inner steel pipe piles 2 The side walls are not in contact with each other, and the tops of the outer steel pipe pile 1 and the inner steel pipe pile 2 are aligned and jointly welded to the lower surface of the backing plate 4 on the top of the pile, so as to ensure that there is no leveling between the outer steel pipe pile 1 and the inner steel pipe pile 2 Relative displacement, the bottom end of the inner steel pipe pile 2 protrudes from the bottom end of the outer steel pipe pile 1, and a pile bottom seal 5 is provided at the bottom ends of the outer steel pipe pile 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com