Automatic cross-cut testing device for corrosion-resistant workpieces

A 100-grid test device, corrosion-resistant technology, applied in the field of automatic 100-grid test device, can solve problems such as manual scribing safety hazards, and achieve the effect of solving hidden safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

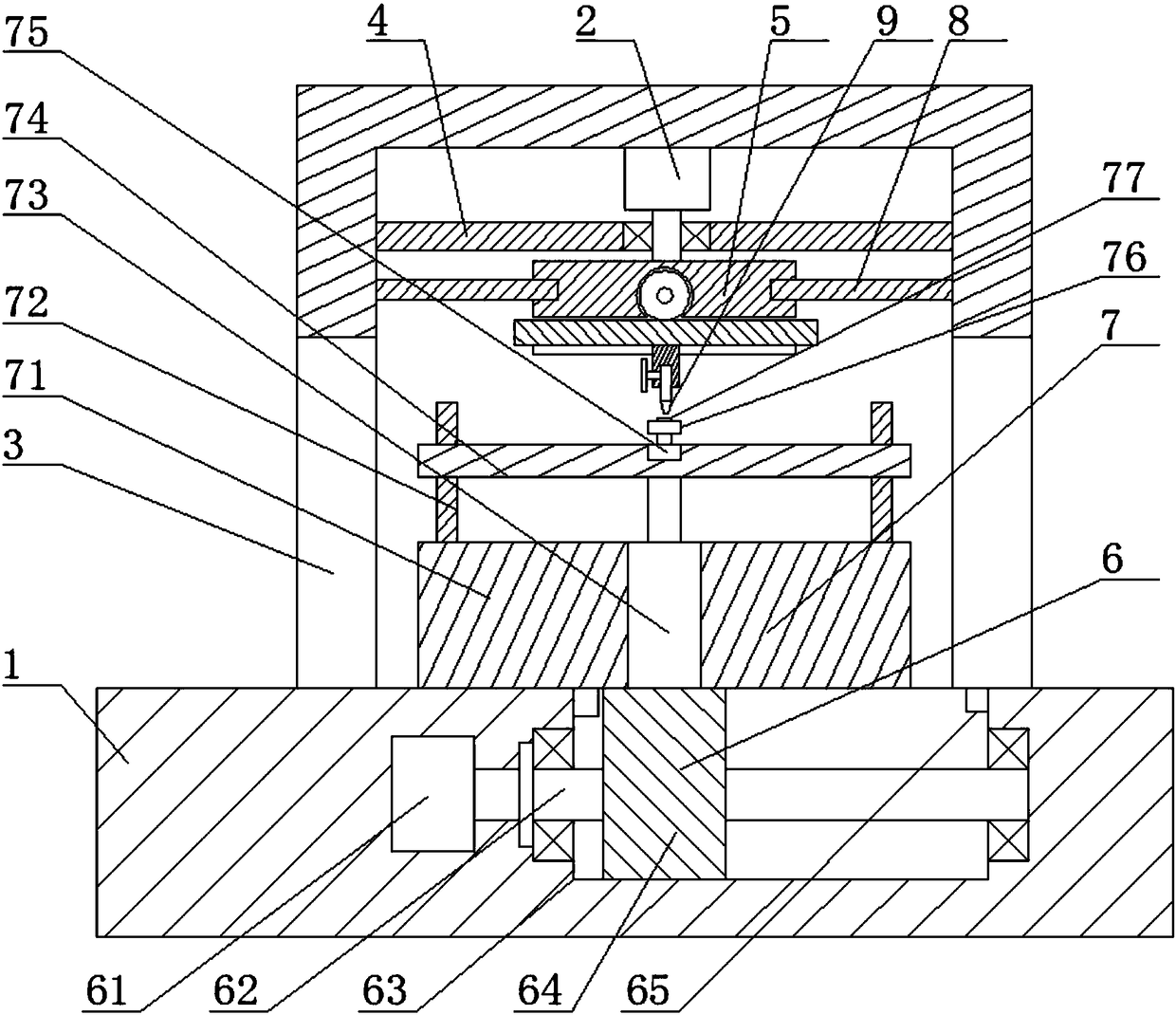

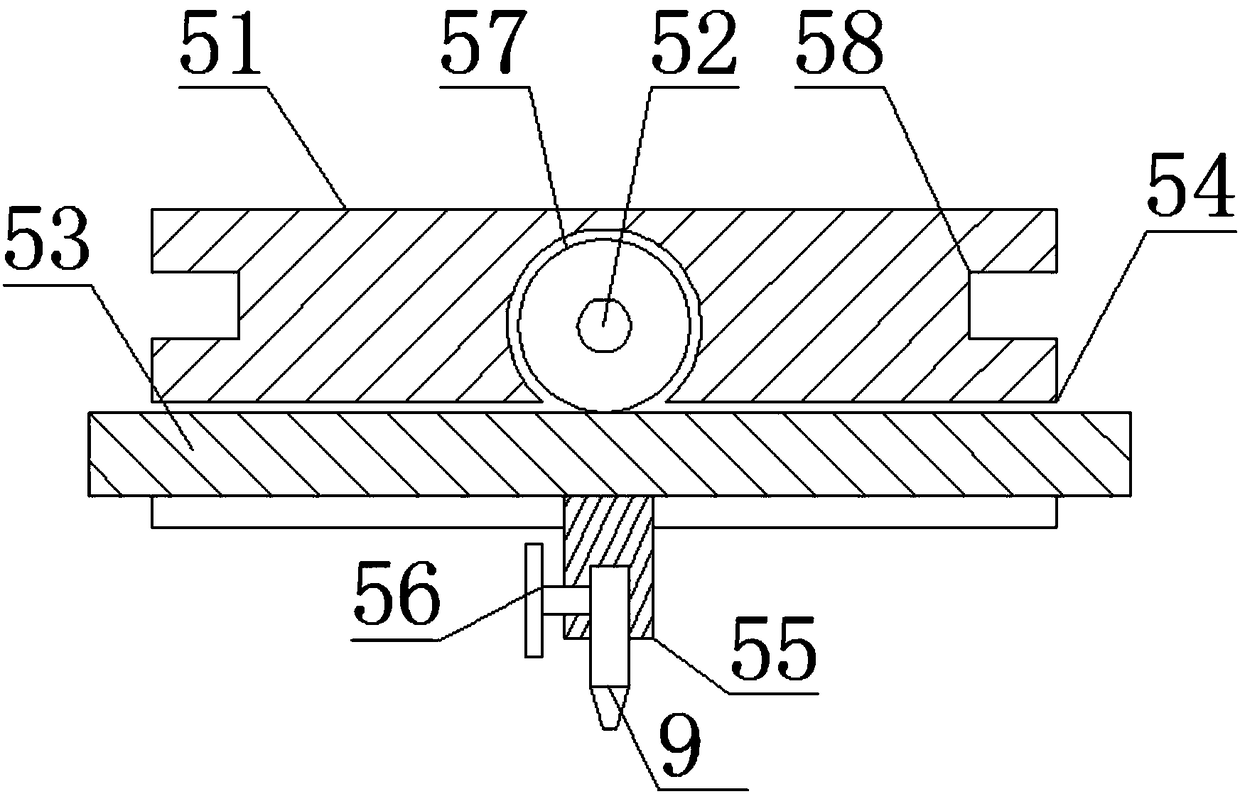

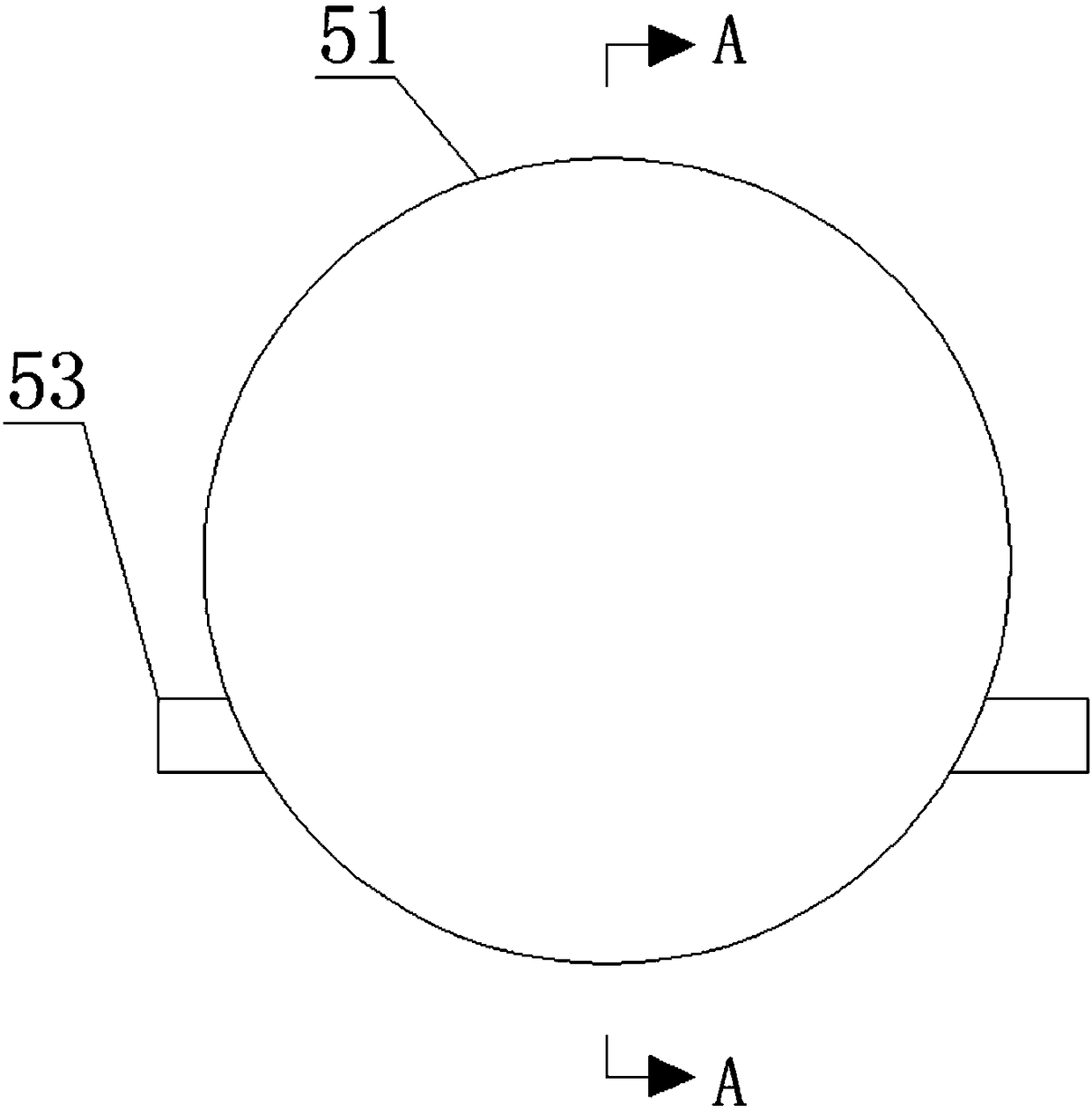

[0023] Such as Figure 1 to Figure 7 As shown, an automatic 100-grid test device for corrosion-resistant workpieces includes a 100-grid knife 9, a base 1 and a controller 10. The base 1 is provided with a moving mechanism 6 inside, and the upper end of the base 1 is fixedly connected with Bracket 3, the upper end of the moving mechanism 6 is fixedly connected with a placement mechanism 7, the center position of the lower end of the top of the bracket 3 is fixedly connected with the first motor 2, and the output shaft of the first motor 2 is keyed to the Baige mechanism 5 , The hundred grid knife 9 is fixed on the hundred grid mechanism 5, and the controller 10 is electrically connected with the first motor 2, the hundred grid mechanism 5, the moving mech...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap