Anti-pole-reversal treatment method for membrane electrode in fuel cell stack

A technology of fuel cell stacks and processing methods, which is applied in the direction of fuel cells, battery electrodes, circuits, etc., can solve the problems of high cost and high cost of fuel cell stacks, and achieve the goals of preventing destructive consequences, reducing consumption, and reducing manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

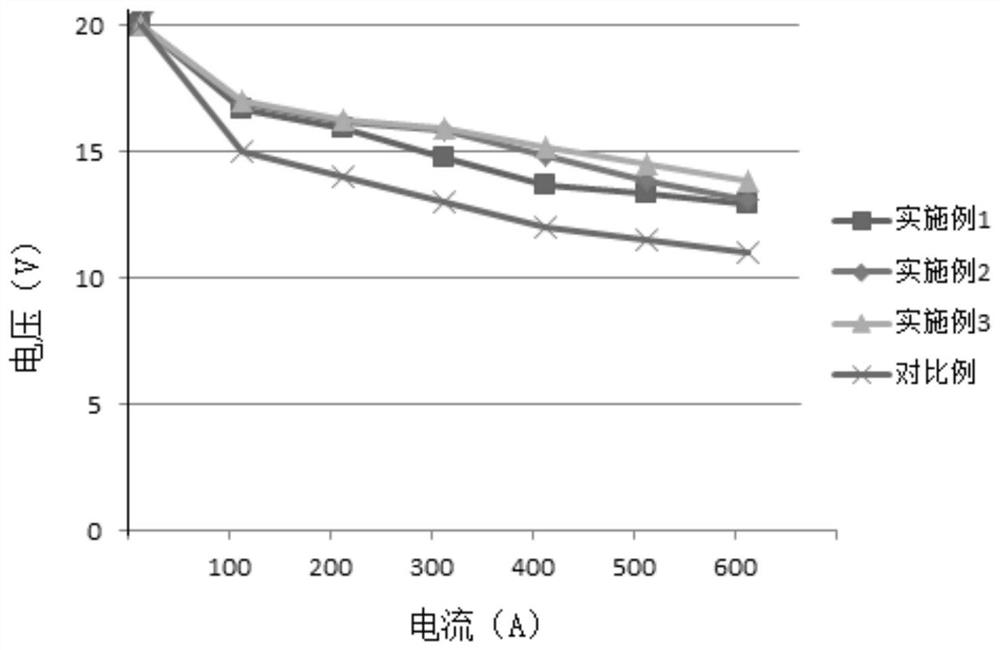

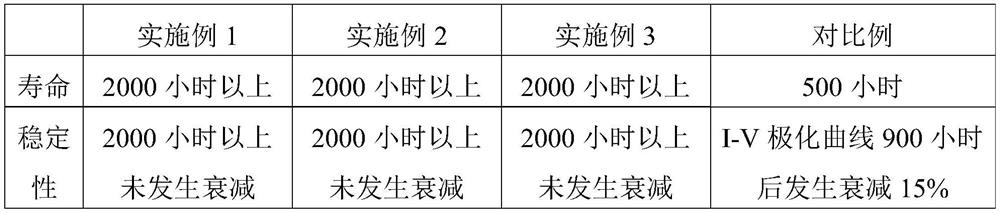

[0026] The invention relates to a method for treating the anti-reverse electrode of the membrane electrode in the fuel cell electric stack. The anti-reverse catalyst is added to the platinum carbon catalyst of the membrane electrode to obtain a mixed catalyst, and the mixed catalyst is used as the hydrogen side catalyst of the membrane electrode.

[0027] More specifically, in this example:

[0028] The platinum-carbon catalyst is a commercially available 60% Pt / C catalyst for fuel cells, and an anti-reverse catalyst is added therein and mixed evenly to obtain a mixed catalyst. Among them, the dosing amount of the anti-anti-electrode catalyst is 0.1-10 mg / cm 2 , in this example, mixed with 1mg / cm 2 anti-reverse catalyst; the mass ratio of platinum carbon catalyst to anti-reverse catalyst is 1:1 to 5:1, in this embodiment, it is 2:1; the anti-reverse catalyst can be selected from iridium oxide or ruthenium oxide or two In this embodiment, iridium oxide is selected as the anti...

Embodiment 2

[0032] A treatment method for anti-reversal of membrane electrodes in a fuel cell stack, the difference from Example 1 is that the amount of anti-reversal catalyst incorporated is 2 mg / cm 2 , the mass ratio of the platinum-carbon catalyst to the anti-reverse catalyst is 0.5:1, and ruthenium oxide is selected as the anti-reverse catalyst. The anti-reverse effect of the assembled fuel cell stack is shown in Table 1 below.

Embodiment 3

[0034] A treatment method for anti-reversed poles of membrane electrodes in a fuel cell stack, the difference from Example 1 is that the dosing amount of the anti-reversed catalyst is 1.5mg / cm 2 , the mass ratio of the platinum carbon catalyst to the anti-reverse catalyst is 0.6:1, and a mixture of iridium oxide and ruthenium oxide is used as the anti-reverse catalyst; Replace the single battery with an anti-reverse single battery. The anti-reverse effect of the assembled fuel cell stack is shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com