Locked-rotor, overload, phase-loss and free-burning motor of high-efficiency and energy-saving water pump

A high-efficiency energy-saving and water pump technology, which is applied in the field of lack of burning motors, high-efficiency energy-saving water pumps, and overload fields. It can solve the problems of large motor damage and easy motor burnout, and achieve the effect of avoiding motor burnout and winding temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

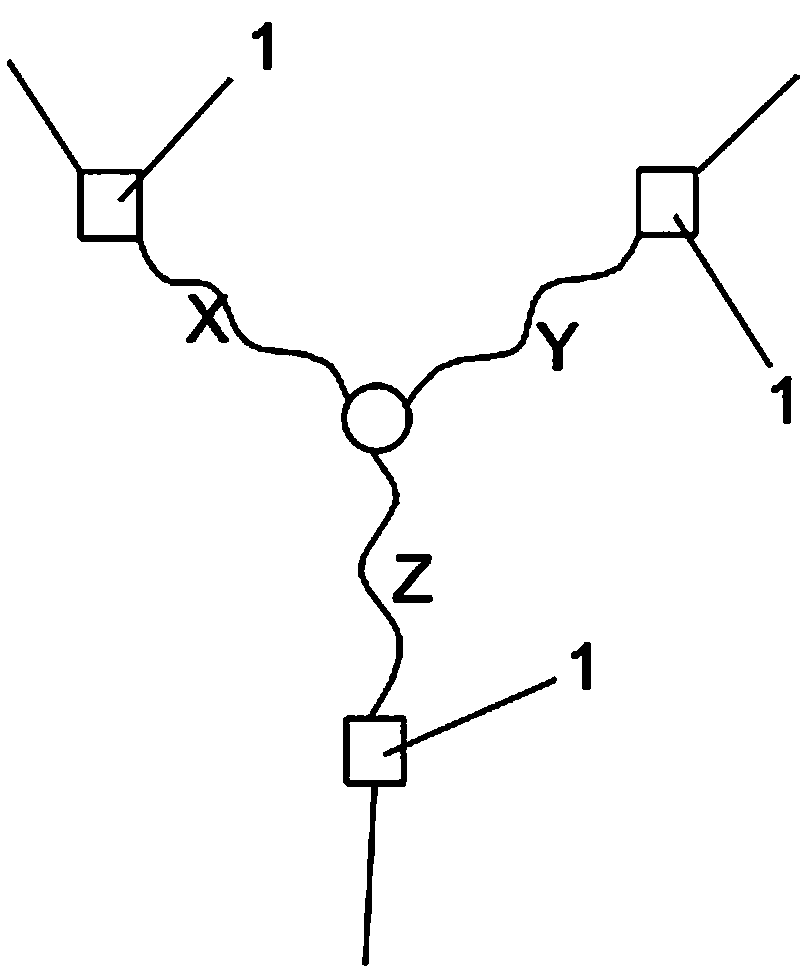

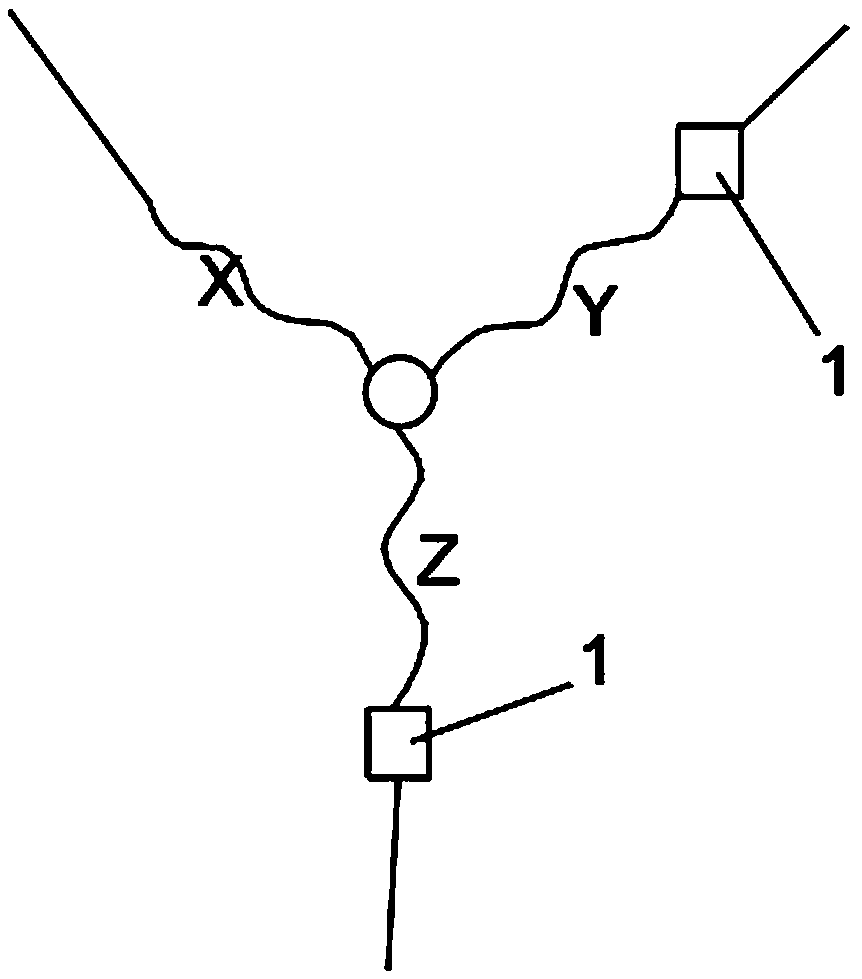

[0023] Such as figure 2 As shown, it is the second embodiment of the present invention, a high-efficiency energy-saving water pump stall, overload, phase loss and non-burning motor, including three-phase windings X, Y, Z with delta connection, and its rated power is less than 7.5 kW, a protector 1 is arranged in series on the windings X, Y, and Z of each phase, and its structure is the same as that of the protector in Embodiment 1.

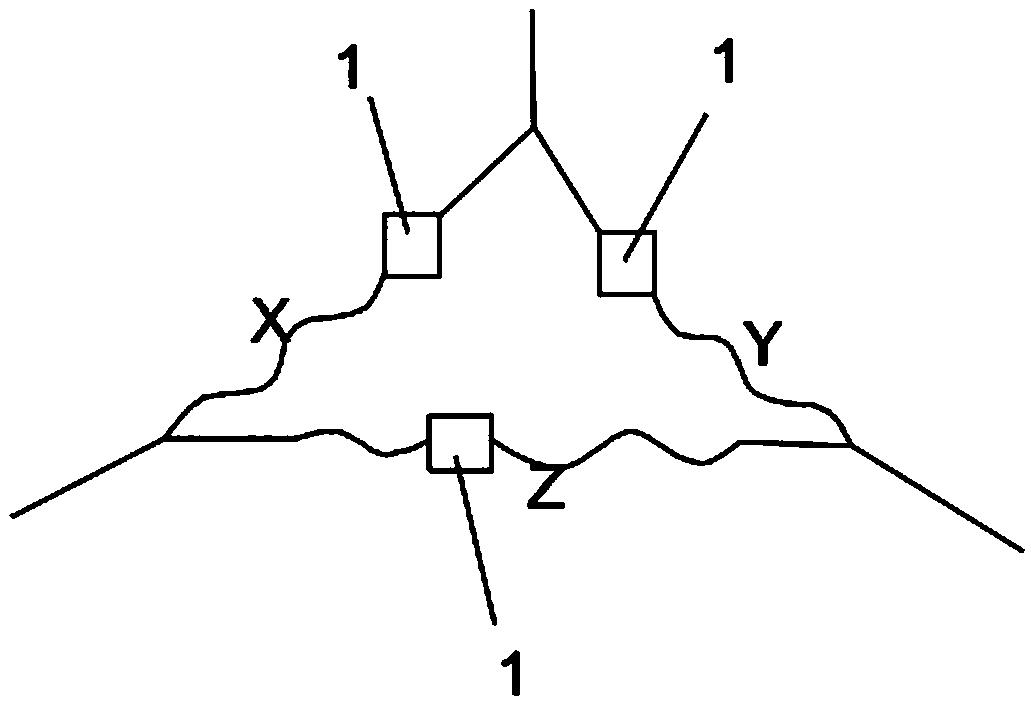

[0024] Such as image 3 As shown, it is the third embodiment of the present invention, a high-efficiency energy-saving water pump stall, overload, phase loss and non-burning motor, including three-phase windings X, Y, Z with delta connection, and its rated power is less than 7.5 kW, a protector 1 is arranged in series on the two phases of the windings X, Y, and Z of each phase, and its structure is the same as that of the protector in Embodiment 1.

[0025] Such as Figure 4 to Figure 6 As shown, the protector 1 includes a moving contact pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com