High-intensity zone prefabricated profiled steel plate viscous damping wall and construction method thereof

A technology of viscous damping wall and profiled steel plate, which is applied in building types, building components, earthquake resistance, etc., can solve the problems of complex on-site construction and insufficient energy consumption capacity of ordinary steel plate walls, and achieves short construction period, fast construction, and safety reserves. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

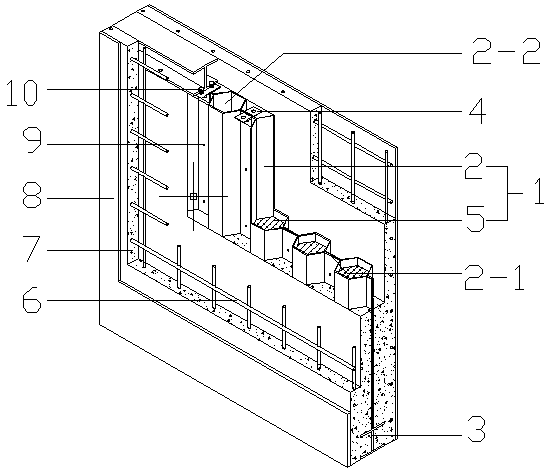

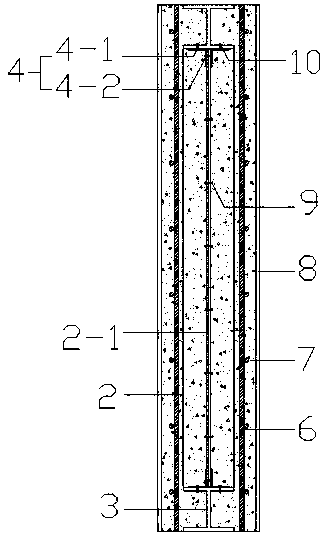

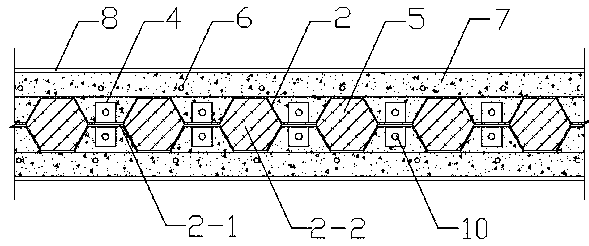

[0022] Example: such as Figure 1-3 As shown, the energy-dissipating inner core plate 1 is composed of two identical profiled steel plates 2 and viscous material 5. The profiled steel plates 2 are provided with tooth grooves 2-1, and self-tapping screws 9 are set on the surface of the tooth grooves 2-1. , the tooth grooves 2-1 on the two profiled steel plates 2 are relatively arranged and in contact with each other, the two profiled steel plates 2 are tightly connected by self-tapping screws 9, and form a hexagonal cavity 2-2, the cavity 2-2 The interior is filled with viscous material 5; the two ends of the energy-dissipating inner core plate 1 are provided with I-beams 3, and the I-beam 3 and the energy-dissipating inner core plate 1 are closely connected by angle steel connectors 4, and the angle steel 4 is connected There are bolt holes a4-1 and bolt holes b4-2 on the piece, the angle steel connecting piece 4 and the lower flange of the I-beam 3 are fastened and connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com