A detection device and detection method for the defect area of the end face of MOX fuel pellets

A technology for fuel pellets and detection methods, which are applied in measurement devices, optical devices, analysis materials, etc., can solve the problems of low radiation level, low enrichment, and can not meet the requirements of industrial production lines, and achieve the effect of ensuring repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

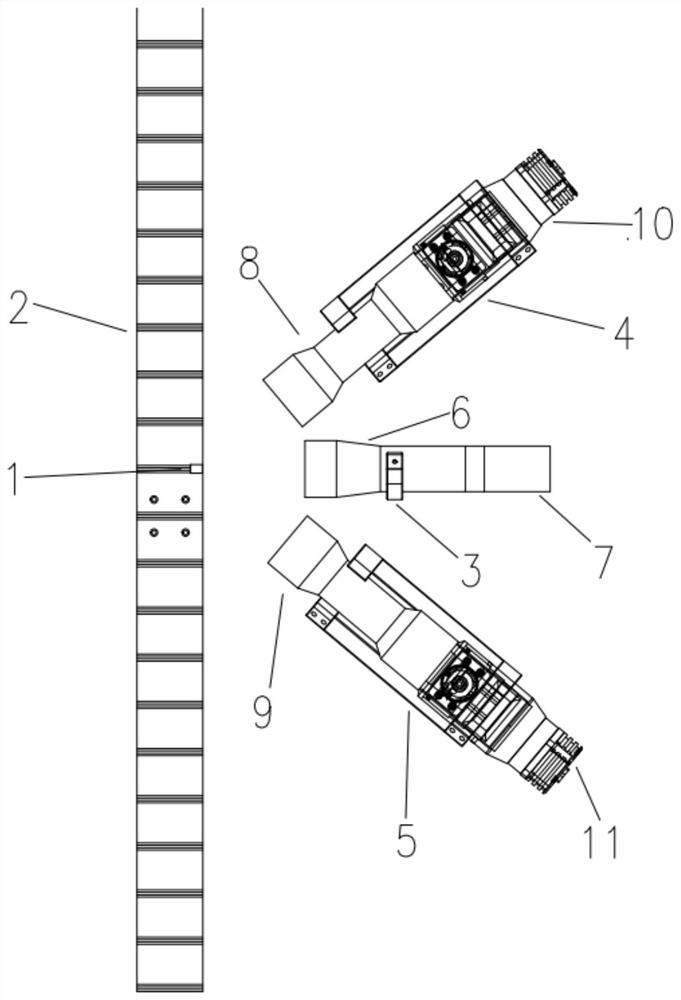

[0036] The composition structure of the detection device of the exemplary MOX fuel pellet end surface defect area of the present invention is as follows figure 1 As shown, it includes a support frame 2, a camera 7, a first light source 10, a second light source 11, an image acquisition device, an image processing device, and a control system (the image acquisition device, the image processing device, and the control system are all in figure 1 not shown). The detection device is a modular detection device, and can be placed in a glove box for operation, maintenance and replacement.

[0037] The support frame 2 on which the fuel pellets 1 are placed drives the fuel pellets 1 for loading and unloading under the control of the control system.

[0038] The camera 7 is used to take an image of the end face of the fuel pellet 1 facin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com