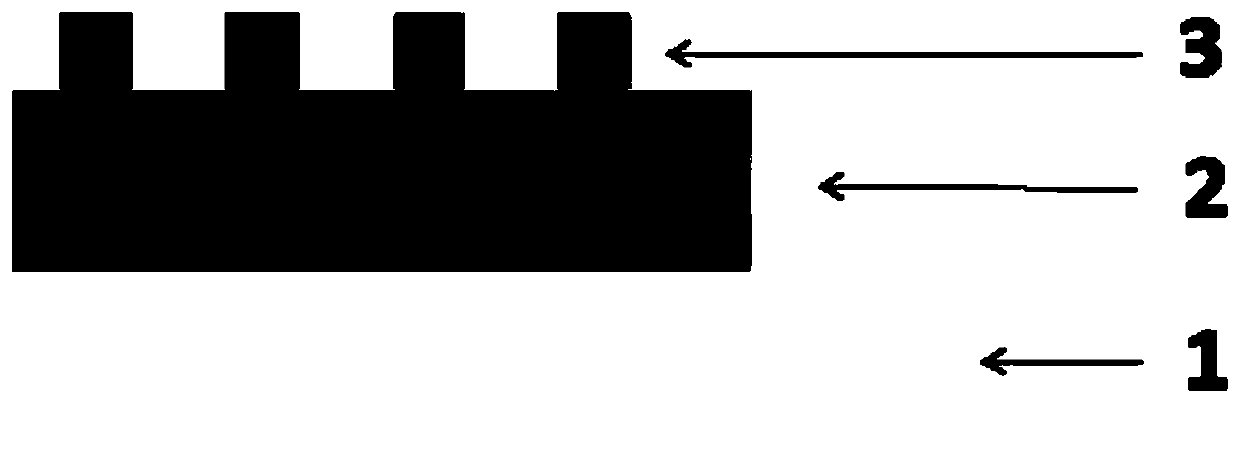

A kind of all-inorganic perovskite resistive variable memory and its preparation method

A technology of resistive memory and inorganic calcium, applied in electrical components and other directions, can solve problems such as solvent cannot be completely removed, secondary phases are prone to appear in the film, and film quality is reduced, and achieves good anti-aging properties, convenient operation, and large storage window. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1. Clean the ITO substrate

[0038] Ultrasonic the ITO substrate in deionized water, acetone, and alcohol for 40 minutes, dry the ITO, stick insulating tape, and irradiate the ITO surface with ultraviolet light for 30 minutes in a UV instrument;

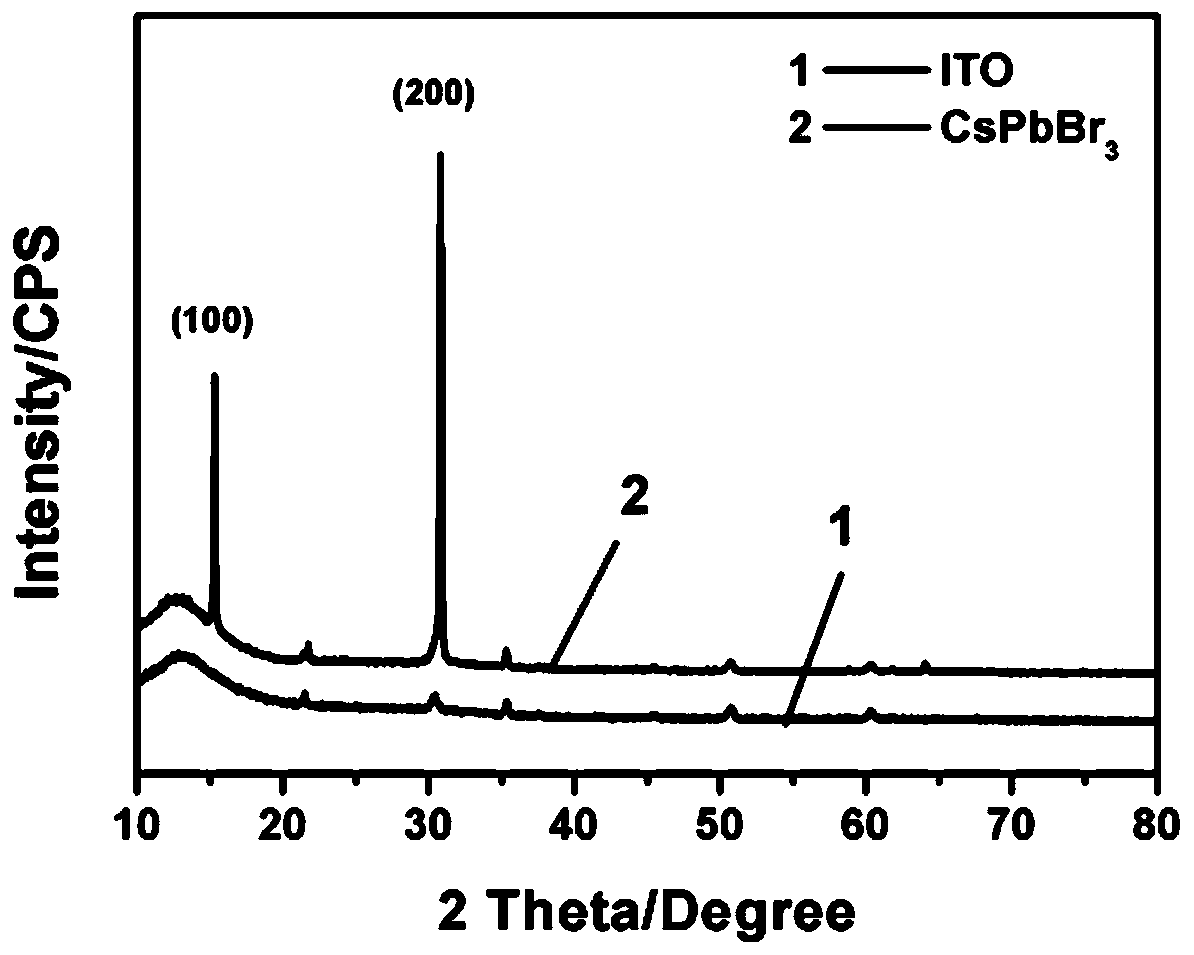

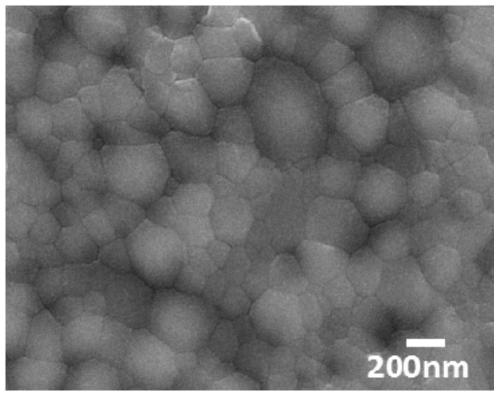

[0039] Step 2. Preparation of all-inorganic CsPbBr 3 powder

[0040] To prepare A solution, 10mmol PbBr 2 The powder was dissolved in 30 mL of 48% water content HBr solution and stirred at room temperature until PbBr 2 completely dissolved. To prepare solution B, dissolve 20 mmol of CsBr powder in 10 mL of deionized water and stir at room temperature until CsBr is completely dissolved. Use a syringe to quickly inject liquid B into liquid A, and the injection time is controlled within 9-10 seconds. Using methanol as the cleaning solution, CsPbBr was obtained after repeated cleaning and suction filtration 3 powder, and finally the CsPbBr 3 The powder was annealed at 100°C for 30 minutes in an argon atmosphere to remo...

Embodiment 2

[0048] Step 1. Clean the ITO substrate

[0049] Ultrasonic the ITO substrate in deionized water, acetone, and alcohol for 40 minutes, dry the ITO, stick insulating tape, and irradiate the ITO surface with ultraviolet light for 30 minutes in a UV instrument;

[0050] Step 2. Preparation of all-inorganic CsPbBr 3 powder

[0051] To prepare A solution, 10mmol PbBr 2 The powder was dissolved in 30 mL of 48% water content HBr solution and stirred at room temperature until PbBr 2 completely dissolved. To prepare solution B, dissolve 20 mmol of CsBr powder in 10 mL of deionized water and stir at room temperature until CsBr is completely dissolved. Use a syringe to quickly inject liquid B into liquid A, and the injection time is controlled within 9-10 seconds. Using methanol as the cleaning solution, CsPbBr was obtained after repeated cleaning and suction filtration 3 powder, and finally the CsPbBr 3 The powder was annealed at 100°C for 30 minutes in an argon atmosphere to remo...

Embodiment 3

[0059] Step 1. Clean the ITO substrate

[0060] Ultrasonic the ITO substrate in deionized water, acetone, and alcohol for 40 minutes, dry the ITO, stick insulating tape, and irradiate the ITO surface with ultraviolet light for 30 minutes in a UV instrument;

[0061] Step 2. Preparation of all-inorganic CsPbBr 3 powder

[0062] To prepare A solution, 10mmol PbBr 2 The powder was dissolved in 30 mL of 48% water content HBr solution and stirred at room temperature until PbBr 2 completely dissolved. To prepare solution B, dissolve 20 mmol of CsBr powder in 10 mL of deionized water and stir at room temperature until CsBr is completely dissolved. Use a syringe to quickly inject liquid B into liquid A, and the injection time is controlled within 9-10 seconds. Using methanol as the cleaning solution, CsPbBr was obtained after repeated cleaning and suction filtration 3 powder, and finally the CsPbBr 3 The powder was annealed at 100°C for 30 minutes in an argon atmosphere to remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com