Waste cotton wool compressor

A technology of compressors and cotton wool, which is applied in the direction of presses, manufacturing tools, etc., can solve the problems of low density of waste cotton wool, large space occupation, high production cost, etc., and achieve the effect of saving manpower and material resources and improving compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Through the description of the embodiments below, the specific implementation of the present invention includes the shape, structure, mutual position and connection relationship between the various parts, the function and working principle of each part, the manufacturing process and the operation and use method of the various components involved. etc., to make further detailed descriptions to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

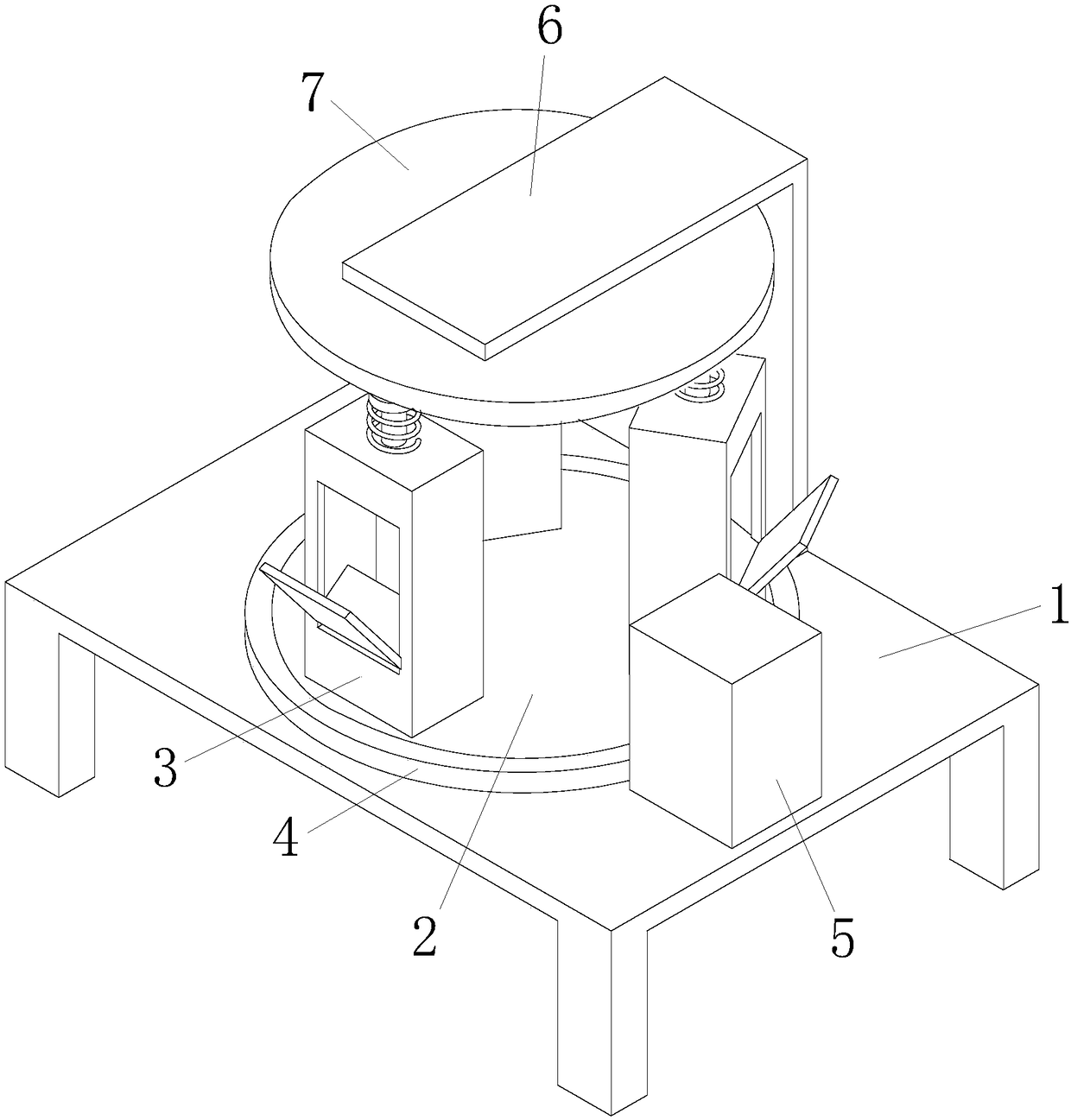

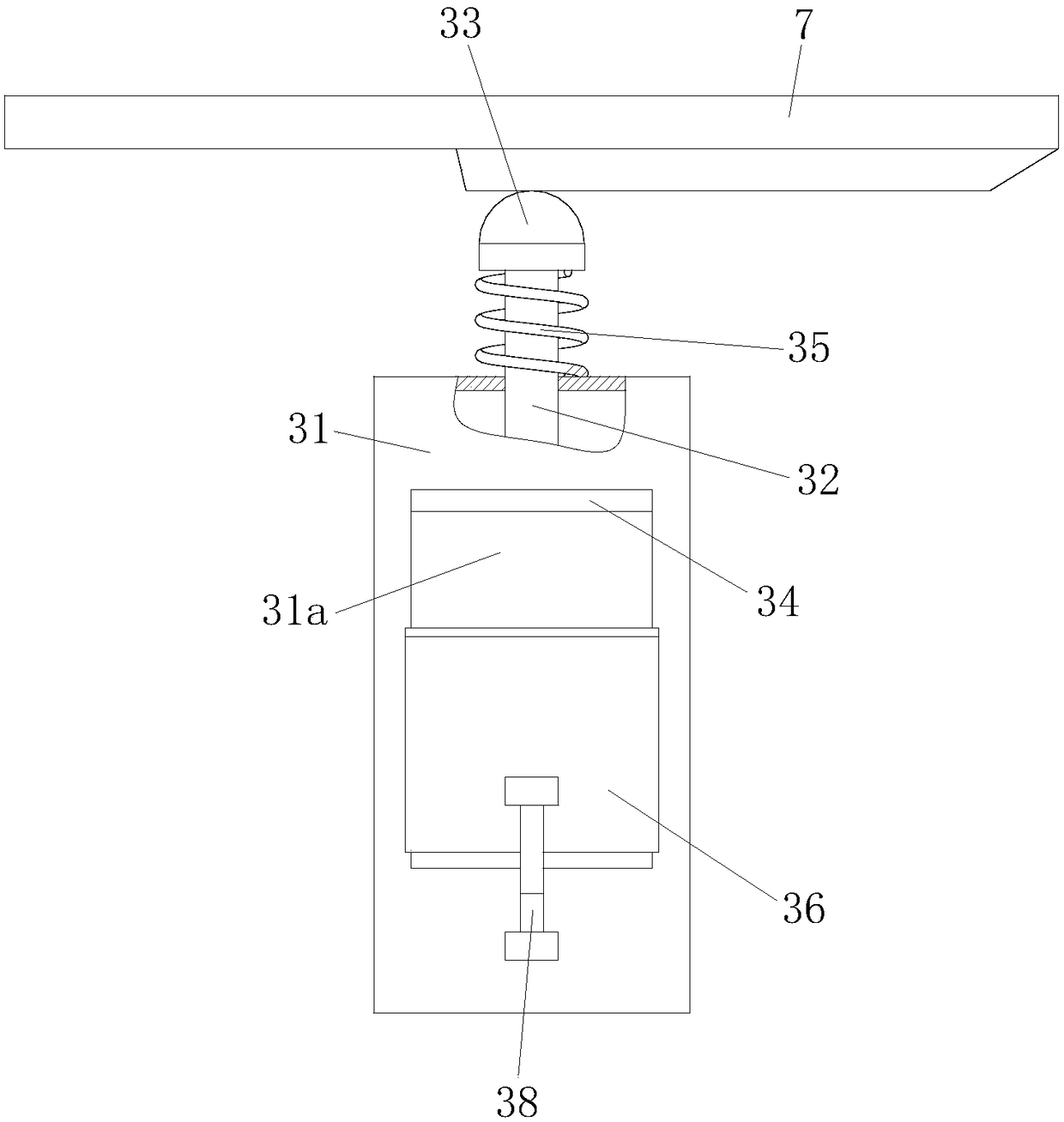

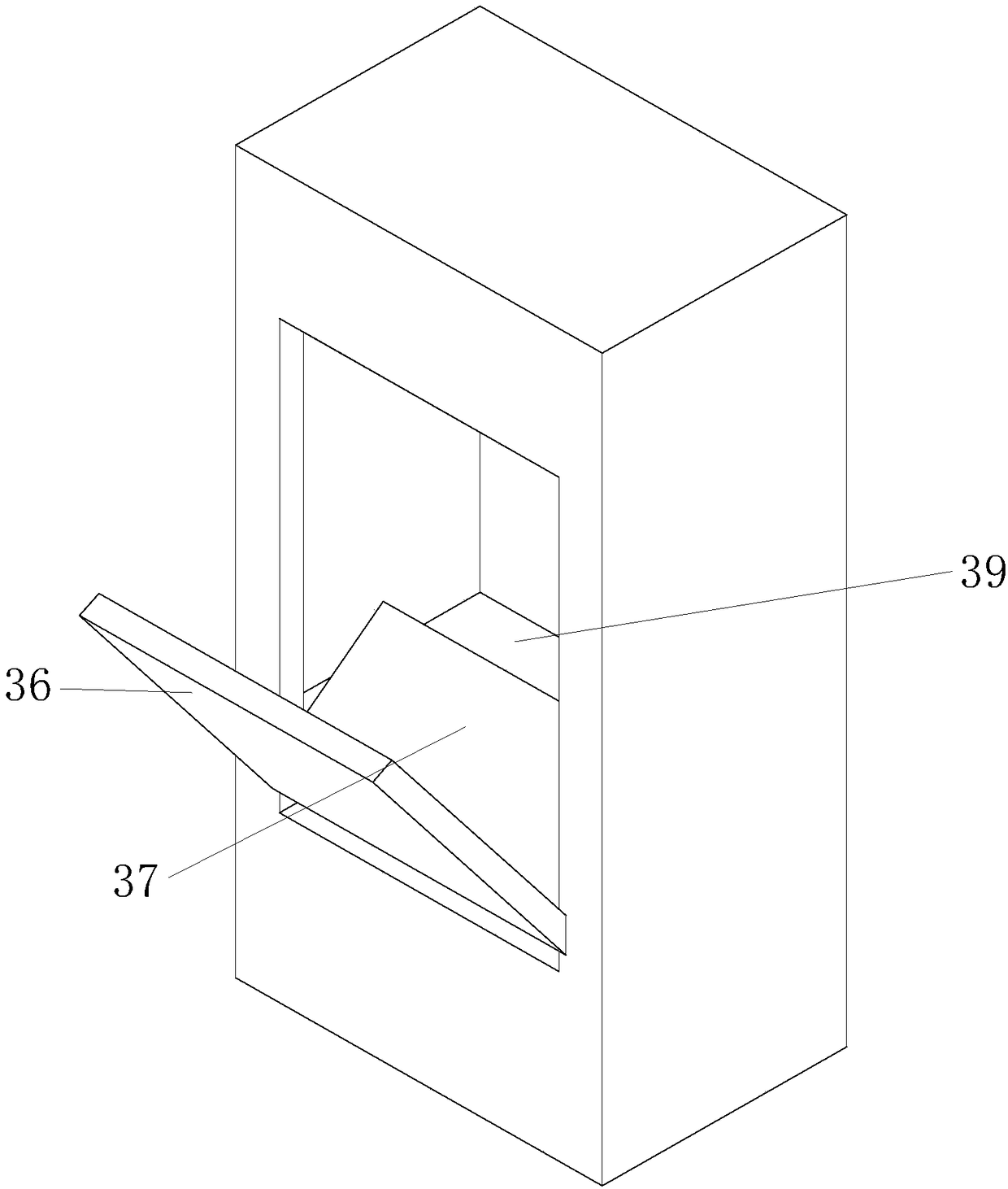

[0018] A waste wadding compressor, comprising a workbench 1, a turntable 2 is installed on the workbench 1 through bearing connection, several groups of compression units 3 are installed on the turntable 2, and the outer wall of the turntable 2 is connected by bolts The ring gear 4 is installed in the way, and the drive assembly 5 is installed on the right part of the workbench 1. The drive assembly 5 includes a drive m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com