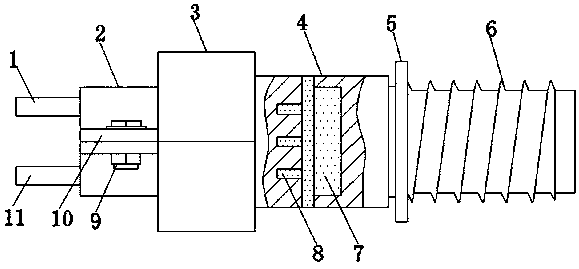

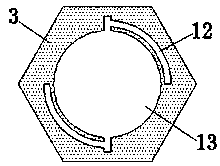

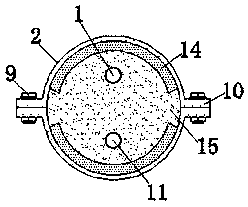

Automobile pressure sensor

A pressure sensor, automobile technology, applied in the direction of fluid pressure measurement by changing ohmic resistance, can solve the problems of unstable power line connection, reverse connection of positive and negative power supply, etc., to solve the problem of unstable connection, avoid danger, avoid The effect of working abnormally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a resin-type nano heat-conducting composite material, comprising the following steps:

[0028] Step 1. Weigh a certain mass of epoxy resin and curing agent PSPA, the mass ratio of the two is 2:1, and mix it in a high-speed mixer at 800 r / min for 2 minutes to make the epoxy matrix and curing agent PSPA mix well;

[0029] Step 2, then Al 2 o 3 Add @ZnO core-shell nanofillers to the mixture of epoxy resin and curing agent (mass ratio of filler to epoxy resin is 3:7), and mix again at 1000 r / min for 2 min;

[0030] Step 3. Pour the mixture into a cylindrical mold with a diameter of 30mm coated with oleic acid as a release agent in advance, place the mold in a vacuum drying oven, and draw a vacuum to make the air bubbles in the mixture escape, and set the curing temperature The temperature is 60℃, and the curing time is 4h;

[0031] Step 4. After the curing is completed, demoulding is performed, and the upper and lower surfaces of the cured product...

Embodiment 2

[0036] Step 2, then Al 2 o 3 @ZnO core-shell nanofillers were added to the mixture of epoxy resin and curing agent (mass ratio of filler to epoxy resin 1:2), and mixed again at 1000 r / min for 2 min; the rest of the preparation was the same as in Example 1.

Embodiment 3

[0038] Step 2, then Al 2 o 3 @ZnO core-shell nanofillers were added to the mixture of epoxy resin and curing agent (the mass ratio of filler to epoxy resin was 3:5), and mixed again at 1000 r / min for 2 min; the rest of the preparation was the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com