Bolt tightening device

A bolt and tightening gun technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor adaptability and stability, and achieve the effect of improving adaptability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

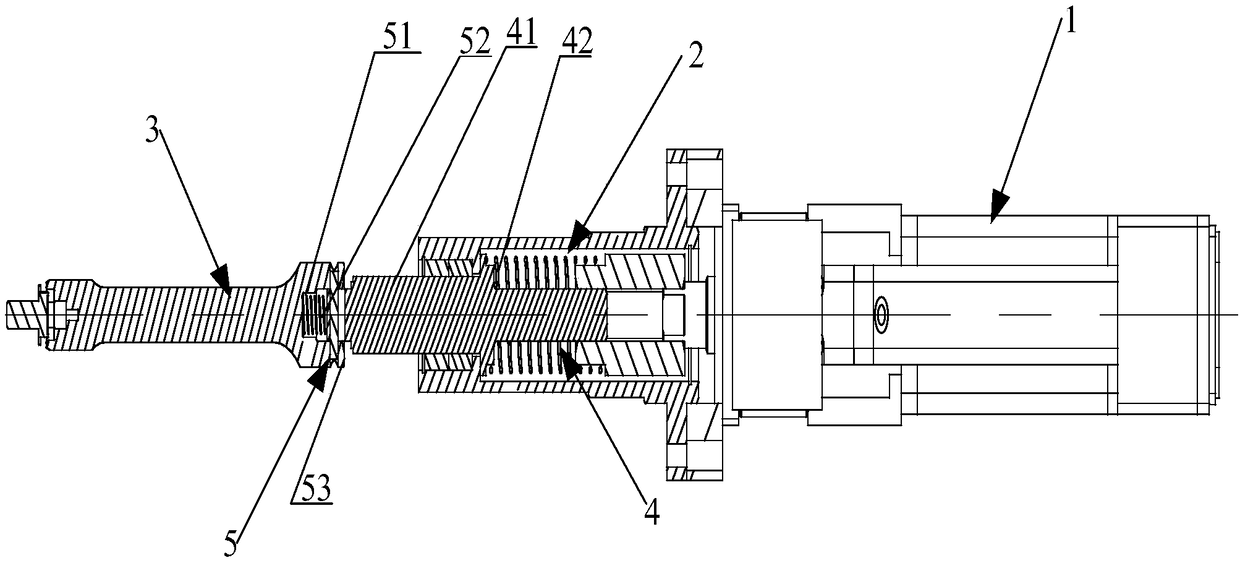

[0028] In view of this, the core of the present invention is to provide a bolt tightening device, which can effectively meet the low elastic coefficient when the bolt and the sleeve are combined and the high elastic coefficient when the bolt is screwed into the threaded hole, thereby improving the adaptability and stability of the equipment .

[0029] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

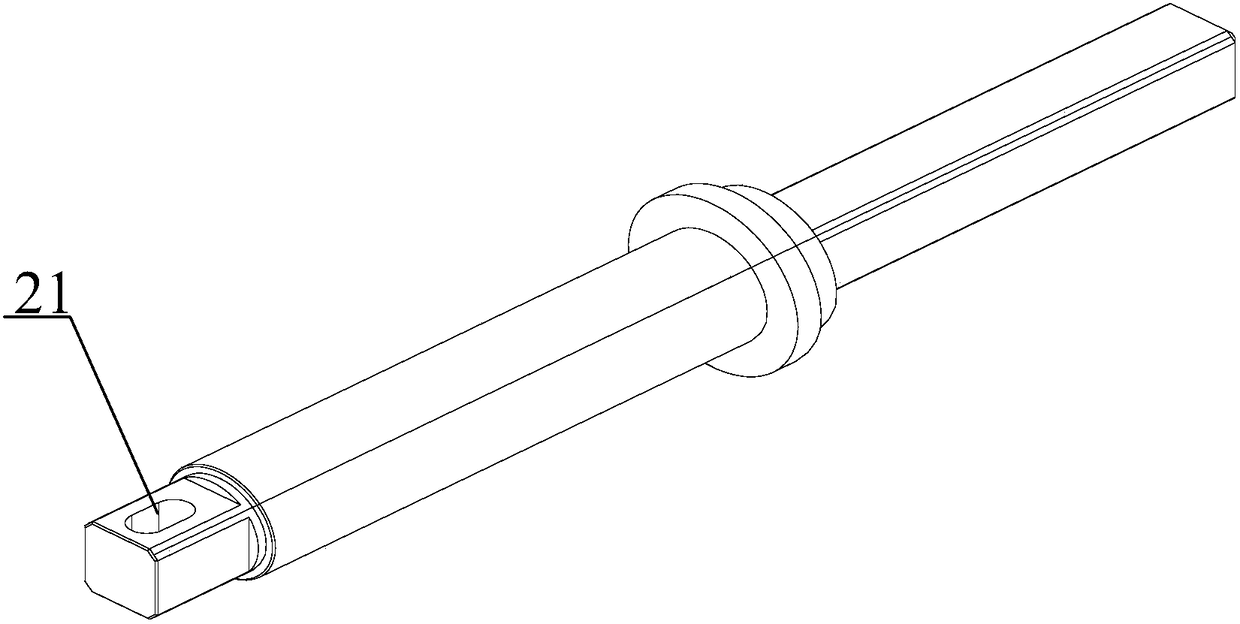

[0030] Such as figure 2 As shown, the bolt tightening device disclosed in the embodiment of the present invention includes a tightening gun 1 connected in sequence, a coupling 2 and a sleeve 3, the coupling 2 is provided with a first elastic telescopic mechanism 4, the coupling 2 and the The joint of the sleeve 3 is also provided with a second elastic telescopic mechanism 5 that enables the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com