An organic light-emitting diode display screen capable of detecting pressing force and a method of manufacturing the same

A technology of light-emitting diodes and display screens, applied in semiconductor/solid-state device manufacturing, data processing input/output process, instruments, etc., can solve problems such as poor uniformity, affecting data processing efficiency, and complex data of pressure detection capacitance change , to achieve the effect of increasing the compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

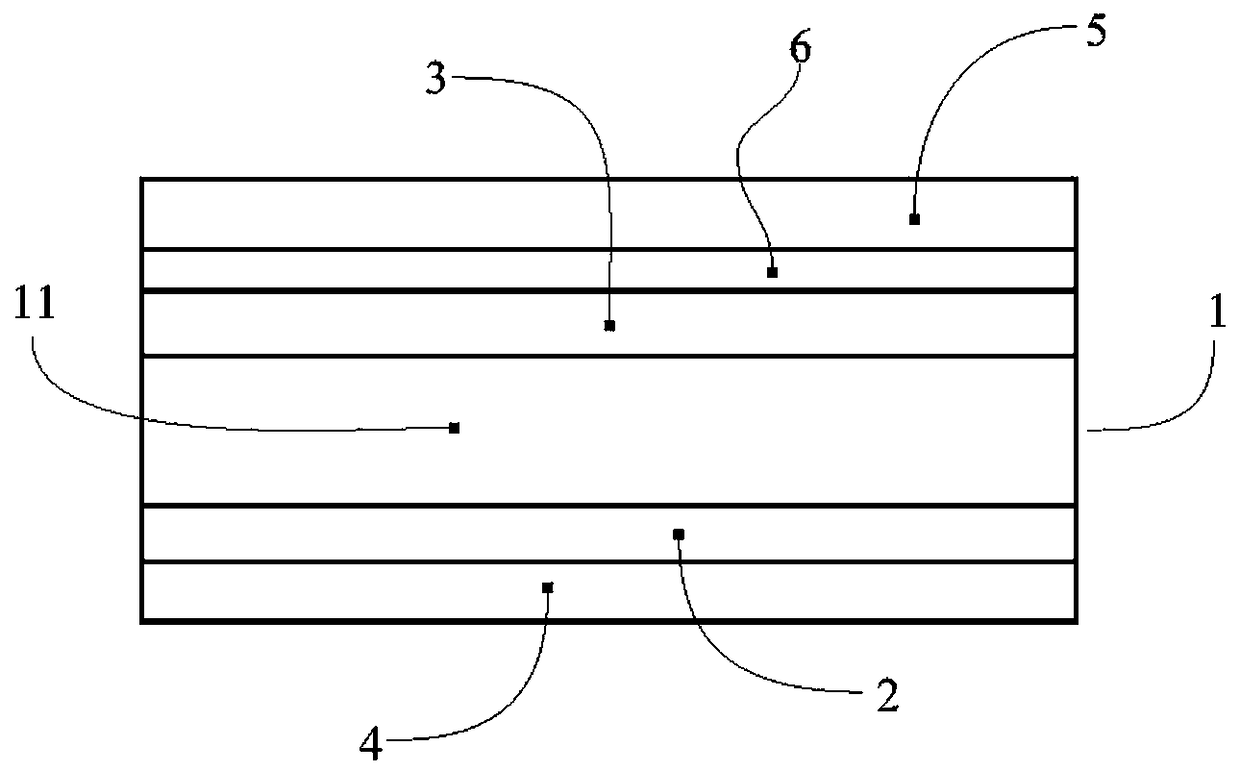

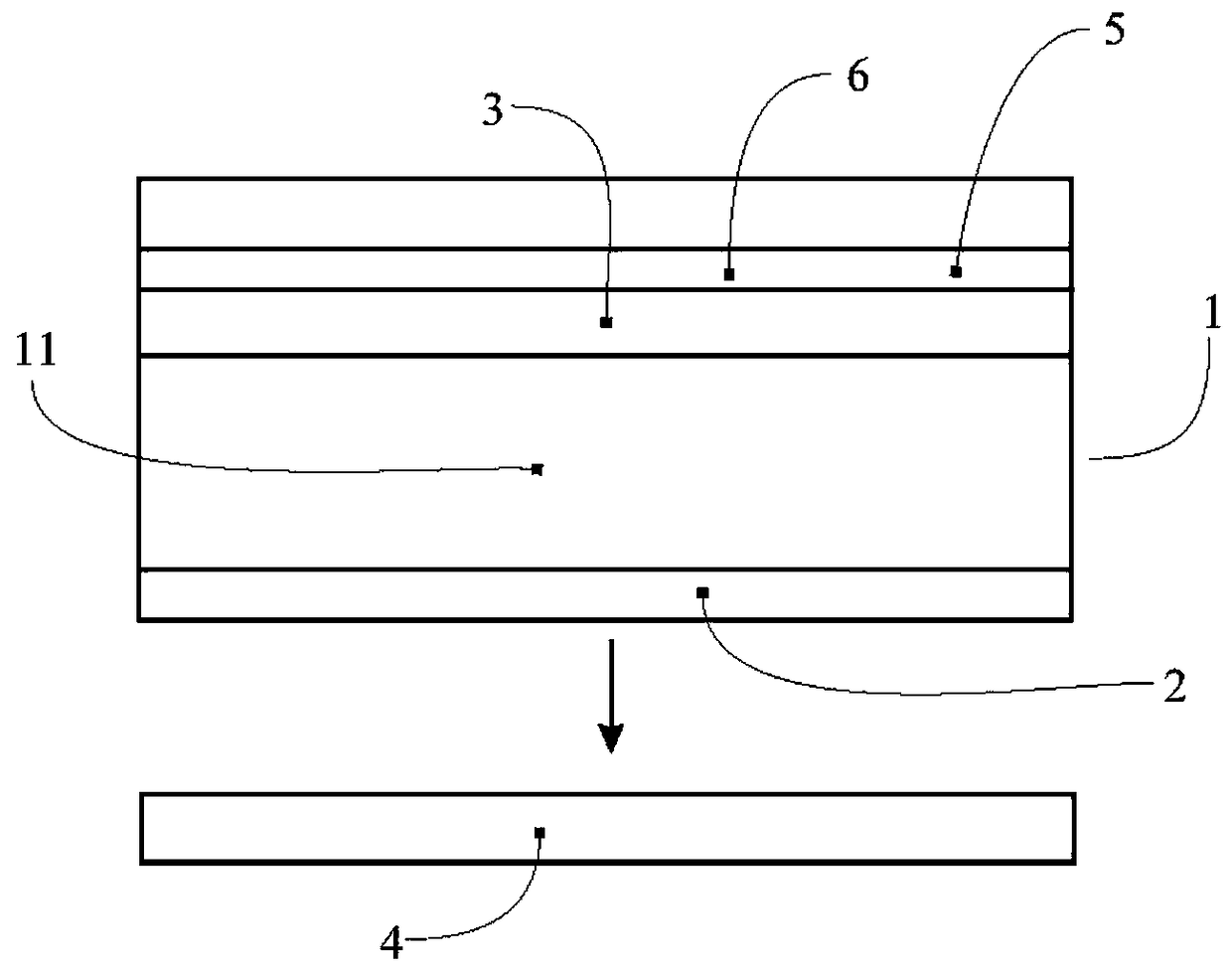

[0030] In the first embodiment of the present invention, the organic light emitting diode OLED display module 3 is an Active Matrix Organic Light Emitting Diode display module, referred to as an AMOLED display module.

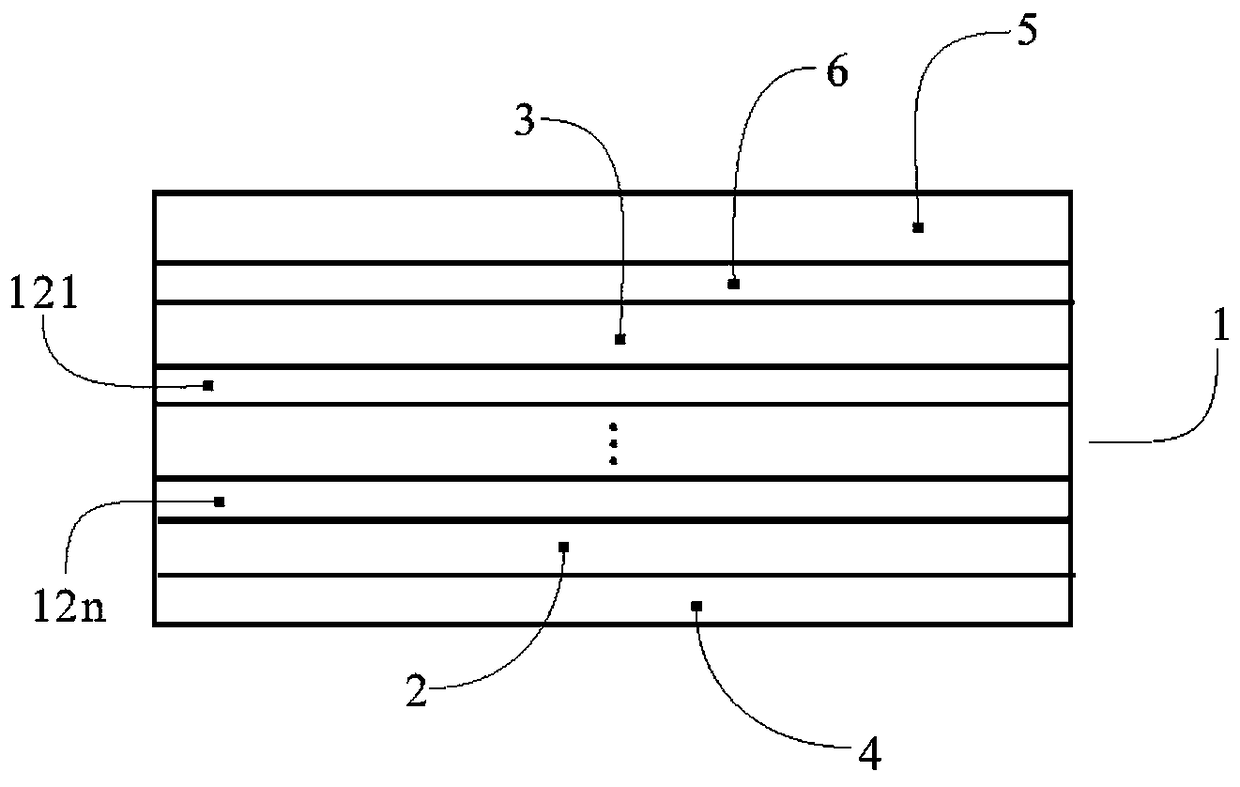

[0031] The second embodiment of the present invention, such as image 3 As shown, the filler 1 is a composite foam formed by laminating at least two foams, that is, the composite foam is formed by laminating foam 121, foam 122, foam 123, ..., foam 12n, n≥2 . The manufacturing material and / or maximum compression ratio of any two foams in the composite foam are different, that is, at least one of the two characteristic data of each layer of foam is different in the manufacturing material and maximum compression ratio, so as to distinguish different foams . For example, two layers of foam are made of the same material but have different maximum compression ratios, or two layers of foam have the same maximum compression ratio but are made of different materials, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com