Explosive bolt protecting device for retarding operational fragments and explosive bolt system

A technology of explosive bolts and protection devices, which is applied in the field of rocket separation, can solve the problems of box rupture, large impact, and debris flying out, and achieve the effects of prolonging the collision time, buffering the impact force of the explosion, and avoiding debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

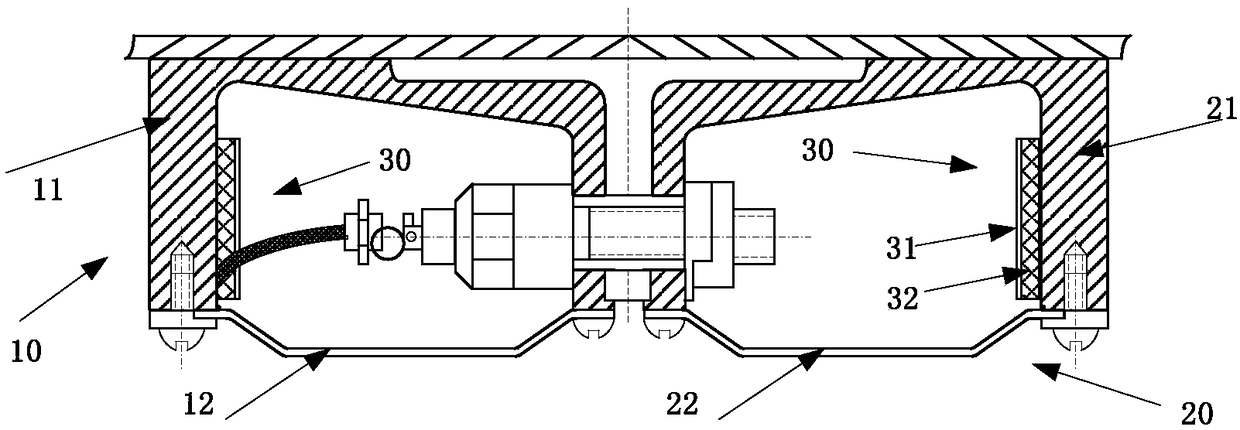

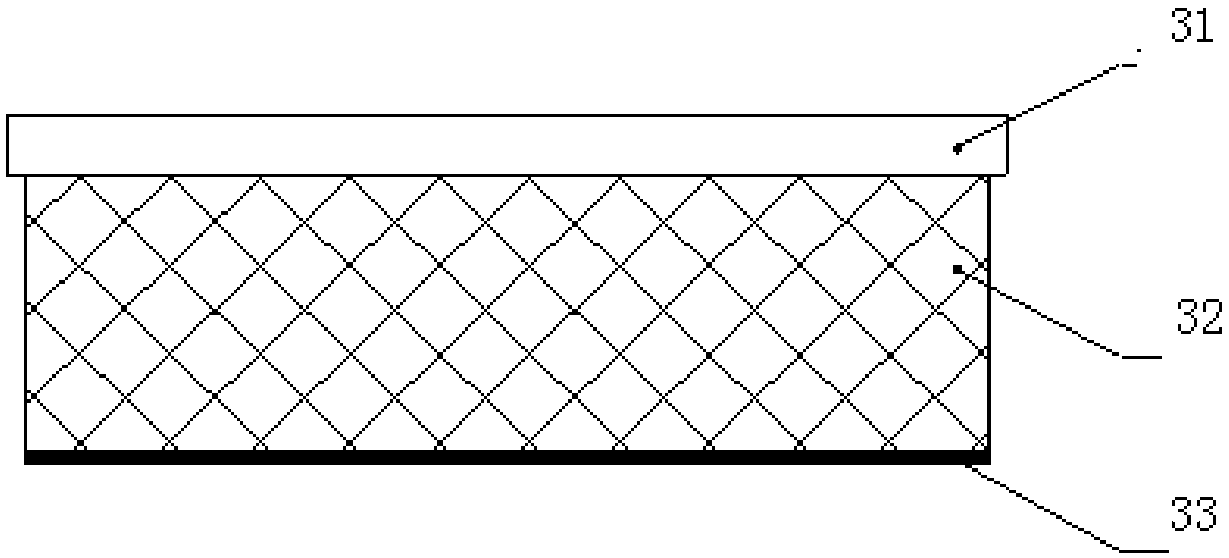

[0039] This embodiment provides an explosive bolt system, including an explosive bolt protection device and an explosive bolt 40, and the explosive bolt 40 is 3CC0-200; the explosive bolt protection device is basically the same as that of Comparative Example 1, and the difference is that it is based on the comparative example , the second side wall of the first box body 11 and the second side wall of the second box body 21 are provided with a buffer assembly 30, the second side wall is opposite to the first side wall, and the buffer assembly 30 includes a laminated first metal layer 31, an elastic buffer layer 32 and a second metal layer 33, the first metal layer 31 is made of 30CrMnSiA material and has a thickness of 3 mm, and the elastic buffer layer 32 is made of a metal rubber material wound by 1Cr18Ni9Ti stainless steel wire with a wire diameter of 0.2 mm. The final thickness is 20mm, and the density is 2750kg / m in the non-loaded state 3 , the second metal layer 33 is mad...

Embodiment 2

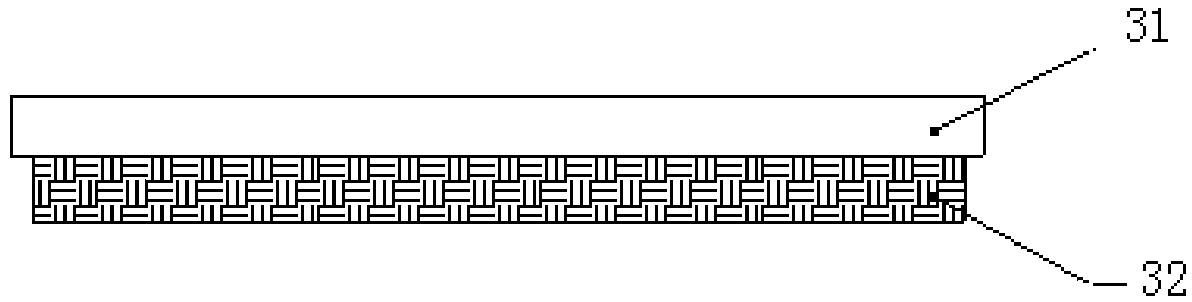

[0041] This embodiment provides an explosive bolt system, including an explosive bolt protection device and an explosive bolt 40, and the explosive bolt 40 is 3CC0-200; the explosive bolt protection device is basically the same as that of Comparative Example 1, and the difference is that it is based on the comparative example , the second side wall of the first box body 11 and the second side wall of the second box body 21 are provided with a buffer assembly 30, the second side wall is opposite to the first side wall, and the buffer assembly 30 includes a laminated first metal layer 31 and the elastic buffer layer 32, the first metal layer 31 is made of 45# steel material with a thickness of 4mm, and the elastic buffer layer 32 is made of rubber plate material with a thickness of 3mm, and the first metal layer 31 is bonded to the elastic buffer layer 32 by bonding Fixedly connected, the elastic buffer layer 32 is fixedly connected to the second side wall by means of adhesive bo...

Embodiment 3

[0043] This embodiment provides an explosive bolt system, including an explosive bolt protection device and an explosive bolt 40, and the explosive bolt 40 is 3CC0-200; the explosive bolt protection device is basically the same as that of Comparative Example 1, and the difference is that it is based on the comparative example , the second side wall of the first box body 11 and the second side wall of the second box body 21 are provided with a buffer assembly 30, the second side wall is opposite to the first side wall, and the buffer assembly 30 includes a laminated first metal layer 31, an elastic buffer layer 32 and a second metal layer 33, the first metal layer 31 is made of 30CrMnSiA material and has a thickness of 3 mm, and the elastic buffer layer 32 is made of a metal rubber material wound by 1Cr18Ni9Ti stainless steel wire with a wire diameter of 0.2 mm. The final thickness is 30mm, and the density is 2750kg / m in the non-loaded state 3 , the second metal layer 33 is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com