Power line carrier/NB-IOT composite communication mine electromechanical equipment management and control system

A technology of electromechanical equipment and power carrier, applied in the field of power carrier/NB-IOT composite communication mine electromechanical equipment management and control system, can solve the problems of high cost, unrealistic, time-consuming and laborious, and achieve short distance, low attenuation and low power consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

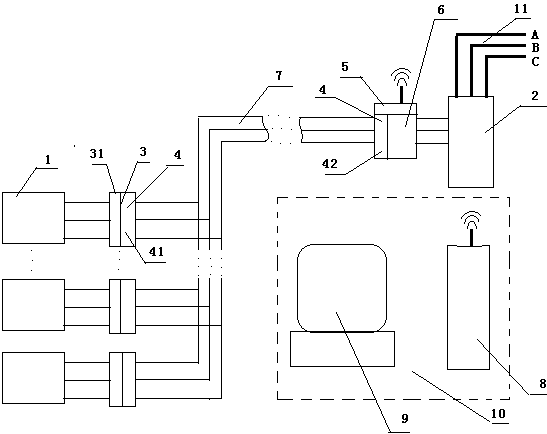

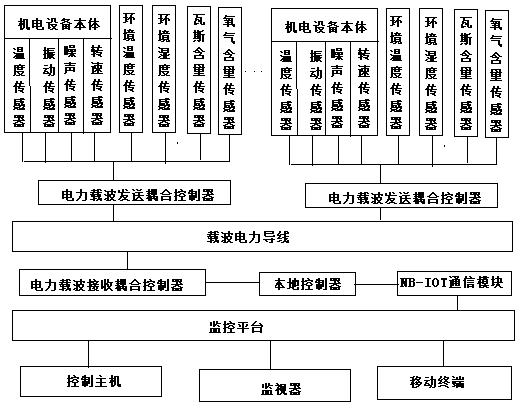

[0023] The mechanical and electrical equipment 1 of this embodiment takes ventilator equipment as an example. There are two identical ventilators underground, of which, one is on and the other is on standby. The input three-phase voltage of the motor is 1140V, and the rated power is 37KW. The terminal of the motor is connected to the AC contactor 31 of the control switch 3 through wires. The AC contactor 31 is a three-phase explosion-proof AC contactor produced by Jiangsu Youpin Electric Co., Ltd. . The contactor 31 has an RS485 communication interface, which is connected to the RS485 interface signal of the power carrier module 4 through a signal line. Here, the power carrier communication module 4 is produced by Qingdao Neusoft Carrier Technology Co., Ltd., and the model is PLCS1653 three-phase carrier module. , the operating parameters such as voltage, current, power and power factor output by the AC contactor 31 can be read through the signal line power carrier module 4 (v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com