Wrench suitable for different nut diameters

A wrench and nut technology, applied in the field of wrenches, can solve the problems of laborious adjustment operation, long time consumption, unfavorable promotion, etc., and achieve the effects of wide application range, small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with specific embodiments and drawings, but it is not intended to limit the present invention.

[0019] In this embodiment, the referred to "many" refers to the quantity greater than or equal to 3, which is called "many".

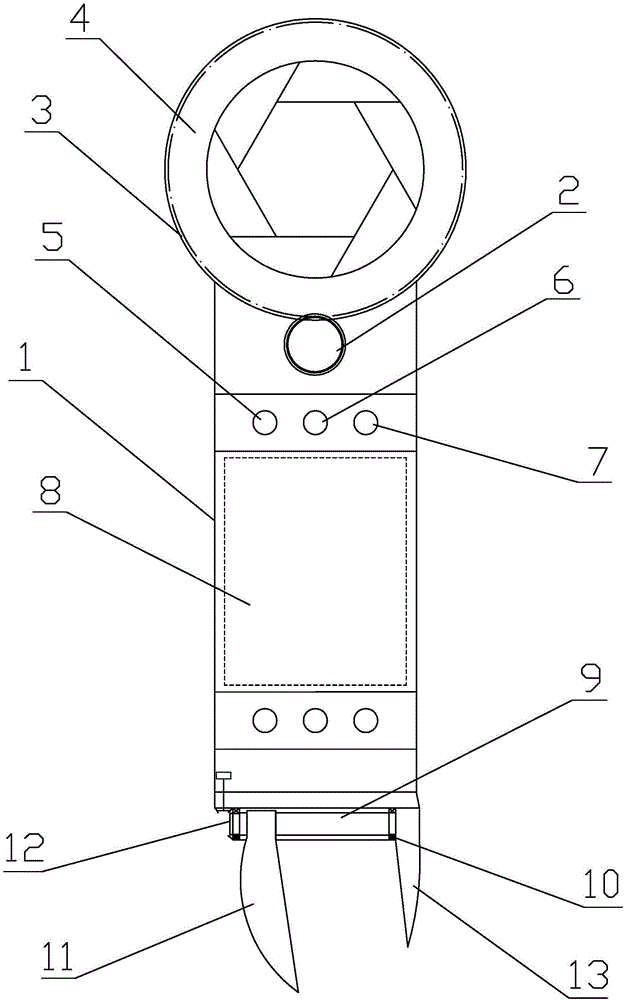

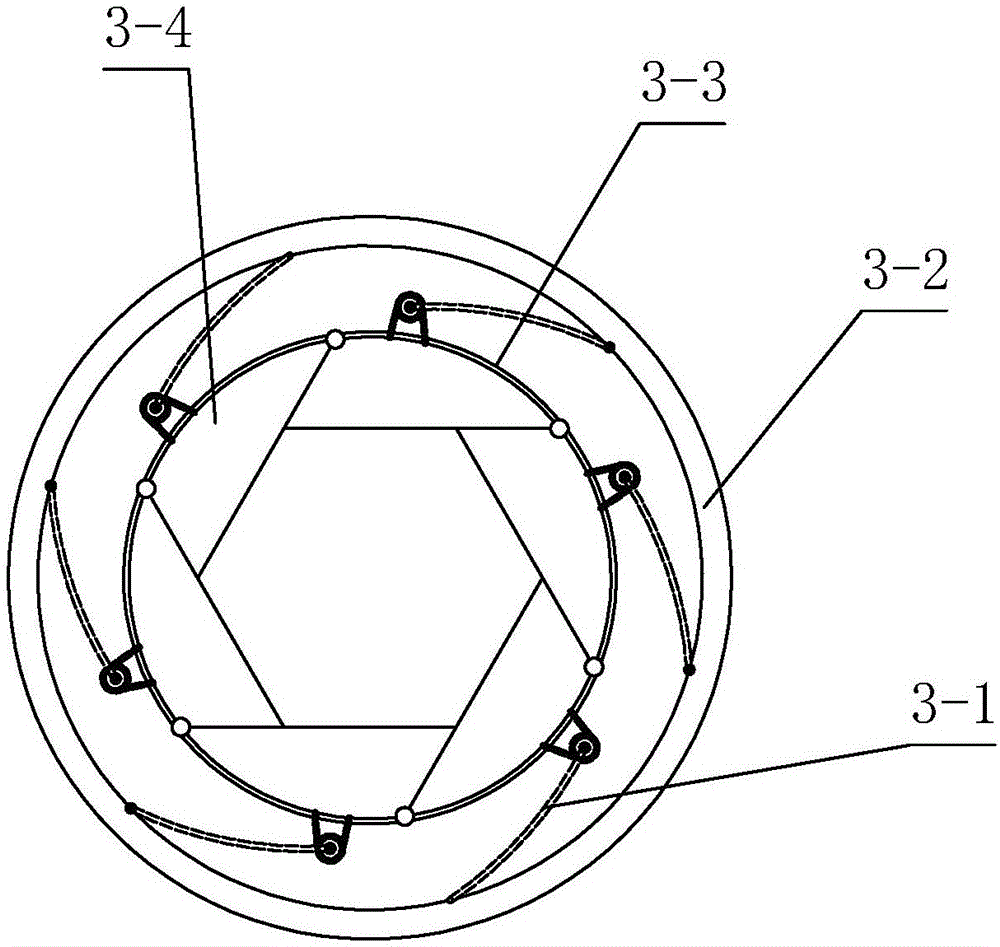

[0020] Such as figure 1 , figure 2 As shown, a wrench adapted to different nut diameters includes a wrench body 1 for gripping and a first clamping mechanism 3 installed at one end of the wrench body 1 . The first clamping mechanism 3 includes a telescopic disc 3-3 for clamping nuts to be disassembled, a power cylinder 3-2 coaxially installed outside the telescopic disc 3-3 and a power cylinder 3 for driving - 2 rotating drive gears 2 . in,

[0021] There is a rotation space 4 between the inner diameter of the power cylinder 3-2 and the outer diameter of the telescopic disk 3-3, and a plurality of transmission rods 3-1 are arranged at intervals in the rotation space 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com