Special clamp integrating milling and drilling

A special fixture and integrated technology, applied in the field of mechanical processing, can solve the problems of long production cycle, inability to directly process holes and planes, occupying funds, etc., and achieve the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

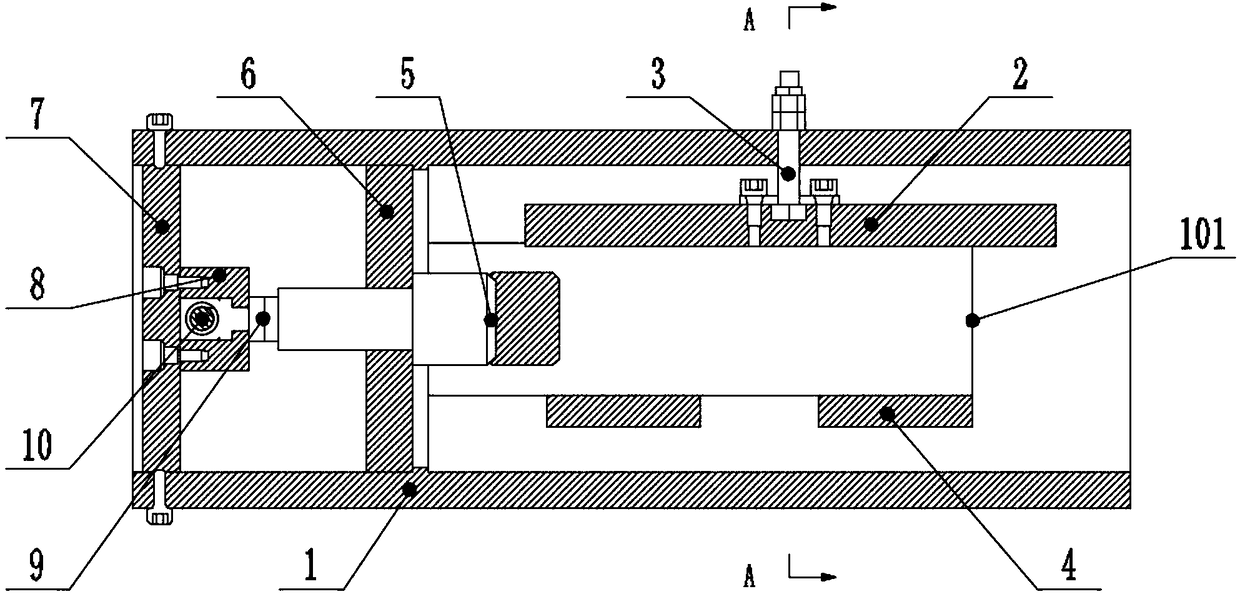

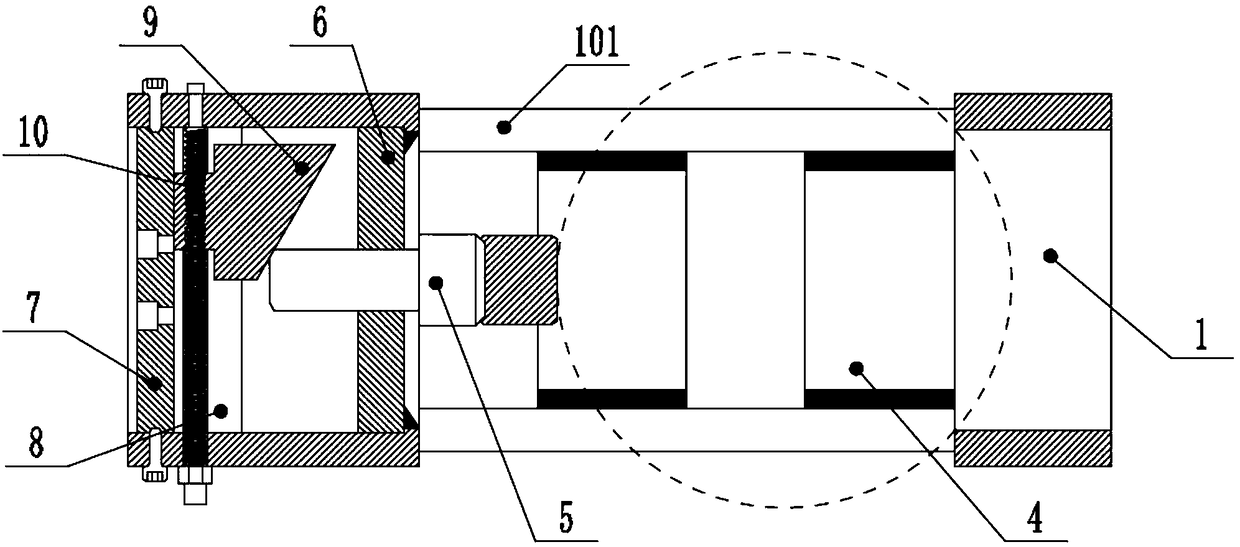

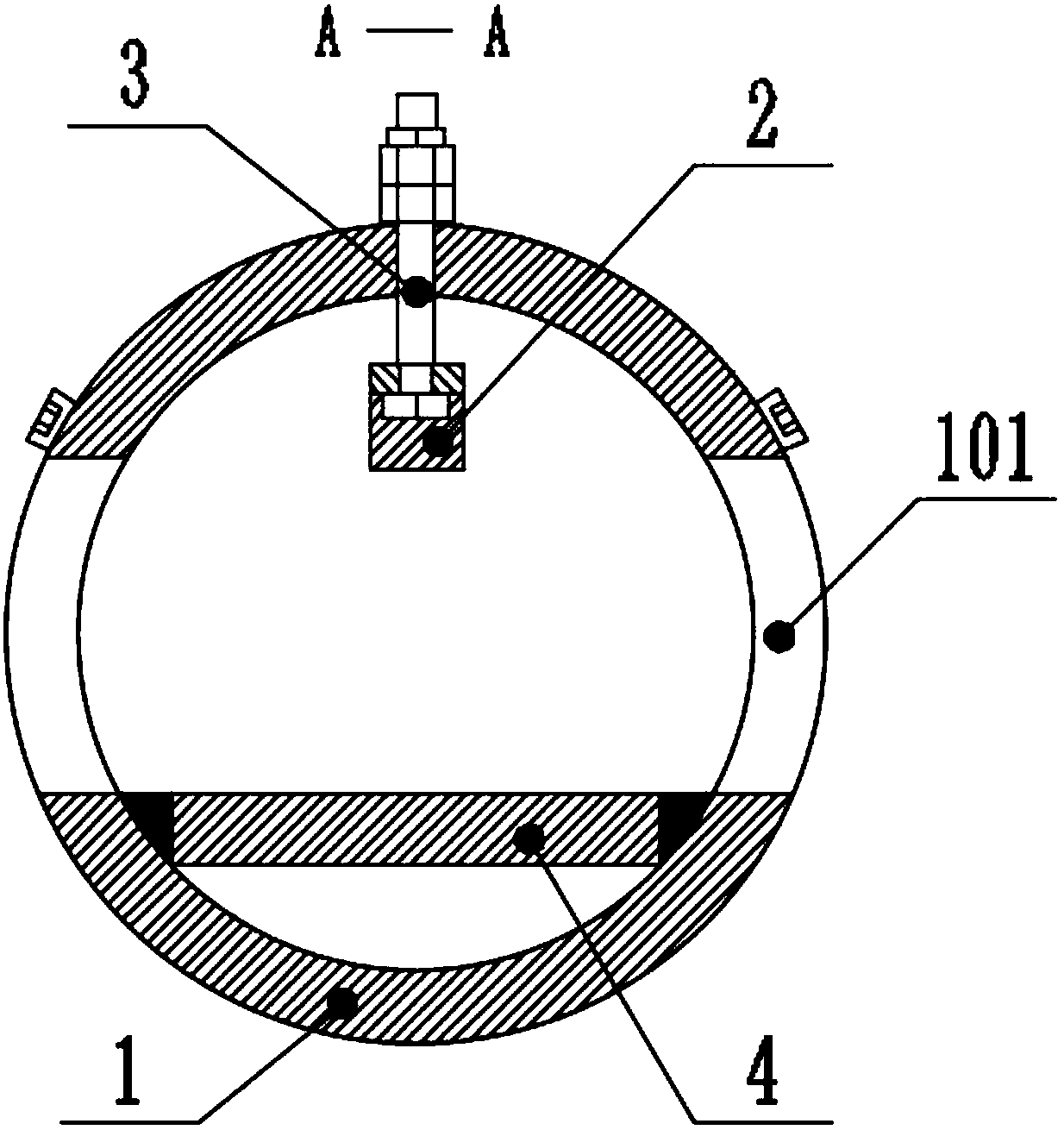

[0024] as attached figure 1 to attach image 3 Shown:

[0025] The invention provides a special fixture for milling and drilling, including a base body 1, a card slot 101, a top pressure plate 2, a tightening mechanism 3, a positioning plate 4, an adjustment shaft 5, a guide plate 6, a baffle plate 7, a slideway 8, and an inclined positioning mechanism 9 and screw rod 10; the base body 1 is a circular tubular structure, and the front and rear sides of the base body 1 are respectively provided with a card slot 101; the top pressure plate 2 is a rectangular plate structure, and the bottom of the tightening mechanism 3 is located on the base body 1 Inside the top; the positioning plate 4 and the adjusting shaft 5 are located inside the base body 1; the guide plate 6 is a disc-shaped structure, and the guide plate 6 is installed inside the base body 1; the baffle plate 7 is installed on the base body 1 through bolts The left end, and the slideway 8 is installed on the right end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com