Test paper tidying and storing device

A storage device and test paper technology, applied in the direction of thin material processing, transportation and packaging, sending objects, etc., can solve the problems of inability to dry, inability to purify the smell of paint, etc., to achieve the effect of easy collection and organization, and improve picture quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, the technical solution of the present invention will be described in detail through specific examples.

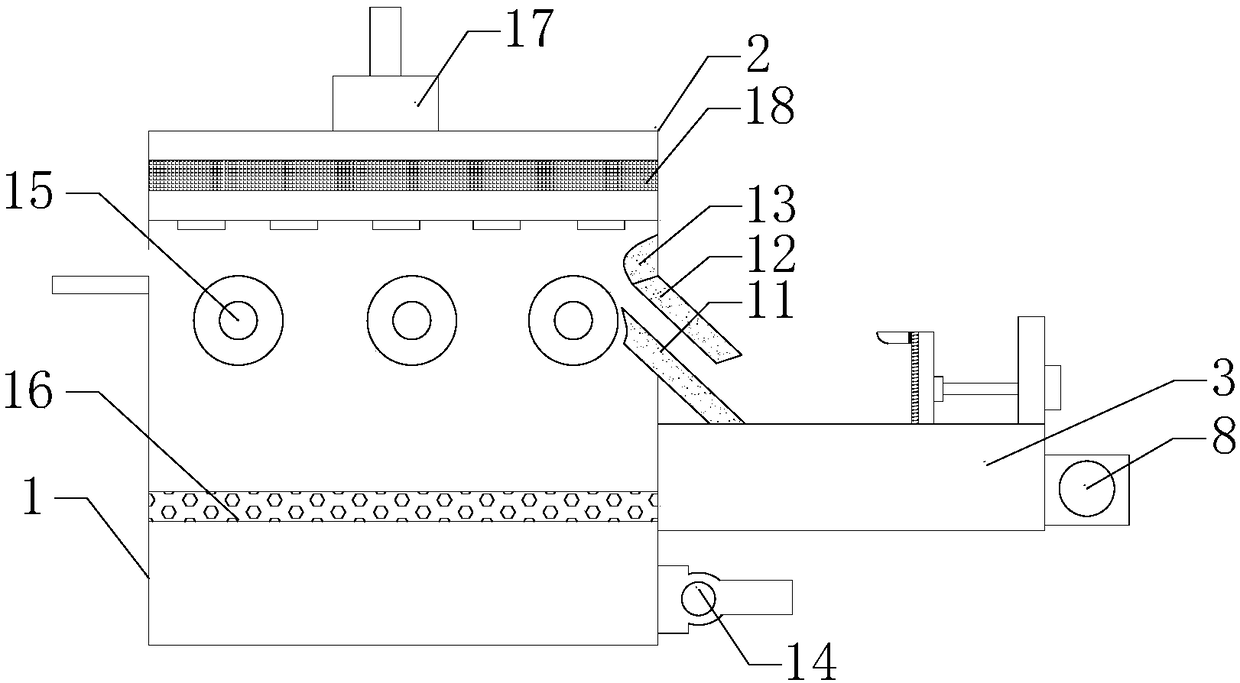

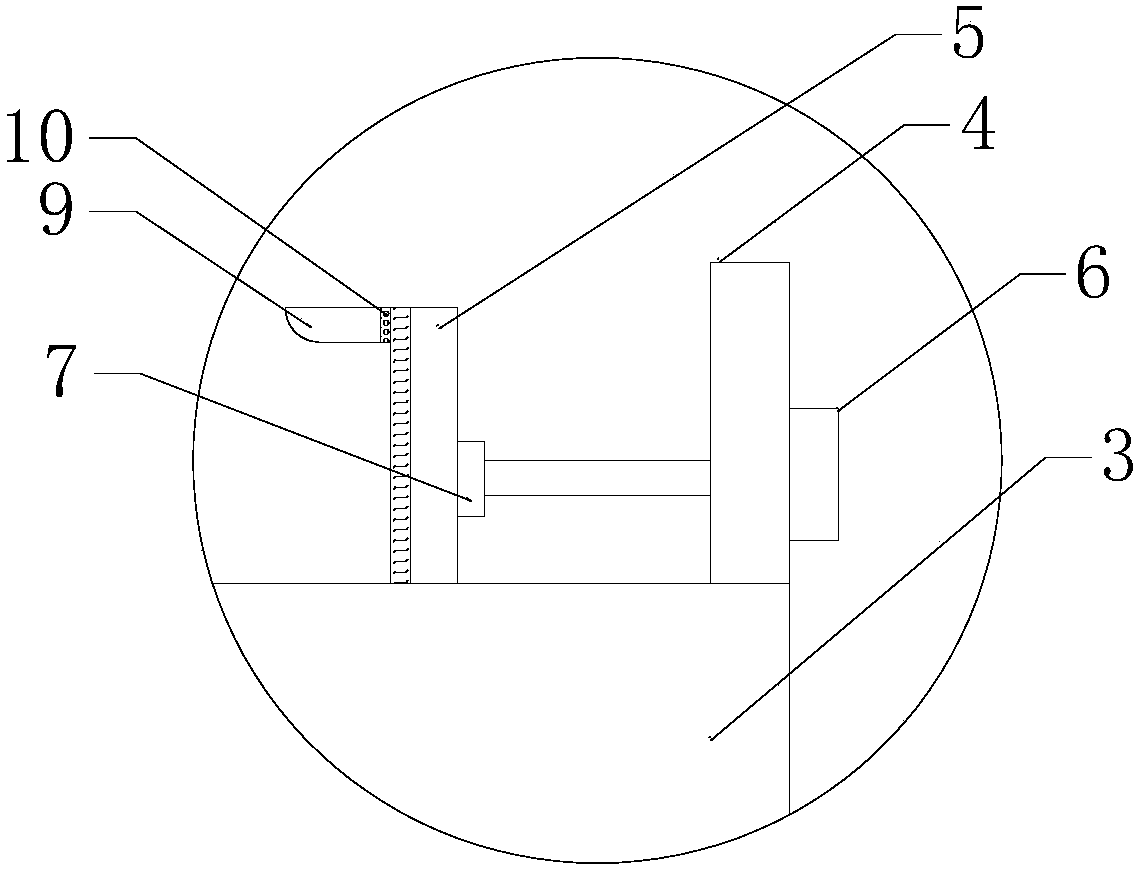

[0019] Such as Figure 1-2 as shown, figure 1 It is a structural schematic diagram of a test paper arrangement and storage device proposed by the present invention; figure 2 It is a schematic diagram of the structure of the supporting plate in a test paper sorting and storing device proposed by the present invention.

[0020] refer to Figure 1-2 , a test paper sorting and storage device proposed by the embodiment of the present invention, comprising: a box body, a first induced draft fan 14, a second induced draft fan 17 and a supporting plate 3, wherein: the box body has a transfer chamber 1 and is located above the transfer chamber 1 and Airflow chamber 2 communicating with transfer chamber 1.

[0021] One side of the transfer chamber 1 is provided with a paper inlet, and the side away from the paper inlet is provided with a paper outlet; inside the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com